Self-centering friction energy consumption support for large deformation pulley block

A technology of friction energy consumption and pulley block, which is applied in the directions of building components, shockproof, building types, etc., can solve the problem of high demand for elastic elongation of pre-tie rods, achieve flexible structure, reduce the demand for elastic elongation, and reduce the demand for elastic elongation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

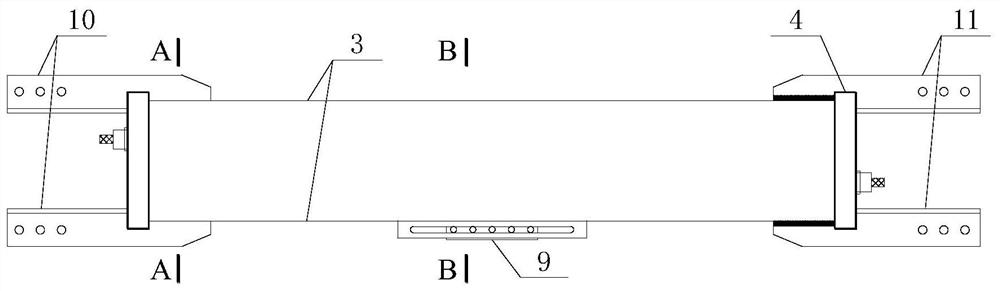

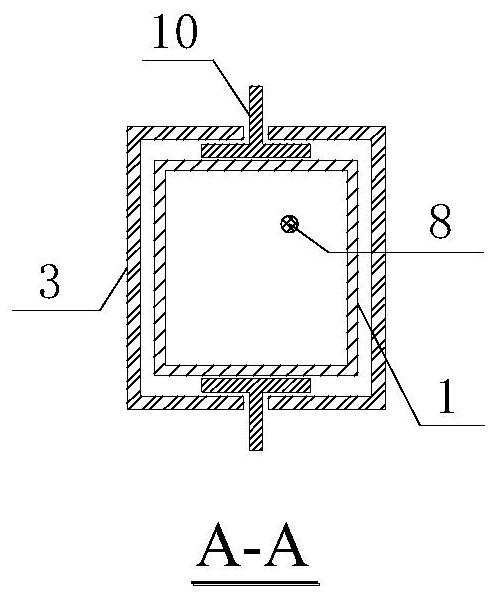

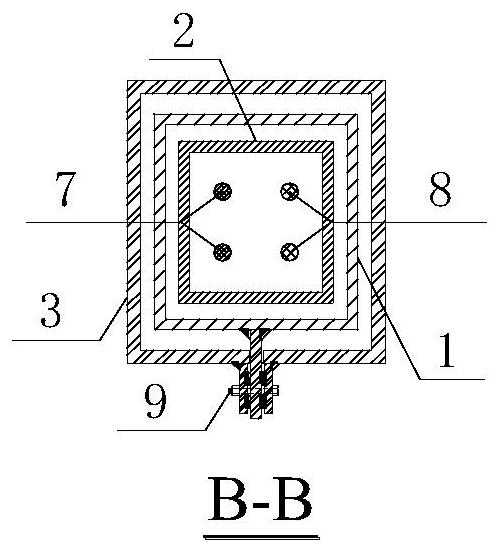

[0032] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] Such as Figure 1 to Figure 8 As shown, the self-centering frictional energy-dissipating support of the large deformation pulley block of the present invention includes a rectangular middle sleeve 1, a rectangular inner sleeve 2 located inside the rectangular middle sleeve 1, and a rectangular inner sleeve set outside the rectangular middle sleeve 1. Outer sleeve 3, two outer end plates 4 arranged at both ends of the rectangular middle sleeve 1, two inner end plates 5 arranged at both ends of the rectangular inner sleeve 2, arranged on the side of the inner end plate 5 close to the rectangular inner sleeve 2 The pulley 6, the first group of pre-tension rods 7 and the second group of pre-tension rods 8 arranged in the rectangular inner sleeve 2, the frictional energy dissipation parts 9 connecting the bottom plate of the rectangular mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com