Mechanical pencil

A technology for mechanical pencils and refills, applied in mechanical pencils, printing, writing utensils, etc., can solve the problems of not easy to observe the existence of refills, not easy to confirm, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

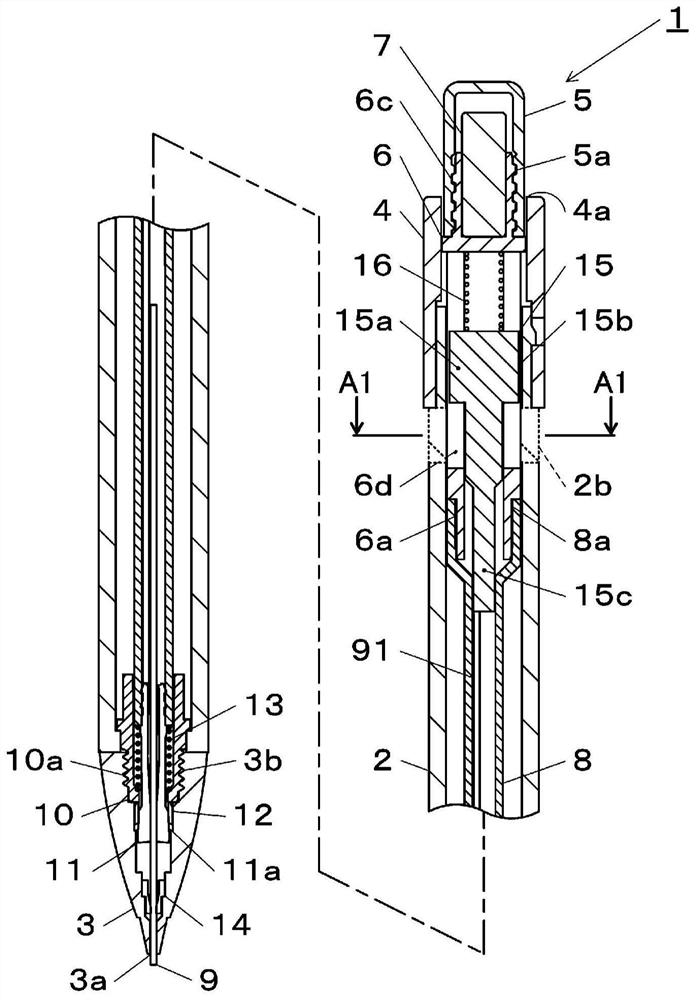

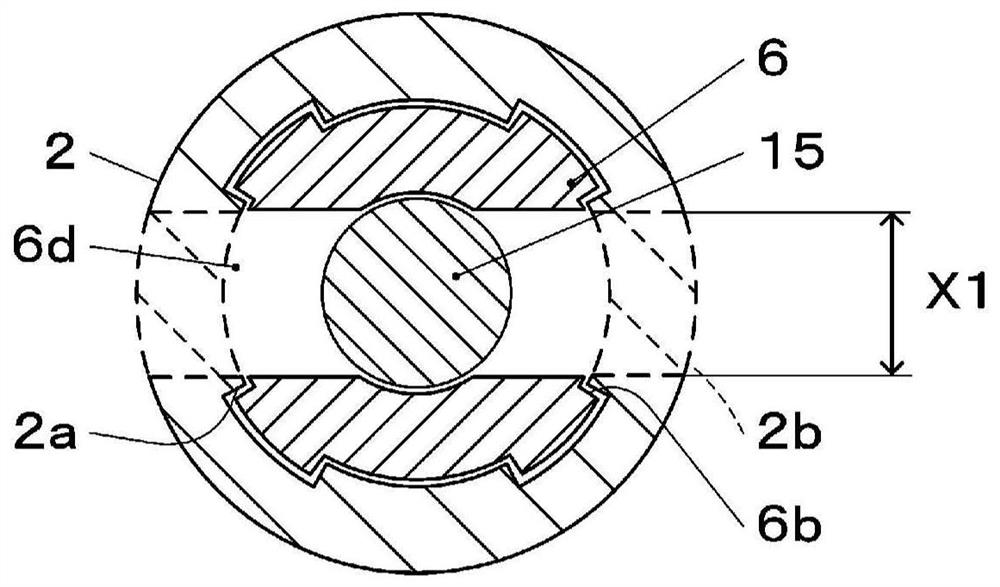

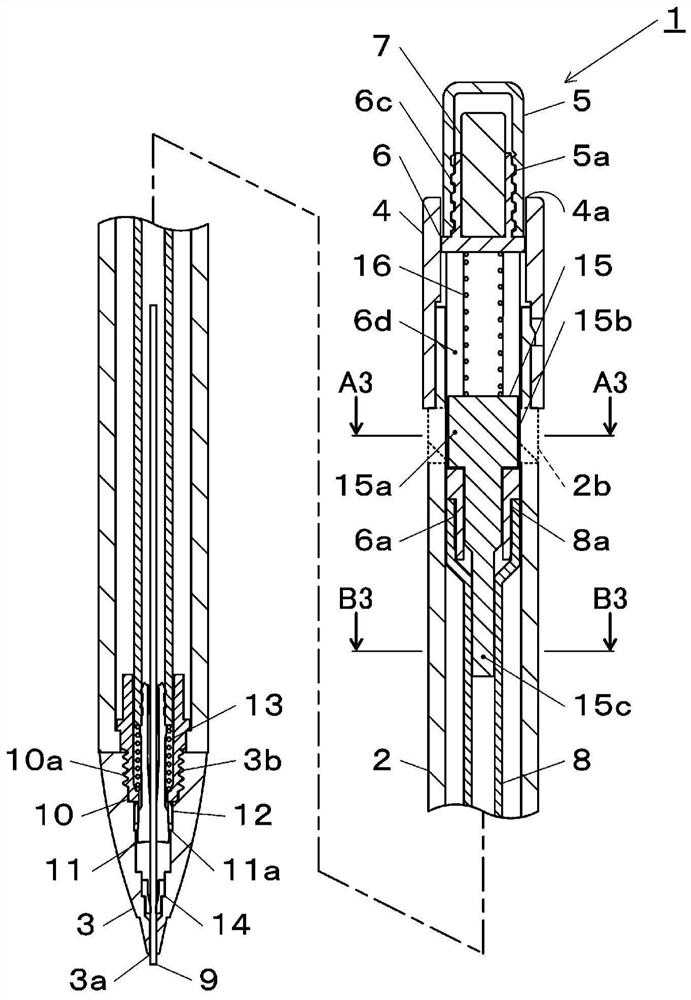

[0040] Hereinafter, the mechanical pencil 1 of this embodiment will be described in detail with reference to the drawings.

[0041] figure 1 It is a longitudinal sectional view showing a state in which a spare refill 91 is provided in the refill tank 8 in the mechanical pencil 1 of the present embodiment, figure 2 yes figure 1 The A1-A1 cross-sectional view of the mechanical pencil 1, image 3 is shown in figure 1 A longitudinal sectional view of a state in which there is no spare refill 91 in the refill tank 8 of the mechanical pencil 1, Figure 4 yes image 3 The A3-A3 cross-sectional view of the mechanical pencil 1, Figure 5 yes image 3 B3-B3 cross-sectional view of Mechanical Pencil 1.

[0042] In addition, in this specification, the direction in which the central axis of the mechanical pencil 1 extends (longitudinal direction, vertical direction in a longitudinal sectional view) is the axial direction, the direction perpendicular to the axial direction is the ra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap