Current collecting ring rotor module and manufacturing method thereof

A manufacturing method and collector ring technology, which is applied in the manufacture of slip rings, current collectors, and rotating collectors, can solve the problems of complex manufacturing methods and the inability to organize the wires connected to the stator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to clearly illustrate the specific implementation mode, structure and achieved effects of the present invention, the illustrations are as follows:

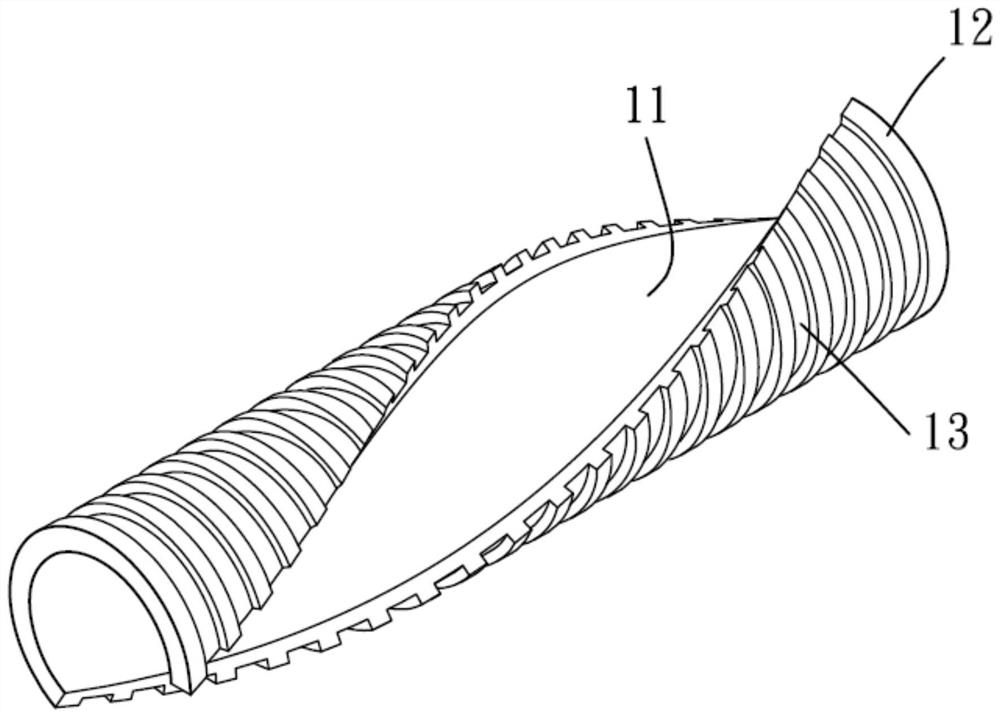

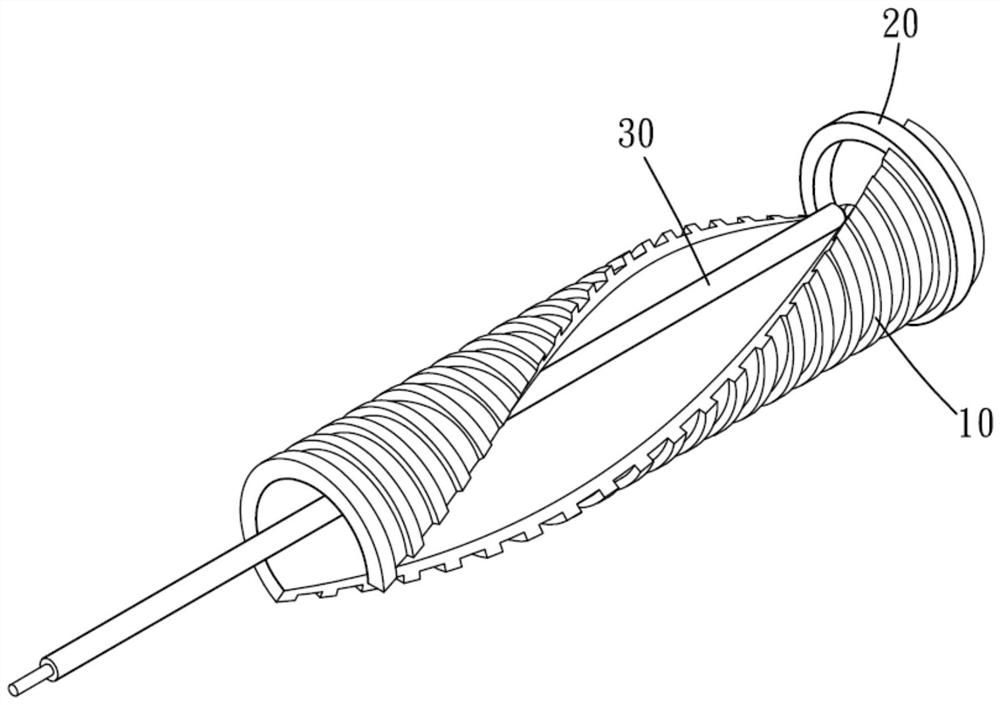

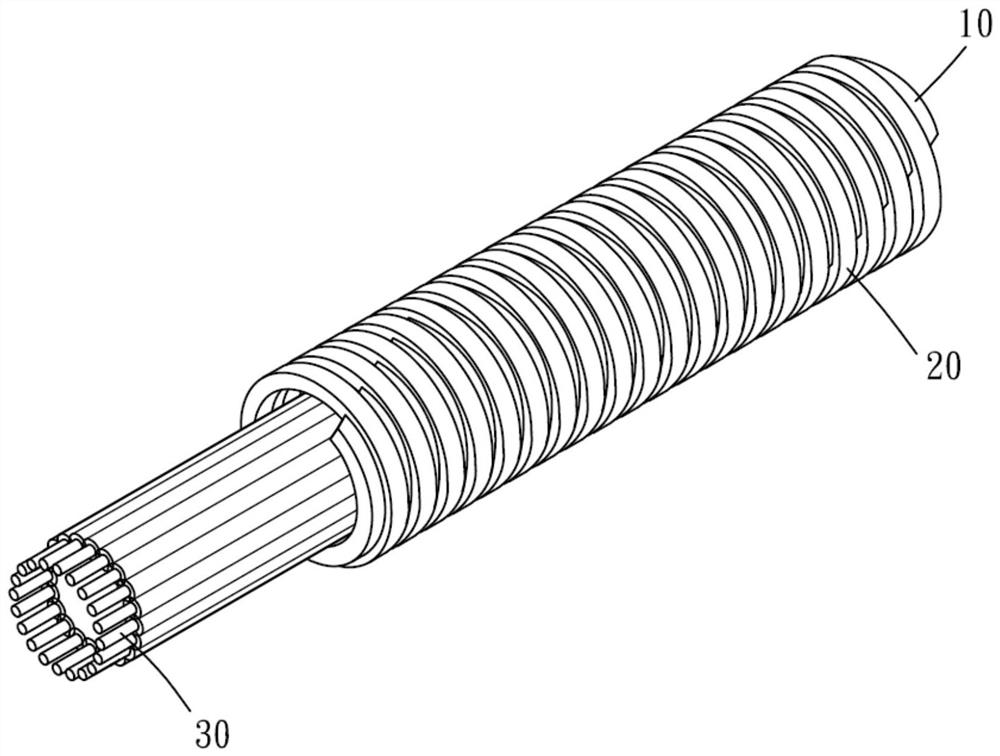

[0018] see figure 1 , shows a structure of a positioning member 10. The positioning member 10 has a side wall that spirally surrounds along the imaginary axis, and the side wall has an inner wall surface 11 facing the virtual axis and an outer wall surface 12 away from the virtual axis. The outer wall surface 12 defines a slightly cylindrical conductive ring positioning area, and is connected with the conductive ring 20 (such as figure 2 shown) in partial contact with the inner ring surface. In other words, the side wall has a spiral outer edge, so that the contact surfaces between the outer wall surface 12 and each conductive ring 20 do not form a closed contour. In addition, the material of the positioning member 10 is an insulator as a whole, and the outer wall surface 12 also has a plurality of conductive ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com