Anti-extrusion heat dissipation fan shell and centrifugal heat dissipation fan

A heat dissipation fan and anti-extrusion technology, which is applied in the direction of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of heat dissipation fan shell deformation, difficulty in taking into account the strength of heat dissipation fans, and easy damage to heat dissipation fans, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

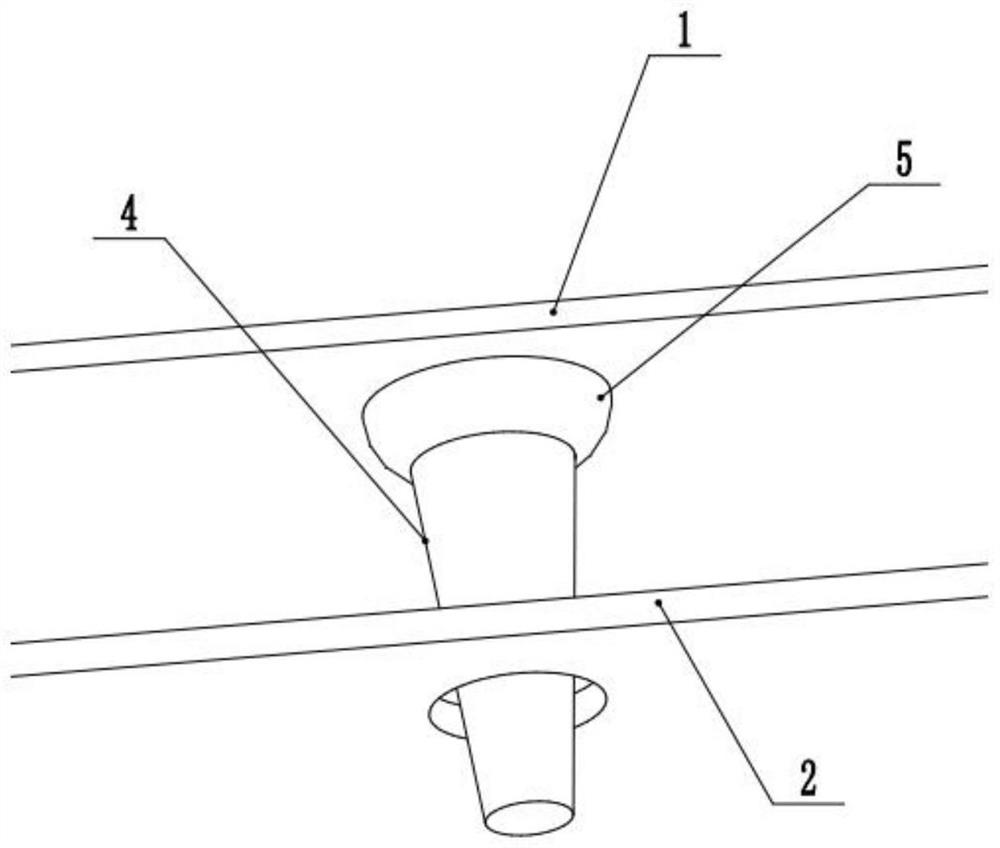

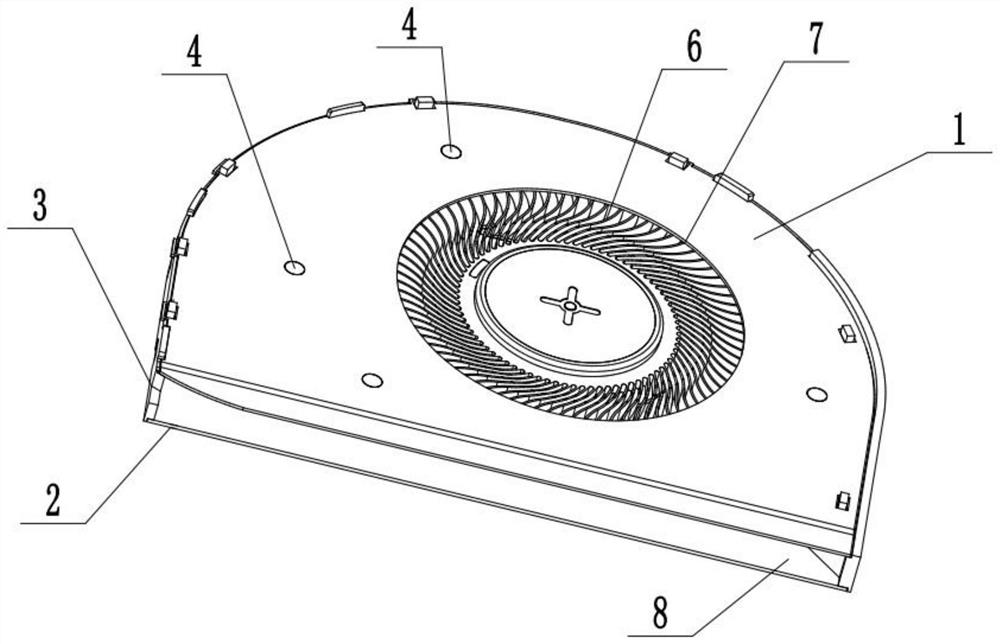

[0023] This embodiment provides an anti-extrusion cooling fan housing, such as Figure 1~2 The application of the anti-extrusion cooling fan housing to the cooling fan of the notebook computer is shown as an example, but not limited to the application to the cooling fan of the notebook computer. In this embodiment, the anti-extrusion cooling fan housing includes a first end plate 1, a second The end plate 2, the support frame 3 and the support column 4, the first end plate 1 and the second end plate 2 are arranged in parallel and respectively clamped with the two ends of the support frame 3, there are several support columns 4, and each support column 4 is connected to the second end plate. One end plate 1 or the second end plate 2 is vertically arranged, and the support column 4 can directly or indirectly transmit the pressure to the supporting structure outside the heat dissipation fan shell when the heat dissipation fan shell is under pressure, so that the first end plate 1 ...

Embodiment 2

[0031] This embodiment provides an anti-extrusion cooling fan housing. The difference between this embodiment and Embodiment 1 is that one end of each support column passes through the first end plate and is fixedly connected with the first end plate, and the support column The other end abuts against the inner surface of the second end plate, and the bottom shell of the notebook computer is provided with an auxiliary support structure fixedly connected or integrally formed with the bottom shell of the notebook computer on the outside of the second end plate and at the corresponding positions of the supporting columns , when the keyboard part of the notebook computer is under pressure, when the pressure is transmitted to the heat dissipation fan shell, because each supporting column extends out of the first end plate, it contacts the keyboard part of the notebook computer before the first end plate, and the supporting column is subjected to the pressure of the notebook computer....

Embodiment 3

[0033] This embodiment provides a centrifugal cooling fan, such as figure 2 As shown, including the fan wheel 6 and the anti-extrusion cooling fan housing of either the first or second embodiment, the first end plate 1 is provided with an air inlet 7 , and the support frame 3 is provided with an air outlet 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com