Method for detecting tool misalignment and packaging machine

A packaging machine and tool technology, which is applied in the field of optimizing the operation of packaging machines, can solve problems such as unsuitable for closing trays, unable to reliably distinguish foreign objects in protruding parts of products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

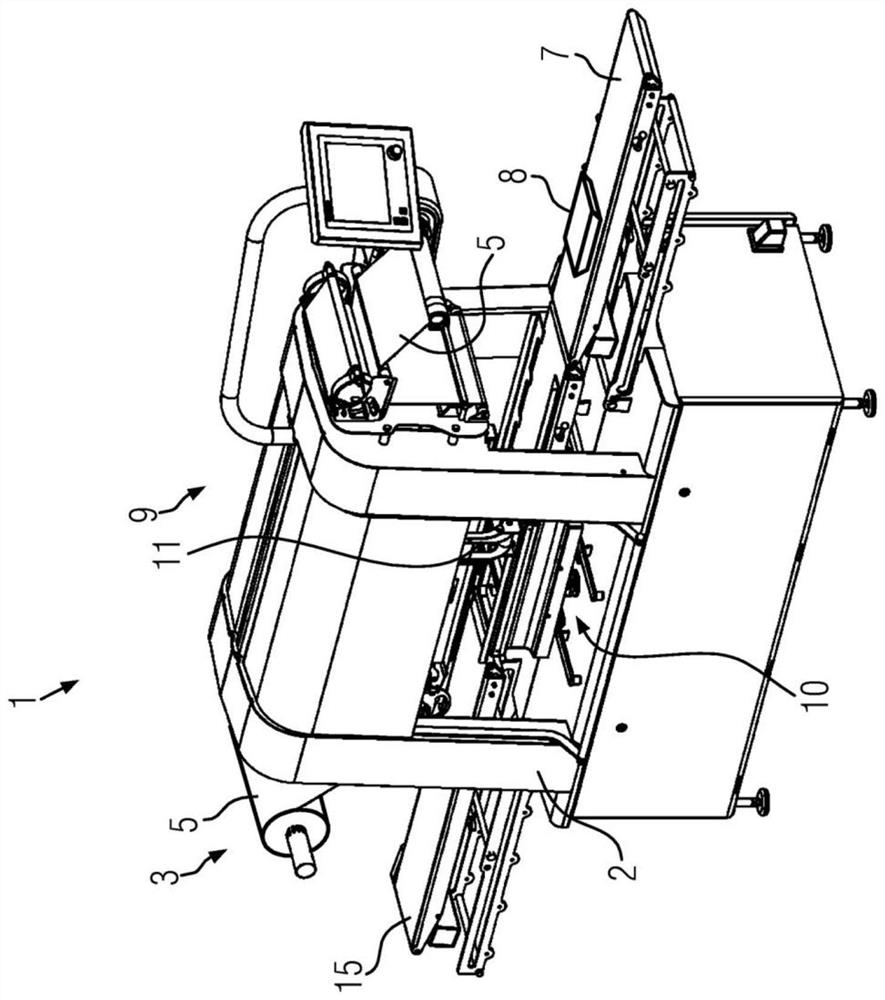

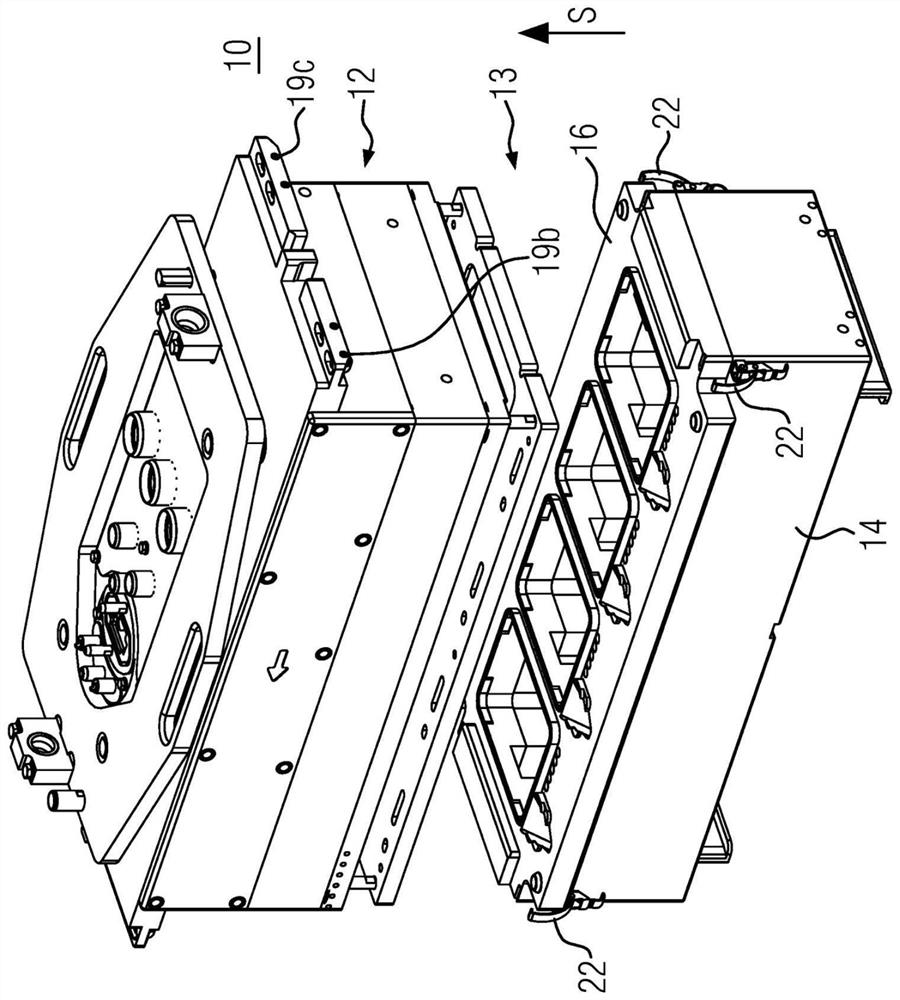

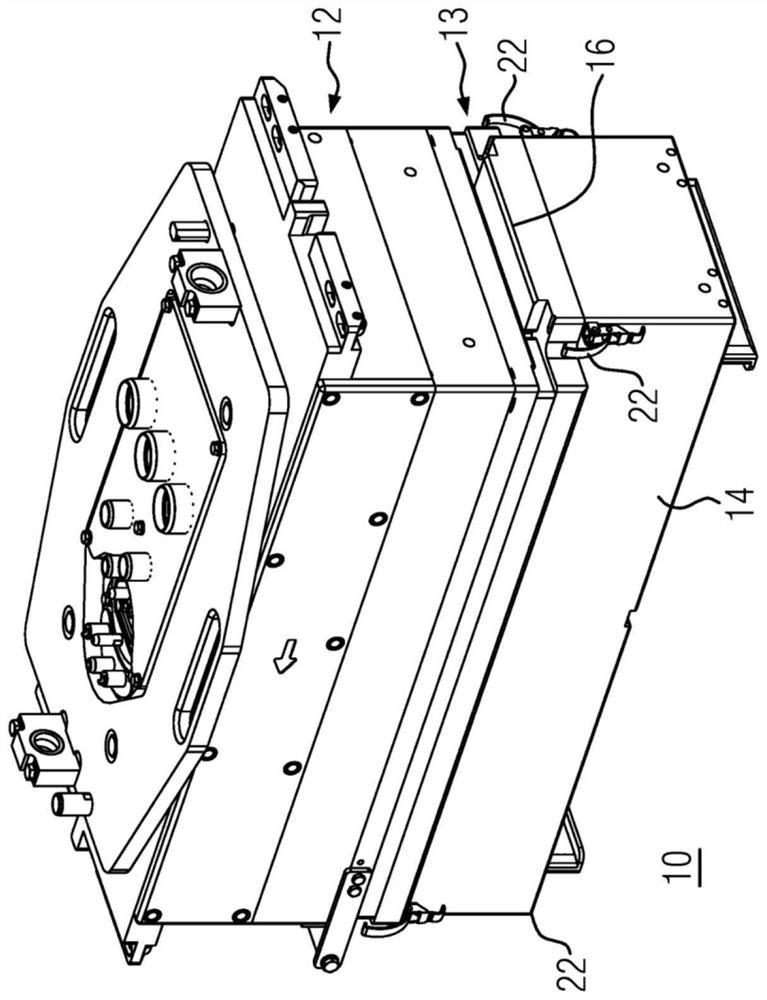

[0031] figure 1 An example of a packaging machine 1 is shown which, as in the present example, may be a tray sealing machine. The packaging machine may comprise a frame 2 . The packaging machine 1 can also have a conveyor belt 7 . Furthermore, the packaging machine can also have a packaging station 9 . The filled but not yet encapsulated trays 8 can be transported to the encapsulation station 9 via the conveyor belt 7 . The tray 8 can be moved by means of the gripping device 11 into the sealing station 9 and sealed there by means of a cover film 5 (film) supplied from above, for example by sealing the cover film 5 . For this purpose, the encapsulation station 9 can comprise a sealing tool 10 , which will be described in more detail below. The package completed in this way can be moved from the packaging station 9 to the output belt 15 via the gripping device 11 .

[0032] After the cover film 5 has been sealed, regions of the cover film 5 corresponding to the package or p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com