Chemical process monitoring method based on time sequence multi-block modeling strategy

A chemical process and timing technology, applied in the direction of program control, comprehensive factory control, and comprehensive factory control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific examples of implementation.

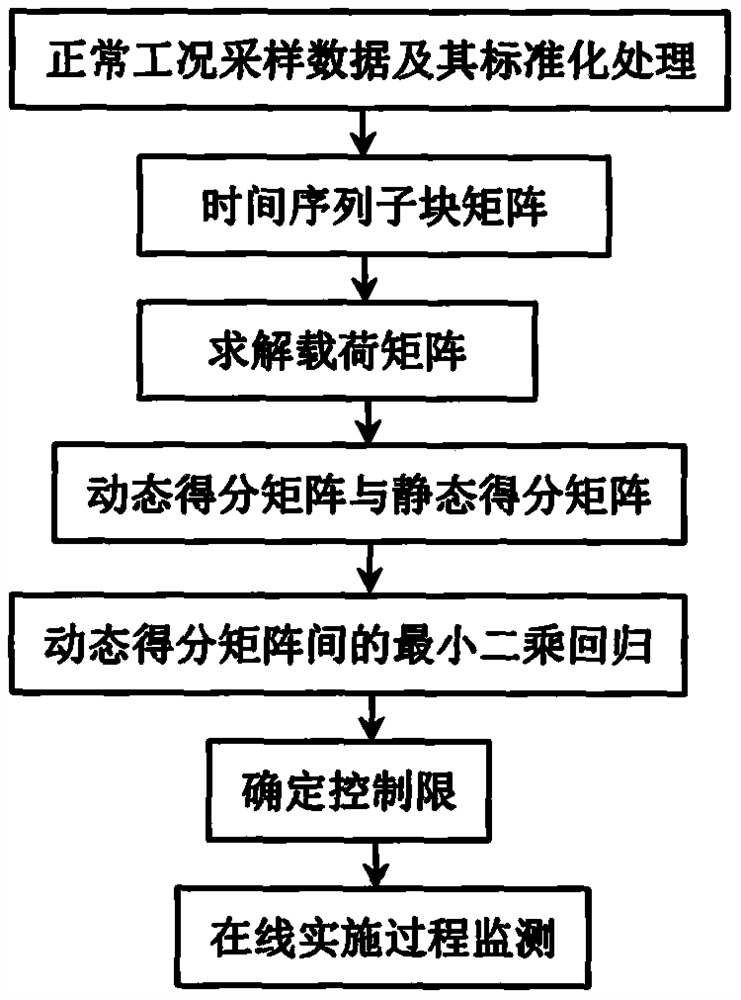

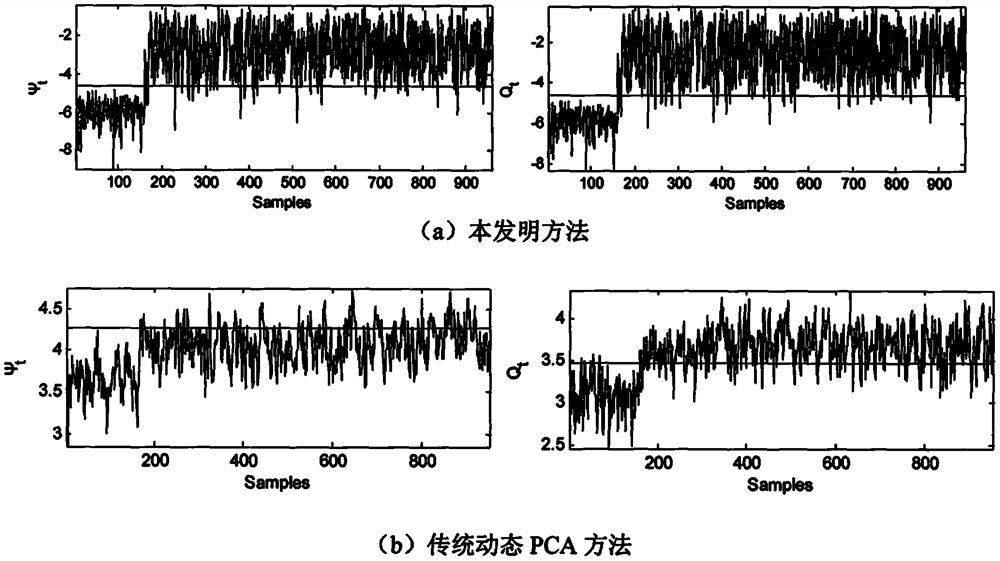

[0041] Such as figure 1 As shown, the present invention discloses a chemical process monitoring method based on a time-series multi-block modeling strategy. The following describes the specific implementation process of the method of the present invention and its superiority over existing methods in conjunction with a specific chemical process object.

[0042] Table 1: TE process monitoring variables.

[0043]

[0044]

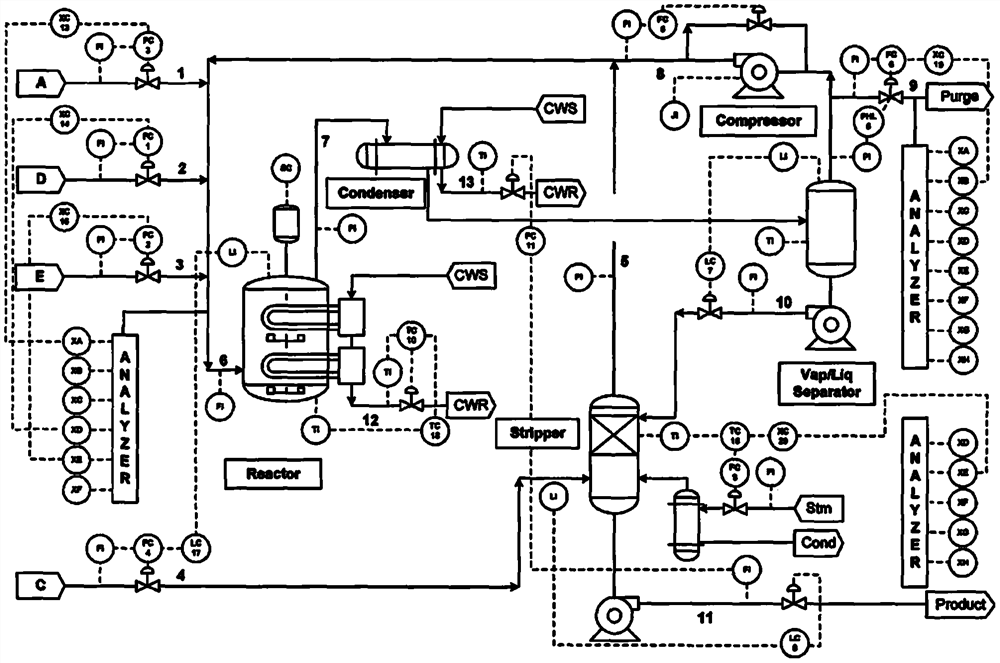

[0045] The application object is from the chemical production process of Tennessee-Eastman (TE) in the United States. The TE process is an actual process flow of the Eastman chemical production workshop. The schematic diagram of the process is as follows figure 2 shown. At present, the TE process has been widely used as a standard experimental platform for process operation status monitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com