Patents

Literature

30 results about "Block modeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

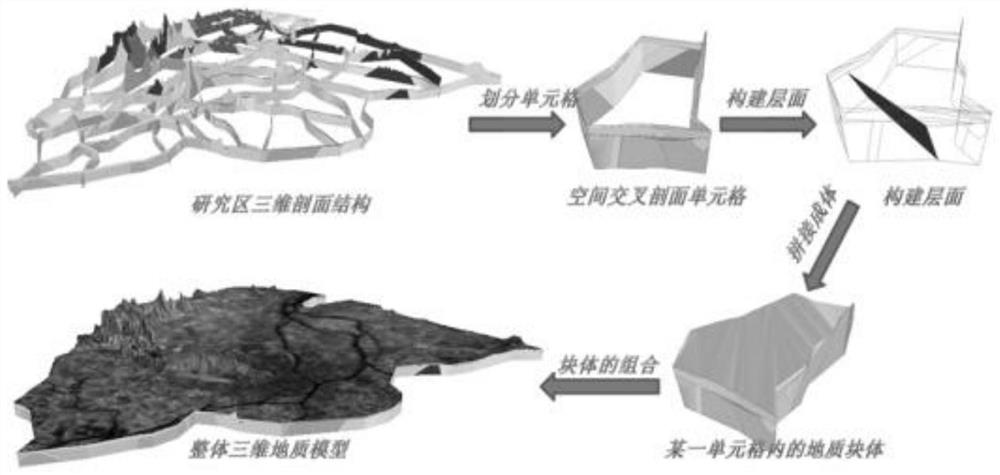

Block model building method for complex geological structure

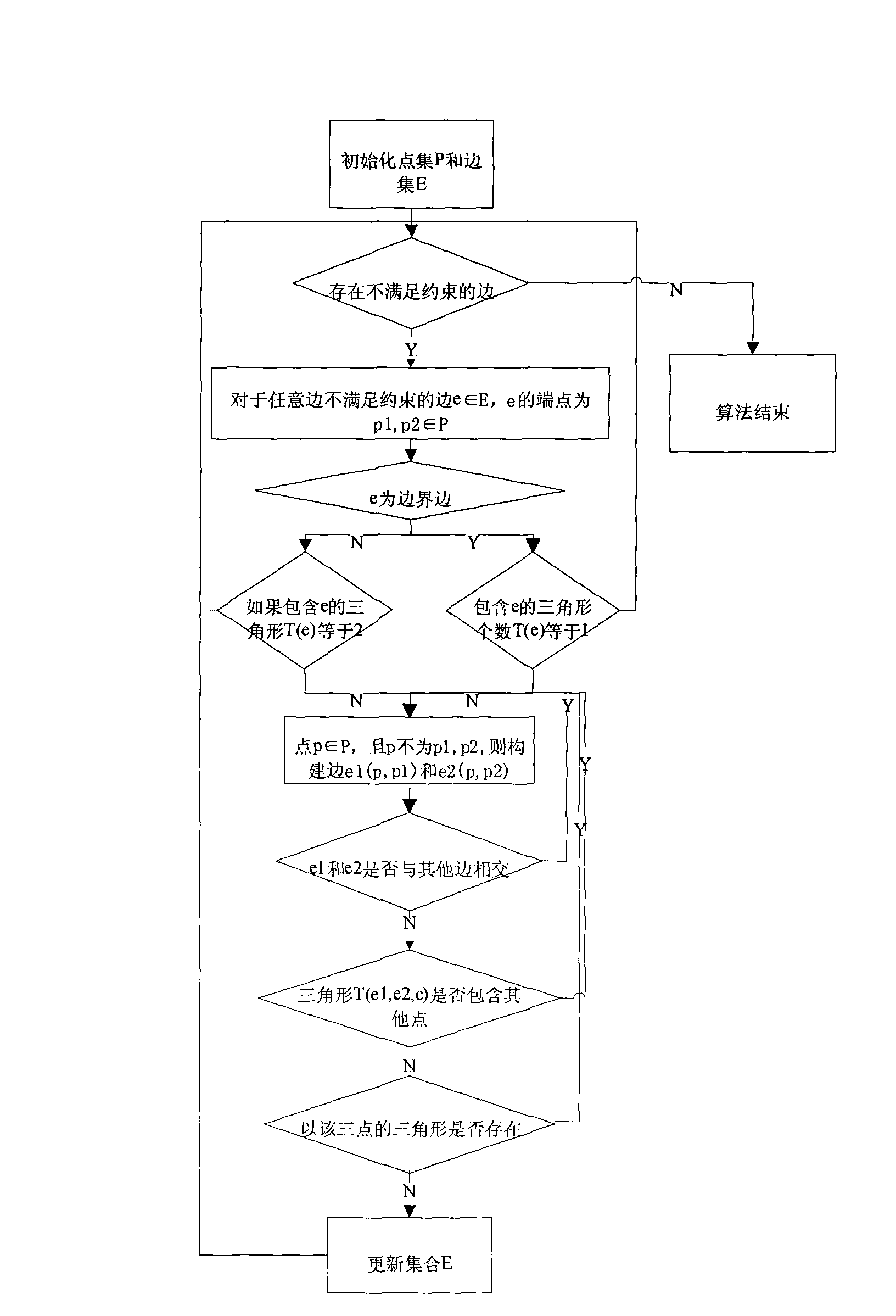

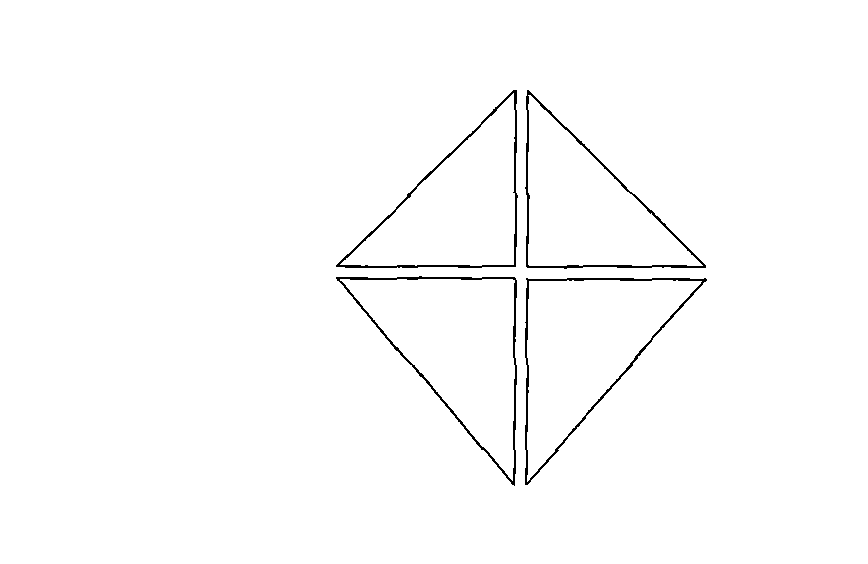

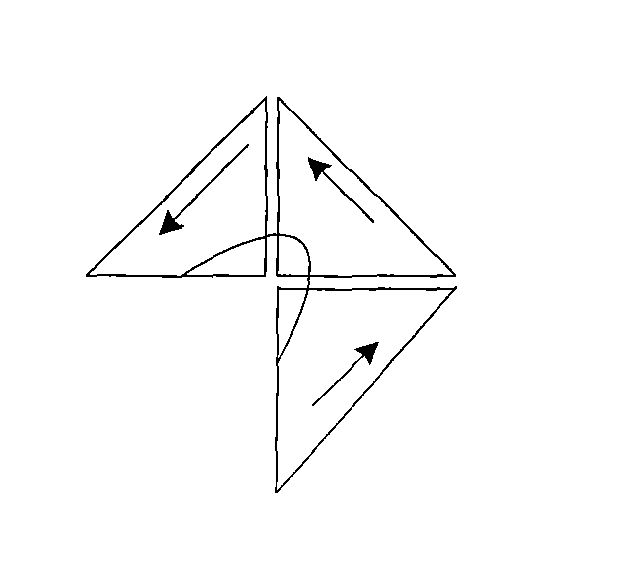

InactiveCN101582173AEasy to buildSmall amount of calculationGeomodelling3D-image renderingGeometric consistencyTopological consistency

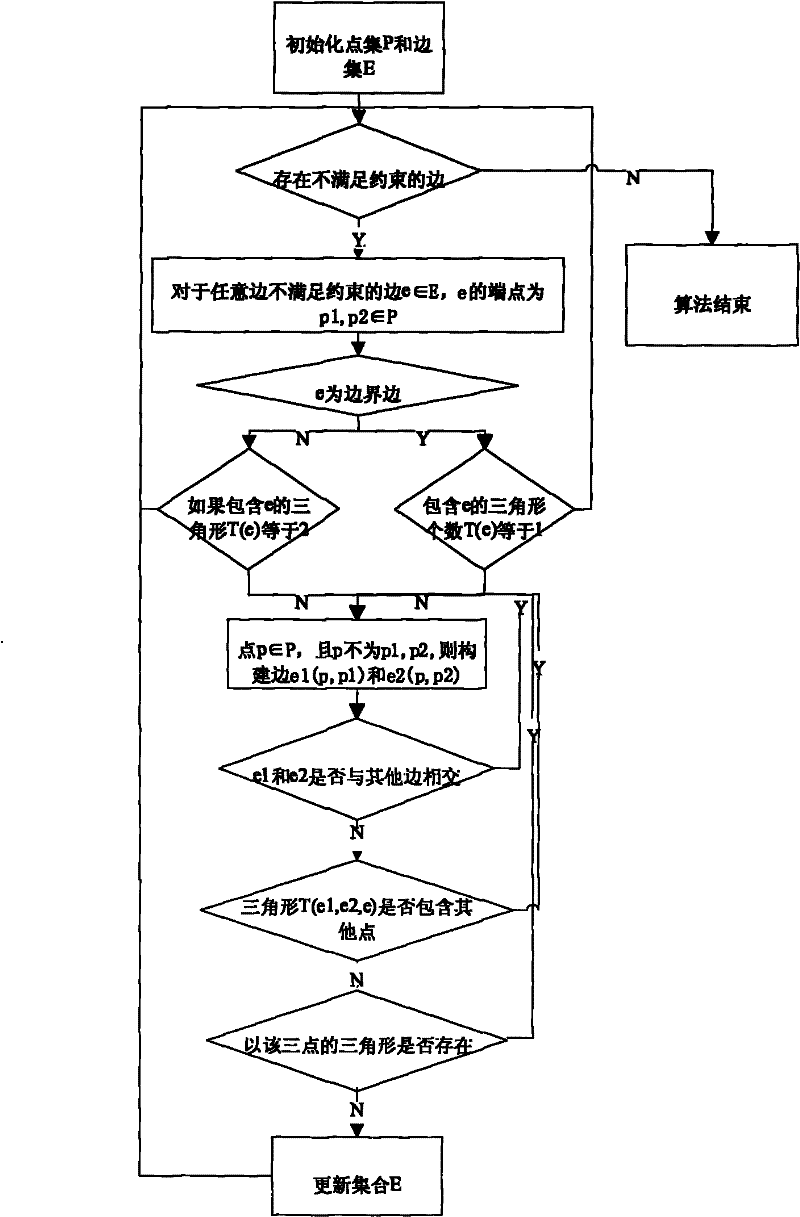

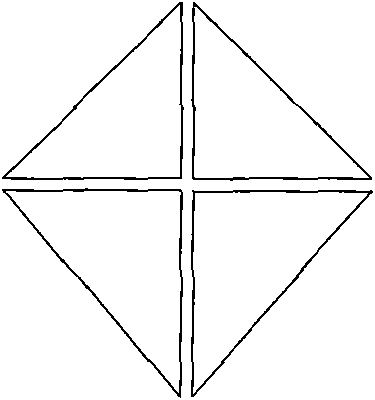

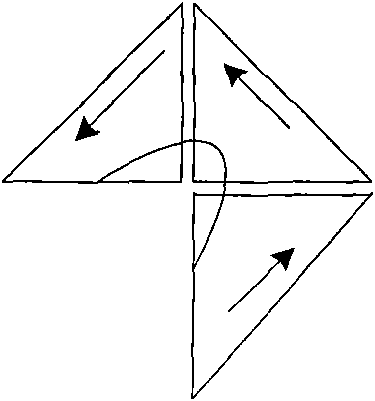

The invention discloses a block model building method for complex geological structure, and relates to the geological field of three-dimension modeling comprising the following steps: a, triangular meshing description is carried out on planes or fault planes; b, after step a, level intersection in block modeling for complex geological structure is converted into triangle intersection in space, whether the two triangles are intersected is judged, points of intersection are found from the two intersected triangles, and a line of intersection is obtained by connecting the points of intersection; c, geometric consistency and topological consistency are carried out on inside of each intersected triangle; d, after step c, enclosing block is extracted to obtain an interface formed by peripheral sides of the enclosing block, and is defined geological attribute to form three dimension model block. The method in the invention completely solves the problems of three dimension model input and blocking in complex geological regions, avoids using equations set with high solving difficulty and calculated amount, and is simple and practical.

Owner:BC P INC CHINA NAT PETROLEUM CORP

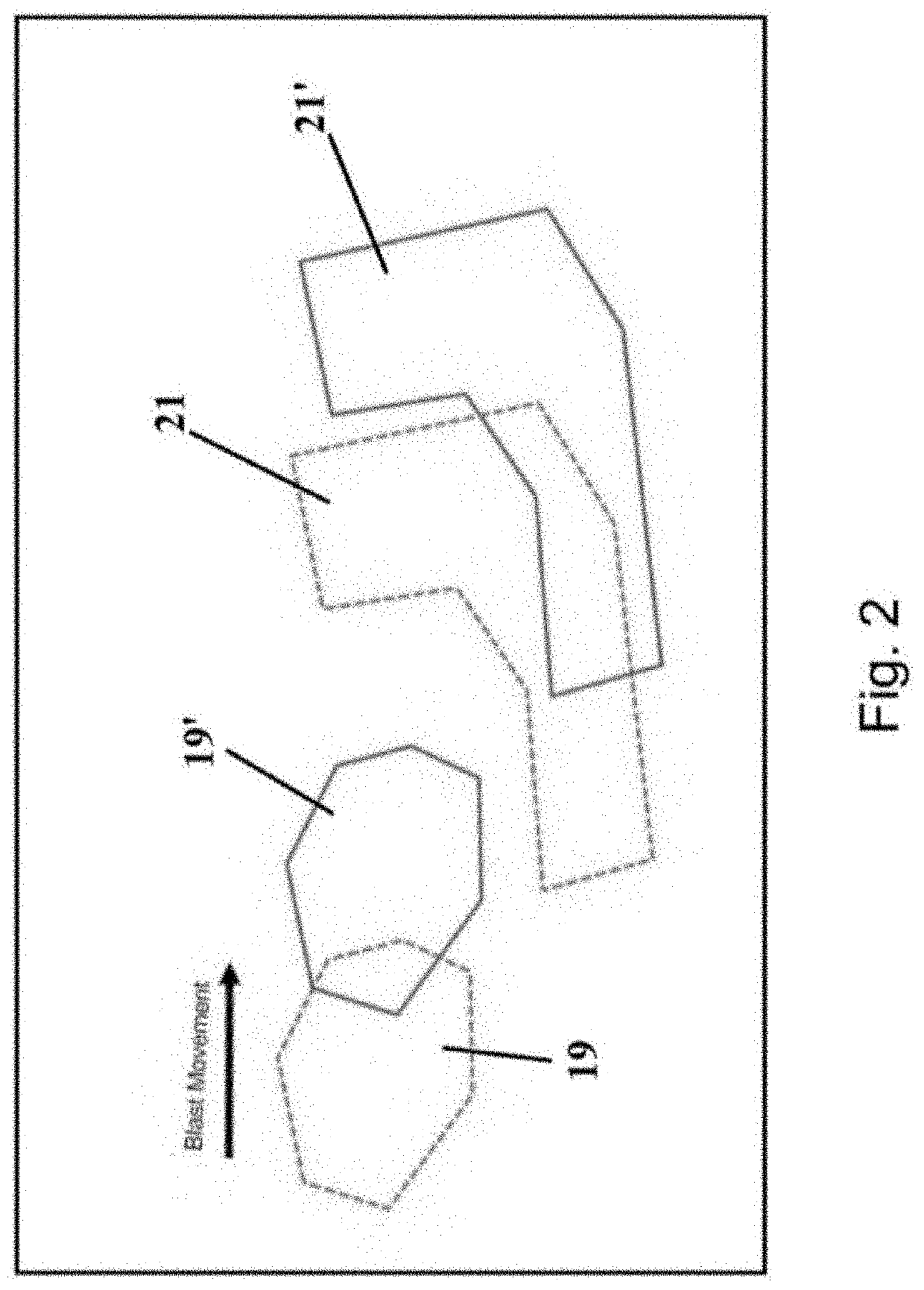

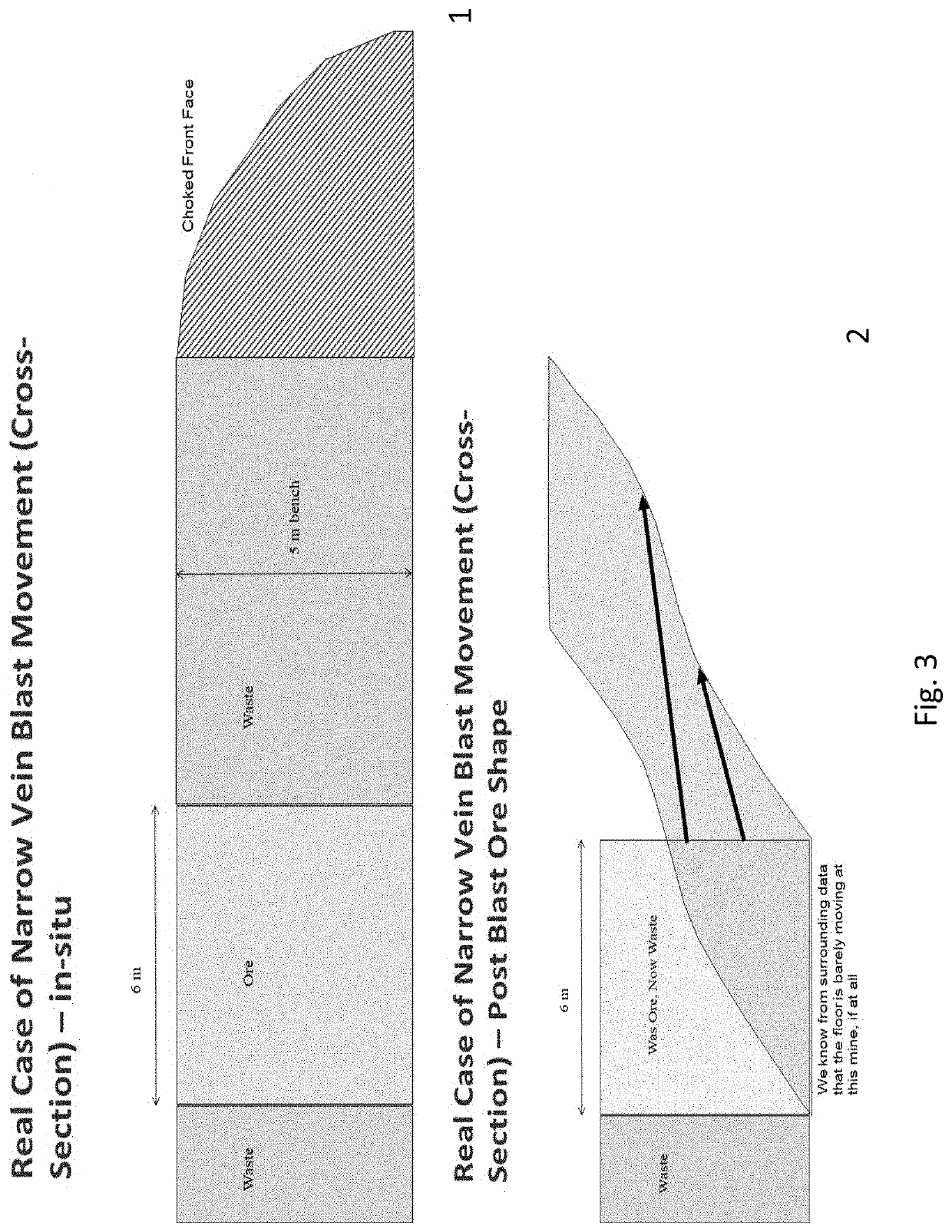

3D block modelling of a resource boundary in a post-blast muckpile to optimize destination delineation

A method for 3-D block modelling of a resource boundary in a post-blast muckpile to optimize destination delineation for resource control is provided. An in-situ pre-blast model of an ore deposit to be mined, movement data, blast design and explosive loading information, and post-blast topographic data are input in to the memory of a general purpose computer. Using the pre-blast block model, movement data, blast design and explosive loading information, and post-blast topographic data a three-dimensional vector field is generated. The method uses the three-dimensional vector field to move a plurality of centroids of the in-situ block model to populate a three-dimensional post-blast location. Then method optimizes the populated three dimensional post-blast location to determine a plurality of sets of optimal dig boundaries.

Owner:ORICA USA

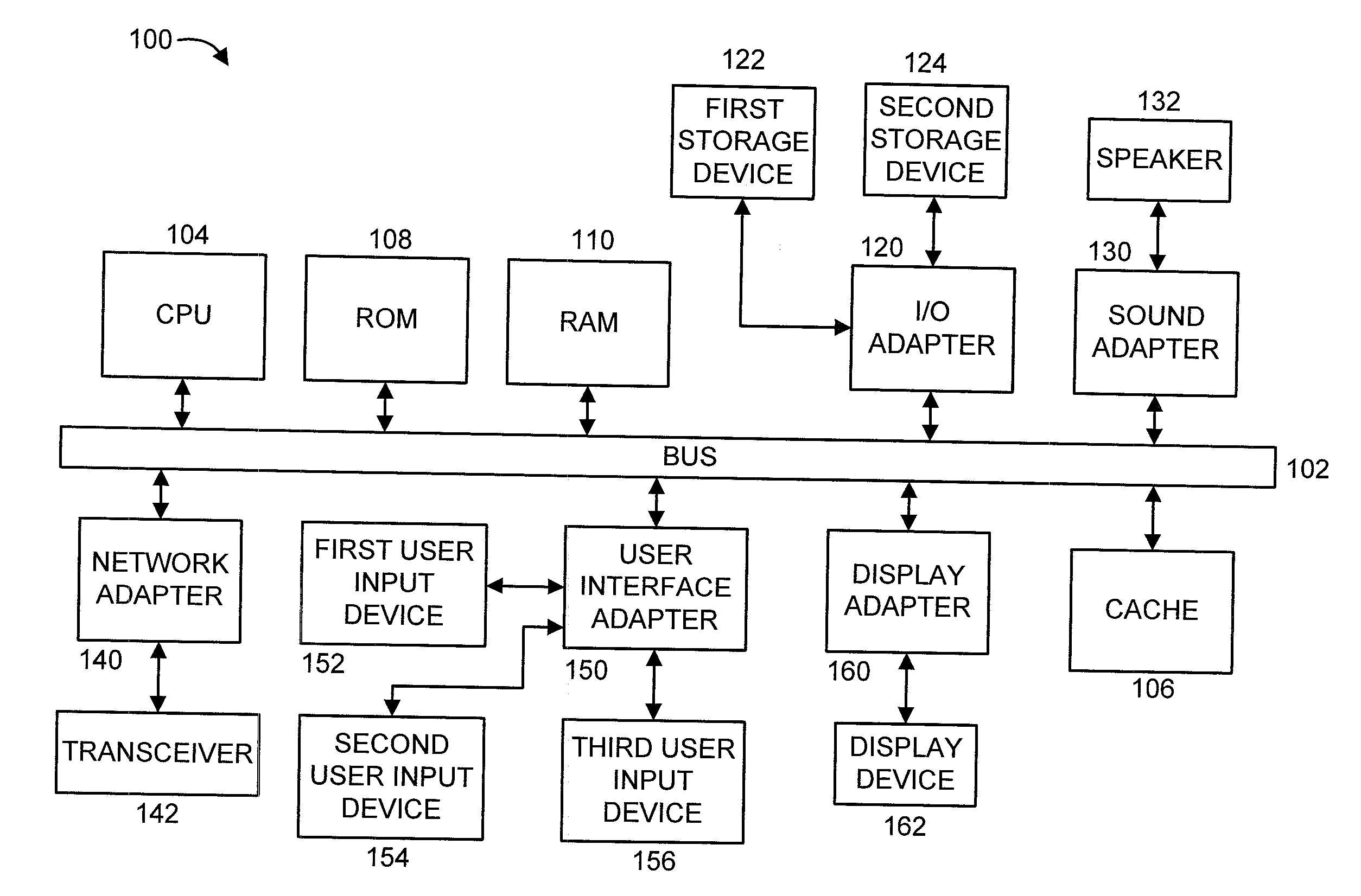

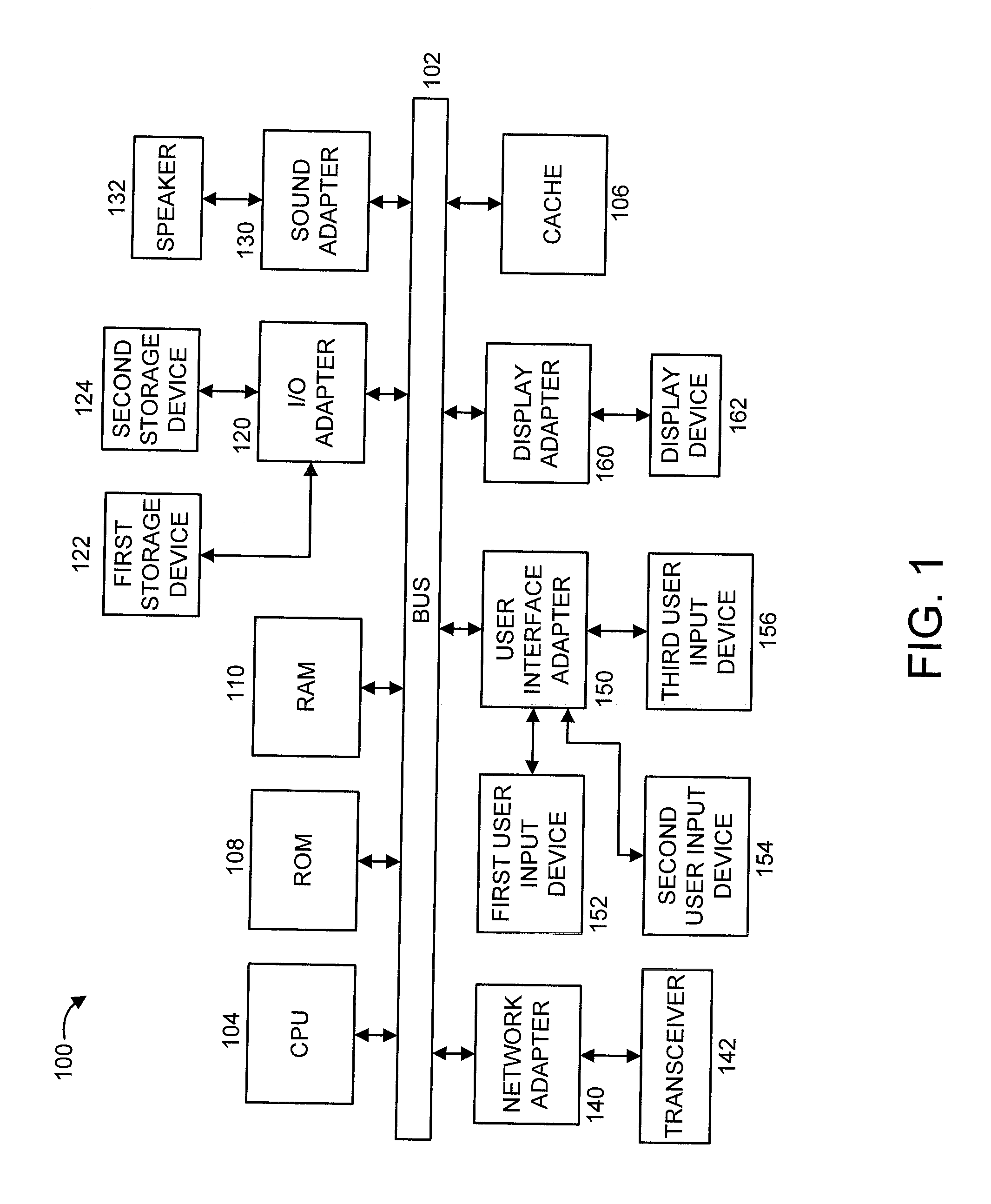

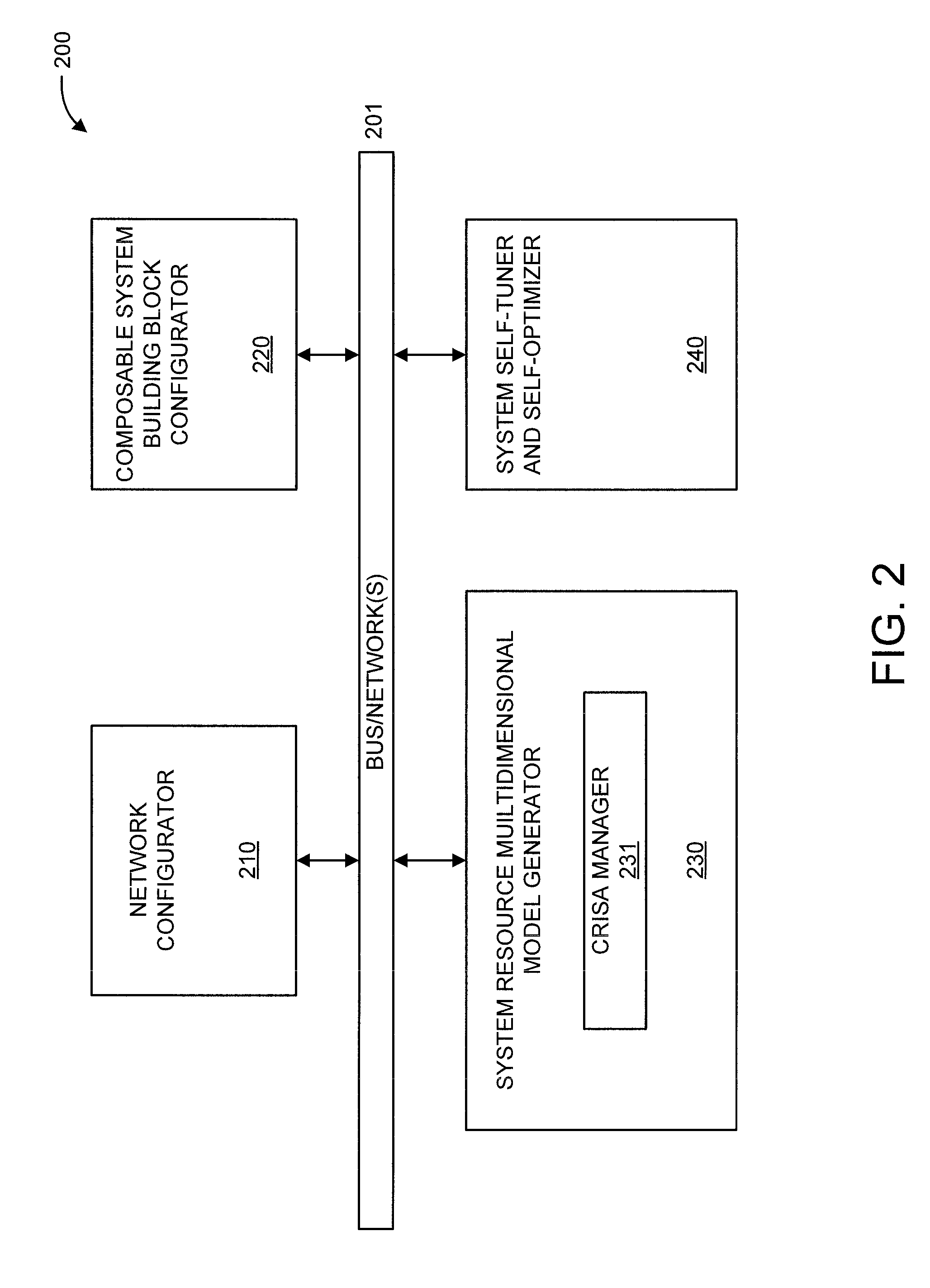

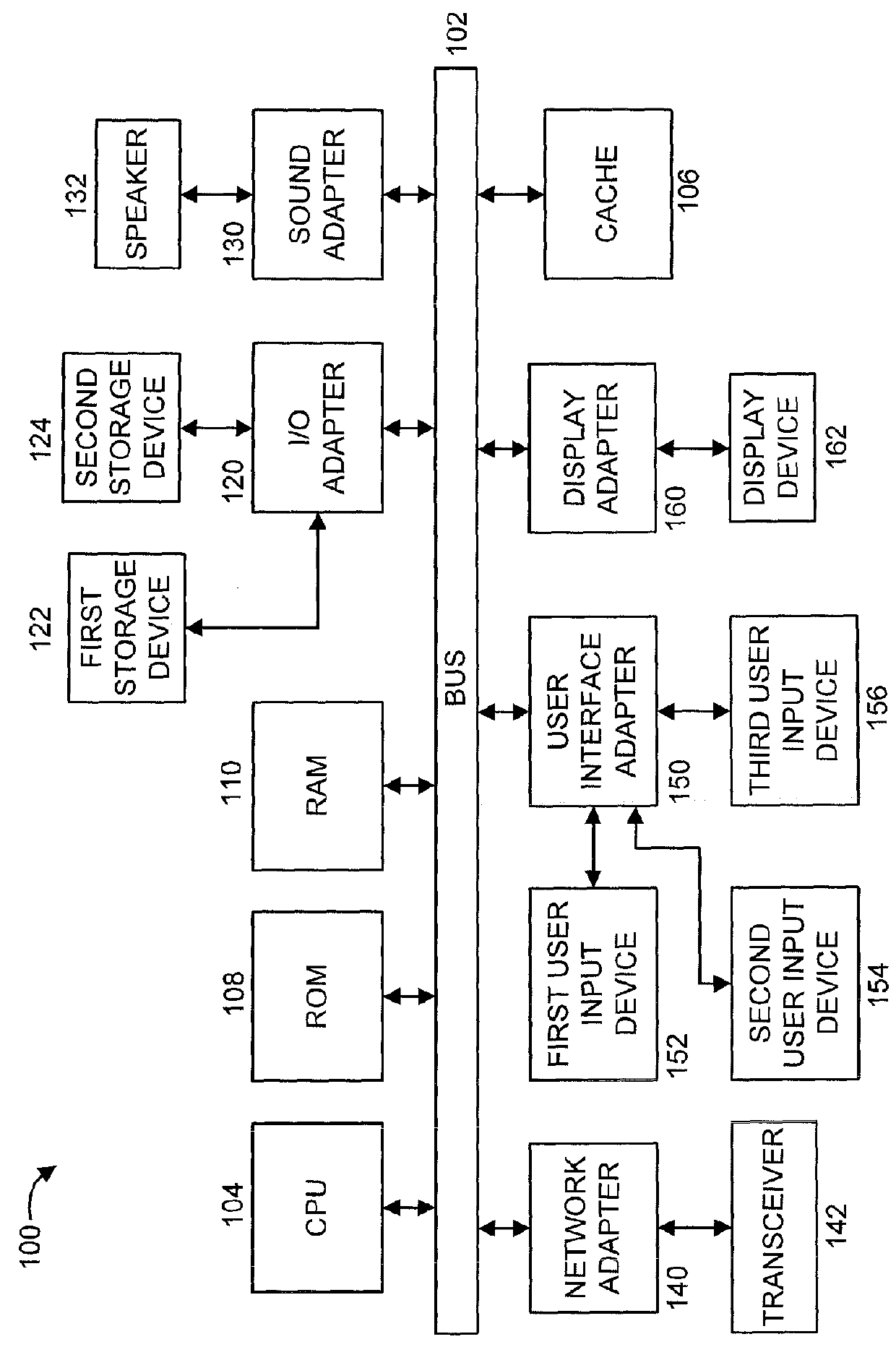

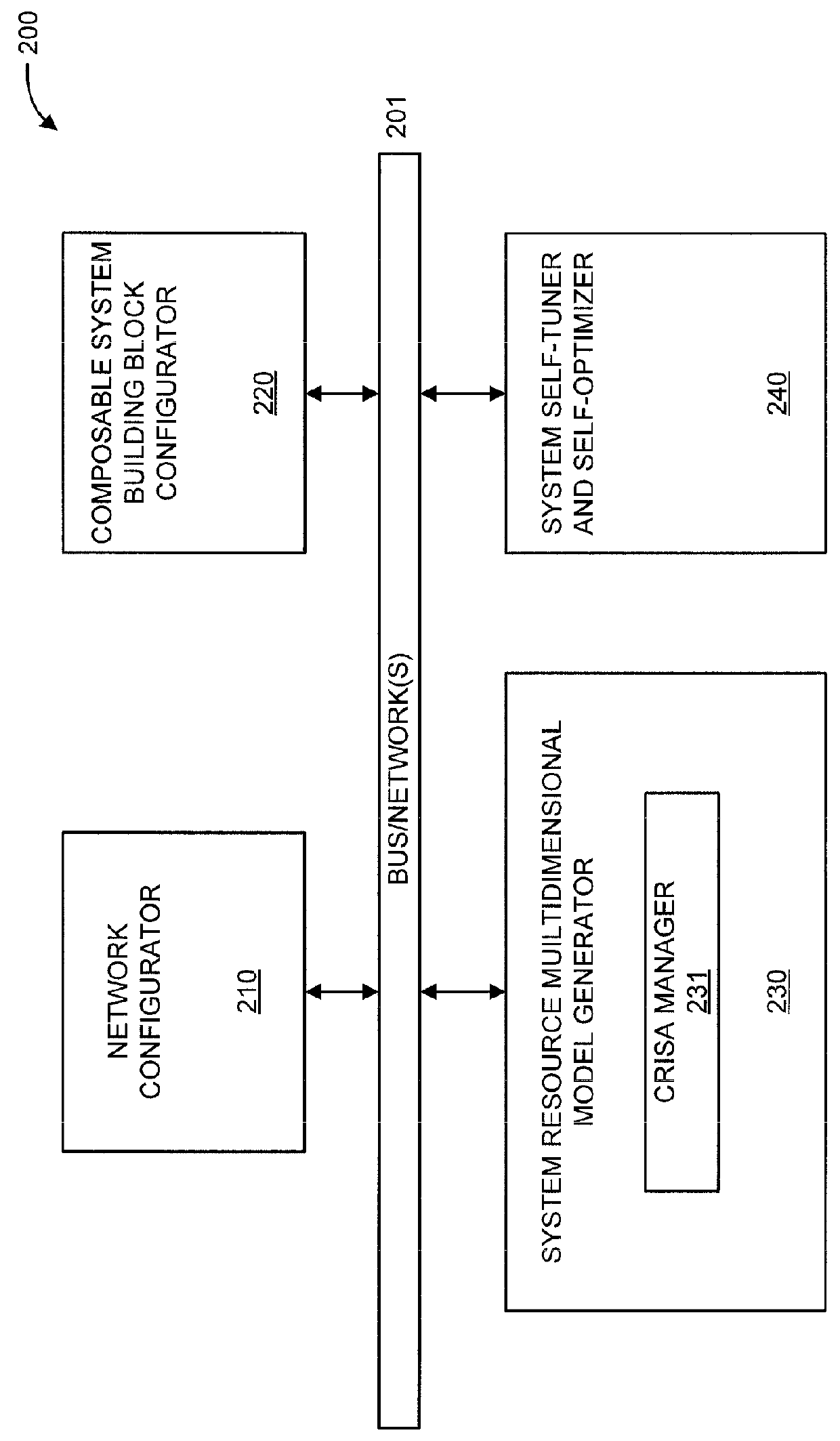

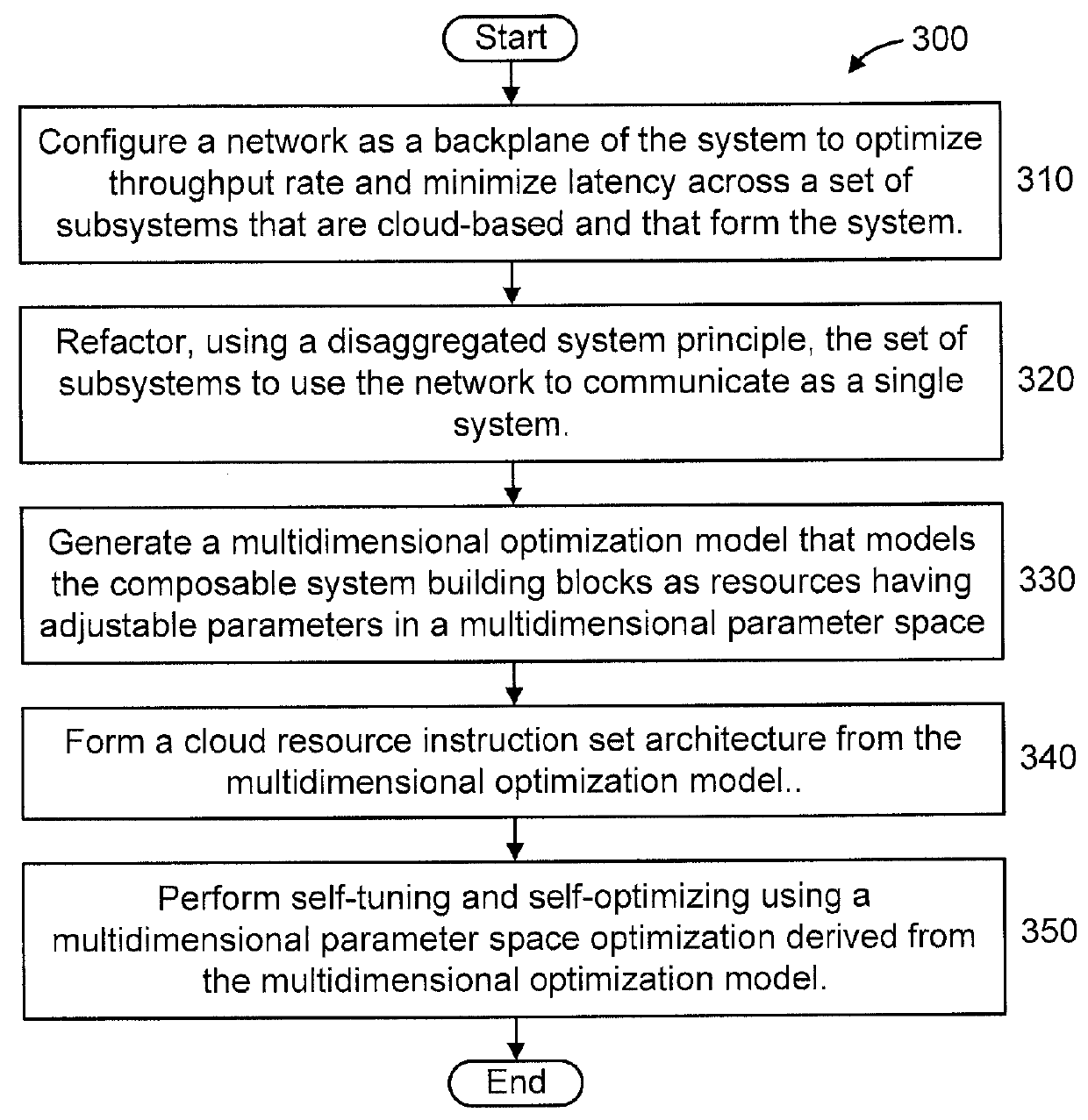

Creating new cloud resource instruction set architecture

ActiveUS20160269229A1Improve throughputDelay minimizationProgram controlData switching networksCloud baseCloud resources

A method and system are provided. The system includes a network configurator for configuring a network as a backplane of the system to optimize throughput rate and minimize latency across a plurality of subsystems that are cloud-based and that form the system. The plurality of subsystems includes hardware and software subsystems. The system further includes a composable system building block configurator for refactoring, based on a disaggregated system principle, the plurality of subsystems to use the network to communicate as a single system. The system also includes a system resource multidimensional model generator for generating a multidimensional optimization model that models the composable system building blocks as resources having adjustable parameters in a multidimensional parameter space.

Owner:IBM CORP

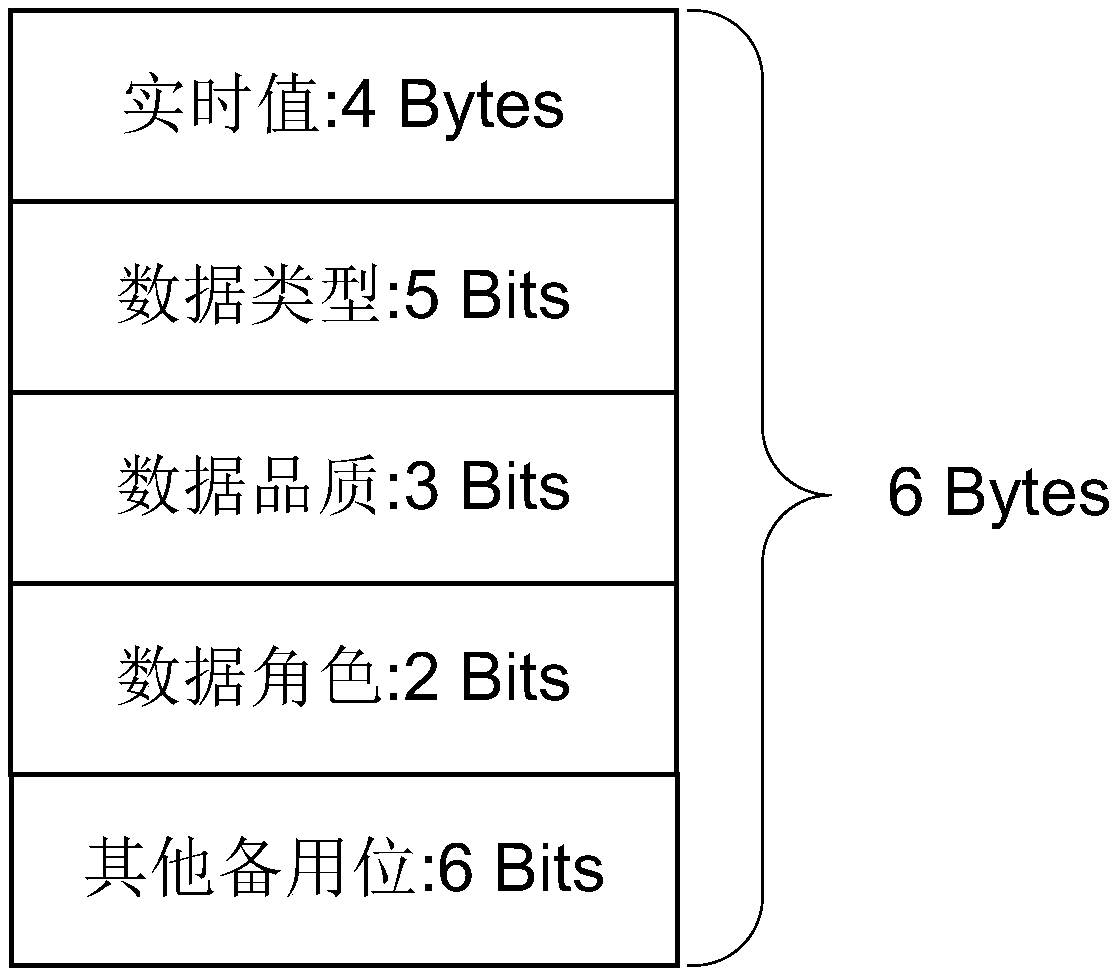

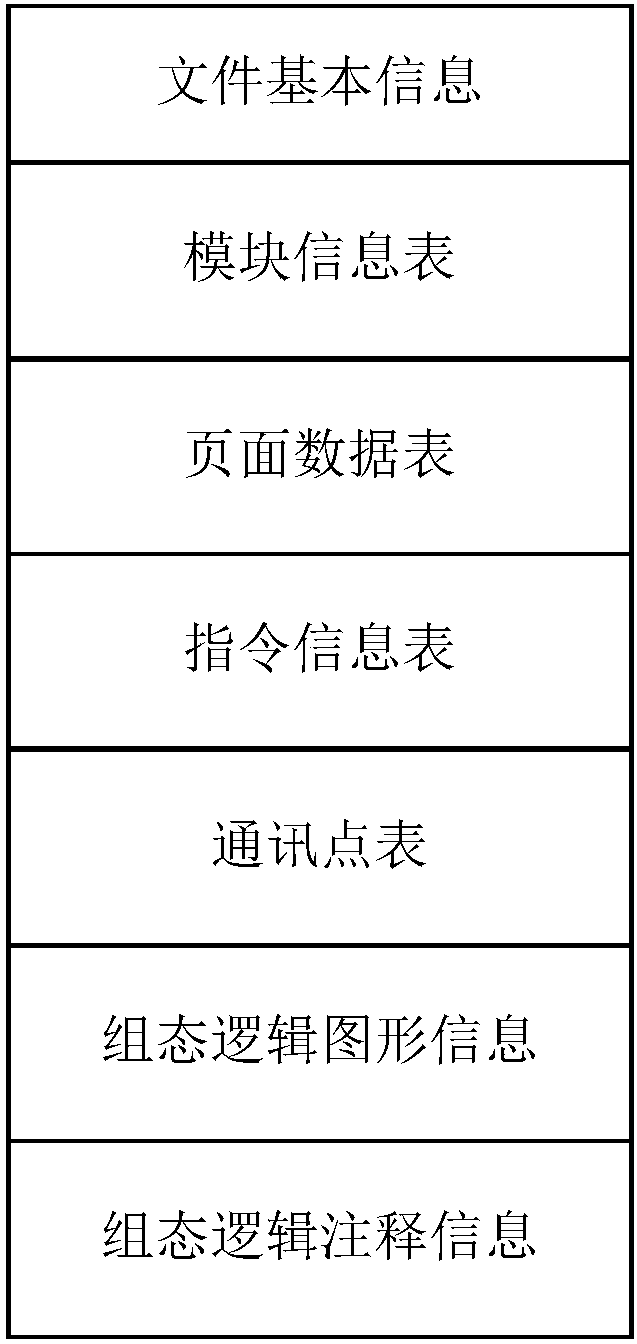

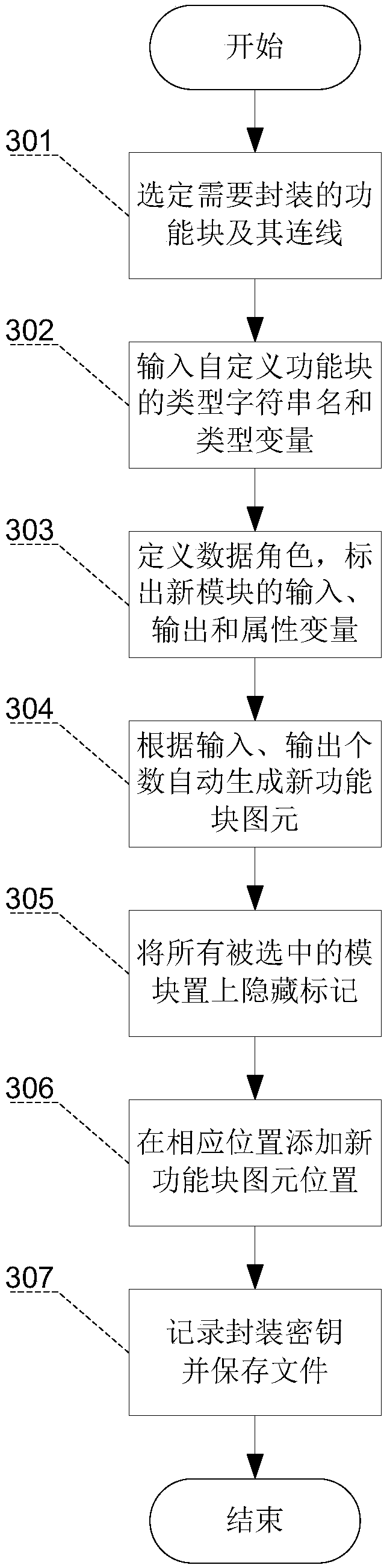

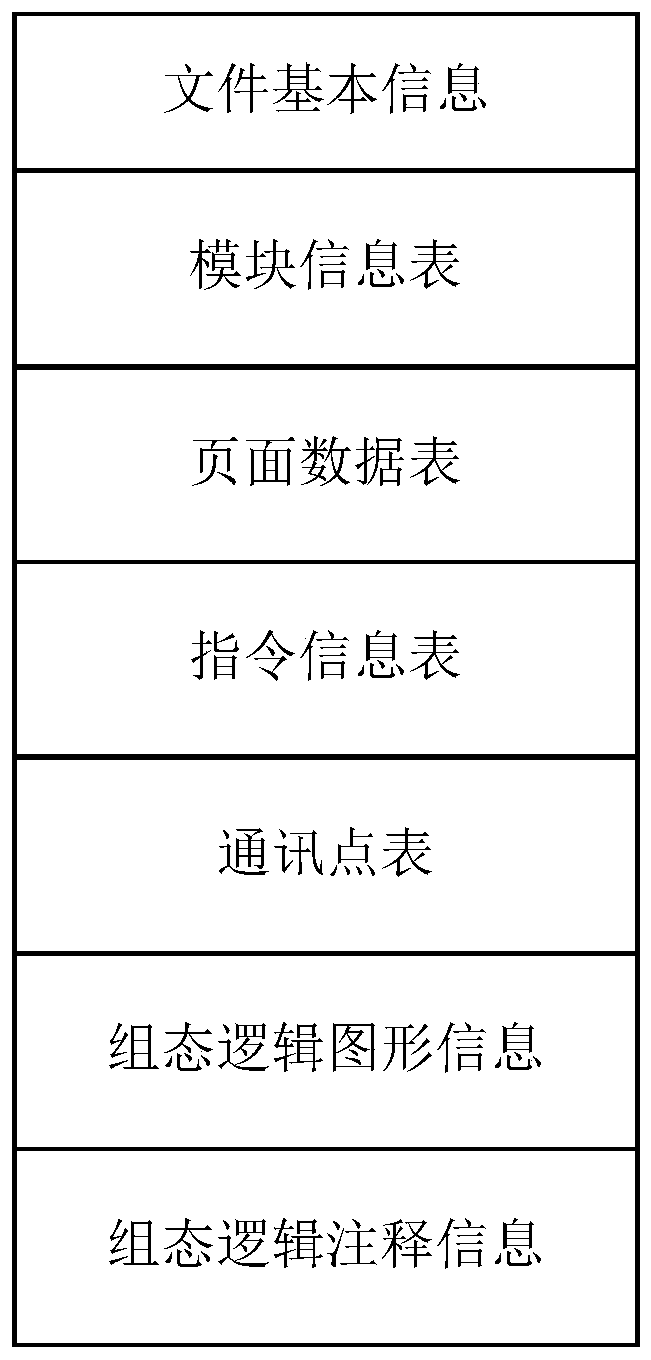

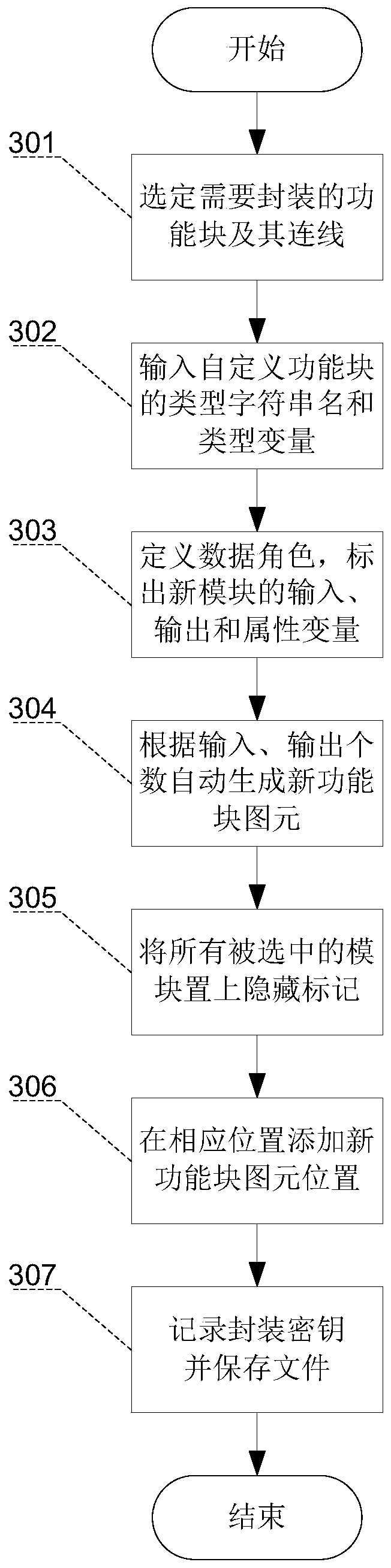

Element model based customized function block and configuration packaging method

ActiveCN107844093AImplement confidentiality managementMeet the characteristicsTotal factory controlProgramme control in sequence/logic controllersElement modelData information

The invention provides an element model based customized function block and configuration packaging method. The method includes steps of a), defining an inheritable function block element model and designing a standard instantiation interface and a uniform data structure; b) instantiating algorithm type function blocks which are universal in industrial control field; c) defining a configuration file structure; d) based on a control strategy of the inheritable function block element model, packaging into a customized function block; e) storing the customized block information into an originalconfiguration file. According to the invention, from the perspective of function block modeling, thought of an object-oriented method is absorbed, typical features and key data information of the algorithm function block are extracted and the inheritable function block element model is established. On this basis, numerous basic algorithm function blocks of an arithmetic type, a logic type, a control type, a time type and the like are instantiated and algorithm configuration and debugging demands in industrial process control can be met.

Owner:NR ELECTRIC CO LTD +1

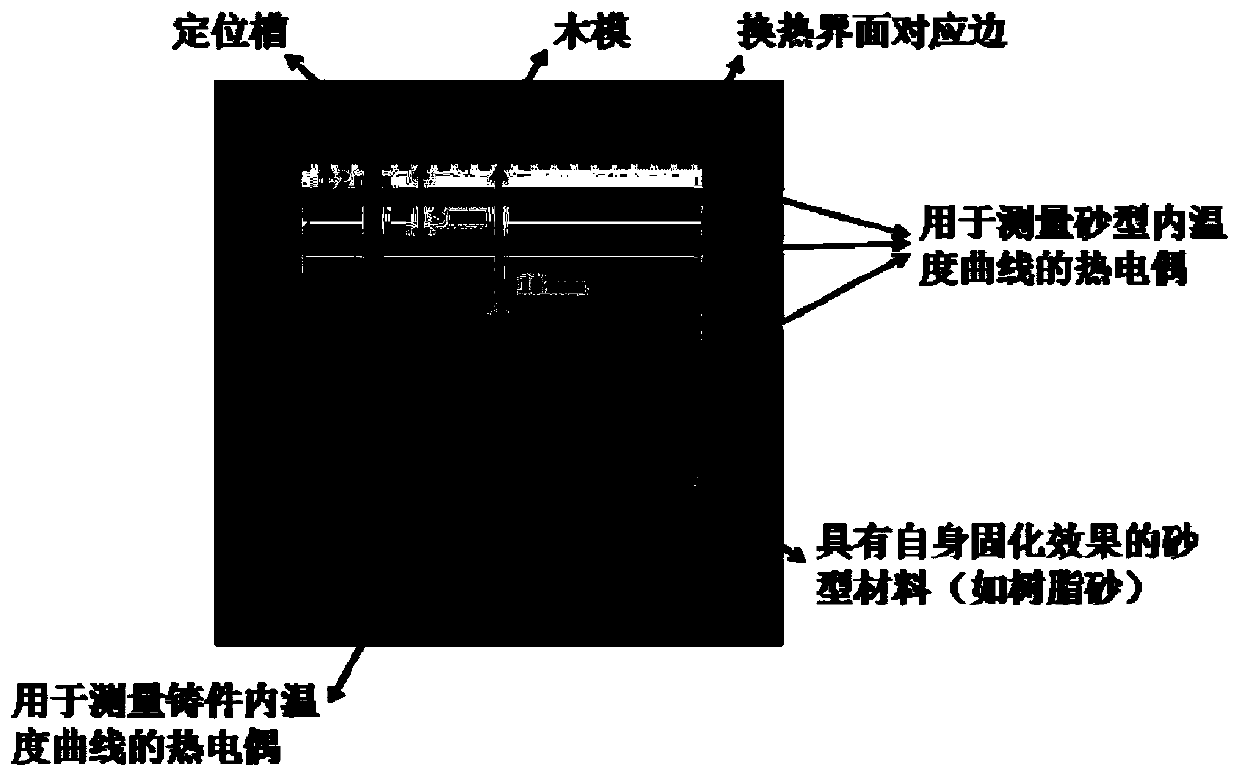

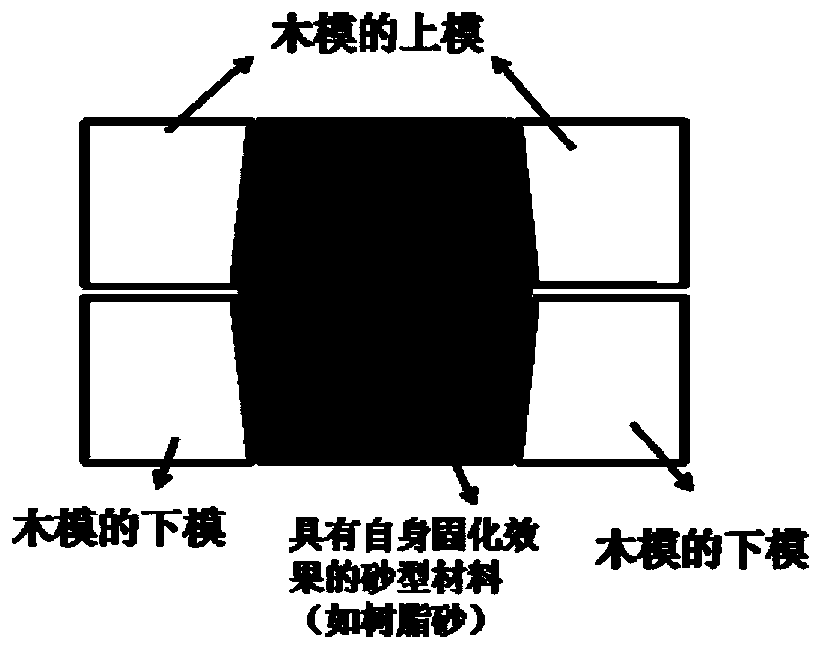

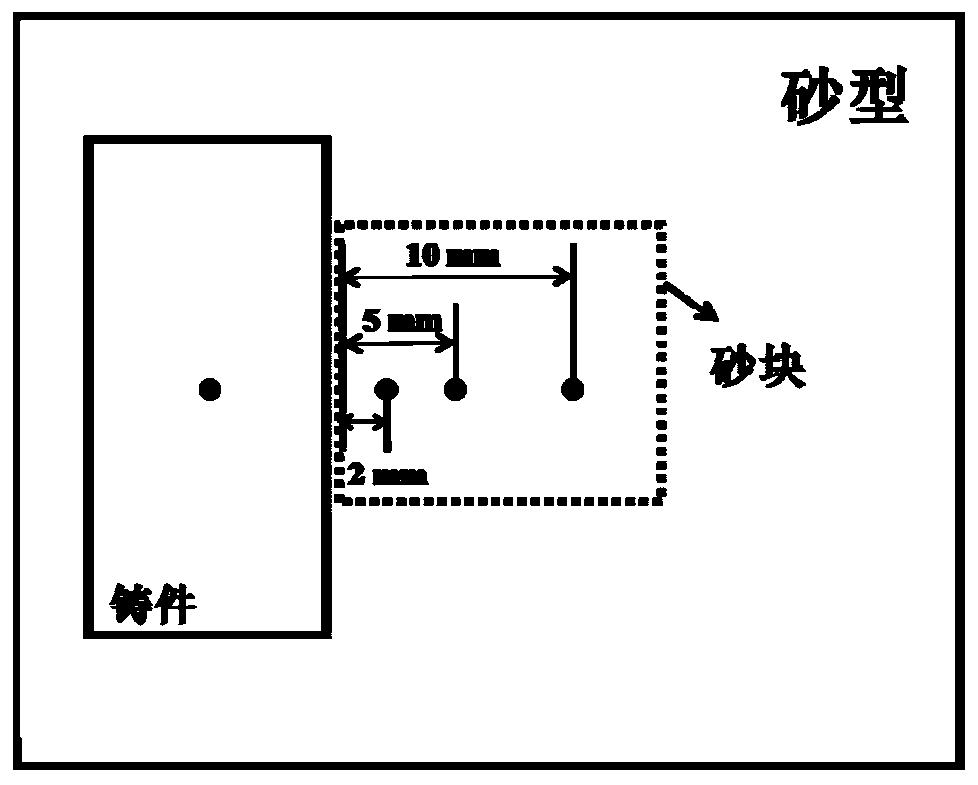

Positioning and fixing method for temperature measuring thermocouple inside sand casting mold

The invention discloses a positioning and fixing method for a temperature measuring thermocouple inside a sand mold casting mold. A positioning and fixing method of a sand mold material with the self-solidification forming characteristic comprises the following steps a wooden mold is used and a sand block modeling mode is adopted for realizing positioning and fixing of the thermocouple, in the overall molding process of the sand mold, a sand block with the fixed thermocouple is fixed in the whole sand mold, the thermocouple is connected with multi-channel temperature acquisition equipment, molten metal is poured in the sand mold, and the temperature at the specified positions in a casting and the sand mold in the casting process are measured. A positioning and fixing method of a sand moldmaterial without the self-solidification forming characteristic comprises the following steps that positioning and fixing of the thermocouple are realized through a metal sheet with holes, in the overall molding process of the sand mold, the metal sheet with the fixed thermocouple is placed in the sand mold, the thermocouple is connected with the multi-channel temperature acquisition equipment, the molten metal is poured in the sand mold, and the temperature at the specified positions in a casting and the sand mold in a solidification process are measured.

Owner:TSINGHUA UNIV

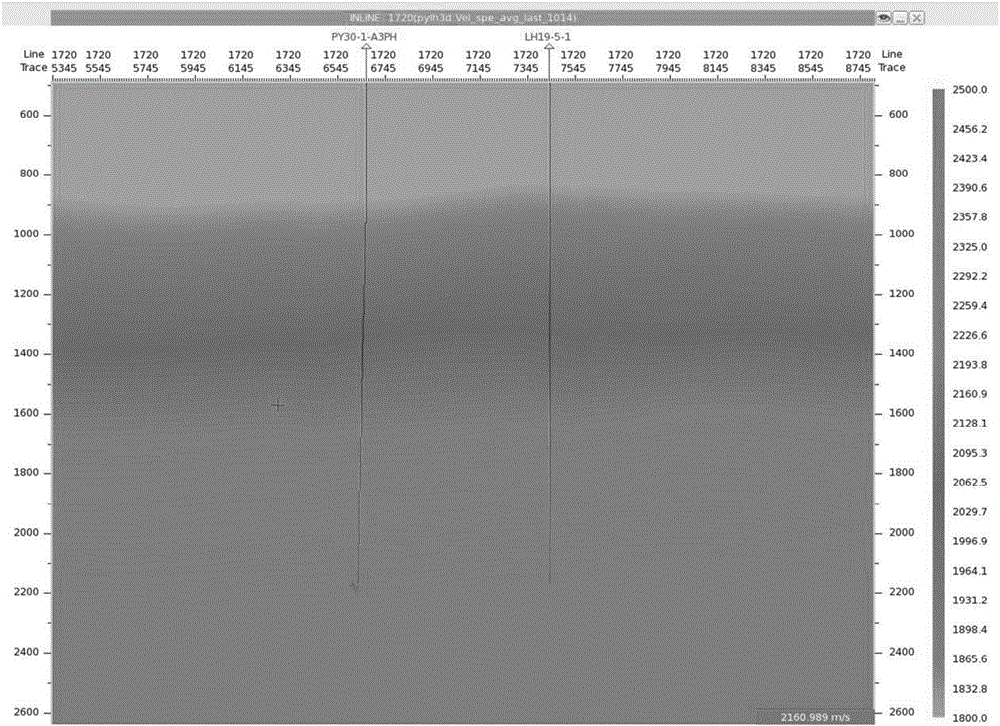

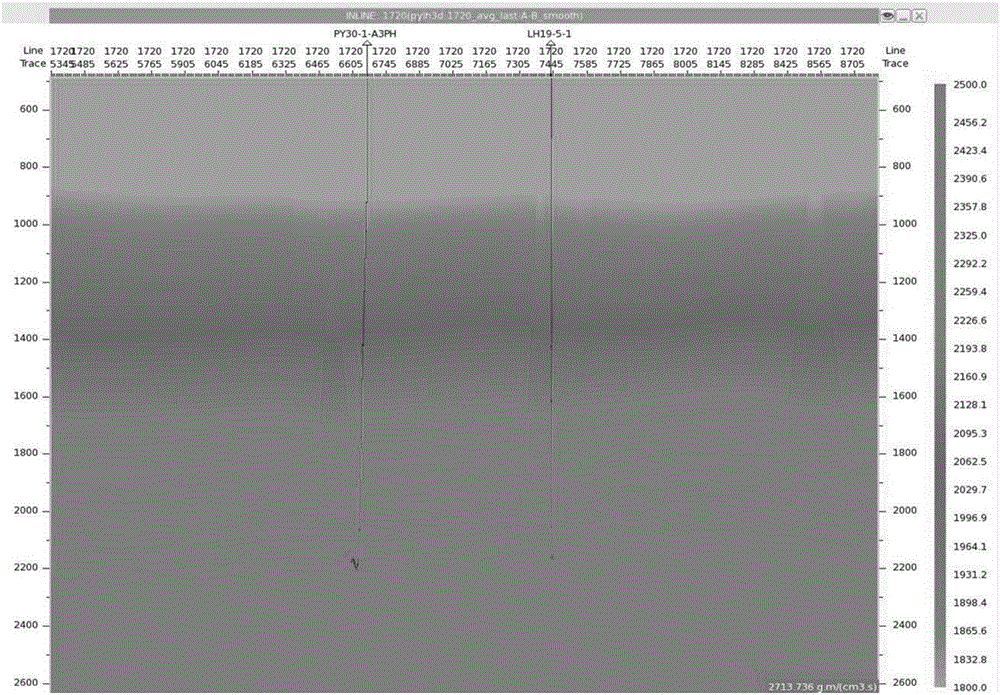

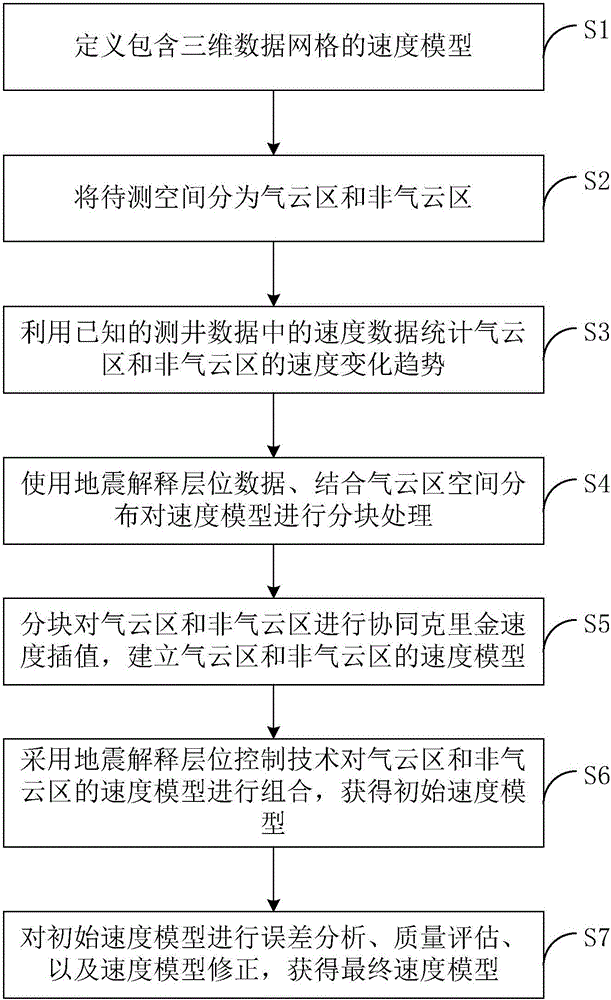

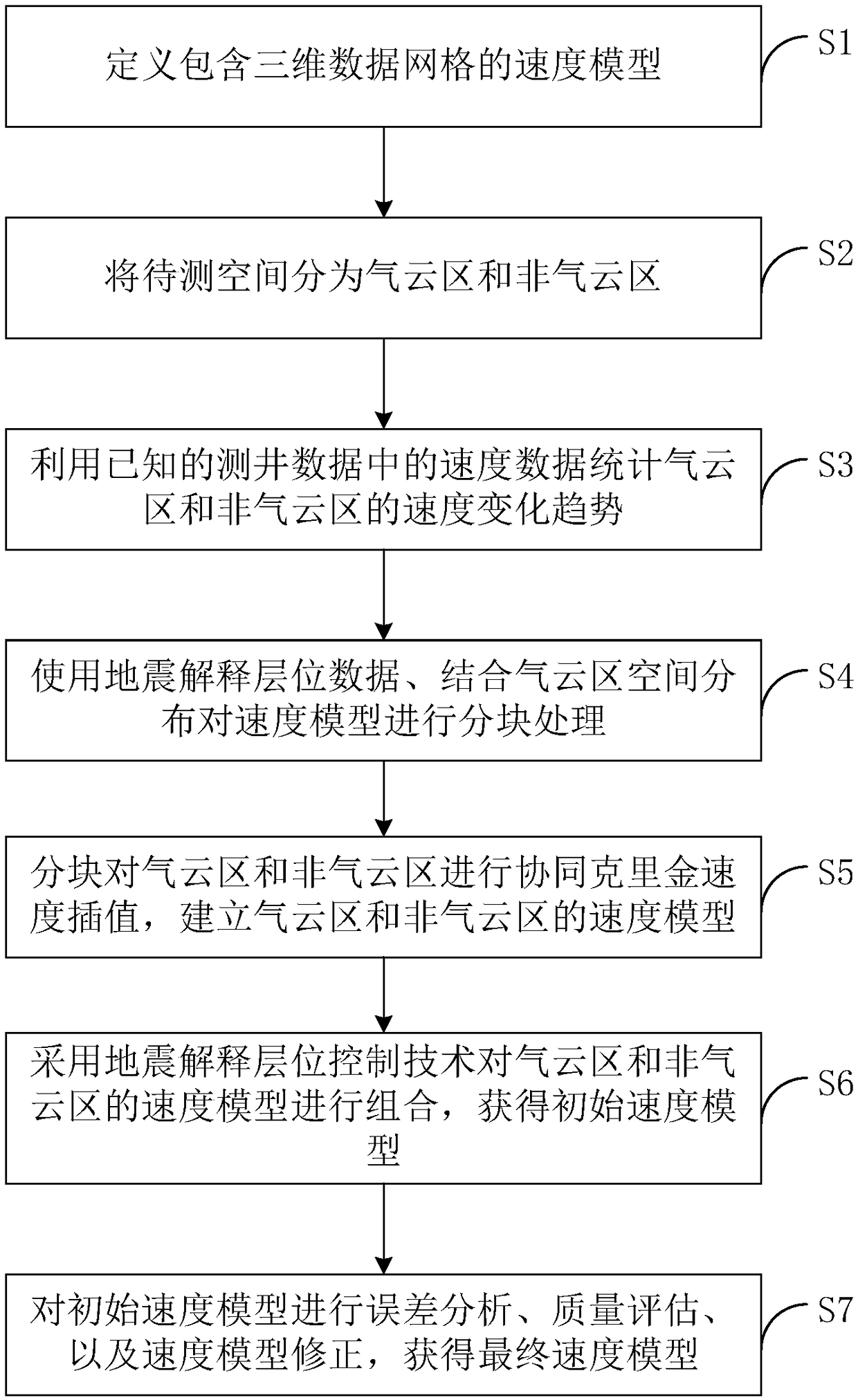

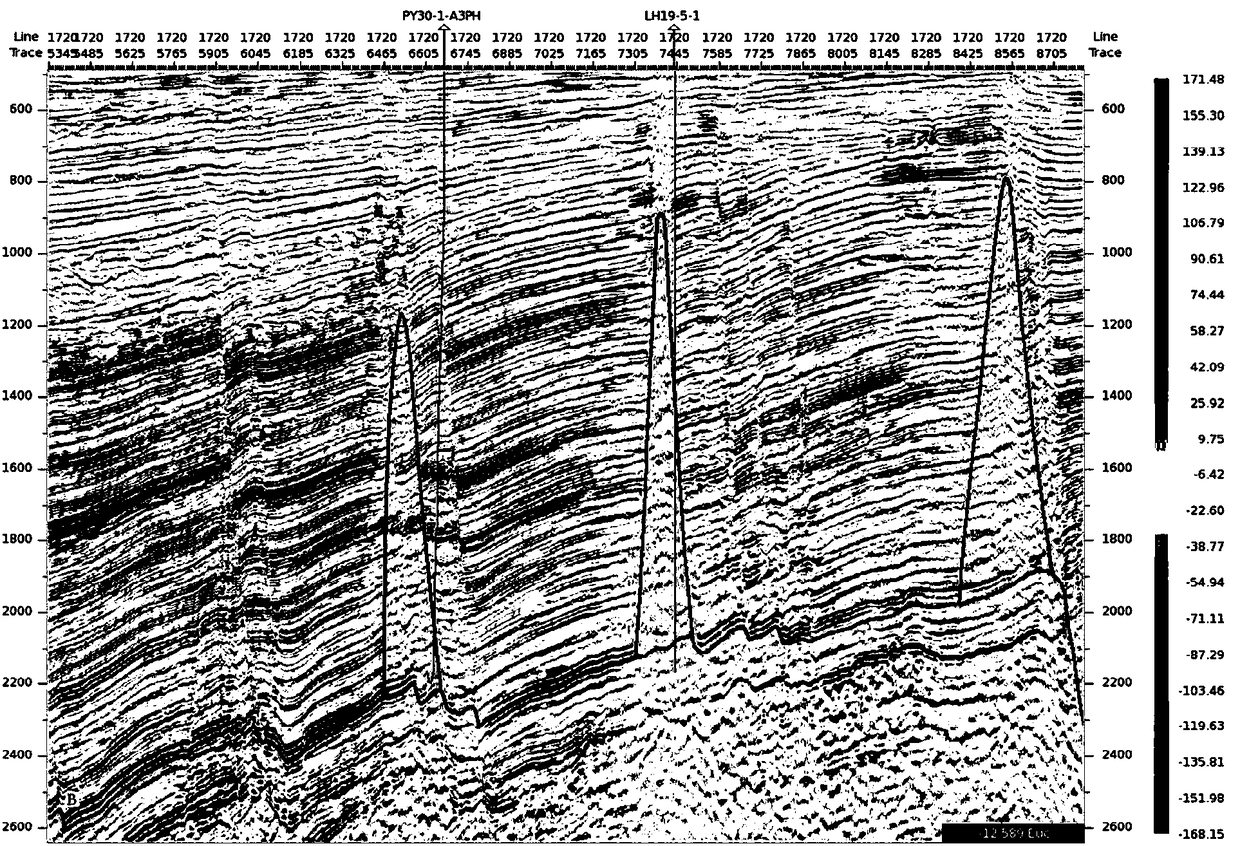

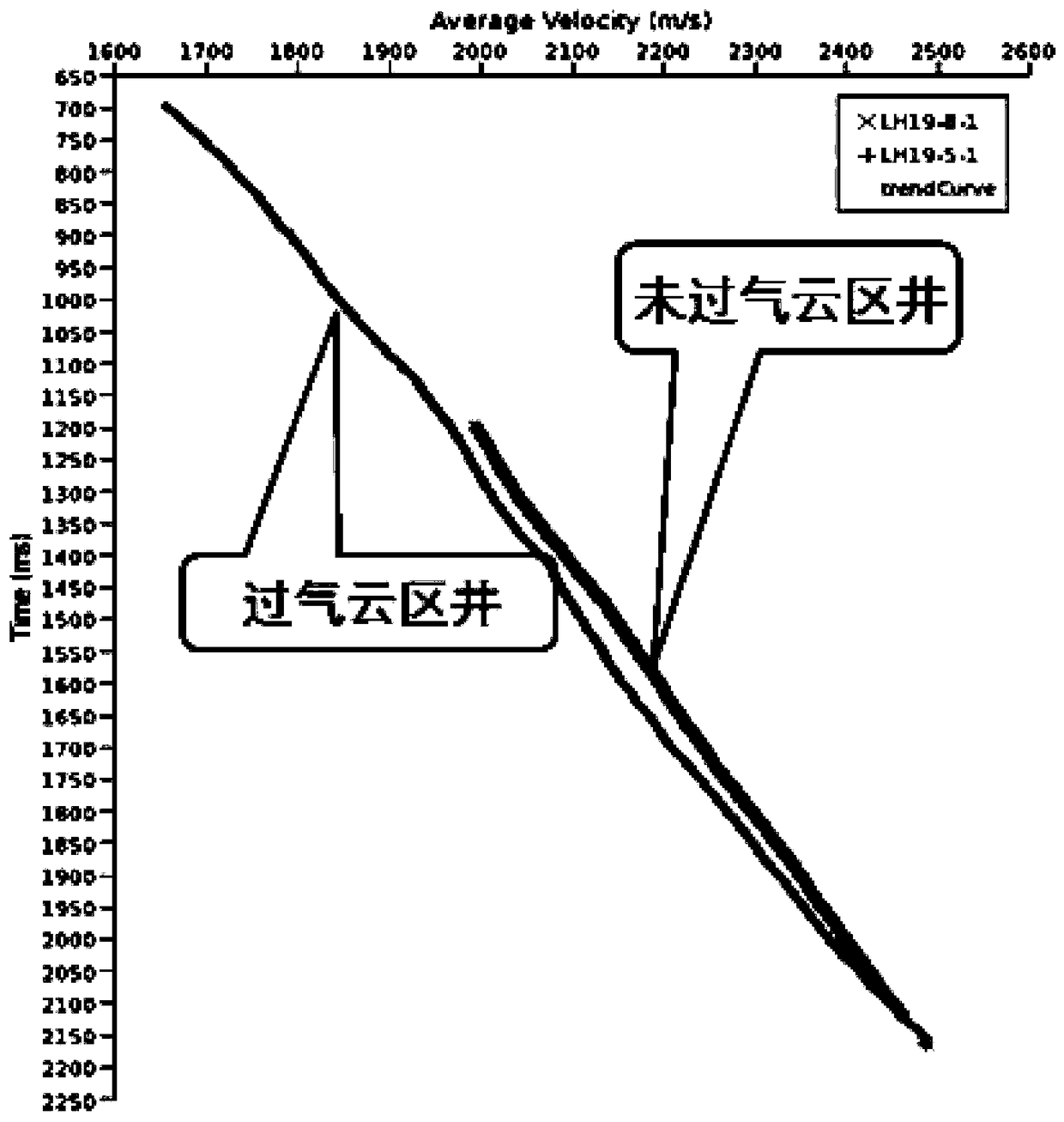

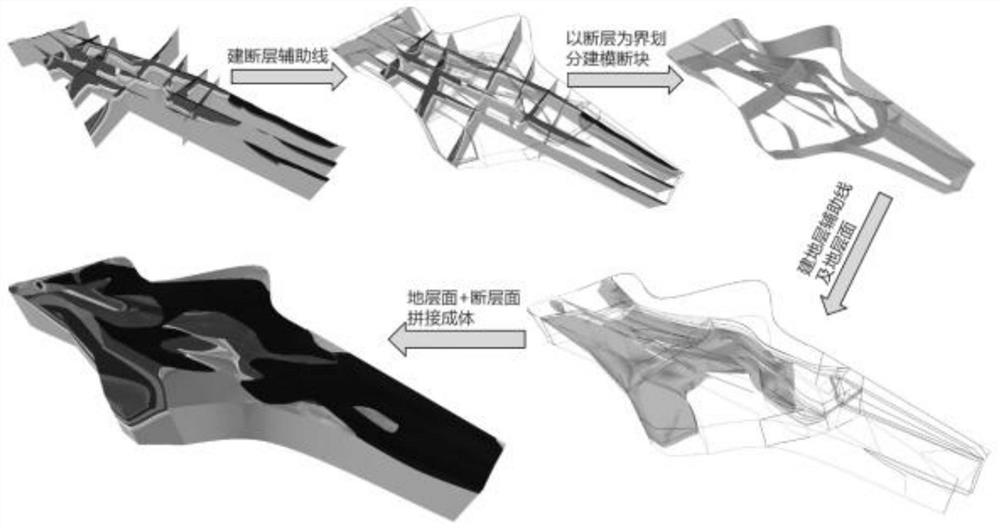

Fine velocity modeling method based on gas cloud region constraints

ActiveCN106125133AEfficient managementImprove application efficiencySeismic signal processingHorizonGeological Phenomena

The invention relates to a fine velocity modeling method based on gas cloud region constraints. The method comprises steps: a velocity model comprising a three-dimensional data mesh is defined, to-be-detected space is divided into a gas cloud region and a non-gas cloud region, and velocity data in the known logging data are used for counting velocity change trends of the gas cloud region and the non-gas cloud region; seismic interpretation horizon data are used and gas cloud region space distribution is combined to carry out block processing on the velocity model; velocity models for the gas cloud region and the non-gas cloud region are built; and a seismic interpretation horizon control technique is adopted to combine the velocity models for the gas cloud region and the non-gas cloud region, and an initial velocity model is acquired. In view of special geological phenomena in the gas cloud region, the gas cloud region and the non-gas cloud region are effectively distinguished, block modeling is carried out on the gas cloud region and the non-gas cloud region respectively, and through research on the velocity change trends of the gas cloud region and the non-gas cloud region, velocity modeling is carried out in a more targeted mode, the actual geological conditions are met, and the time-depth conversion precision is high.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Creating new cloud resource instruction set architecture

ActiveUS9967146B2Improve throughputDelay minimizationResource allocationData switching networksCloud baseSystem building

Owner:INT BUSINESS MASCH CORP

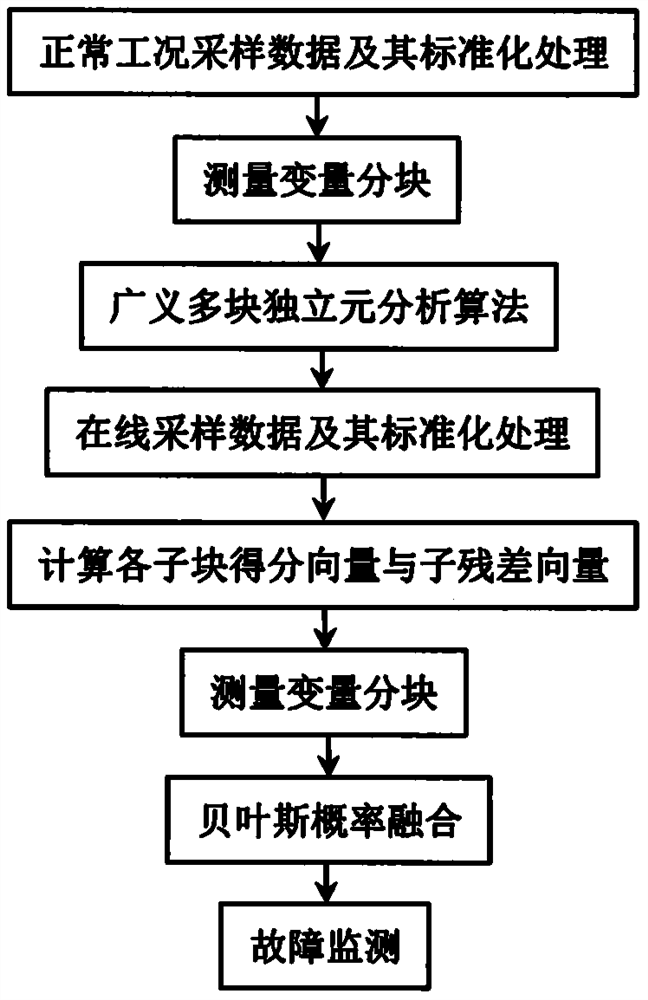

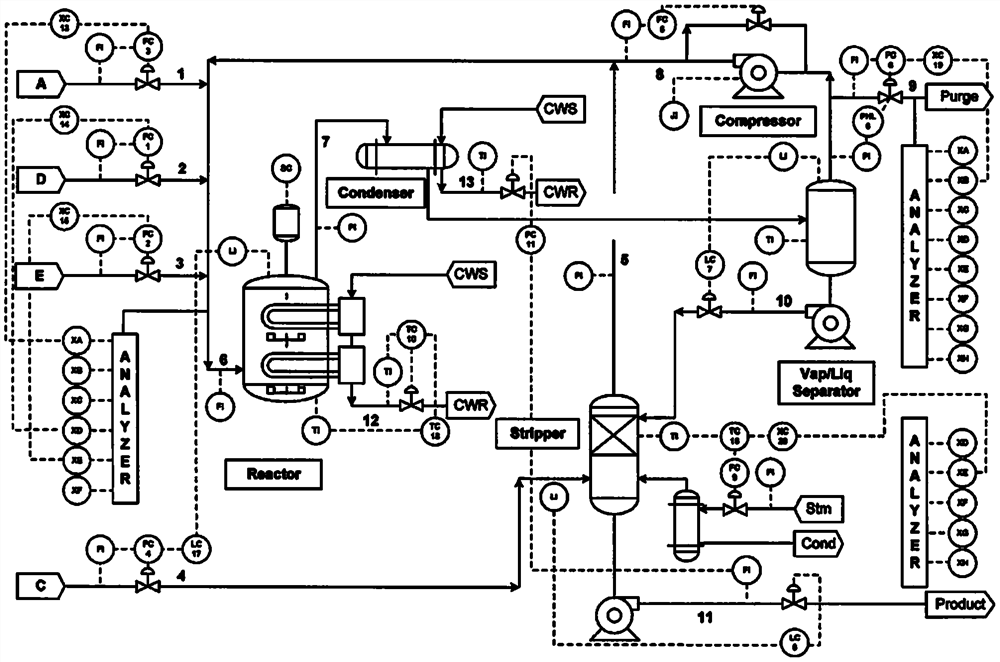

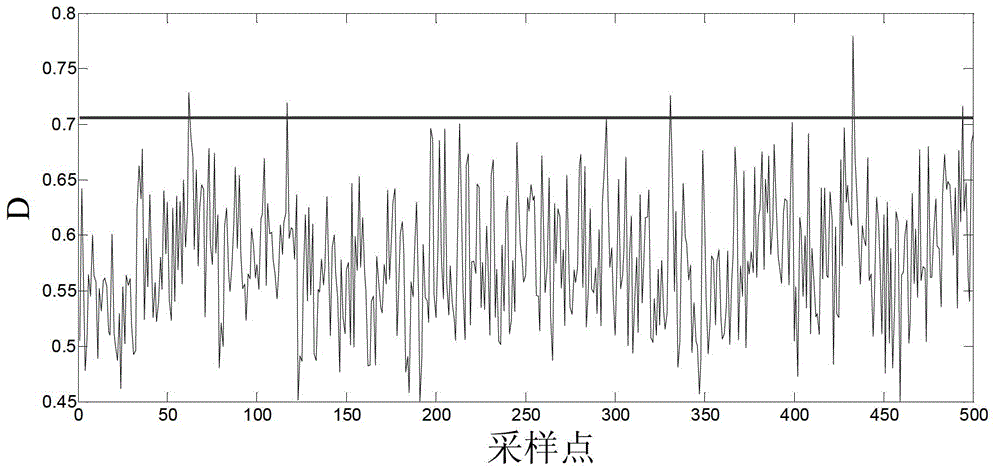

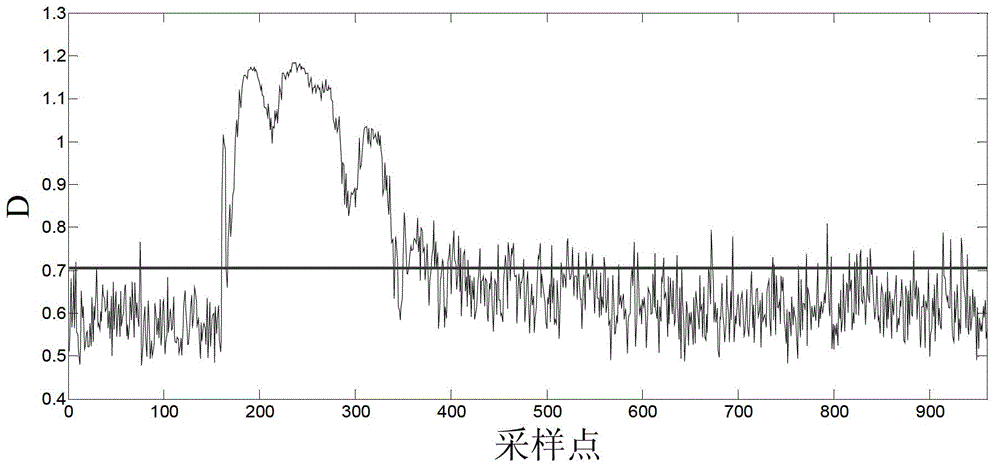

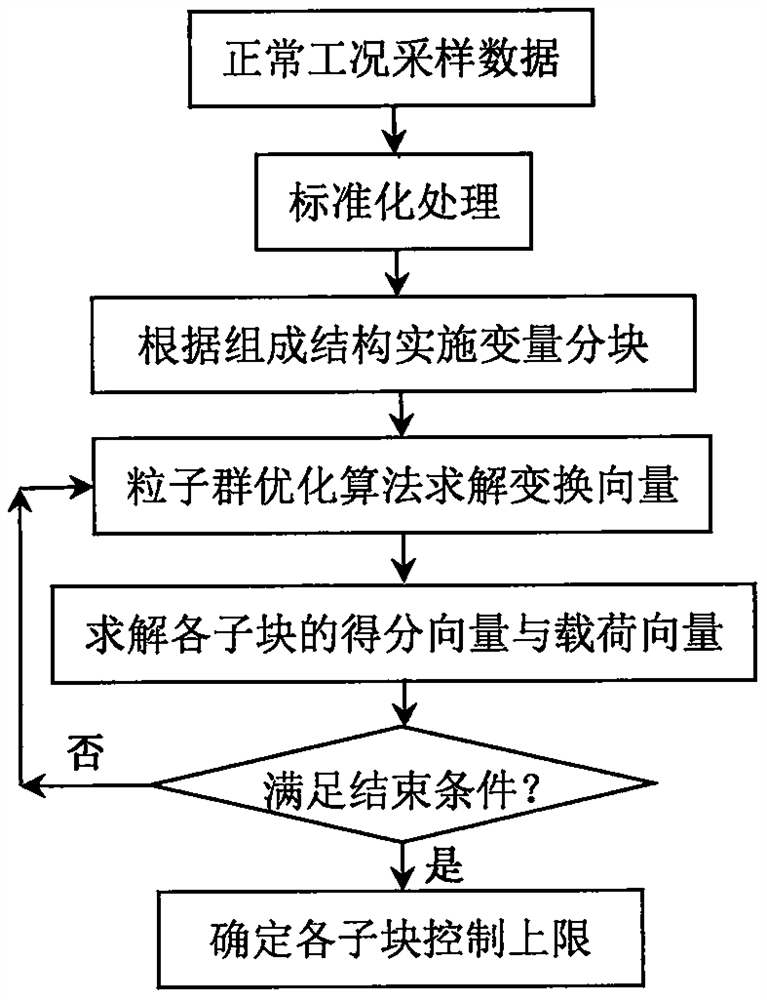

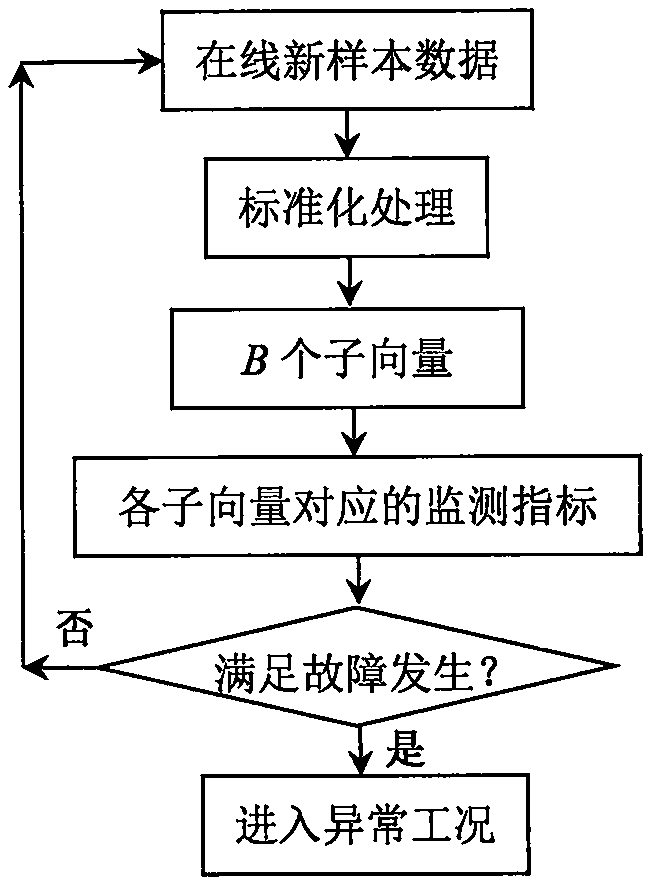

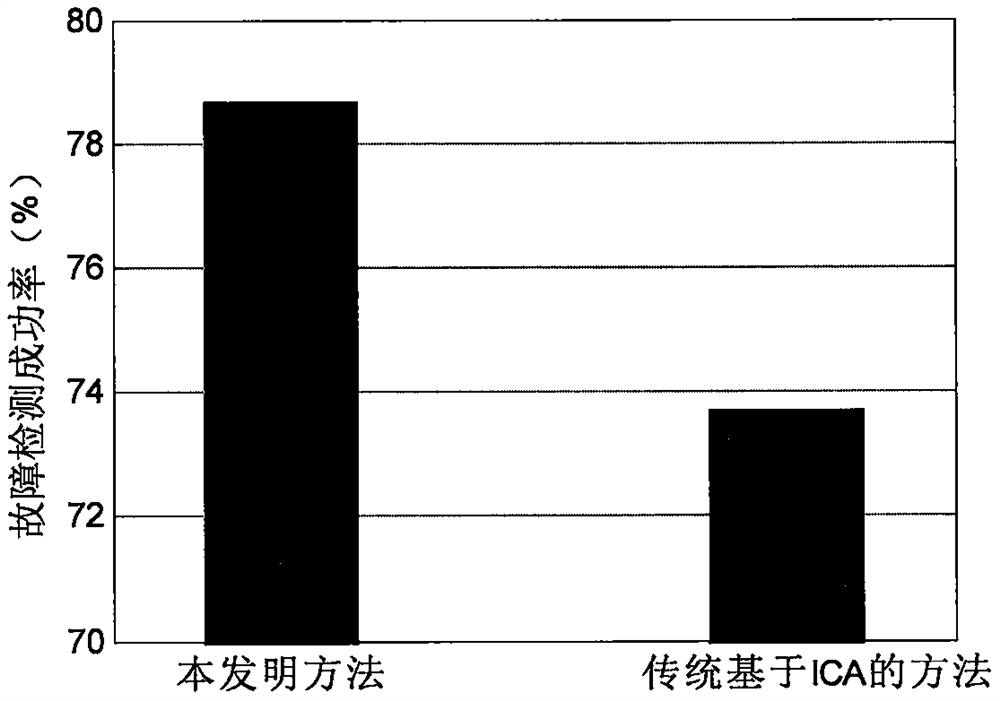

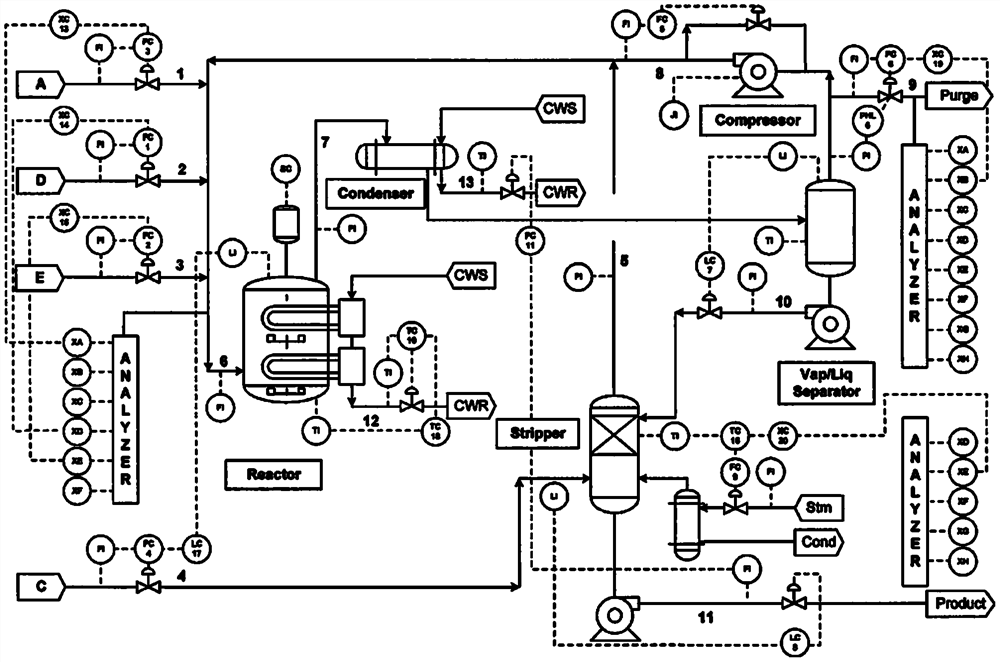

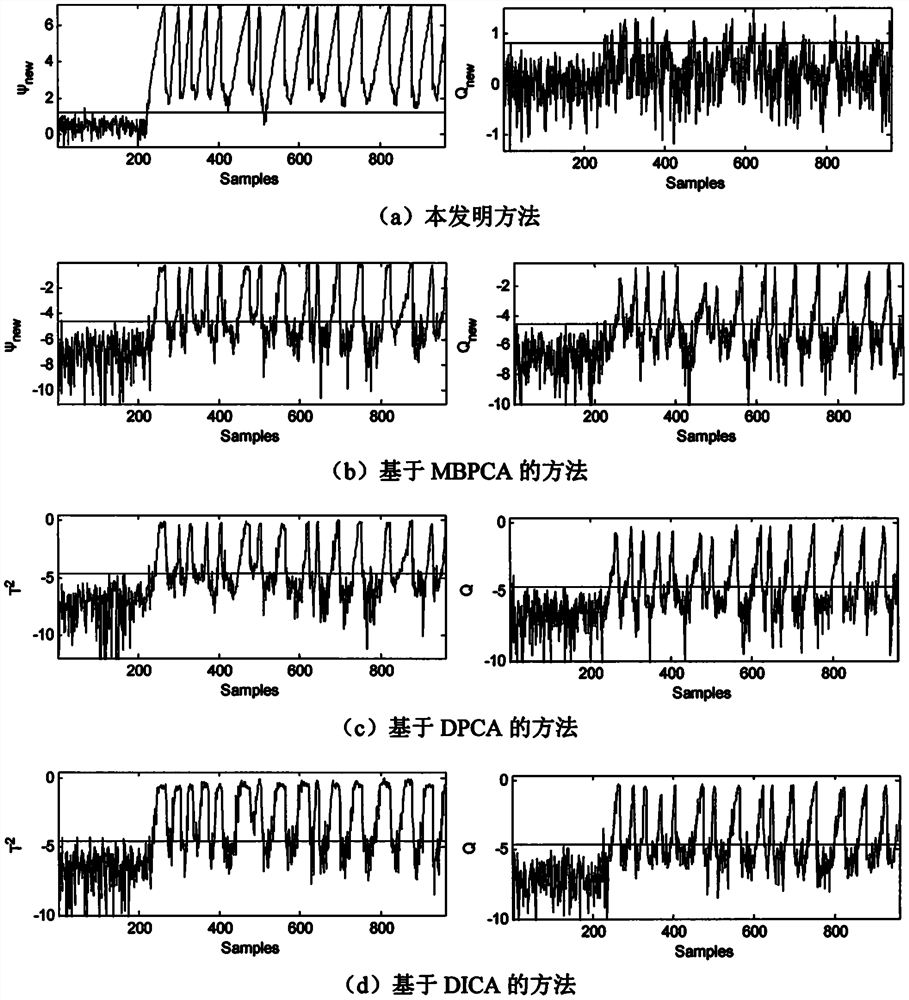

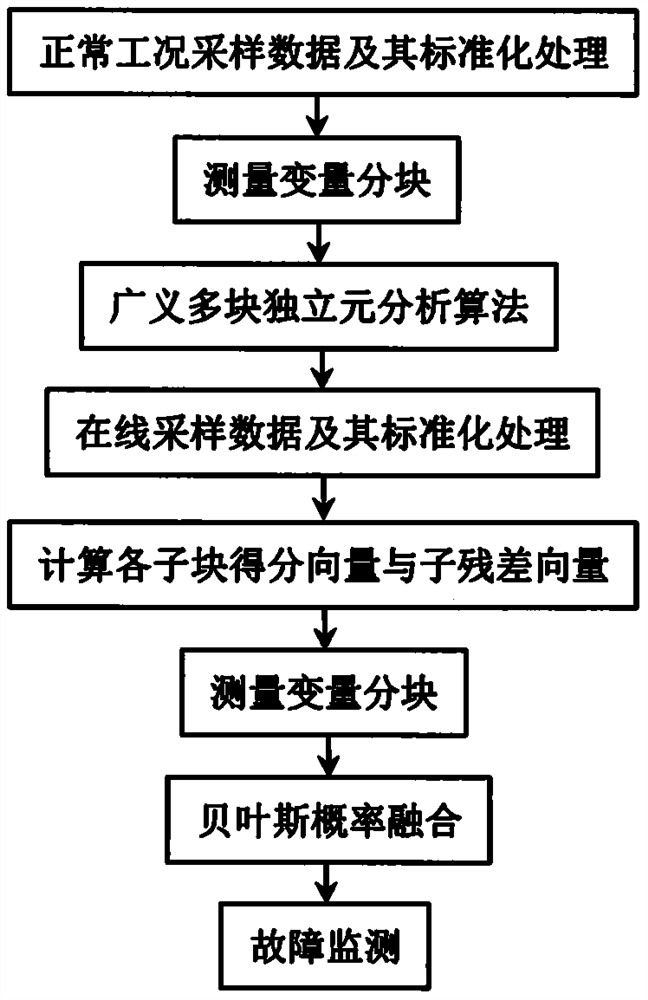

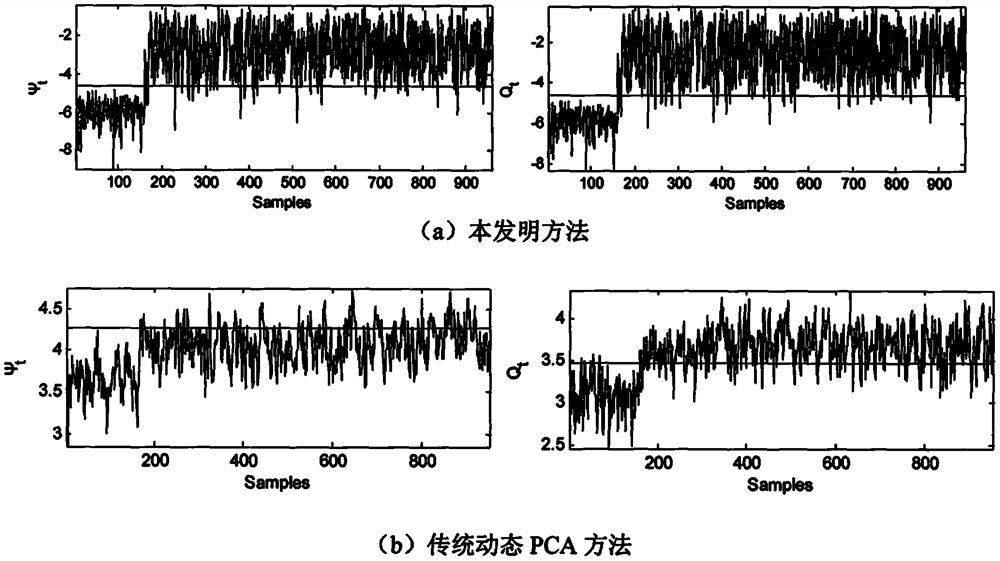

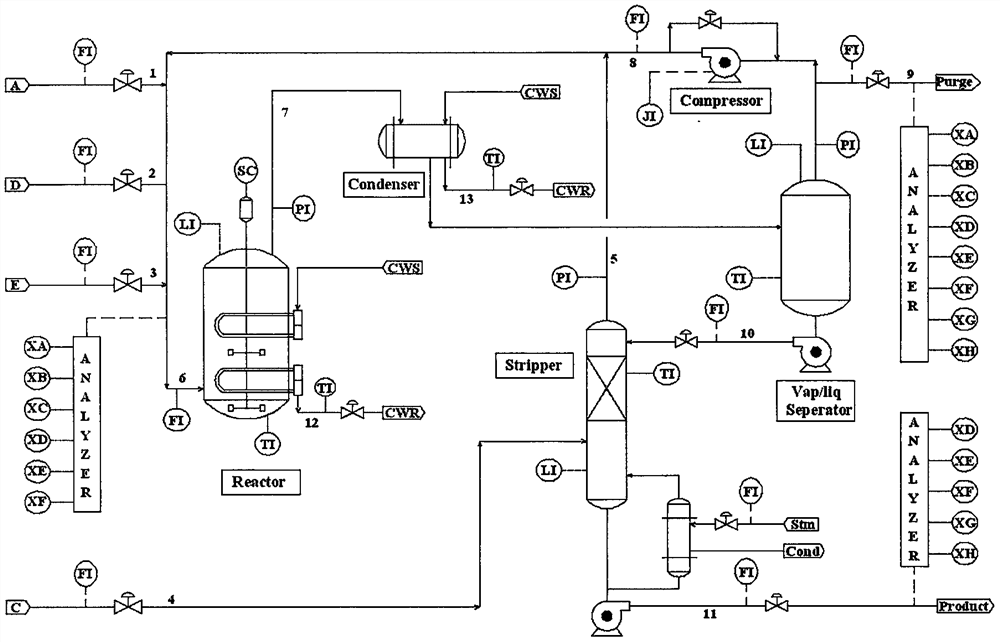

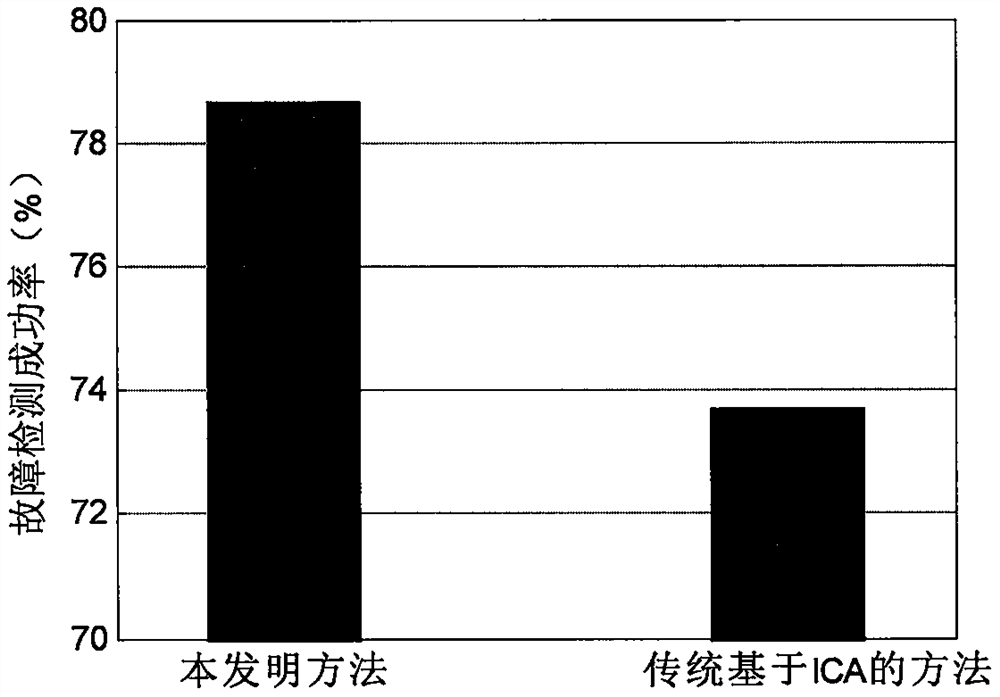

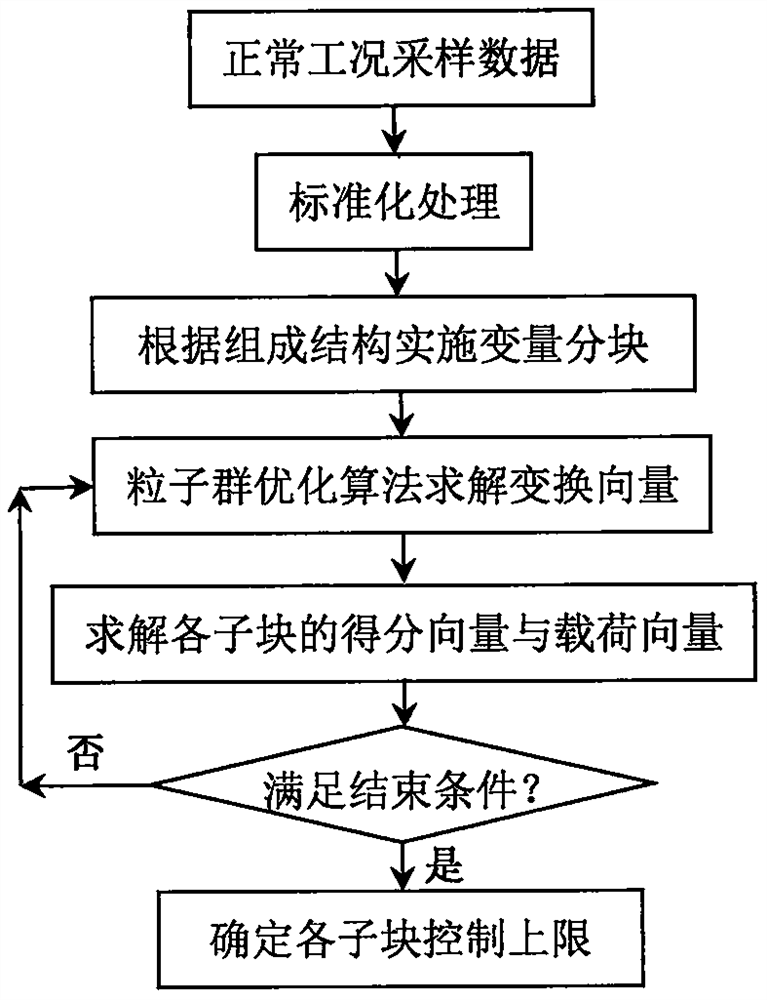

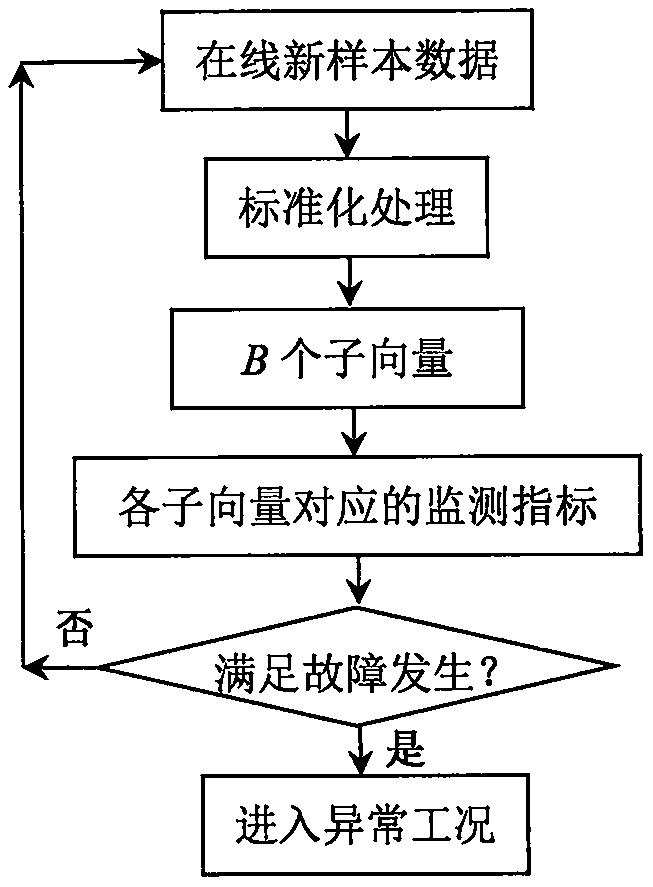

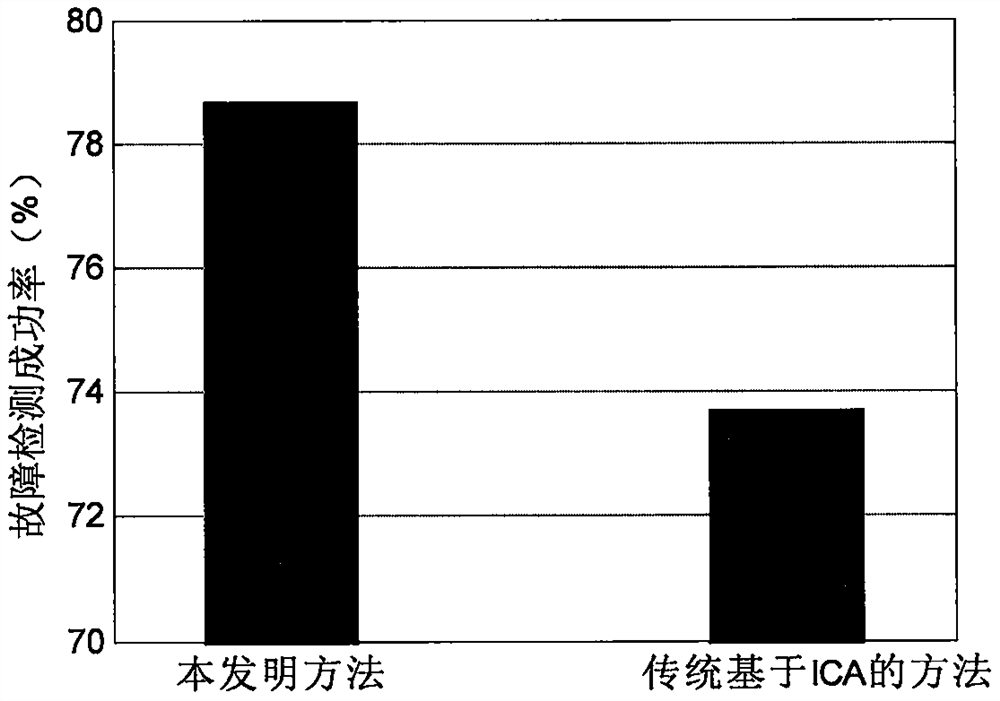

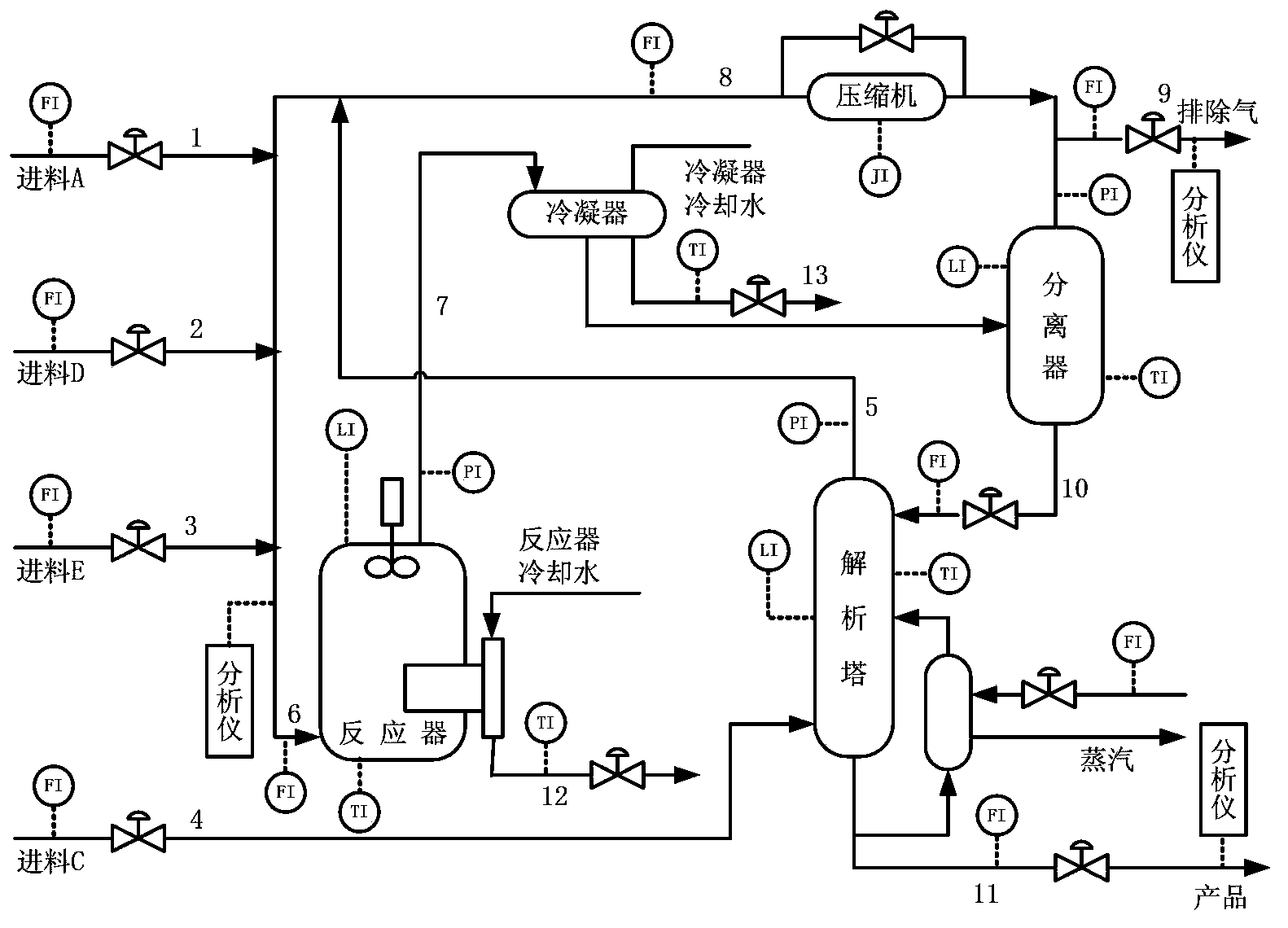

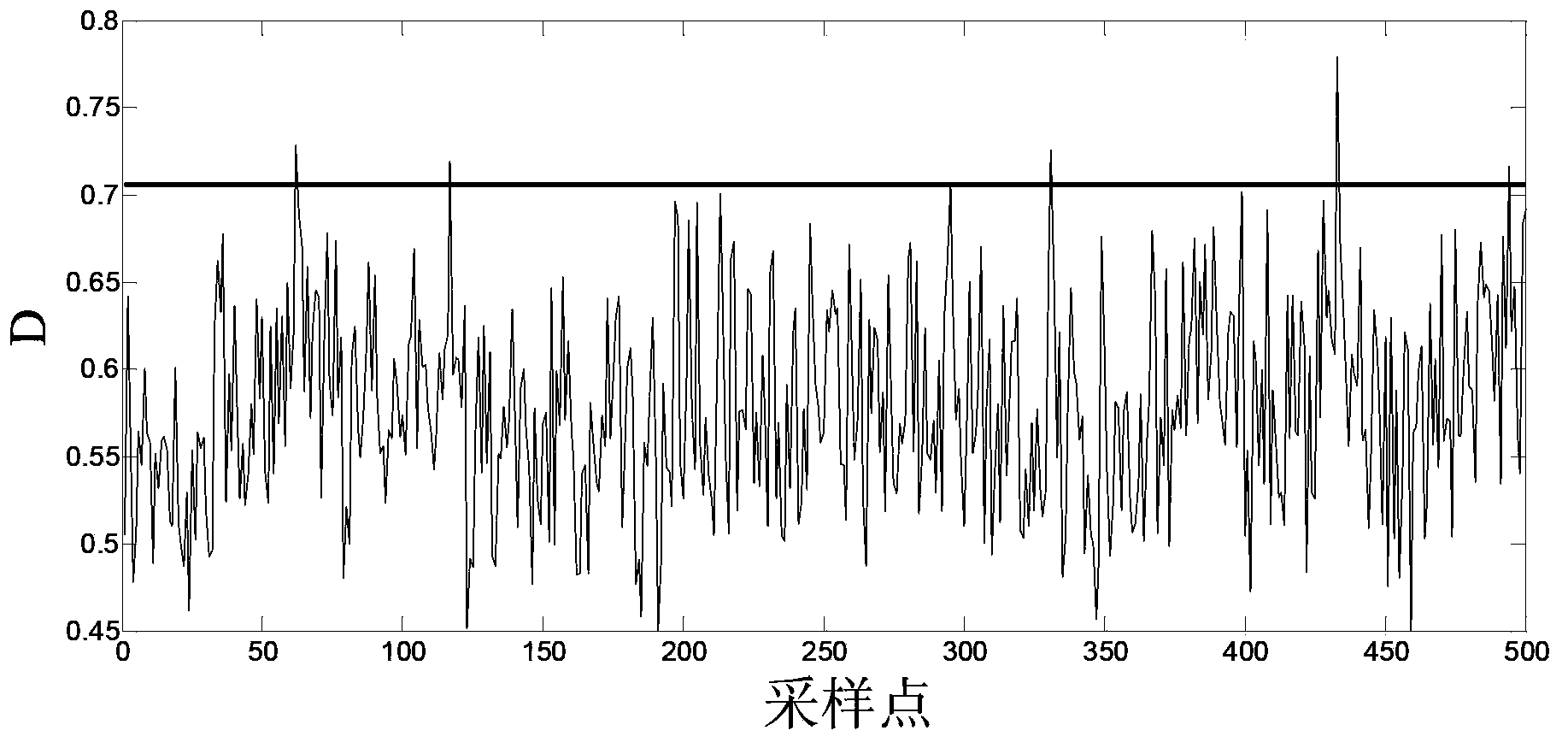

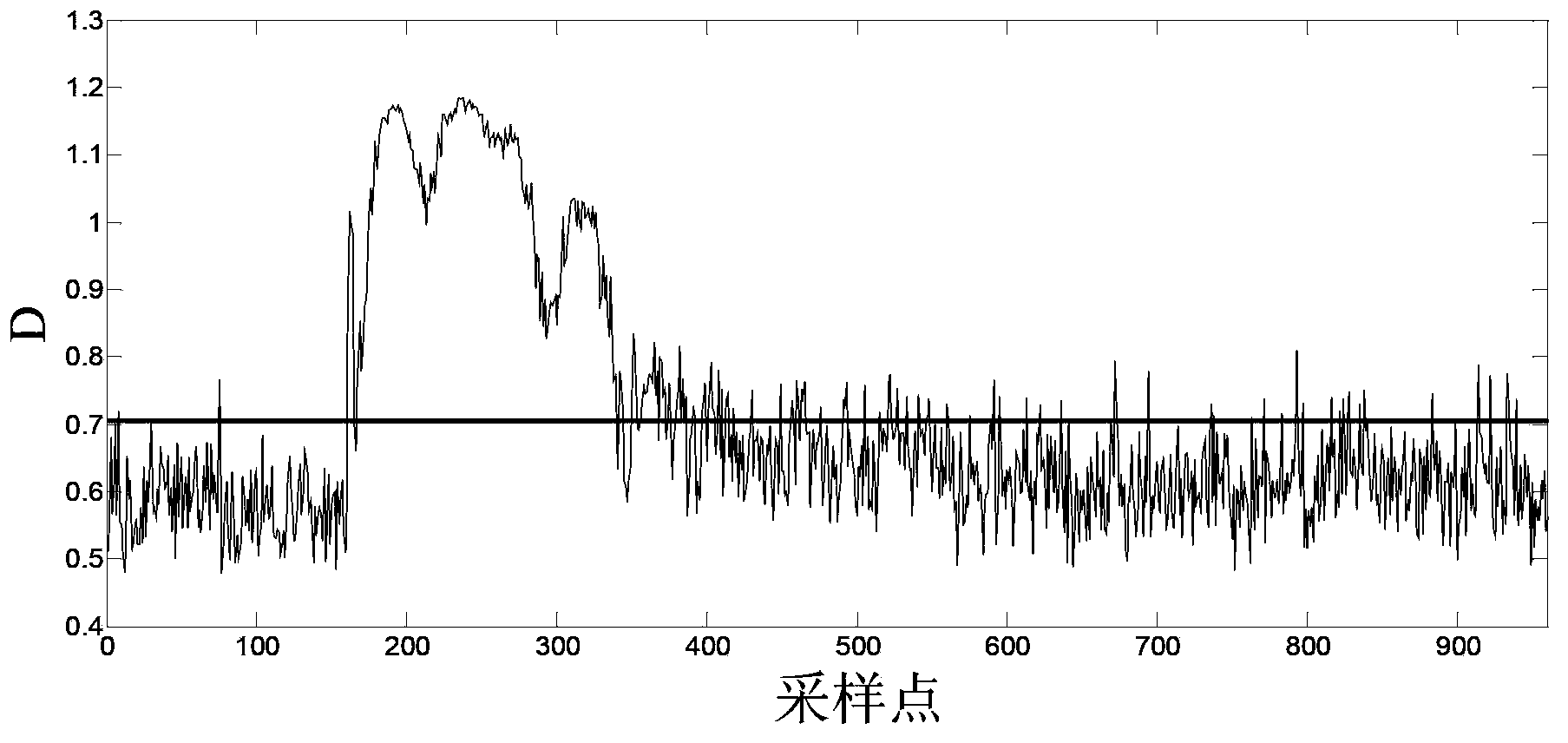

Chemical fault monitoring method based on generalized multi-block independent element analysis model

ActiveCN111913462AImprove general performanceProgramme controlElectric testing/monitoringAlgorithmMonitoring methods

The invention discloses a chemical fault monitoring method based on a generalized multi-block independent element analysis model, and aims to provide a generalized multi-block independent element analysis algorithm, and non-Gaussian multi-block modeling can be implemented for overlapped and non-overlapped variable sub-block division, so that the distributed fault monitoring is implemented by utilizing the generalized multi-block independent element analysis algorithm. According to the method, in the modeling process based on the independent meta-analysis algorithm, the uniqueness of each sub-block and the integrity between the sub-blocks are considered at the same time, and a mutually-staggered one-by-one extraction strategy from overall separation to local sub-block extraction and from local sub-block return to overall separation is adopted. Therefore, the method is a brand new non-Gaussian multi-block modeling and fault monitoring method. In addition, the superiority of the method provided by the invention can be verified by the specific embodiment, so that the method provided by the invention is a more optimal non-Gaussian distributed fault monitoring method.

Owner:SHANDONG XINHUA LONGXIN CHEM

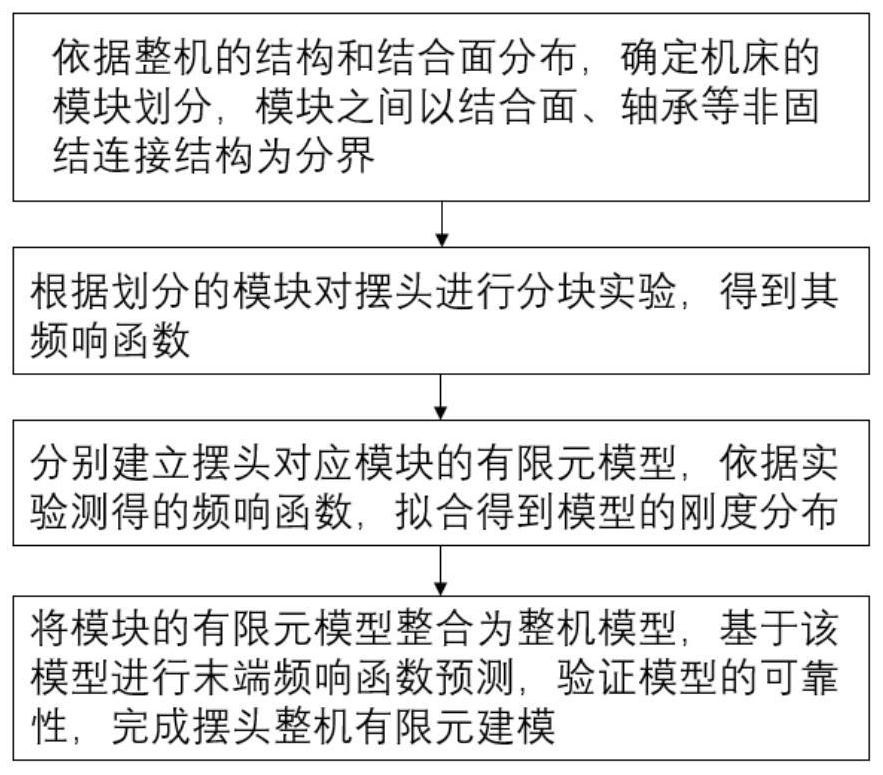

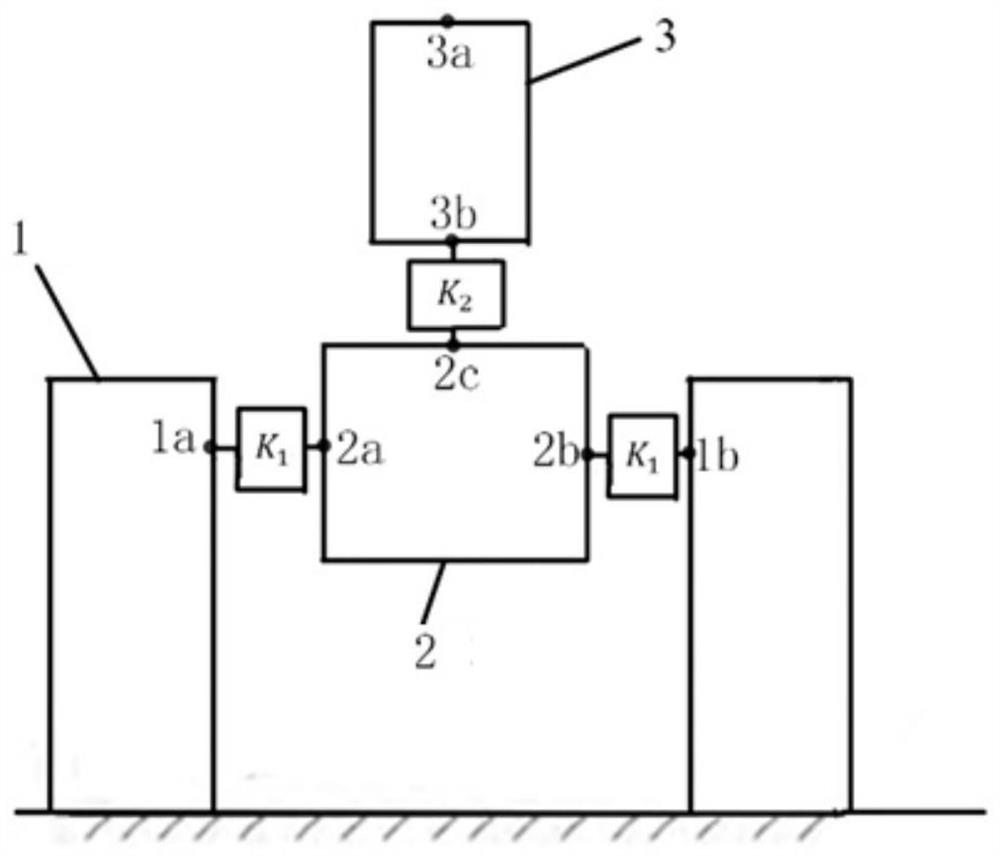

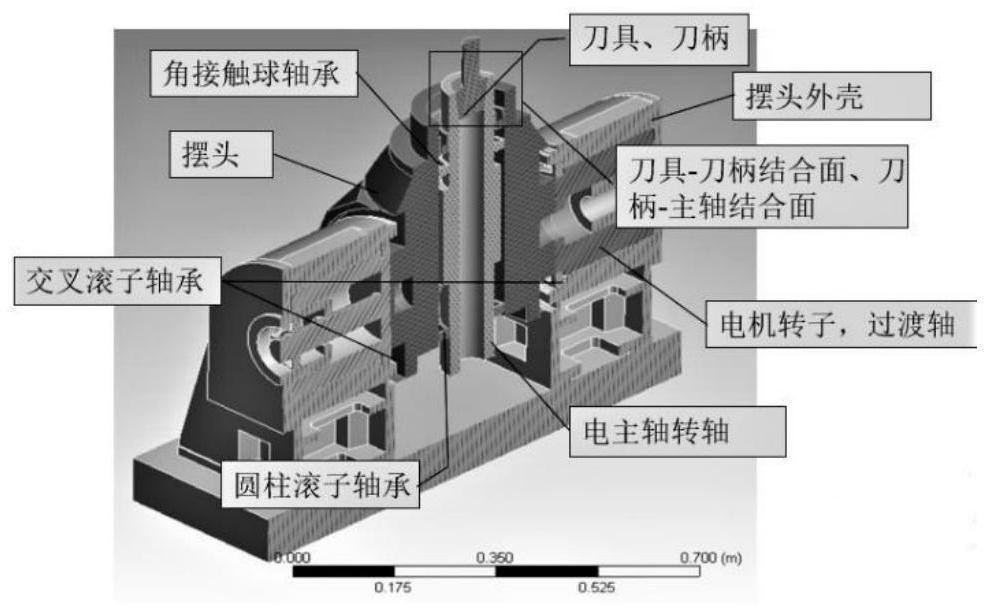

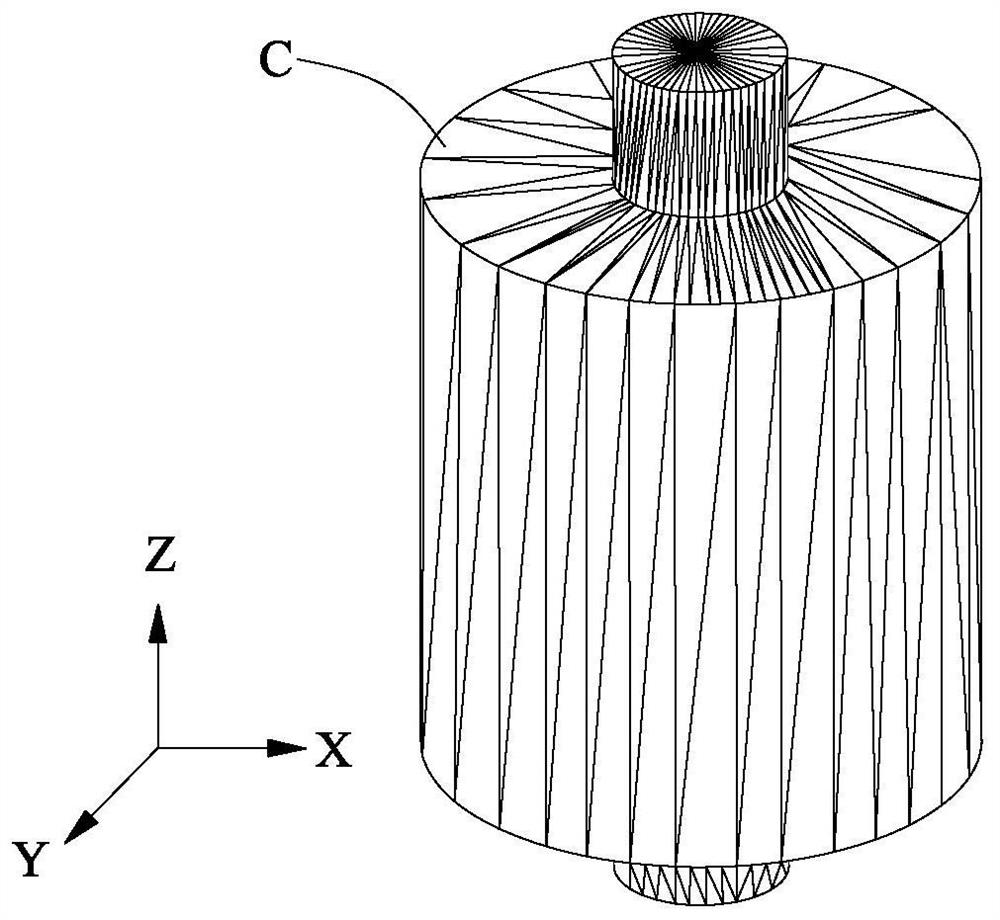

Modeling method for swing angle milling head complete machine based on block modeling and experimental parameter identification

InactiveCN112069611AAccurate predictionHigh precisionGeometric CADDesign optimisation/simulationElement modelKinetics equation

The invention discloses a modeling method for a swing angle milling head complete machine based on block modeling and experimental parameter identification, and belongs to the technical field of modeling. According to the method, module division is determined according to the structure and junction surface distribution of a swing head, non-consolidation connection structures such as junction surfaces and bearings are used as boundaries among modules, an equivalent kinetic model is established, and a kinetic equation is solved. Then, a machine tool is split according to the divided modules, excitation experiments are conducted on the modules respectively, frequency response functions are collected, finite element models of corresponding modules are established, and joint surface parameterscapable of minimizing errors between theoretical values and measured values of the frequency response functions are searched through an optimization algorithm; The searched joint surface parameters are added to the finite element model of each module. The finite element models of all the modules are integrated into a model of the swing head complete machine, solving a tail end frequency response function ,the tail end frequency response function is compared with an actually measured frequency response function, and the reliability of the model and the feasibility of the modeling method.

Owner:TSINGHUA UNIV

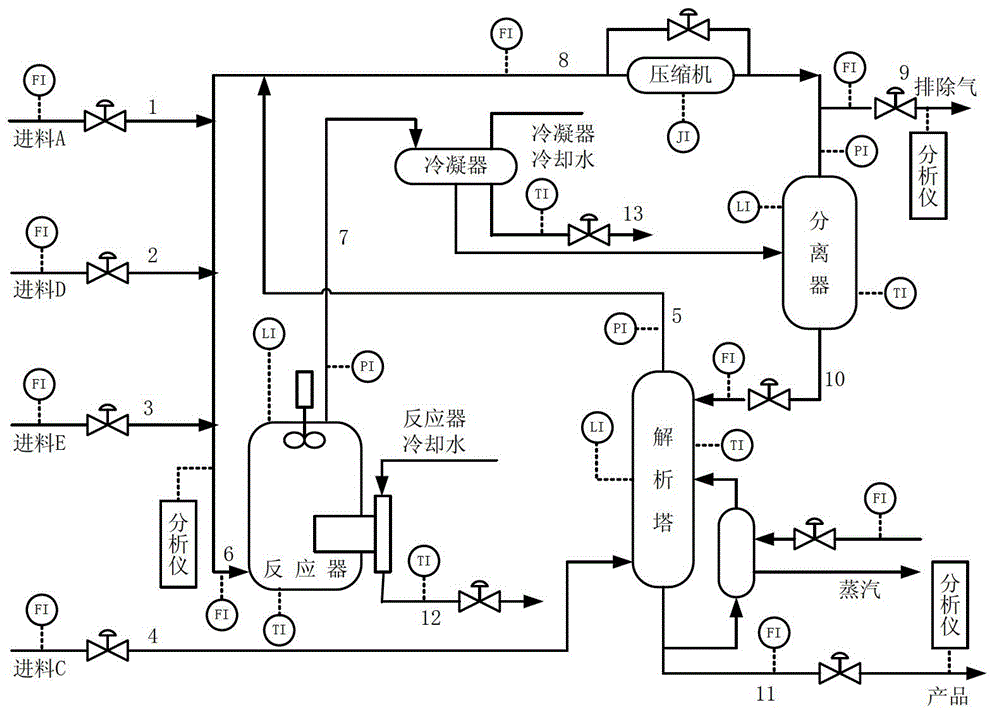

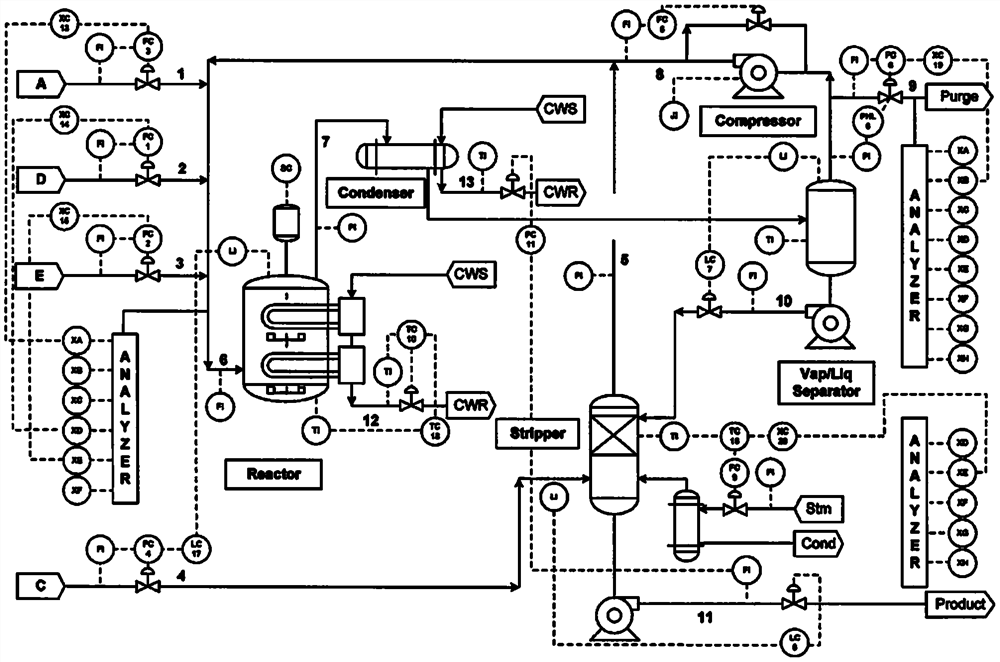

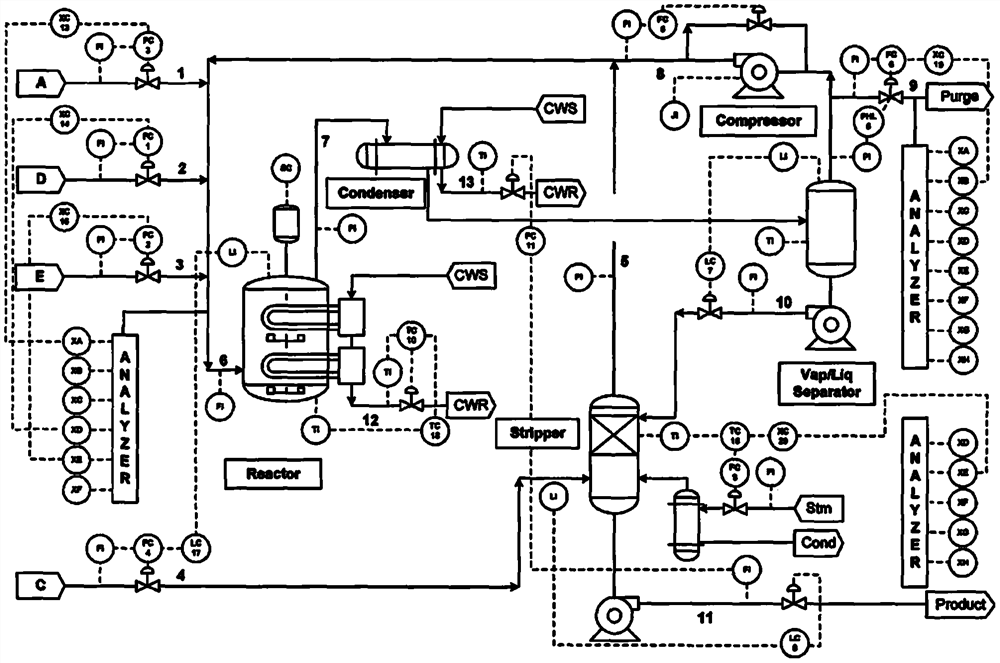

Double-layer data model-driven plant-level chemical process monitoring method

InactiveCN102880151AImprove monitoring effectImprove good performanceTotal factory controlProgramme total factory controlStatistical analysisMonitoring methods

The invention discloses a double-layer data model-driven plant-level chemical process monitoring method. Relationships between sub-modules are modeled by constructing a double-layer data statistical analysis model on the basis of blocking modeling, so that a plant-level process is globally monitored. Compared with the conventional other plant-level process monitoring methods, the method has the advantages that each unit of the process can be monitored in each sub-module, relationship information between the sub-modules of the plant-level process can be effectively combined, and the whole plant-level process is globally monitored by utilizing a second-layer data model, so that the monitoring performance of the plant-level chemical process is greatly improved, and the industrial automation of the plant-level process can be favorably expanded and implemented.

Owner:ZHEJIANG UNIV

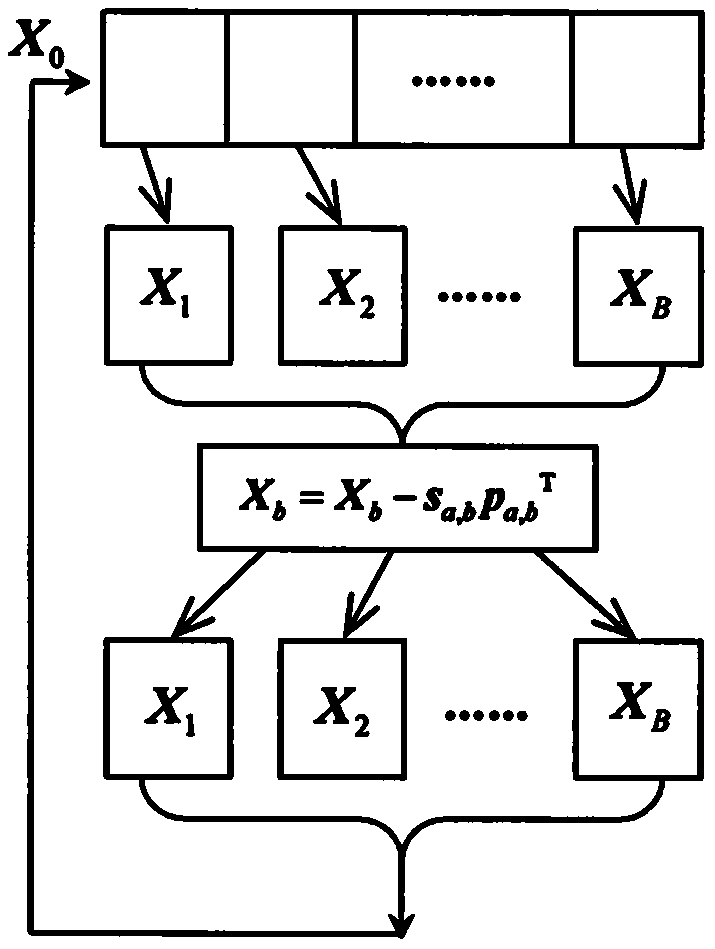

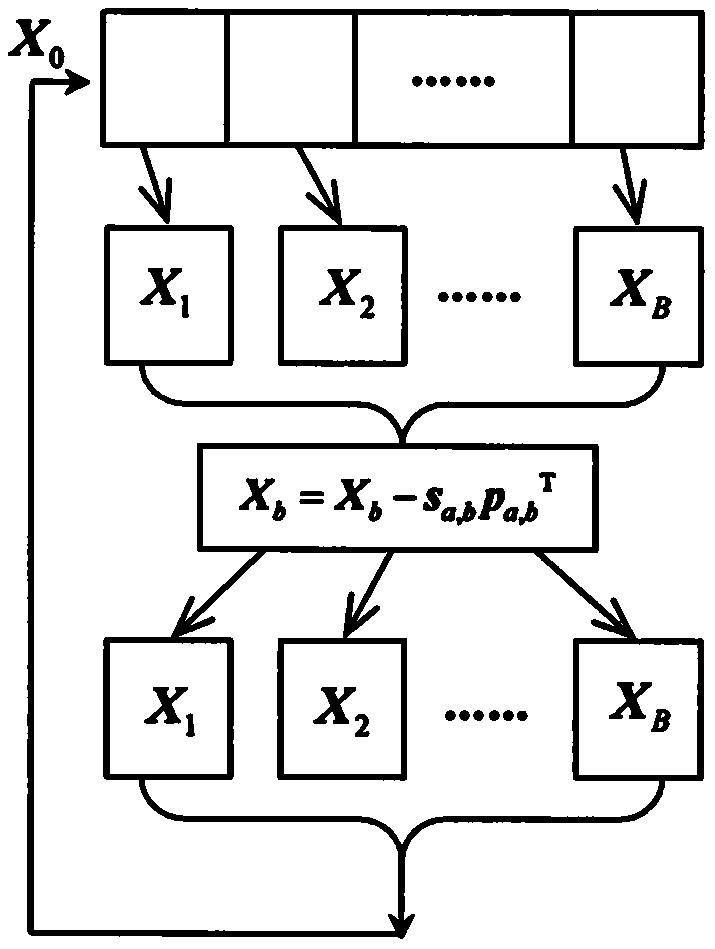

Distributed process monitoring method based on multi-block independent component analysis algorithm

ActiveCN111694328AVerify superiorityTotal factory controlProgramme total factory controlAlgorithmMonitoring methods

The invention discloses a distributed process monitoring method based on a multi-block independent component analysis algorithm, and aims to provide a novel multi-block independent component analysisalgorithm, and distributed non-Gaussian process monitoring is monitored by using the algorithm, so that the uniqueness of each sub-block and the integrity between the sub-blocks can be considered simultaneously in the modeling process. According to the method, in the process of implementing multi-block modeling, score vectors are not simply extracted for each sub-block, and the strategy of extracting the sub-blocks one by one from the whole to the local sub-blocks and then from the local sub-blocks to the whole in a staggered mode is adopted. Therefore, the novel multi-block independent component analysis algorithm provided by the invention not only considers the uniqueness of each sub-block, but also considers the global integrity. Therefore, the provided method is a brand-new distributednon-Gaussian process monitoring method. In addition, the superiority of the method provided by the invention can be verified by a specific embodiment, so that the method provided by the invention isa more optimal non-Gaussian process monitoring method.

Owner:恩施自治州聪慧科技发展有限责任公司

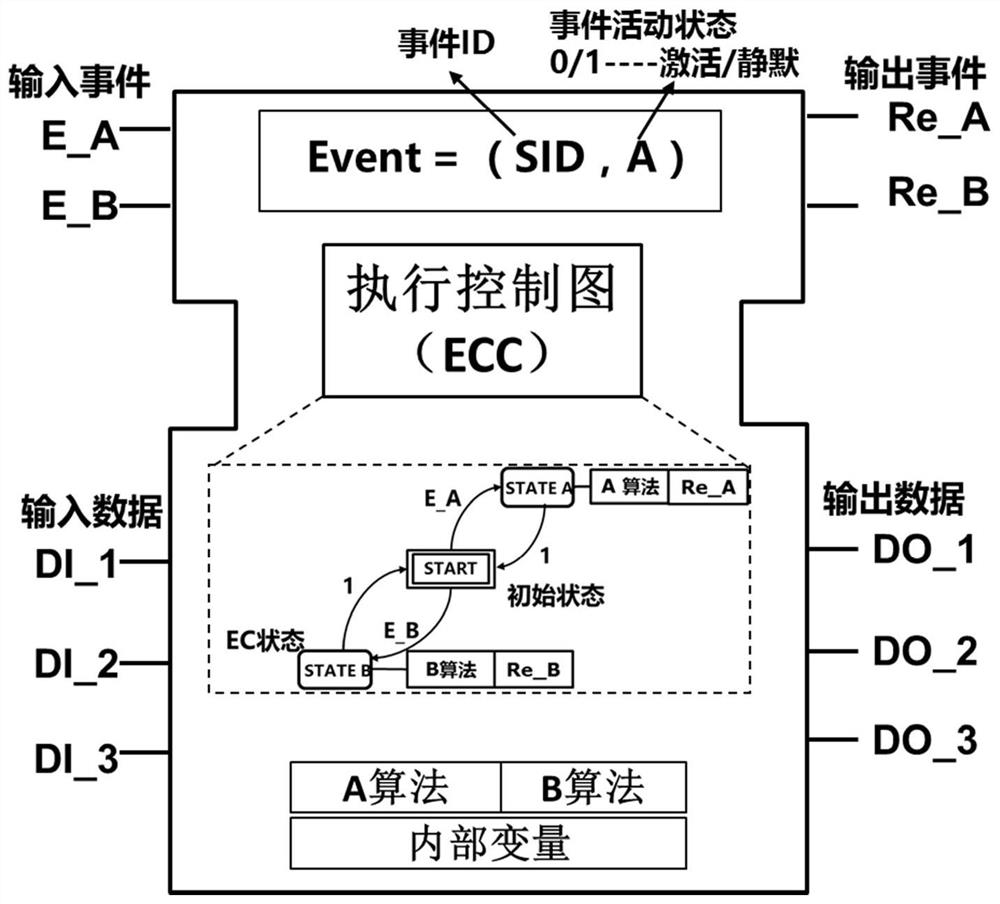

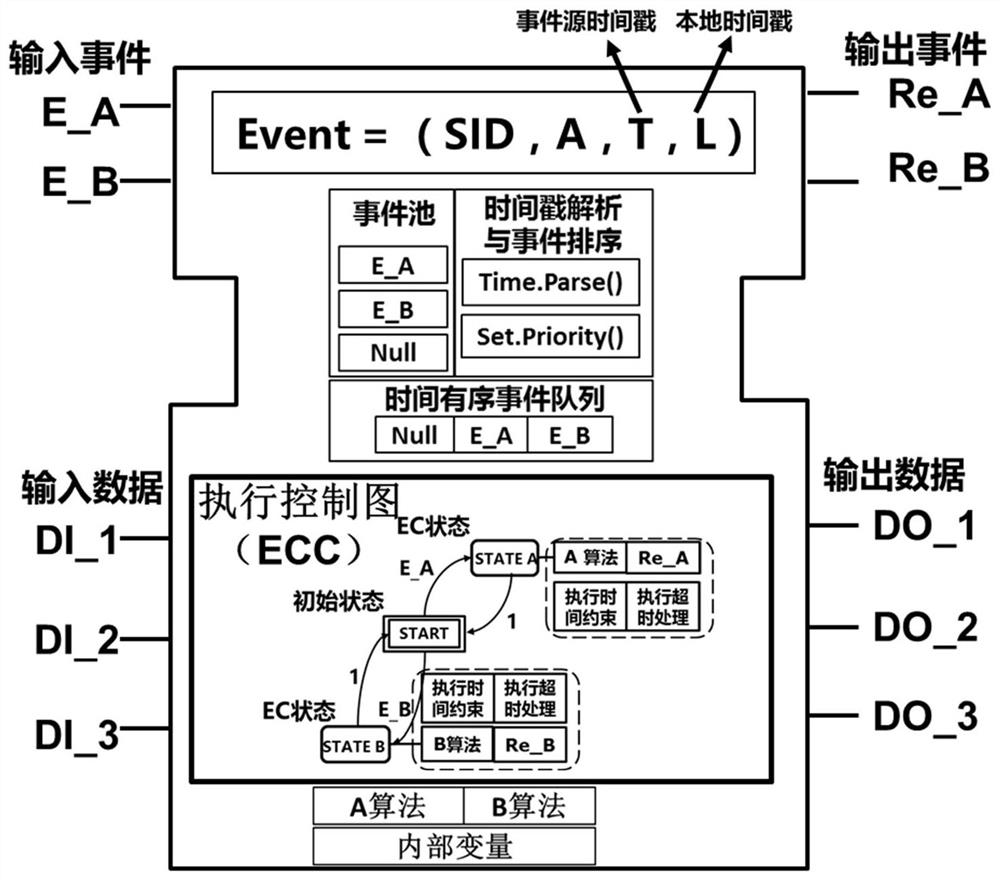

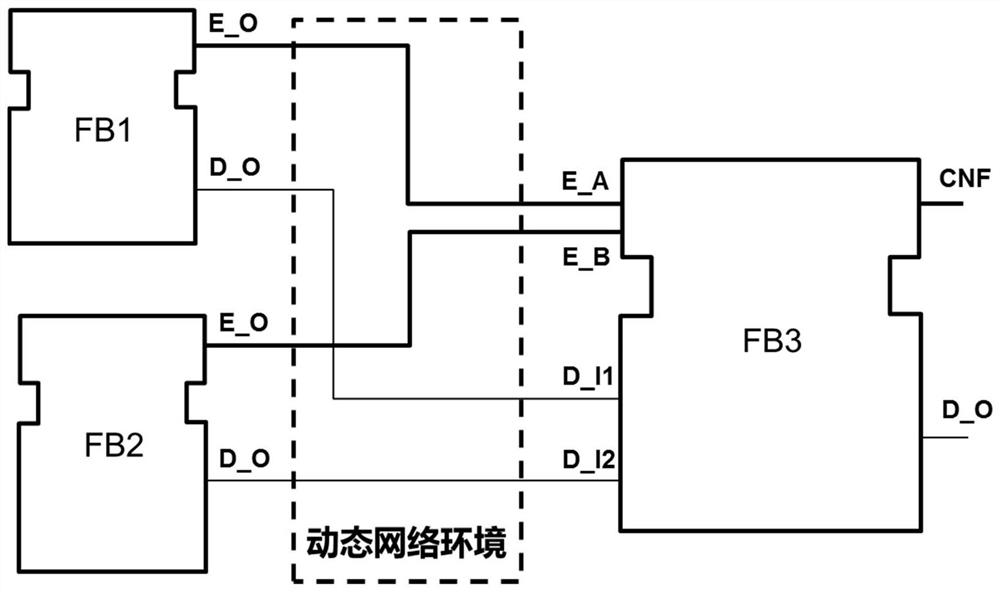

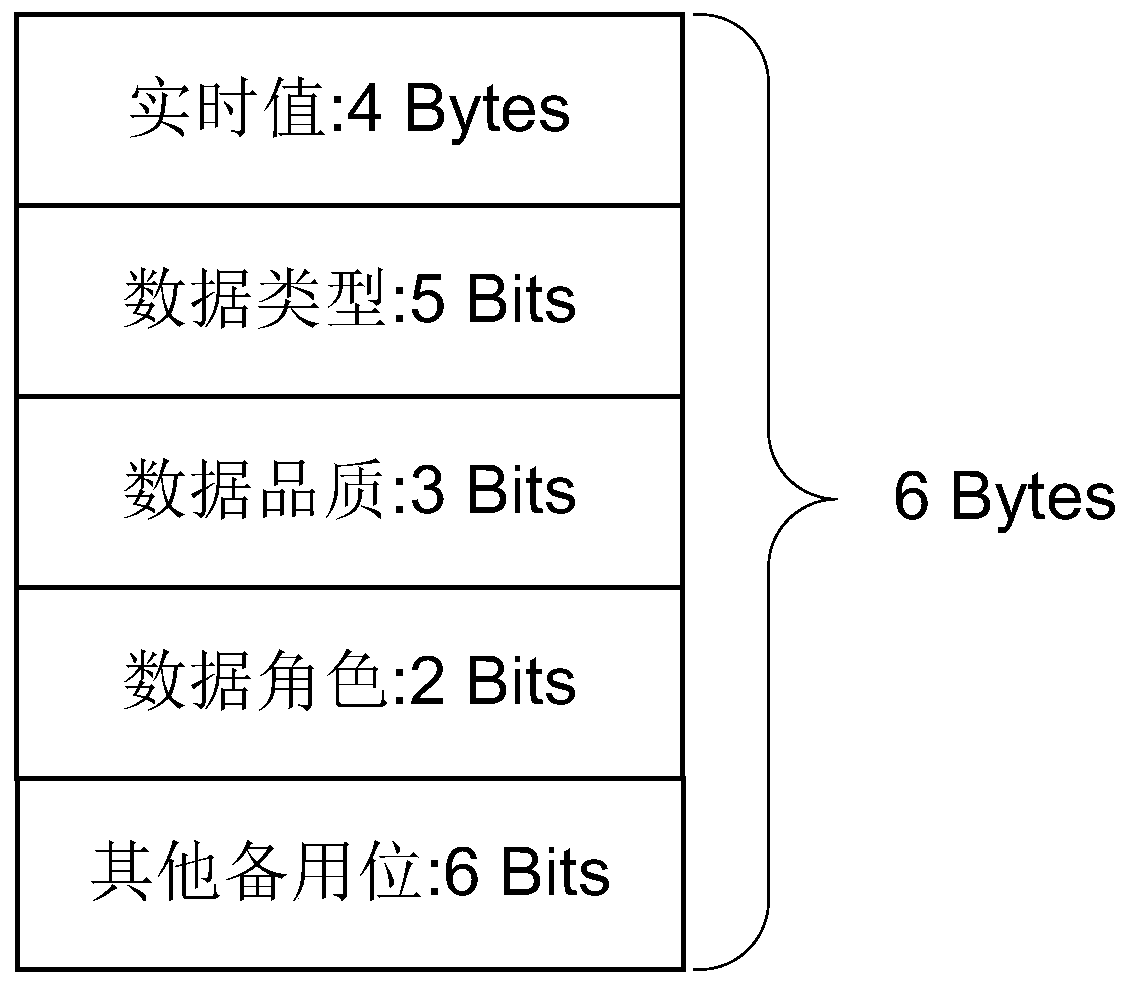

IEC 61499 functional block modeling method for determining calculation time sequence

PendingCN111611029AEnrichment-driven execution mechanismsResolve Incident Response SequenceExecution paradigmsTotal factory controlTimestampingProcessing

The invention relates to an IEC 61499 functional block modeling method capable of ensuring calculation time sequence determinacy. The method comprises the following steps of: redefining an event interface of a functional block for defining an event as an event structure body containing a timestamp; adding a time sequence management module of a function block to the arrival event, analyzing the arrived local event, arranging the events according to the time sequence, and ensuring that the events in the event queue are responded according to the determined time sequence; and adding an algorithmexecution management module and using for defining algorithm execution time constraints and an overtime response processing algorithm interface, managing an ECC execution response algorithm and monitoring a program execution state. According to the method, the determinacy of cooperative computing of the distributed system is guaranteed by extending the IEC 61499 basic function blocks, and the function block structure can guarantee the consistency of event execution time sequences and the determinacy of event response algorithm execution in the distributed system with high concurrency of asynchronous events.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

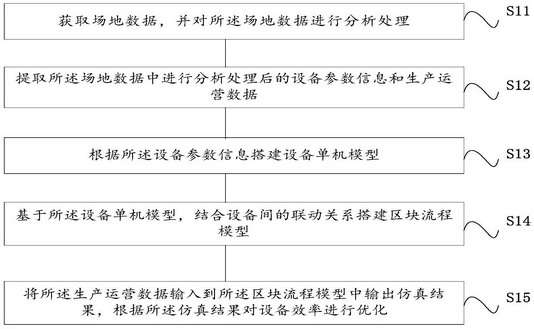

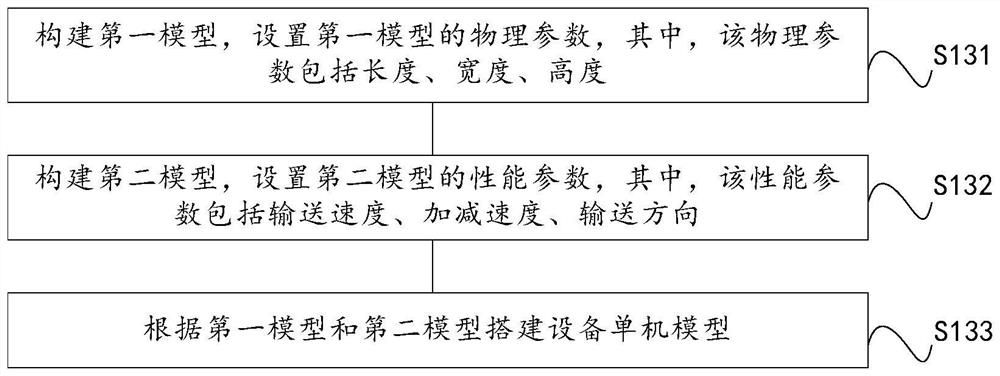

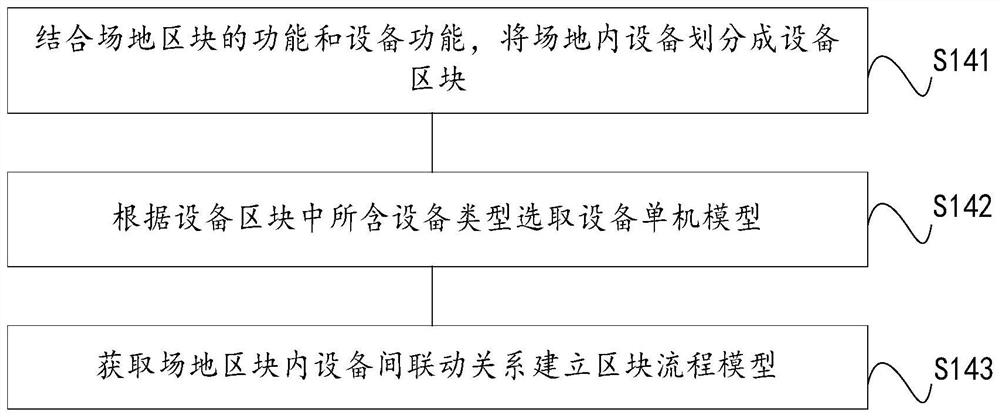

Logistics site equipment efficiency optimization method and system

PendingCN111626650ARapid modelingDesign optimisation/simulationLogisticsLogistics managementModelSim

The invention discloses a logistics site equipment efficiency optimization method and system. The method comprises the following steps: acquiring site data, and analyzing and processing the site data;extracting equipment parameter information and production operation data which are analyzed and processed in the field data; establishing an equipment single-machine model according to the equipmentparameter information; based on the equipment single-machine model, establishing a block process model in combination with a linkage relationship between equipment; and inputting the production operation data into the block flow model to output a simulation result, and optimizing the equipment efficiency according to the simulation result. According to the method, the stand-alone simulation modelis established according to the equipment principle, the actual condition of equipment operation is restored to the maximum extent, rapid modeling of a complex system can be achieved through block modeling, and the relation between stand-alone simulation models does not need to be established one by one.

Owner:SF TECH

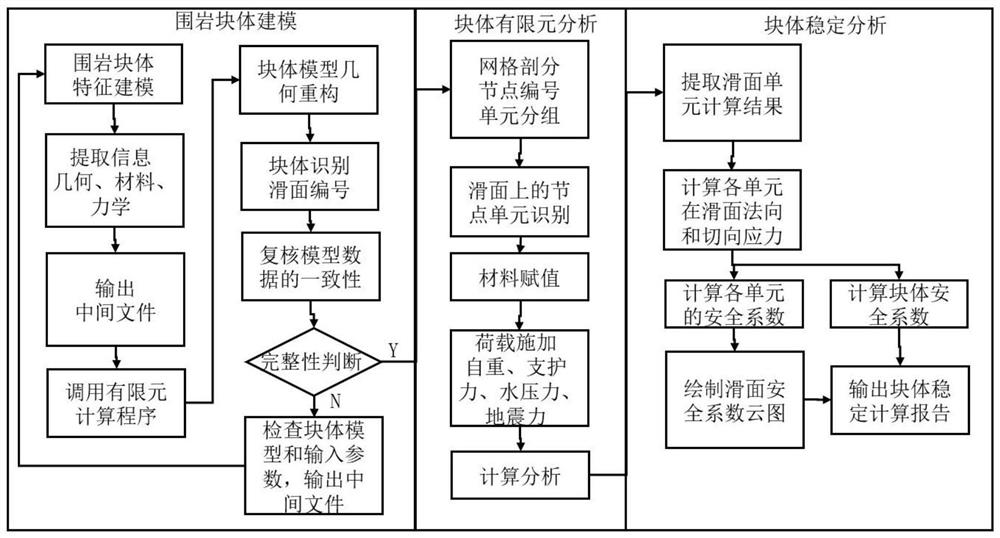

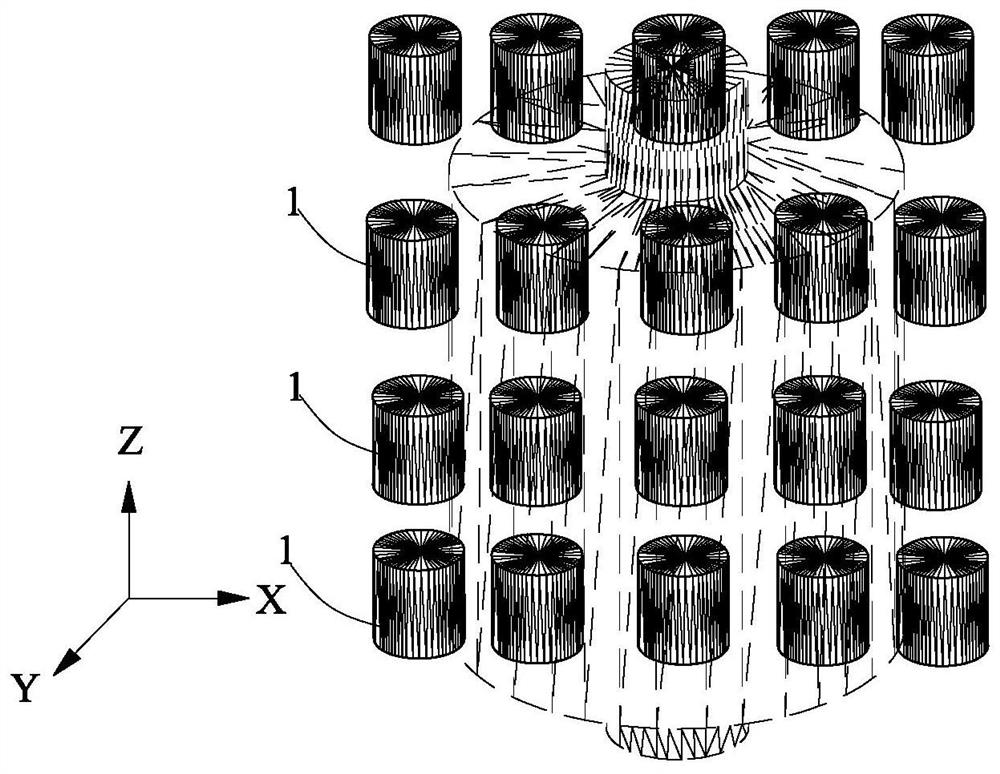

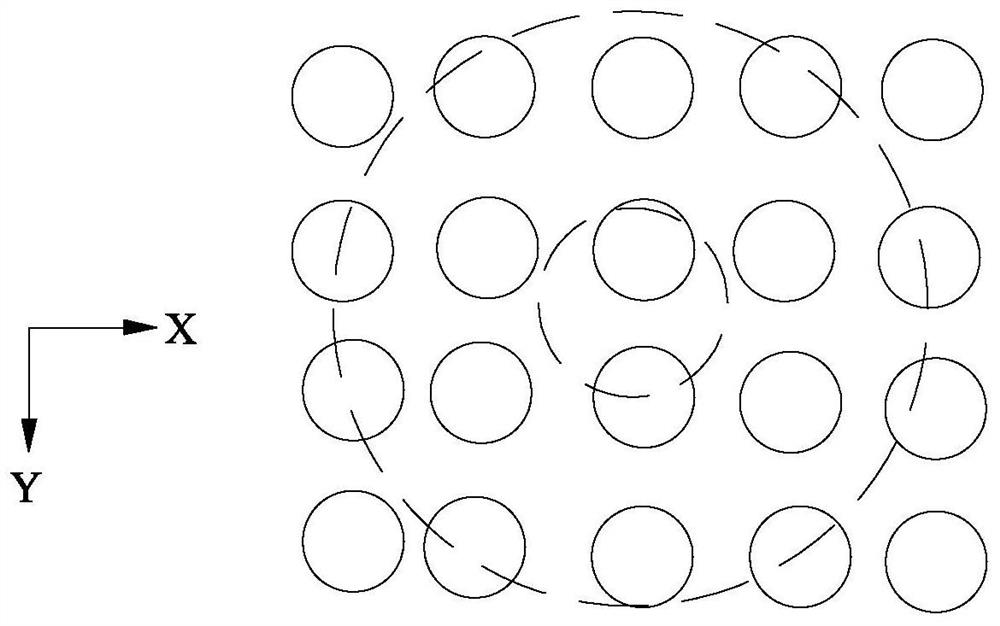

Underground cavern surrounding rock complex block modeling and stability analysis integrated method

ActiveCN113947000AReduce intensityRapid modelingGeometric CADDesign optimisation/simulationUnderground cavernFinite element analysis software

The invention relates to underground engineering three-dimensional modeling and analysis, and discloses an underground cavern surrounding rock complex block modeling and stability analysis integrated method which realizes rapid modeling and automatic analysis and calculation so as to reduce the modeling and analysis working intensity of design engineers and improve the design working efficiency. According to the method, on the basis of an underground cavern model, a block sliding surface is established through the exposed position and occurrence of the block; direction judgment and cutting operation are carried out based on the block sliding surface, a surrounding rock block feature object is generated, and attribute assignment is carried out; feature decoding on the surrounding rock block feature object is performed, and the analyzed information is stored in an external file; finite element analysis software is called to read and analyze the file; a block three-dimensional model is reconstructed according to the analysis information, block identification and sliding surface numbering are performed, and then integrated solution and computational analysis are performed; and the stress magnitude and direction of the unit and node of each sliding surface are extracted according to the solving result, then the safety coefficient of the whole block is calculated, and a stability analysis report is outputted.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

Block model building method for complex geological structure

InactiveCN101582173BEasy to buildSmall amount of calculation3D-image rendering3D modellingGeometric consistencyTopological consistency

The invention discloses a block model building method for complex geological structure, and relates to the geological field of three-dimension modeling comprising the following steps: a, triangular meshing description is carried out on planes or fault planes; b, after step a, level intersection in block modeling for complex geological structure is converted into triangle intersection in space, whether the two triangles are intersected is judged, points of intersection are found from the two intersected triangles, and a line of intersection is obtained by connecting the points of intersection;c, geometric consistency and topological consistency are carried out on inside of each intersected triangle; d, after step c, enclosing block is extracted to obtain an interface formed by peripheral sides of the enclosing block, and is defined geological attribute to form three dimension model block. The method in the invention completely solves the problems of three dimension model input and blocking in complex geological regions, avoids using equations set with high solving difficulty and calculated amount, and is simple and practical.

Owner:CHINA NAT PETROLEUM CORP

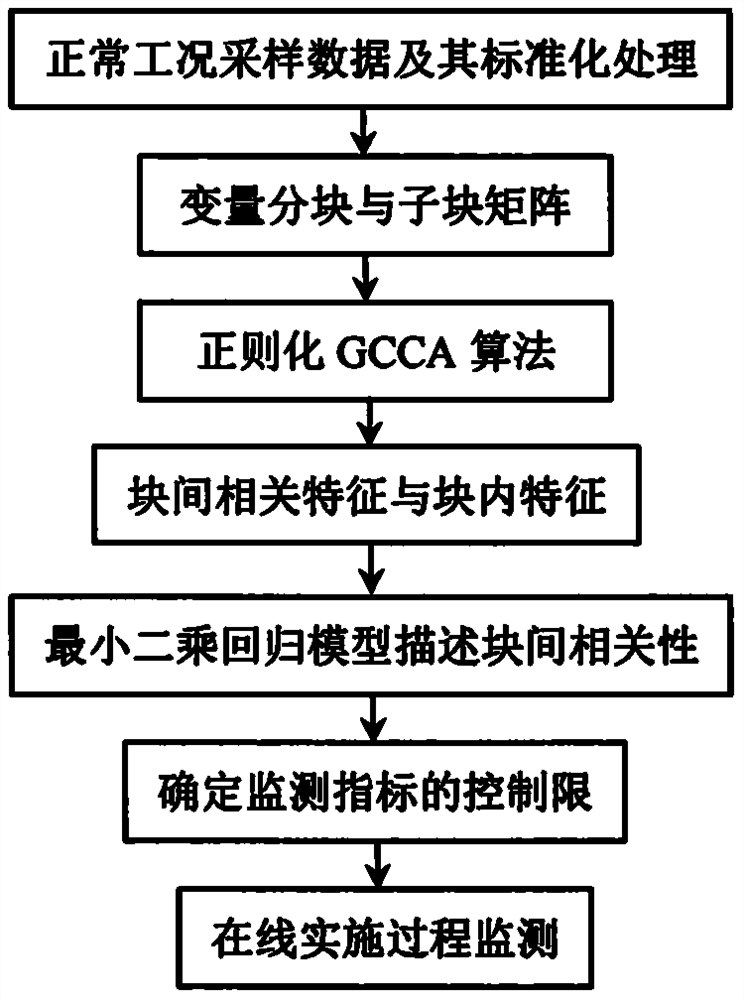

A Distributed Chemical Process Monitoring Method Based on Regularized GCCA Model

ActiveCN111913461BCommon changeChange uniquenessProgramme controlElectric testing/monitoringCorrelation coefficientAlgorithm

The invention discloses a distributed chemical process monitoring method based on a regularized GCCA model, which is used to solve the problem of distributed chemical process monitoring. The method of the present invention utilizes the involved regularized generalized canonical correlation analysis (GCCA) algorithm to simultaneously consider the commonality between variable blocks and the uniqueness within each block when implementing multi-block modeling, and can be applied to overlapping and non-overlapping variables at the same time Chunking mode. Compared with the traditional method, the regularized GCCA algorithm involved in the method of the present invention takes the common features between the variable sub-blocks into consideration through the square of the typical correlation coefficient, and further uses the least squares regression algorithm to describe the inter-block correlation features. relationship between. In addition, the method of the present invention also considers inter-block correlation features and intra-block features separately, and uses two comprehensive monitoring indicators to implement monitoring separately. Therefore, the method of the present invention is a more superior distributed chemical process operation state monitoring method.

Owner:SHANDONG LONGSHENGHE CHEM CO LTD

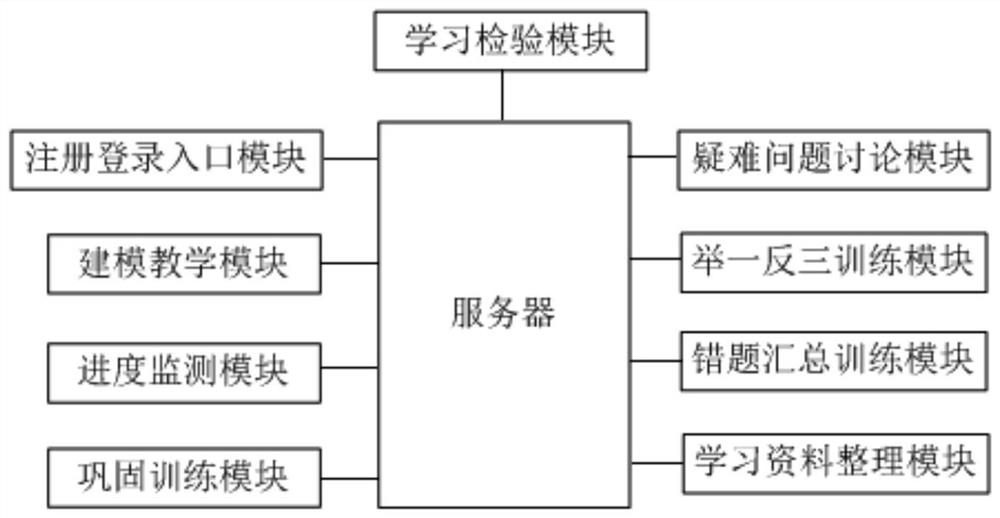

Mathematical modeling teaching learning system

PendingCN111858554AImprove learning efficiencyAchieve repeated memoryData processing applicationsDesign optimisation/simulationMathematical modelSoftware engineering

The invention relates to the field of mathematics teaching systems, in particular to a mathematics modeling teaching learning system. The system comprises a registration login entrance module, a modeling teaching module, a consolidation training module, a one-back-three training module, a learning inspection module, a wrong question summary training module and a difficult question discussion module. The mathematical model carrying modeling and de-modeling step marks is adopted to realize demonstration of modeling and de-modeling processes of various classic mathematical models, so that learners can clearly know each modeling and de-modeling step, and the learning efficiency of mathematical modeling learning can be remarkably improved.

Owner:HARBIN NORMAL UNIVERSITY

A chemical fault monitoring method based on generalized multi-block independent element analysis model

ActiveCN111913462BImprove general performanceProgramme controlElectric testing/monitoringAlgorithmComputer science

The invention discloses a chemical fault monitoring method based on a generalized multi-block independent element analysis model, and aims to propose a generalized multi-block independent element analysis algorithm, which can implement non-Gaussian multi-block for overlapping and non-overlapping variable sub-block divisions Modeling, so as to use the generalized multi-block independent meta-analysis algorithm to implement distributed fault monitoring. In the process of implementing the modeling based on the independent element analysis algorithm, the method of the present invention simultaneously considers the uniqueness of each sub-block and the integrity between the sub-blocks, from the separation of the whole to the extraction of local sub-blocks, and then returns from the local sub-blocks to the whole Separate interleaved one-by-one extraction strategies. Therefore, the method of the present invention is a brand new non-Gaussian multi-block modeling and fault monitoring method. In addition, the superiority of the method of the present invention will be verified in specific implementation cases, thereby illustrating that the method of the present invention is a more preferred non-Gaussian distributed fault monitoring method.

Owner:SHANDONG XINHUA LONGXIN CHEM

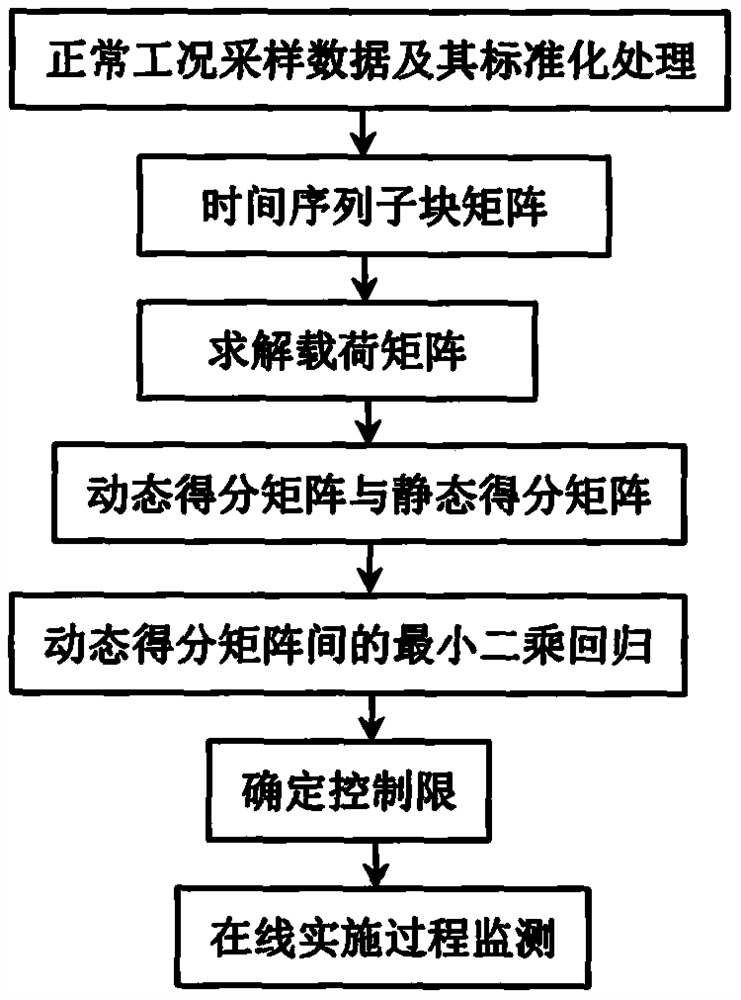

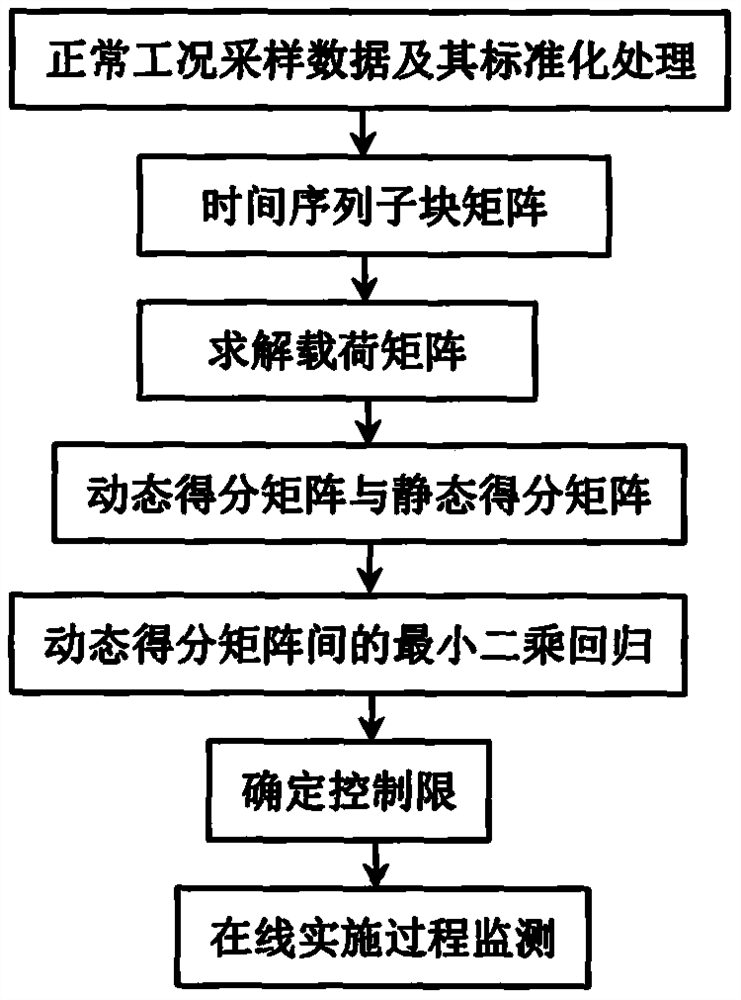

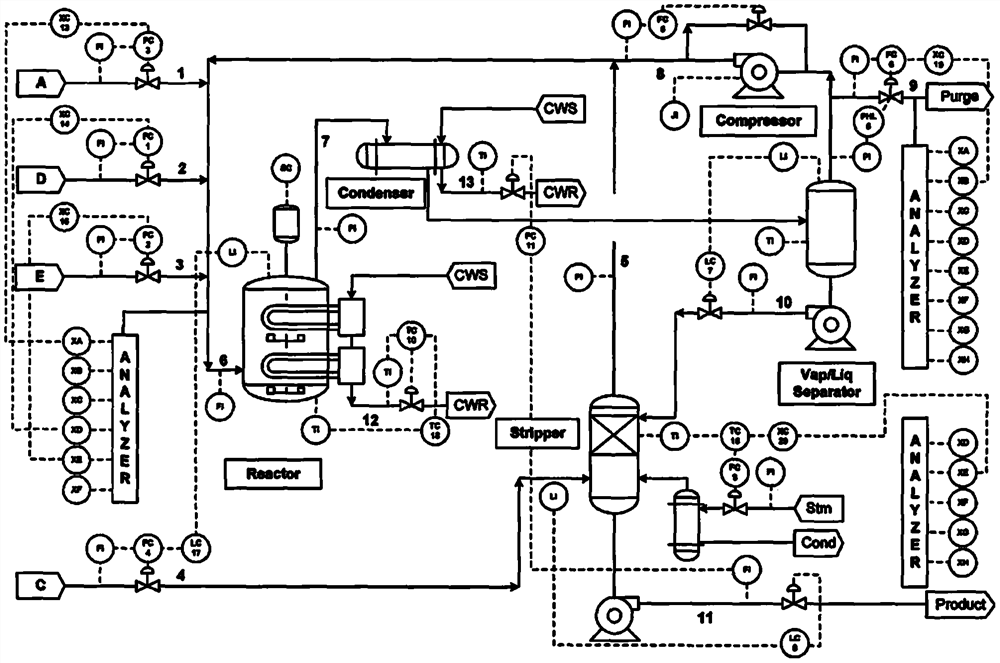

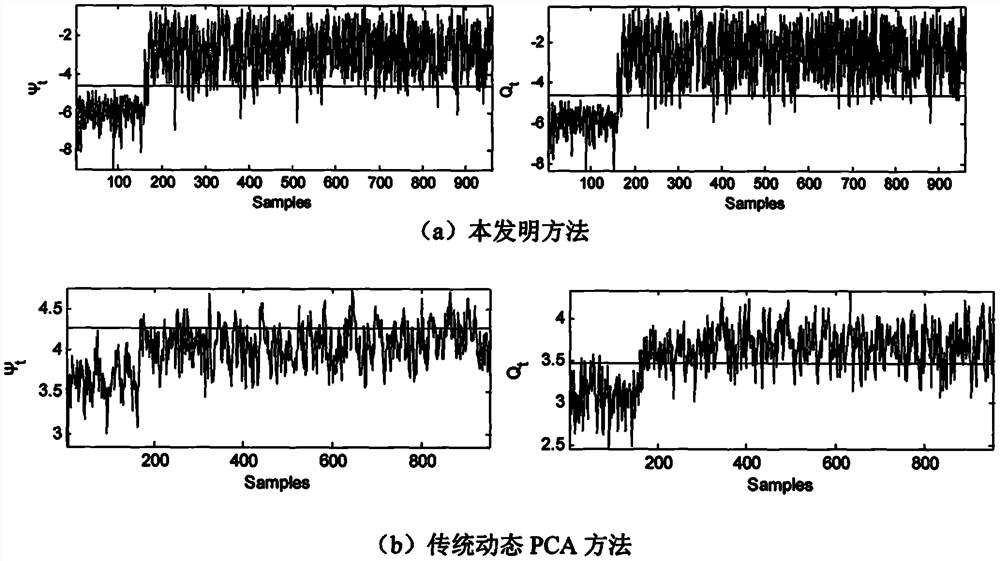

Chemical process monitoring method based on time sequence multi-block modeling strategy

ActiveCN111913444ASuperior dynamic monitoring method for chemical processTotal factory controlProgramme total factory controlGeneralized canonical correlationDynamic monitoring

The invention discloses a chemical process monitoring method based on a time sequence multi-block modeling strategy, and aims to establish an integrated implementation framework of multi-block modeling and dynamic process monitoring so as to implement effective dynamic process monitoring. Different from the traditional dynamic process modeling thought, the method comprises the following steps of firstly, sampling nodes according to a time sequence, and dividing an augmented matrix or vector into a plurality of variable blocks; and then, optimizing a projection transformation base for each variable sub-block by utilizing the thought of generalized canonical correlation analysis so as to extract the cross correlation between the variable sub-blocks, i.e., extracting the auto-correlation characteristics on the time sequence. In order to comprehensively consider the results given by the monitoring indexes of the multiple models, the method provided by the invention also uses the comprehensive monitoring indexes to respectively monitor the changes of the dynamic and static score information. In addition, the superiority of the method provided by the invention can be verified by a specific embodiment, so that the method provided by the invention is a more superior chemical process dynamic monitoring method.

Owner:日照市三星化工有限公司

A Fine Velocity Modeling Method Based on the Constraint of Gas Cloud Area

ActiveCN106125133BEfficient managementImprove application efficiencySeismic signal processingHorizonGeological Phenomena

The invention relates to a fine velocity modeling method based on gas cloud region constraints. The method comprises steps: a velocity model comprising a three-dimensional data mesh is defined, to-be-detected space is divided into a gas cloud region and a non-gas cloud region, and velocity data in the known logging data are used for counting velocity change trends of the gas cloud region and the non-gas cloud region; seismic interpretation horizon data are used and gas cloud region space distribution is combined to carry out block processing on the velocity model; velocity models for the gas cloud region and the non-gas cloud region are built; and a seismic interpretation horizon control technique is adopted to combine the velocity models for the gas cloud region and the non-gas cloud region, and an initial velocity model is acquired. In view of special geological phenomena in the gas cloud region, the gas cloud region and the non-gas cloud region are effectively distinguished, block modeling is carried out on the gas cloud region and the non-gas cloud region respectively, and through research on the velocity change trends of the gas cloud region and the non-gas cloud region, velocity modeling is carried out in a more targeted mode, the actual geological conditions are met, and the time-depth conversion precision is high.

Owner:CHINA NAT OFFSHORE OIL CORP +2

A chemical process monitoring method based on time-series multi-block modeling strategy

ActiveCN111913444BSuperior dynamic monitoring method for chemical processTotal factory controlProgramme total factory controlDynamic monitoringAugmented matrix

Owner:日照市三星化工有限公司

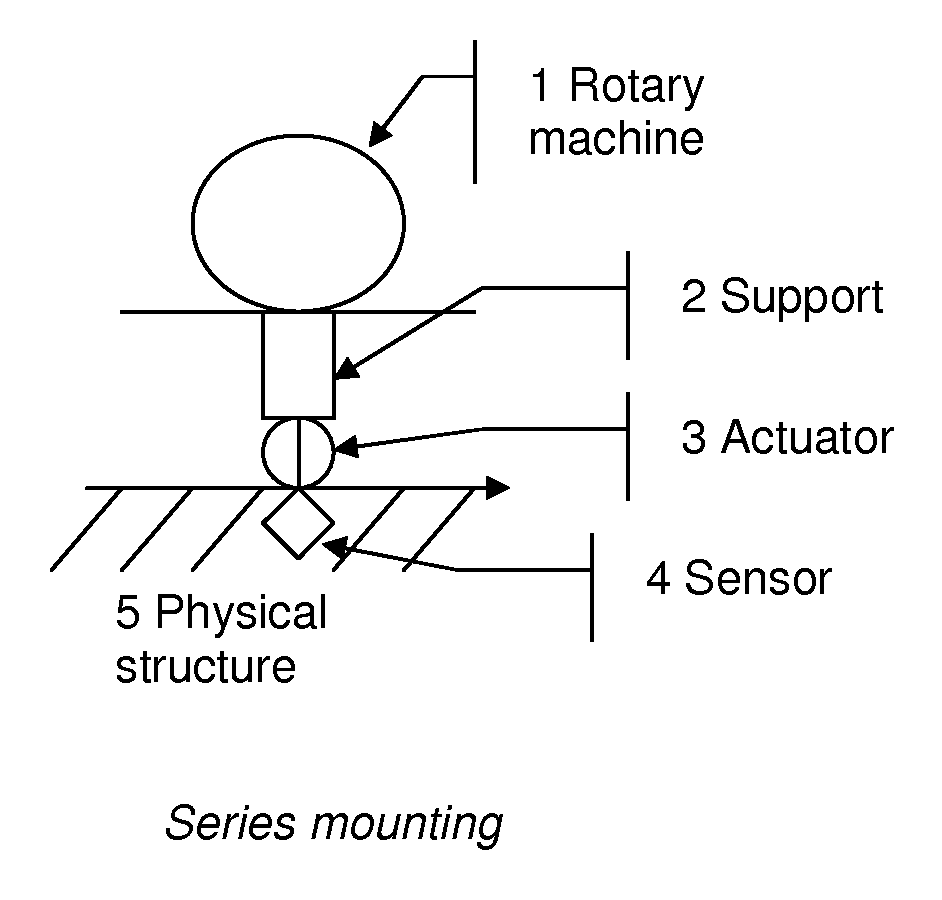

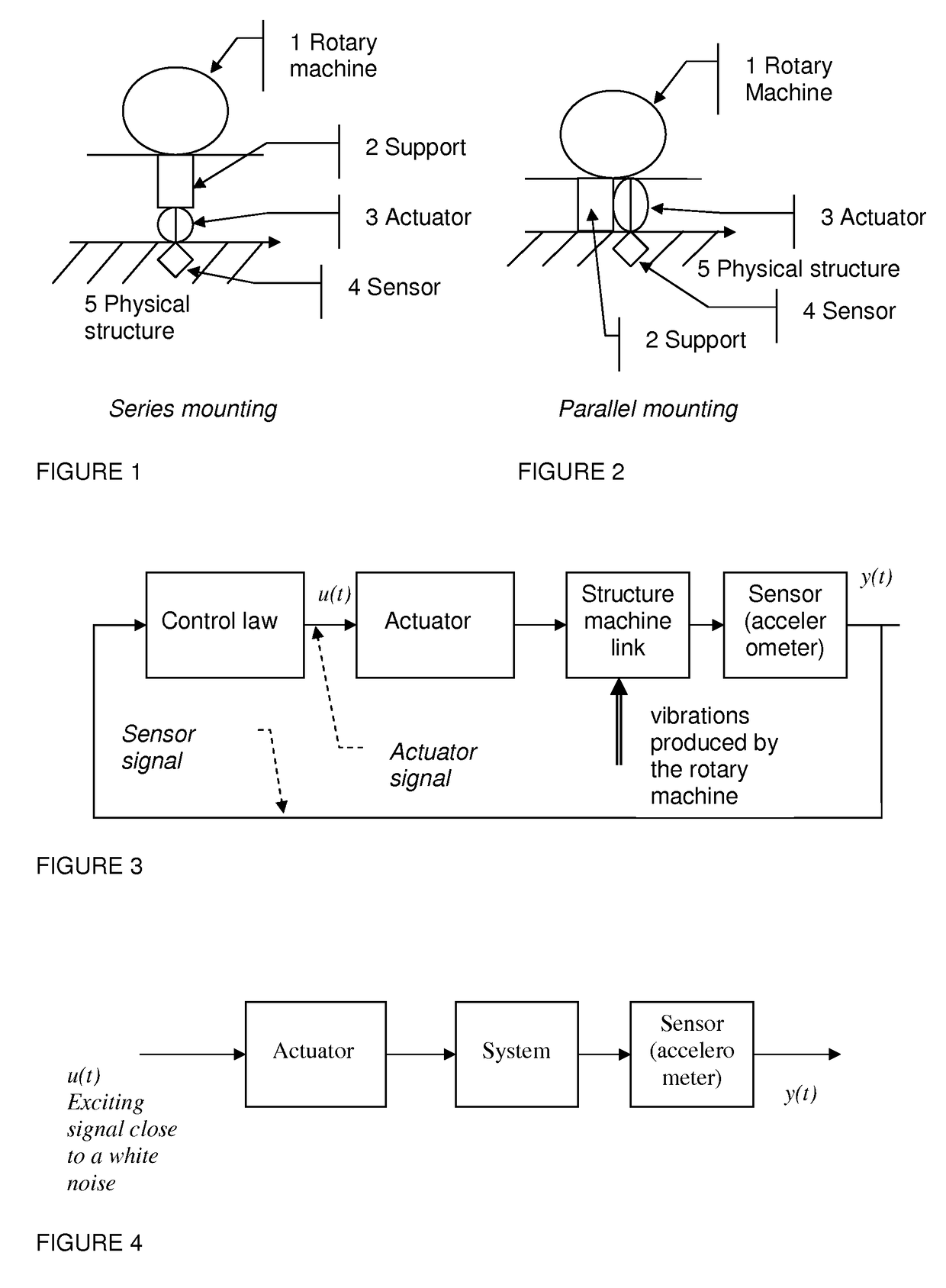

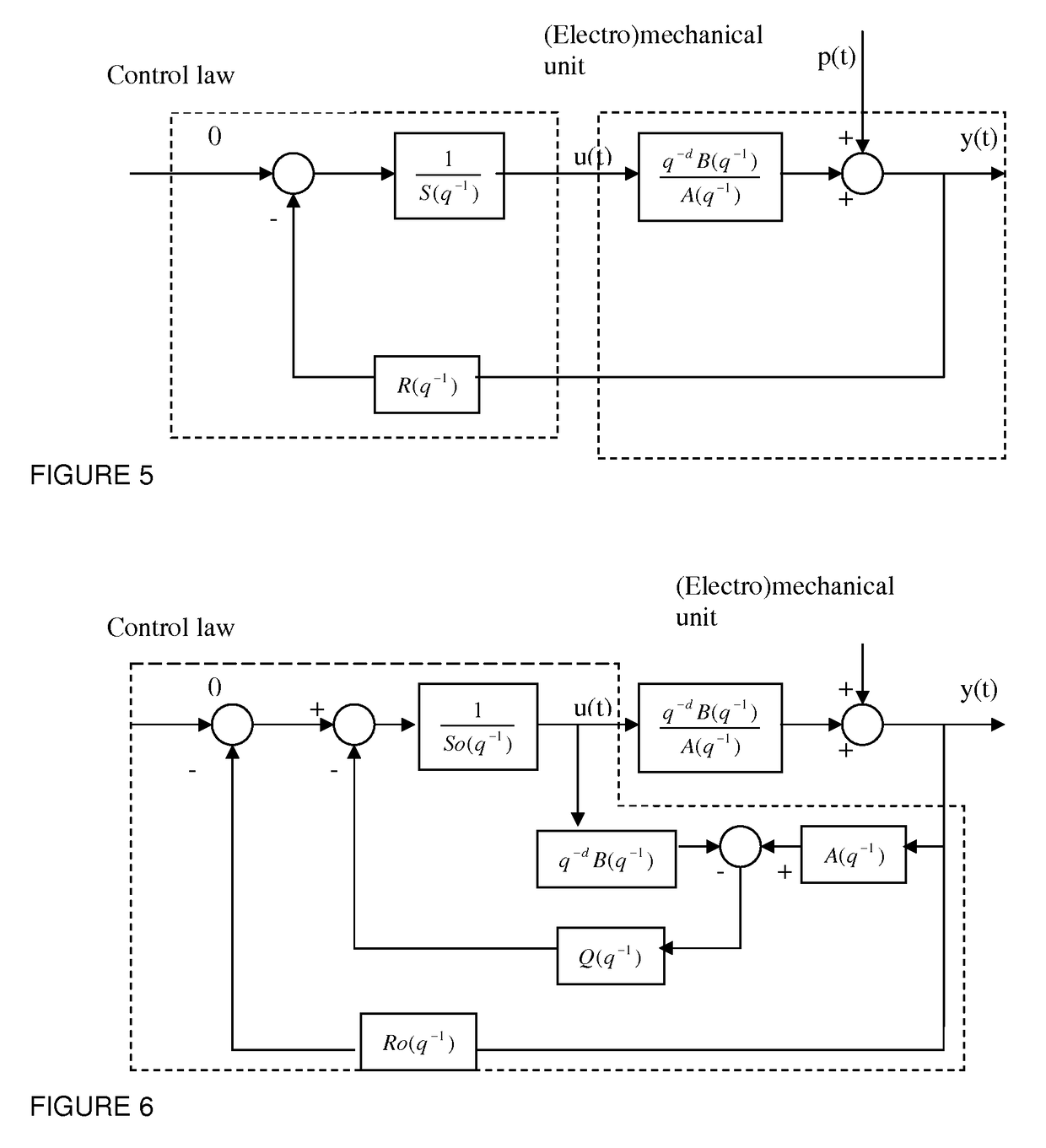

Method and device for active control of mechanical vibrations by implementation of a control law consisting of a central corrector and a Youla parameter

ActiveUS9600000B2Reduce vibrationReduce vibration intensitySampled-variable control systemsMechanical oscillations controlUltrasound attenuationEngineering

A method and a device are based on the application of an active correcting system with central corrector and Youla parameter for the attenuation of essentially monofrequency mechanical vibratory perturbations generated in a material structure by a rotating machine. Previously, a control law corresponding to a block modeling of the system is established and calculated, the blocks being, on the other hand, those of the central corrector and, on the other hand, a Youla parameter block, the modeling being such that only the Youla parameter, in the form of an infinite impulse response filter, has coefficients dependent on the vibratory perturbation frequency. During a phase of use, in real time, the frequency of the current perturbation is determined and the control law is calculated using for the Youla parameter the stored coefficients of a determined perturbation frequency corresponding to the current perturbation frequency.

Owner:EXAIL

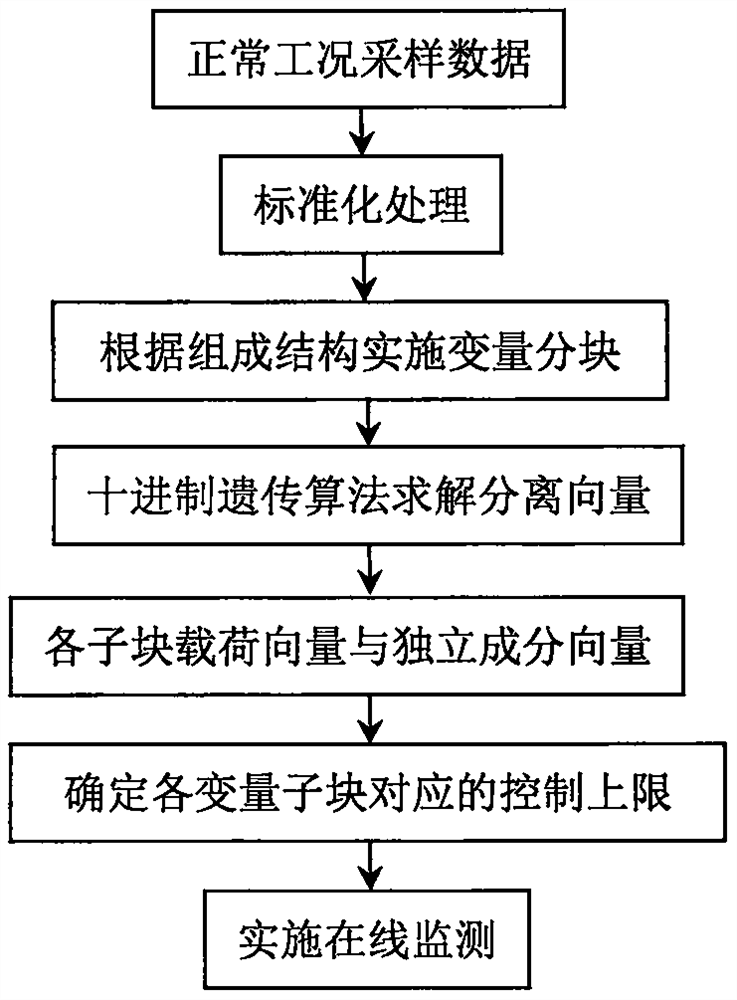

Novel distributed non-Gaussian process monitoring method based on GA-ICA

PendingCN111695229AVerify superiorityCharacter and pattern recognitionDesign optimisation/simulationAlgorithmGenetics algorithms

The invention discloses a novel distributed non-Gaussian process monitoring method based on GA-ICA, and aims to solve an ICA model by using a decimal genetic algorithm and derive an implementation process of multiple ICA algorithms, and on the basis, distributed non-Gaussian process monitoring can be implemented. According to the method, in the process of implementing multi-block modeling, separated vectors and independent components corresponding to all measurement variables are solved by utilizing a decimal genetic algorithm, and then the independent components corresponding to each variablesub-block are separated according to the uniqueness of each variable sub-block. Therefore, the integrity of all measured variables and the local characteristics of each variable sub-block are comprehensively considered when multi-block modeling is implemented, and the distributed non-Gaussian process monitoring method is a brand-new distributed non-Gaussian process monitoring method. In addition,the superiority of the method provided by the invention is verified by a specific embodiment, so that the method provided by the invention is a more optimal distributed non-Gaussian process monitoring method.

Owner:NINGBO UNIV

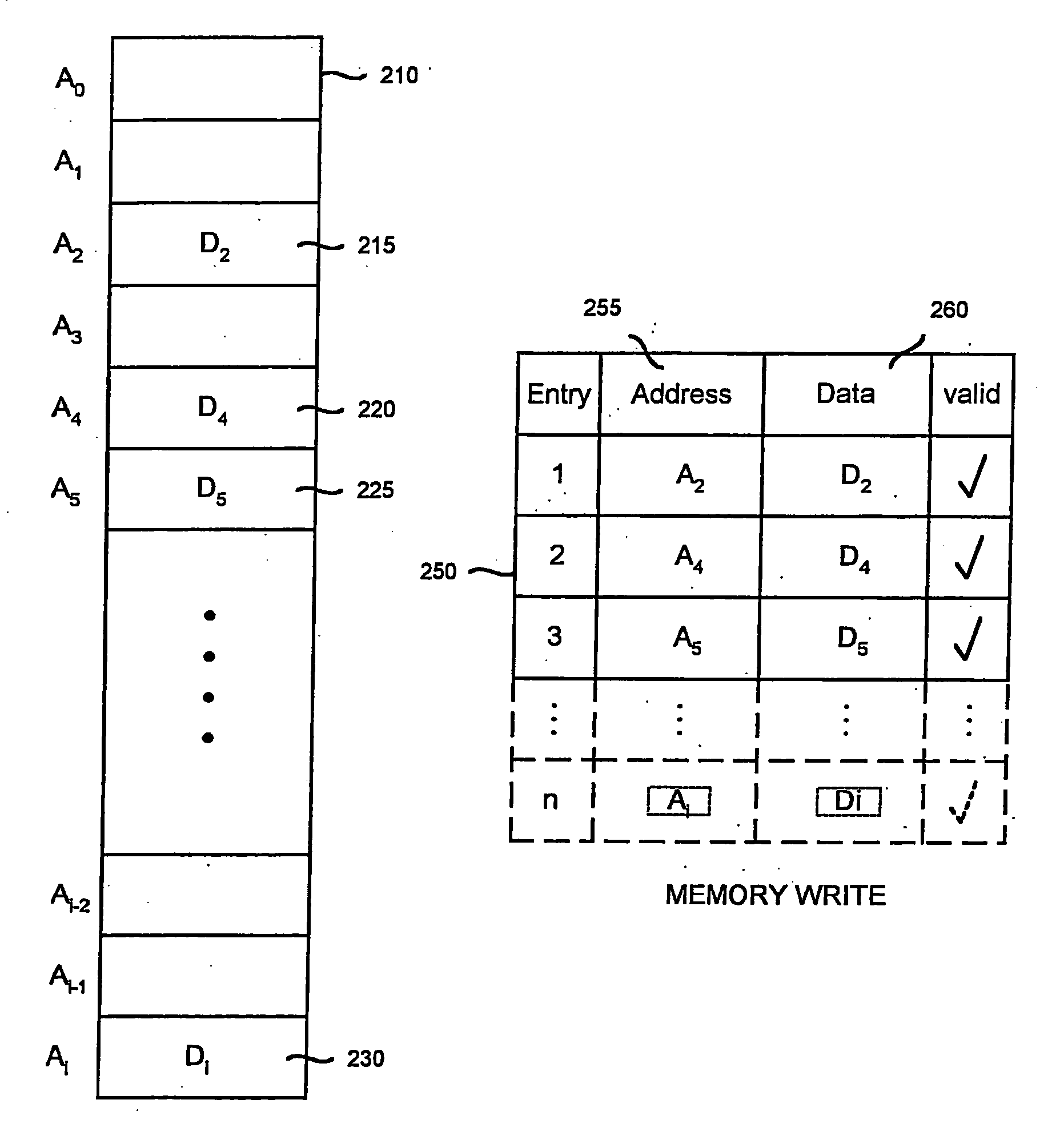

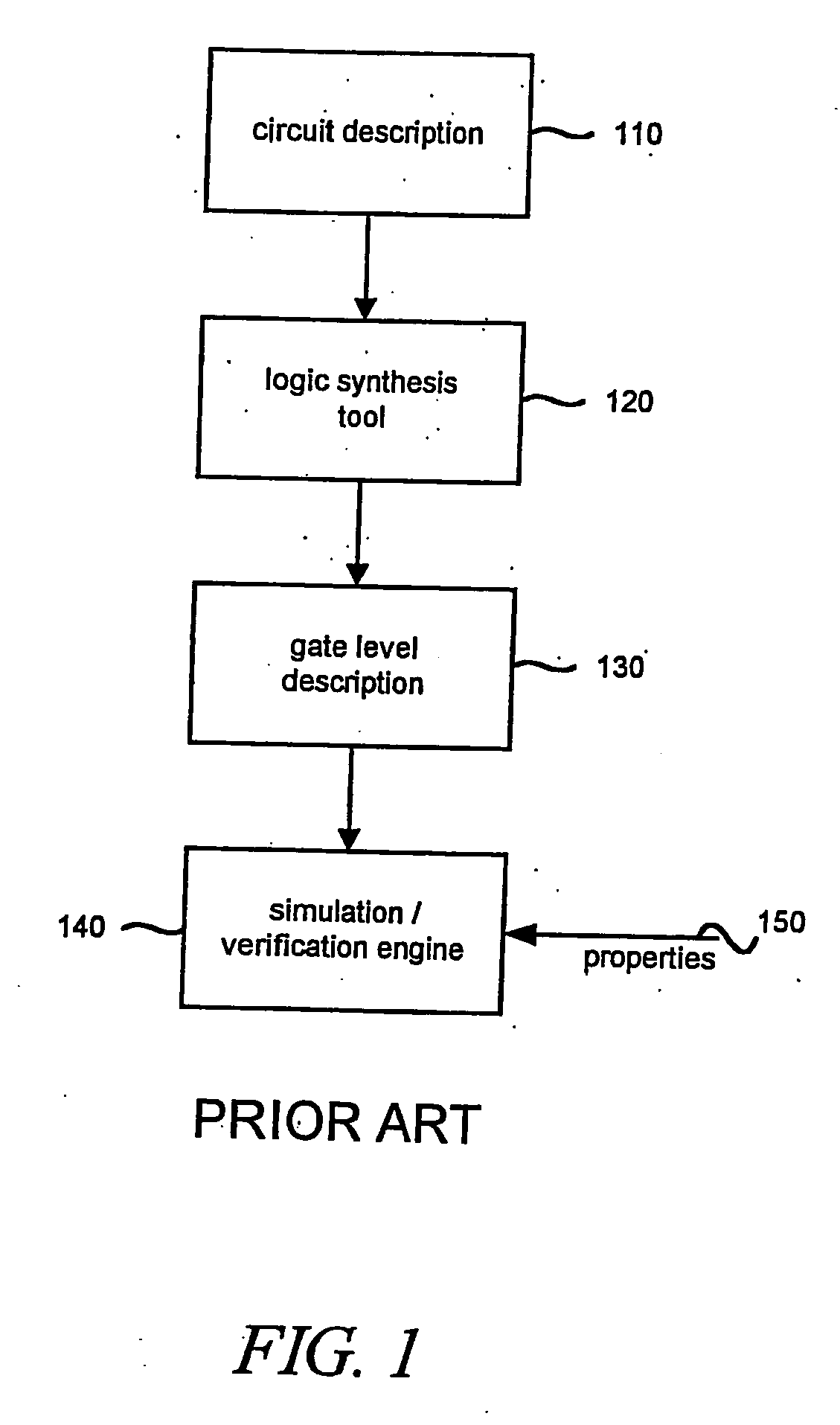

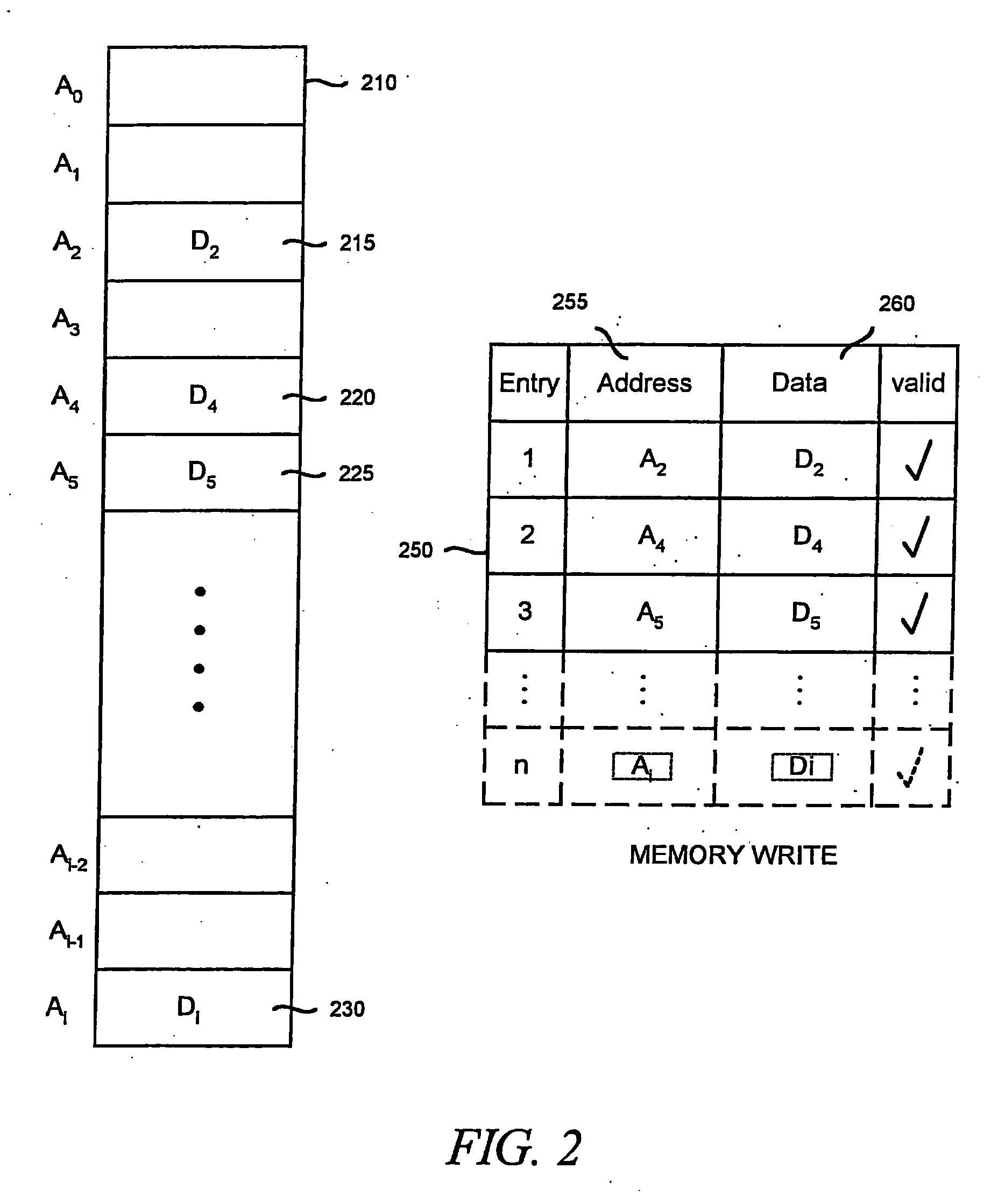

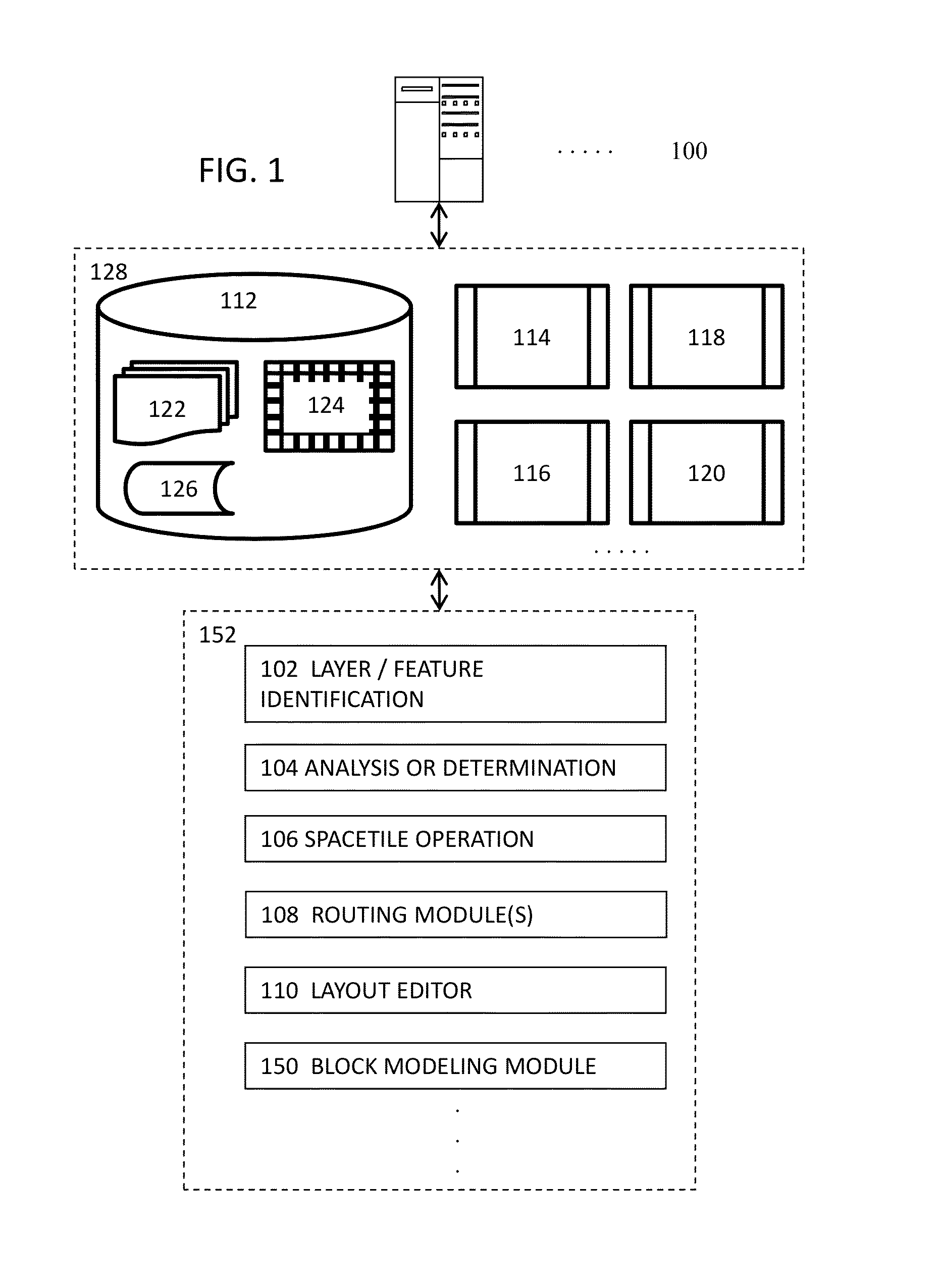

Circuit-level memory and combinational block modeling

InactiveUS20060064290A1Analogue computers for electric apparatusComputation using non-denominational number representationParallel computingLookup table

A method and apparatus for creating a memory model for use in modeling a physical memory of an electronic circuit design. Memory write operations to the physical memory and memory read operations are modeled in a lookup table. The number of entries in the lookup table is limited by an upper bound representing a total number of memory operations that can occur over a given number of clock cycles.

Owner:AVERANT

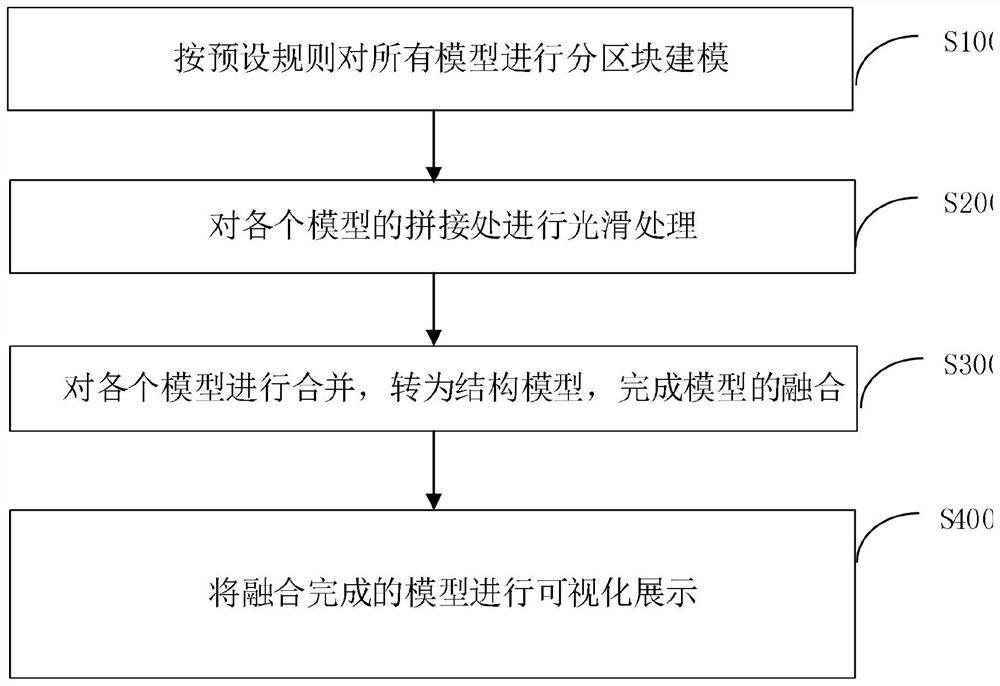

Three-dimensional geologic model automatic merging method for block modeling

PendingCN114880849ASolve the problem of poor smoothnessDesign optimisation/simulationSpecial data processing applicationsAlgorithmTheoretical computer science

The invention discloses a method for automatically merging three-dimensional geologic models through block modeling. The method comprises the following steps: carrying out block modeling on all models according to a preset rule; carrying out smoothing processing on the splicing part of each model; the models are merged and converted into structural models, and fusion of the models is completed; and carrying out visual display on the fused model. The problems that in the prior art, a model lacks integrity, splicing traces of modeling units are obvious, and the smoothness of the model is poor are solved.

Owner:山东省地质调查院

A self-defined function block and configuration encapsulation method based on component model

ActiveCN107844093BImplement confidentiality managementMeet application needsTotal factory controlProgramme control in sequence/logic controllersElement modelTheoretical computer science

The invention provides an element model based customized function block and configuration packaging method. The method includes steps of a), defining an inheritable function block element model and designing a standard instantiation interface and a uniform data structure; b) instantiating algorithm type function blocks which are universal in industrial control field; c) defining a configuration file structure; d) based on a control strategy of the inheritable function block element model, packaging into a customized function block; e) storing the customized block information into an originalconfiguration file. According to the invention, from the perspective of function block modeling, thought of an object-oriented method is absorbed, typical features and key data information of the algorithm function block are extracted and the inheritable function block element model is established. On this basis, numerous basic algorithm function blocks of an arithmetic type, a logic type, a control type, a time type and the like are instantiated and algorithm configuration and debugging demands in industrial process control can be met.

Owner:NR ELECTRIC CO LTD +1

A Distributed Process Monitoring Method Based on Multi-Block Independent Component Analysis Algorithm

ActiveCN111694328BVerify superiorityTotal factory controlProgramme total factory controlAlgorithmMonitoring methods

The invention discloses a distributed process monitoring method based on a multi-block independent component analysis algorithm, and aims to propose a novel multi-block independent component analysis algorithm, and use the algorithm to implement distributed non-Gaussian process monitoring, so that it can be used in construction In the process of modeling, the uniqueness of each sub-block and the integrity between sub-blocks are considered at the same time. In the process of implementing multi-block modeling, the method of the present invention does not simply extract score vectors for each sub-block, but an interleaved one-by-one extraction strategy from the whole to local sub-blocks, and then from local sub-blocks to the whole. Therefore, the novel multi-block independent component analysis algorithm proposed by the method of the present invention not only considers the uniqueness of each sub-block, but also considers the overall integrity. Therefore, the method of the present invention is a brand-new distributed non-Gaussian process monitoring method. In addition, the superiority of the method of the present invention will be verified in specific implementation cases, thus illustrating that the method of the present invention is a more preferred non-Gaussian process monitoring method.

Owner:恩施自治州聪慧科技发展有限责任公司

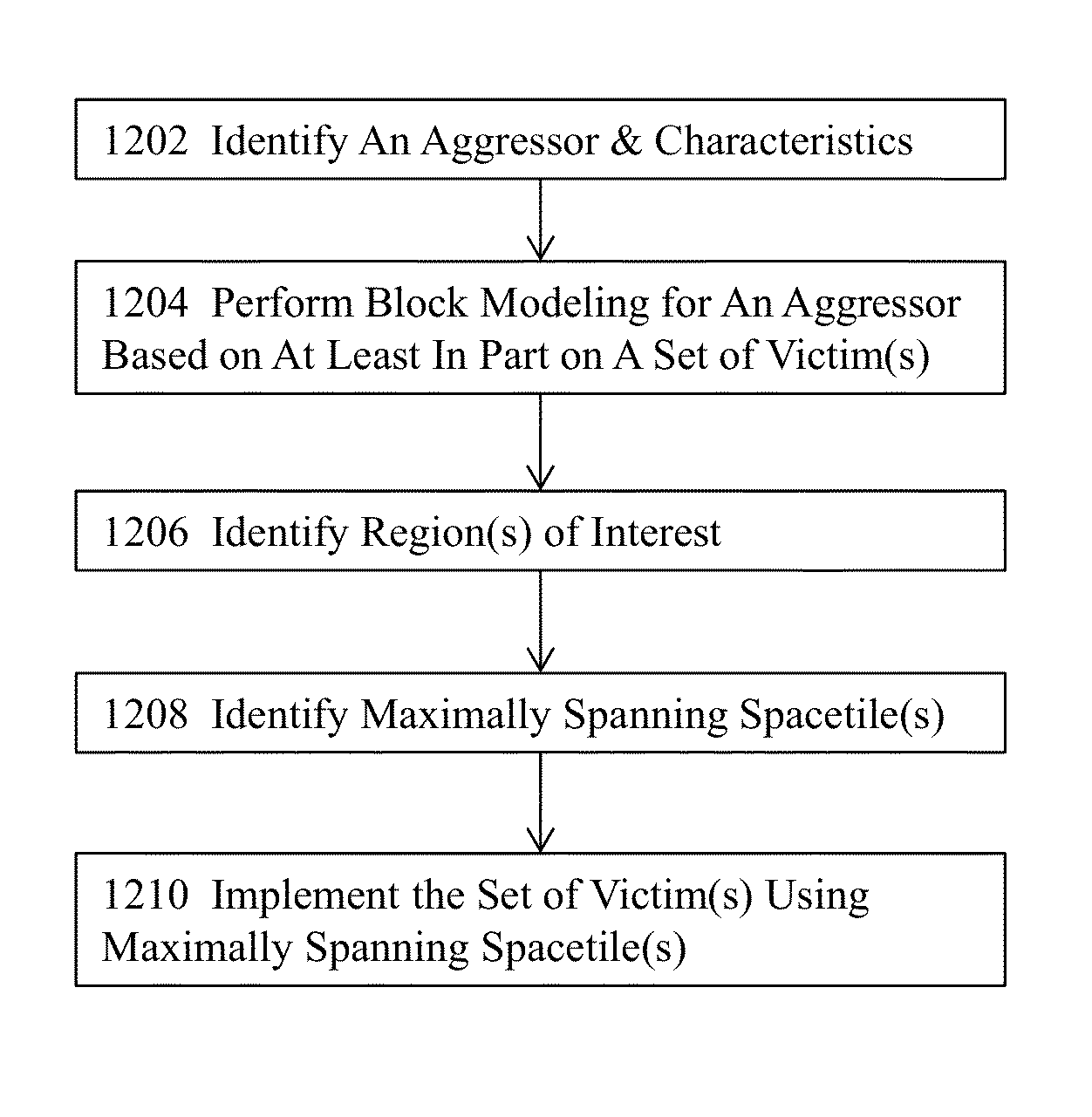

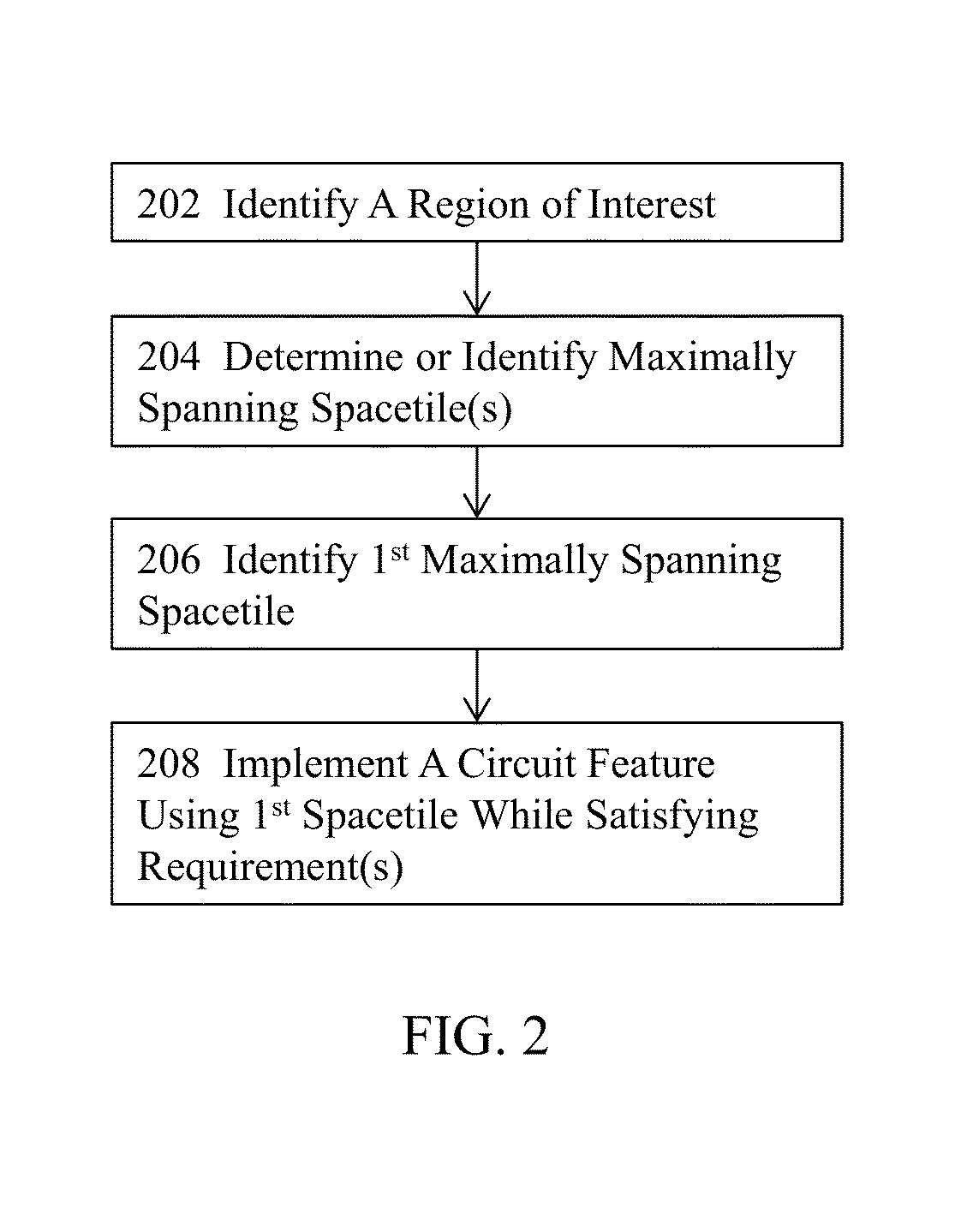

Methods, systems, and articles of manufacture for generating multi-layer local maximal orthogonal routing paths in fractured space

ActiveUS8910107B1Computer programmed simultaneously with data introductionComputer aided designEngineeringBlock modeling

Owner:CADENCE DESIGN SYST INC

Double-layer data model-driven plant-level chemical process monitoring method

InactiveCN102880151BImprove monitoring effectImprove good performanceTotal factory controlProgramme total factory controlStatistical analysisMonitoring methods

The invention discloses a double-layer data model-driven plant-level chemical process monitoring method. Relationships between sub-modules are modeled by constructing a double-layer data statistical analysis model on the basis of blocking modeling, so that a plant-level process is globally monitored. Compared with the conventional other plant-level process monitoring methods, the method has the advantages that each unit of the process can be monitored in each sub-module, relationship information between the sub-modules of the plant-level process can be effectively combined, and the whole plant-level process is globally monitored by utilizing a second-layer data model, so that the monitoring performance of the plant-level chemical process is greatly improved, and the industrial automation of the plant-level process can be favorably expanded and implemented.

Owner:ZHEJIANG UNIV

Design method of hollow mold or smooth inner cavity of hollow sand core

ActiveCN111085667BReduce crackingAvoid crackingAdditive manufacturing apparatusFoundry mouldsClassical mechanicsStructural engineering

The invention provides a method for designing a smooth inner cavity of a hollow casting mold or a hollow sand core, which includes modeling a standard block, and the surface of the constructed standard block is smooth, and then outputting an STL format file; outputting in a modeling software The STL format file of the mold or sand core; read the STL format file of the standard block, and scale the size of the corresponding direction of the standard block; read the STL format file of the mold or sand core; convert the scaled standard Blocks are arrayed; in each cross-section perpendicular to the X, Y or Z axis, judge the relationship between the contour of the standard block and the contour of the mold or sand core; judge the shape of the mold or sand core The distance between the outline and the outline of each standard block; reverse the normals of all the triangular faces of the finally retained standard block, and add the reversed standard block to the STL format file of the sand mold or sand core , to generate an STL file of a hollowed-out mold or sand core with a smooth cavity.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com