Positioning and fixing method for temperature measuring thermocouple inside sand casting mold

A temperature-measuring thermocouple and fixing method technology, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of thermocouple positioning failure, clay sand blocks are easy to break, etc., and achieve the controllable temperature measuring point position, The effects of small heat transfer effects and simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

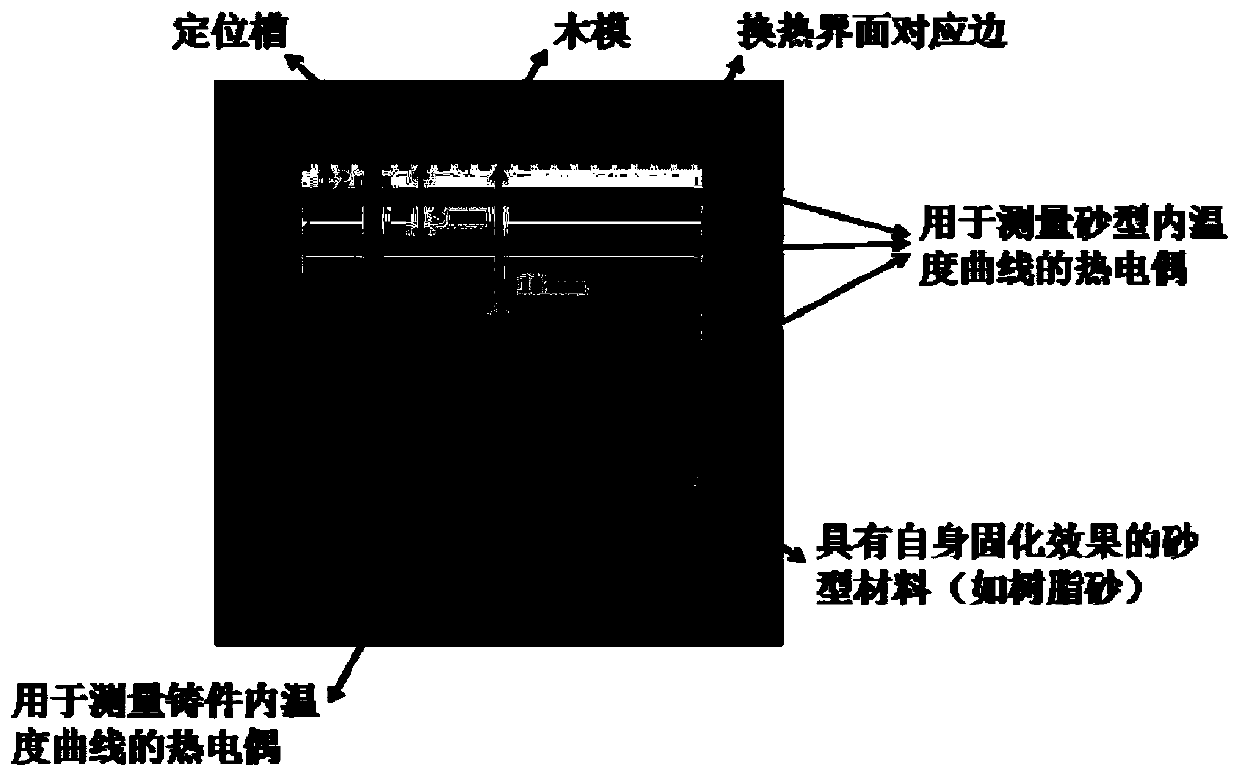

[0051] Such as figure 1 As shown, the specific operation steps of the positioning and fixing method of the sand material with its own solidification and forming characteristics:

[0052] 1. Prepare resin sand materials, casting molds and sand block wooden molds. The casting molds have the same shape and size as the castings. The shape is plate-shaped, and the length, width and height are 100mm, 100mm, and 30mm respectively.

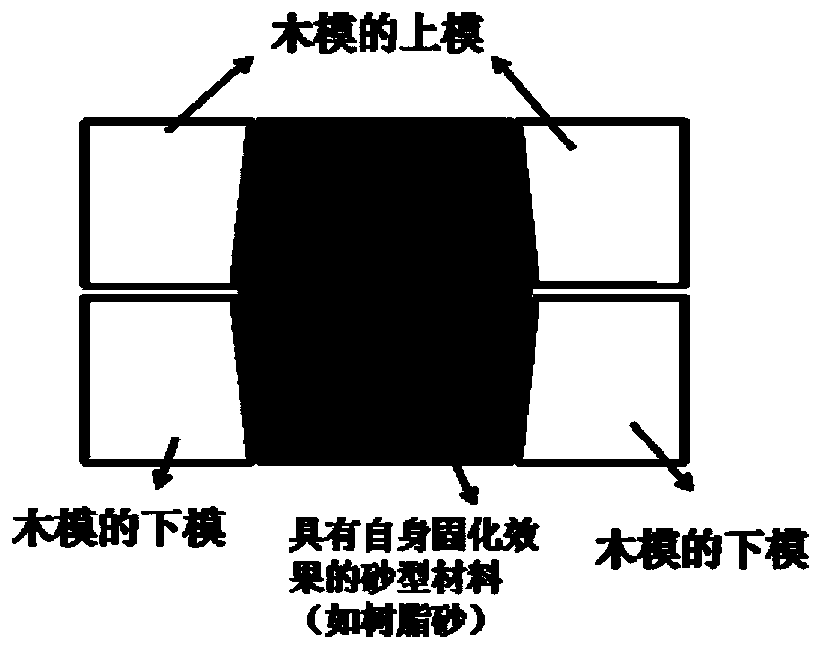

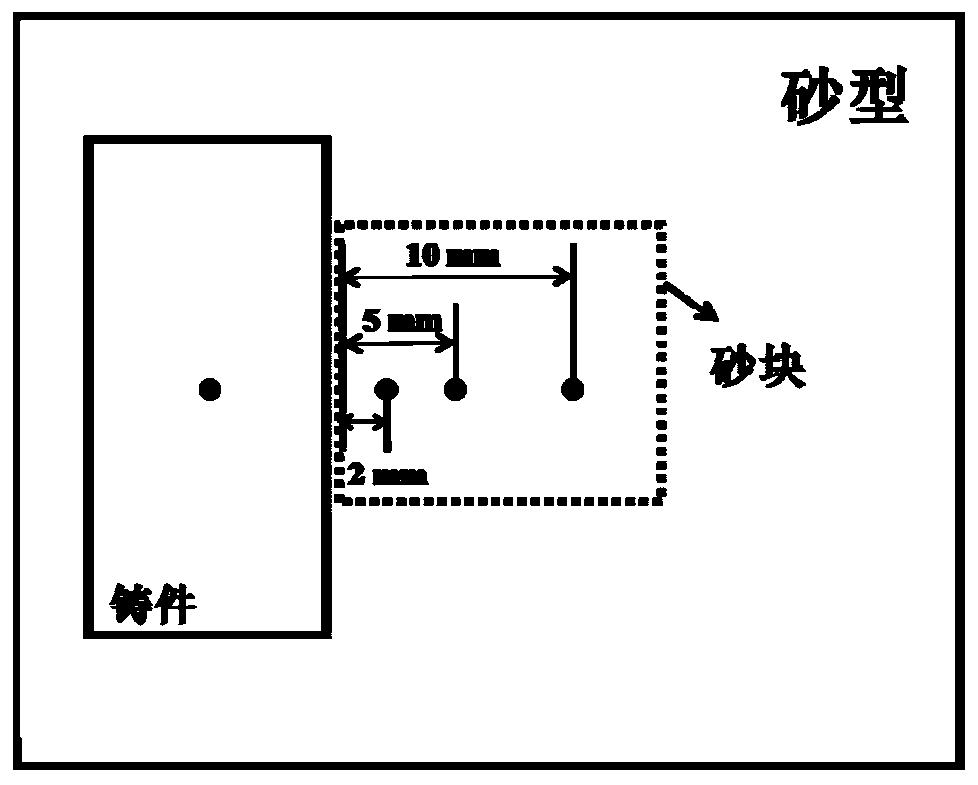

[0053] 2. Place the lower mold of the sand block wooden mold on the horizontal table, pass the three thermocouples that need to be arranged in the sand mold and one thermocouple (both with a diameter of 1mm) arranged in the casting through the penetrating hole with a depth of 1.5mm The positioning straight groove is fixed in the lower mold of the wooden mold, and the length of the positioning blind groove used to fix the temperature measurement point of the thermocouple placed in the sand mold is 1mm, such as image 3 As shown, the distances from the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com