Design method of hollow mold or smooth inner cavity of hollow sand core

A design method and sand core technology, applied in casting molding equipment, cores, molds, etc., can solve the problems of lack of hollow mold or hollow sand core design method, lack of design method, etc., to reduce 3D printing time, The effect of reducing deformation and reducing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method for designing the smooth inner cavity of the hollow casting mold or the hollow sand core according to the present invention will be described in detail below with reference to the accompanying drawings.

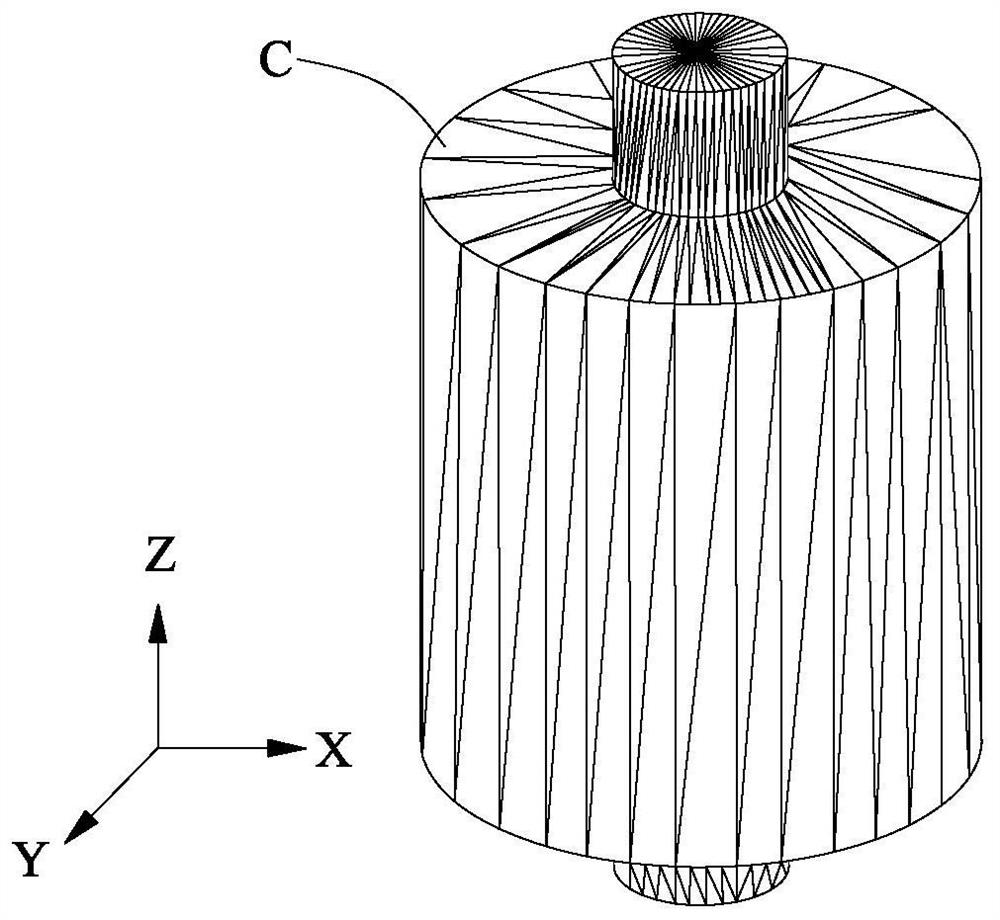

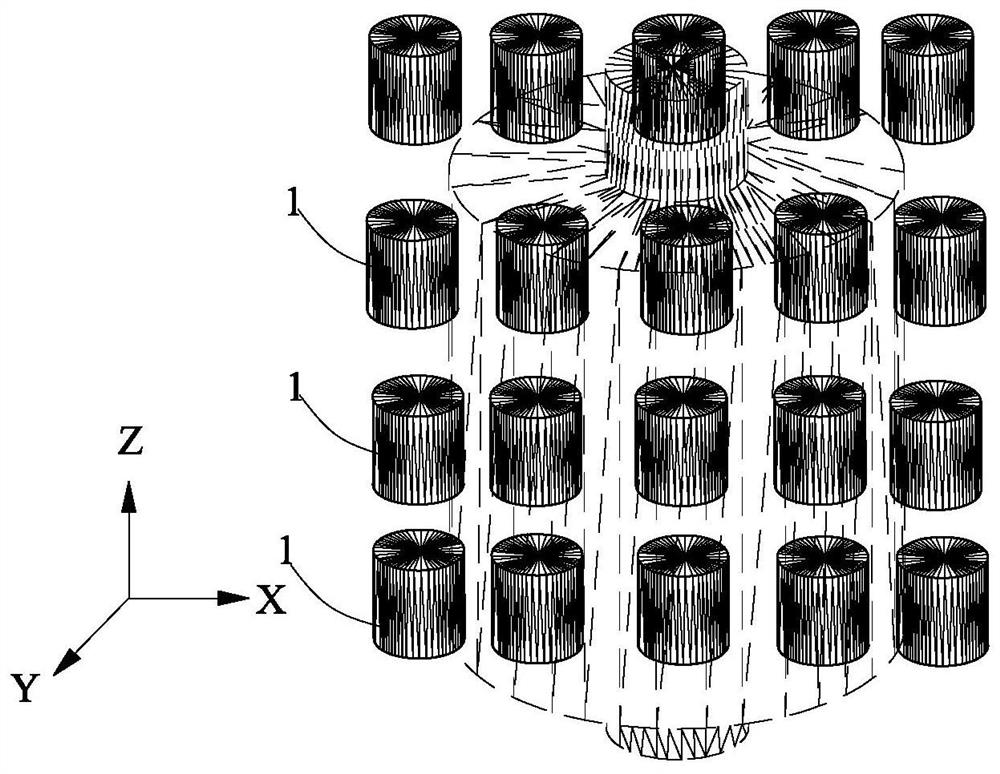

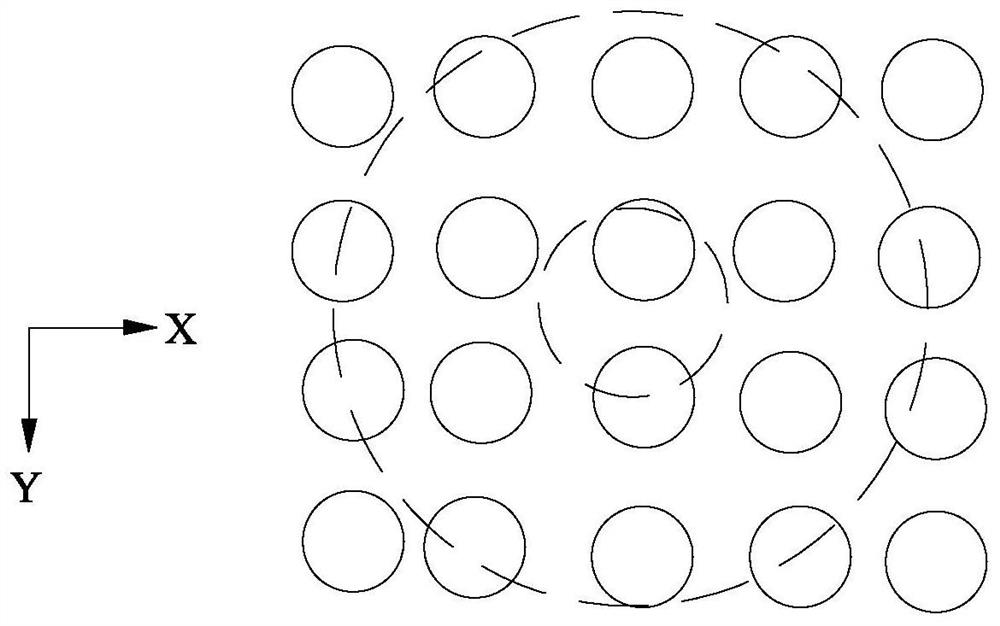

[0020] The method for designing the smooth inner cavity of the hollow casting mold or the hollow sand core according to the present invention comprises: adopting modeling software to model the standard block 1, and the surface of the standard block 1 constructed is smooth (no edges and corners), and then output the standard block 1 STL format file. For existing mold or sand core C, export the STL format file of described mold or sand core C in modeling software (referring to figure 1 ). Read the STL format file of the standard block 1, take the coordinate system of the existing mold or sand core C as the reference coordinate system, and scale the standard block according to the X, Y, and Z directions of the existing mold or sand core C 1 corresponds to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com