Double-layer data model-driven plant-level chemical process monitoring method

A chemical process and data model technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as affecting the performance of factory-level process monitoring, ignoring the relationship between sub-modules, etc. The effect of improving monitoring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

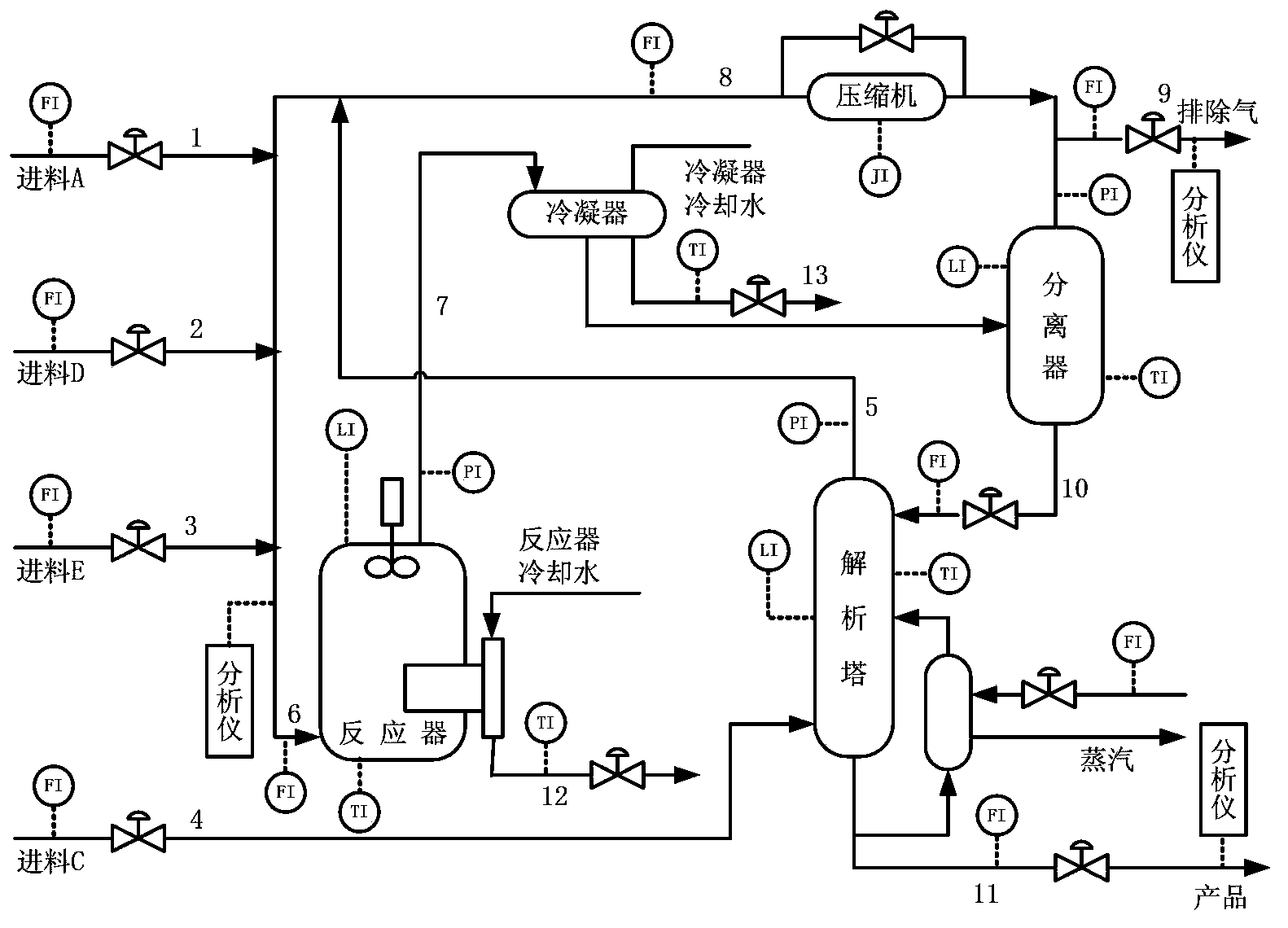

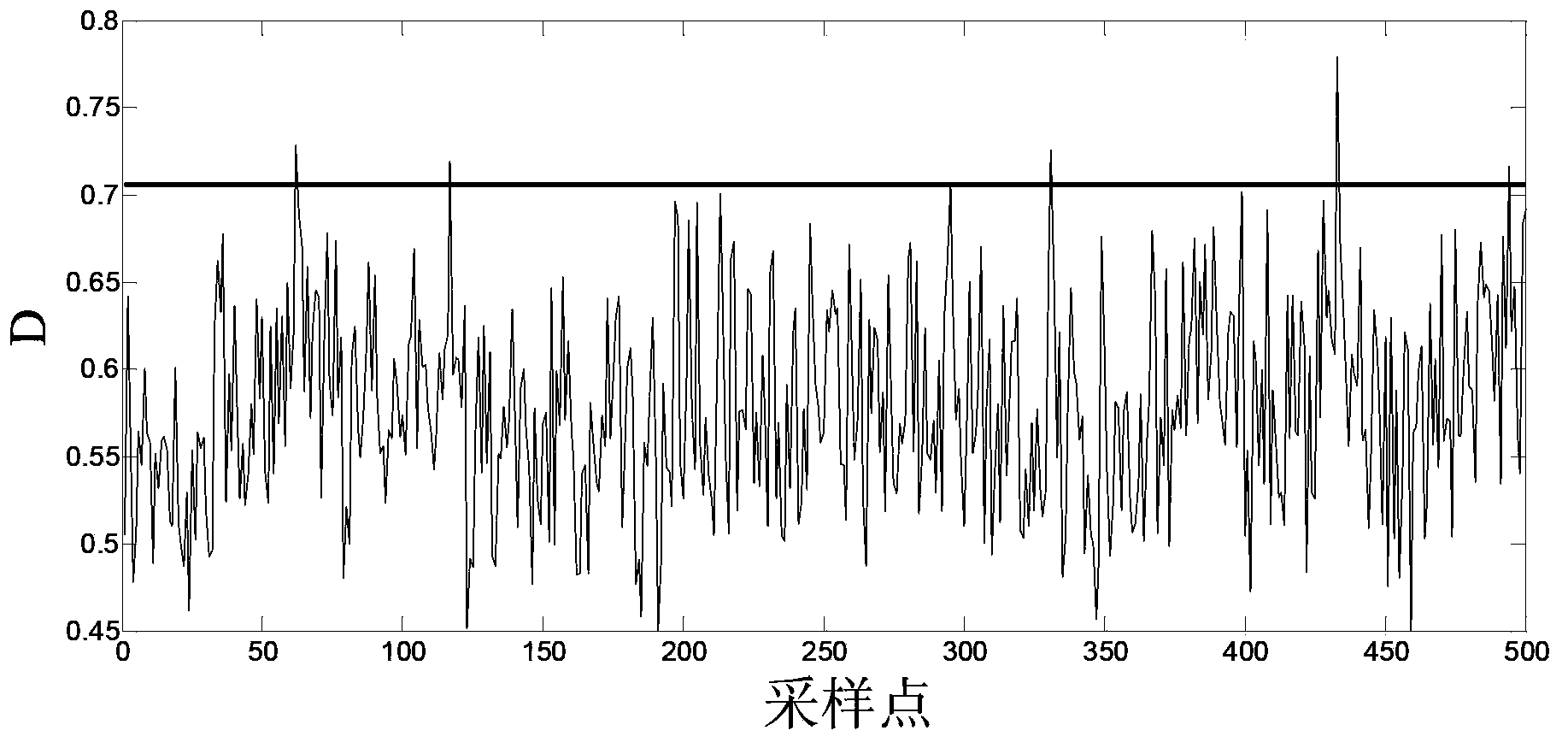

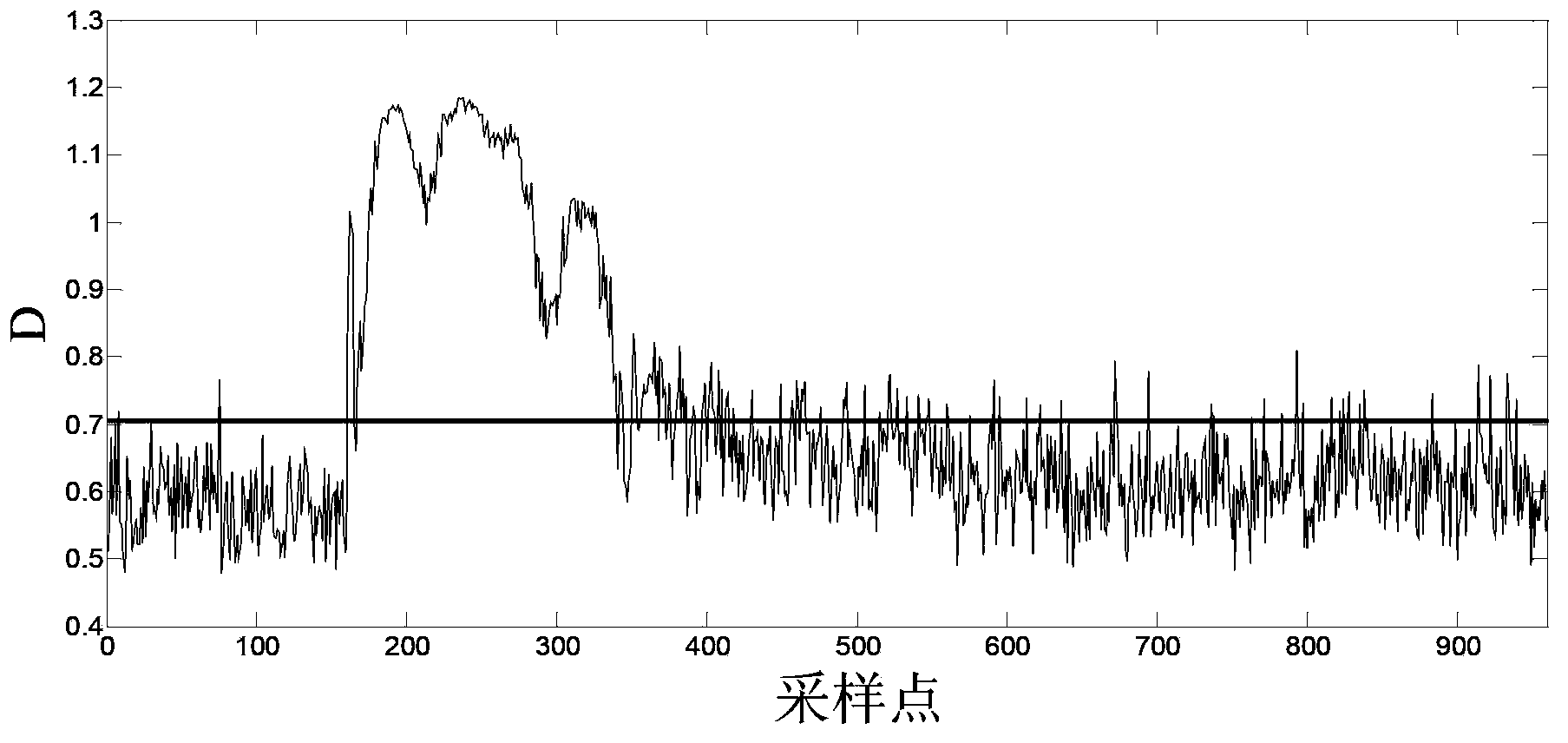

[0018] Aiming at the monitoring problem of factory-level chemical process, the present invention first collects the data of the process by using the distributed control system, performs necessary preprocessing and normalization on it, and then divides the whole process data set into different sub-modules. For the data set corresponding to each sub-module, a principal component analysis model is established respectively, and the control limits of the monitoring statistics are established. After obtaining the principal component information corresponding to each sub-module data set, recombine it into a new data set, and then use a single-class support vector machine to model it. When monitoring new process data, the data is also divided into different sub-modules, and the mean value and standard deviation of the modeling data of each sub-module are used to normalize them. After obtaining the standard data, each sub-module is used The principal component analysis model of the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com