Double-layer data model-driven plant-level chemical process monitoring method

A chemical process and data model technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems affecting the performance of factory-level process monitoring and ignoring the relationship between sub-modules, so as to facilitate expansion and implementation, Effect of Improving Monitoring Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

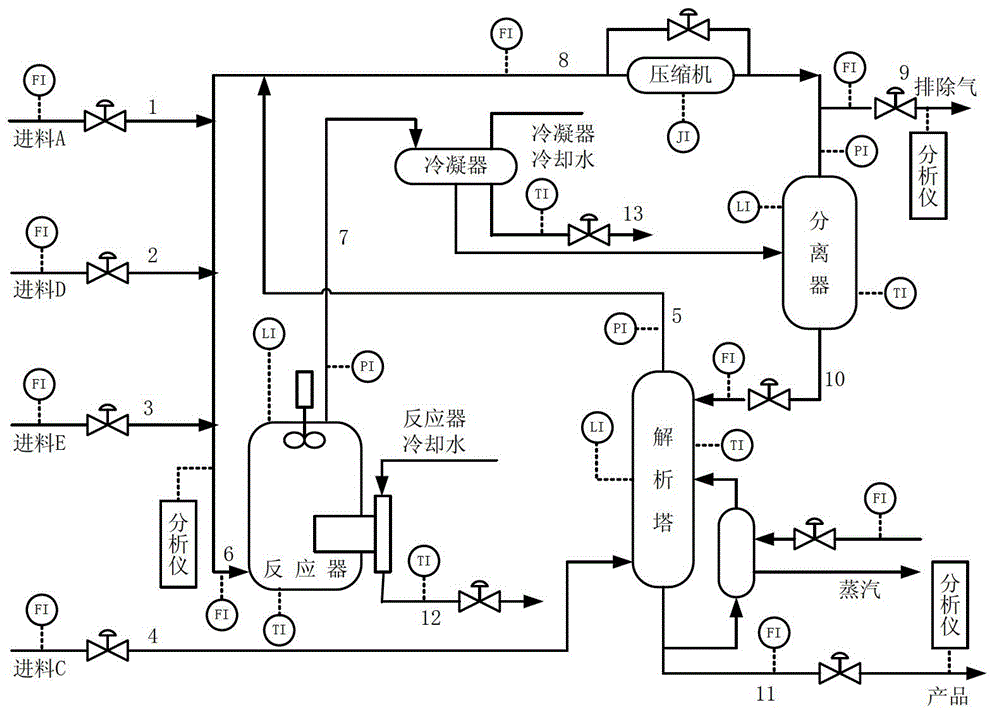

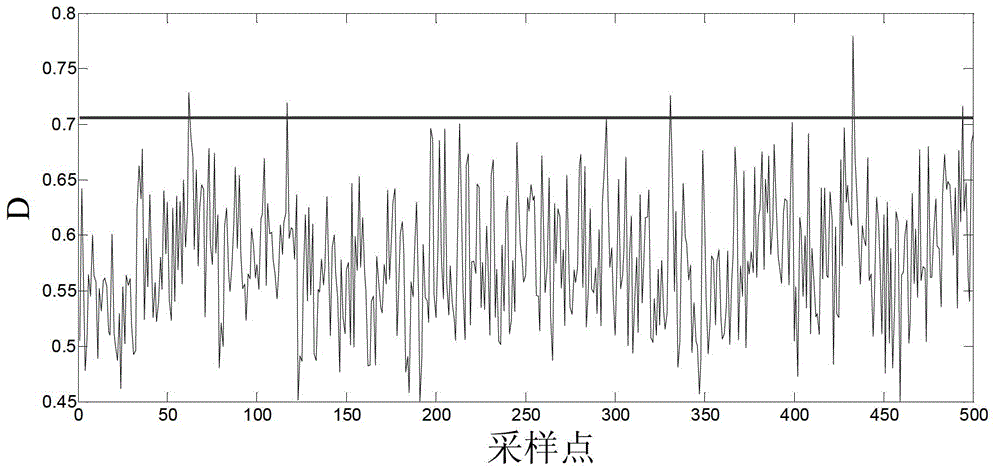

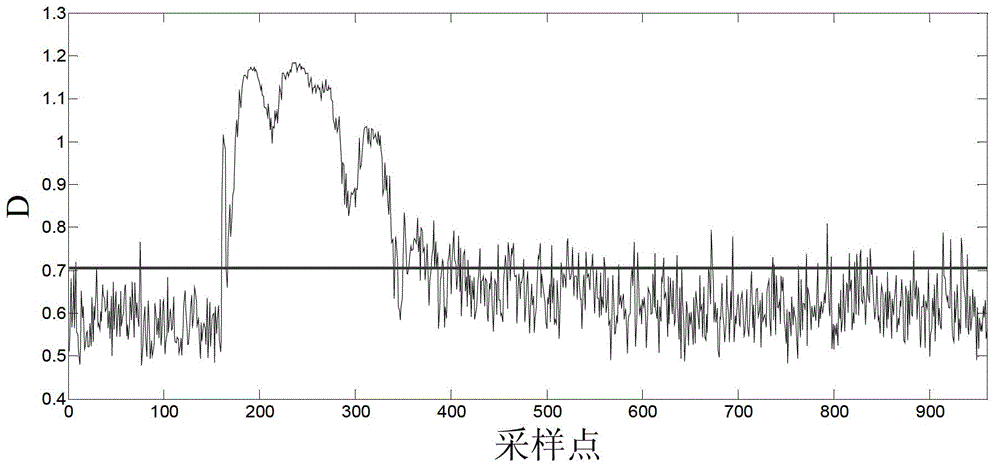

[0018] Aiming at the monitoring problem of the plant-level chemical process, the present invention first collects the process data by using a distributed control system, performs necessary preprocessing and normalization, and then divides the entire process data set into different sub-modules. For the data set corresponding to each sub-module, establish a principal component analysis model and establish the control limits of monitoring statistics. After obtaining the principal element information corresponding to each sub-module data set, it is recombined into a new data set, and then a single-class support vector machine is used to model it. When monitoring new process data, the data is also divided into different sub-modules, and the mean and standard deviation of the modeling data of each sub-module are used to normalize it. After obtaining the standard data, use each The principal component analysis model of the sub-module calculates the principal component information of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com