Window Progressive Laser Cleaning Method

A laser cleaning and progressive technology, applied in the field of laser cleaning, can solve the problems of inability to adapt to the cleaning environment, inconvenient automatic control, etc., to avoid damage to the substrate, save control costs, and achieve the effect of good cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

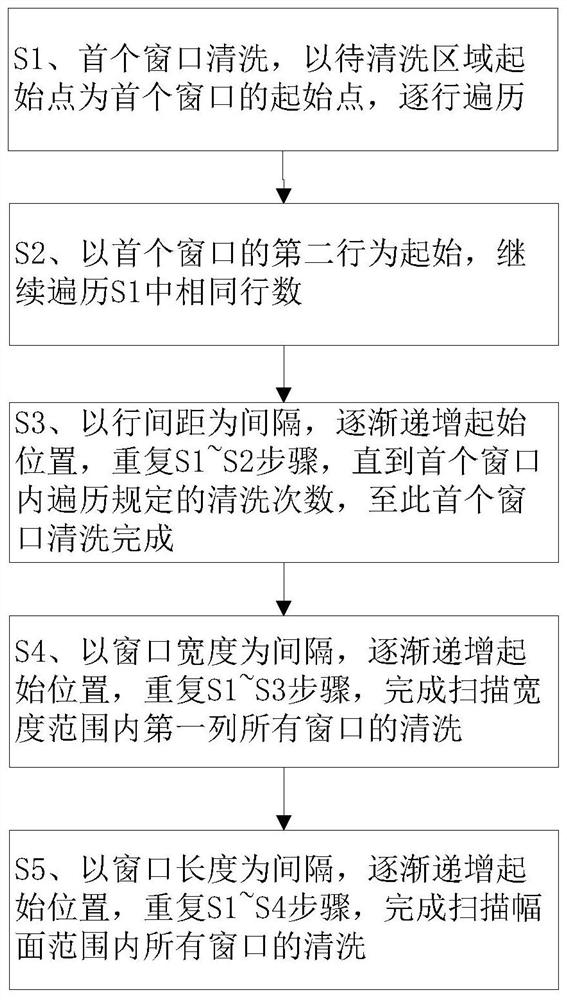

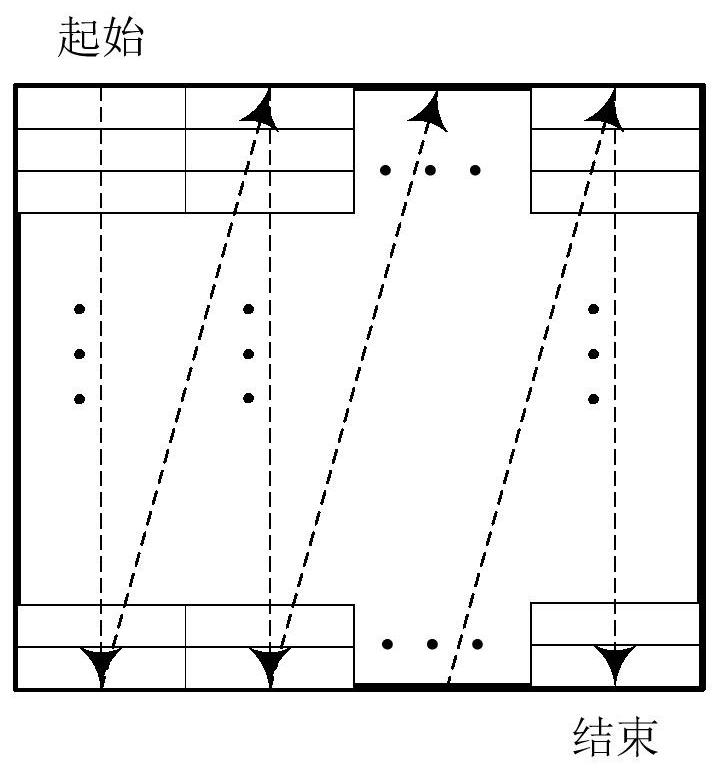

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings and embodiments. However, this should not limit the protection scope of the present invention.

[0032] The laser cleaning device in this embodiment is a laser marking machine, using a 1064nm fiber laser, the power is set to 50W, the cleaning speed is 4000mm / s, and the cleaning object is the rust on the surface of the steel plate. The specific steps are as follows:

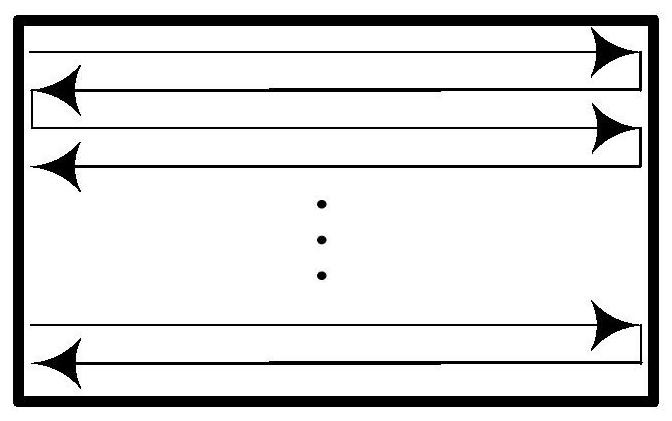

[0033] 1) The first window cleaning: in the present invention, the line spacing is 20um, and the window length and width are 20mm and 2mm respectively, then the number of lines=window width / line spacing, which is 100 lines. Complete the cleaning of lines 1 to 100, done in a bow shape, such as figure 2 shown. In this embodiment, the line spacing of 20um is preferred, which can ensure that the contamination layer is completely cleaned and there is no residue. The size of the line spacing can be selected accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com