A special industrial dust removal equipment

A technology of dust removal equipment and industry, applied in the field of purification equipment and dust removal equipment, can solve problems such as affecting battery life, increasing additional energy consumption, affecting production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

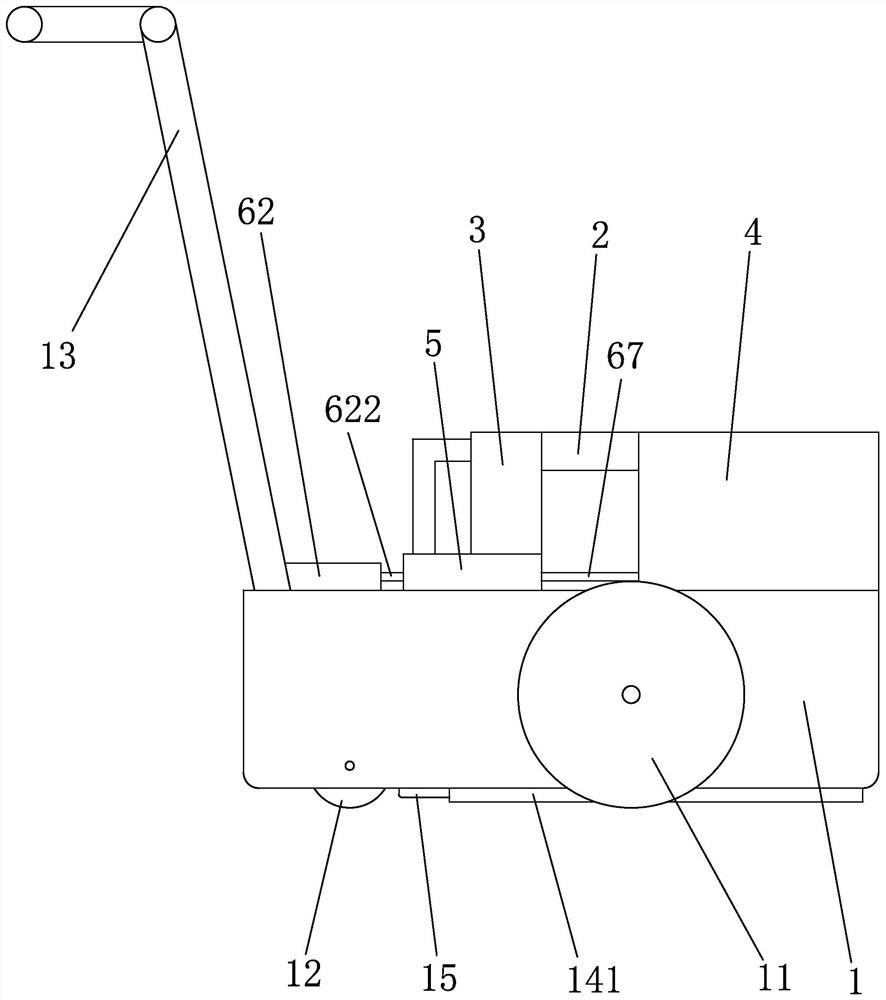

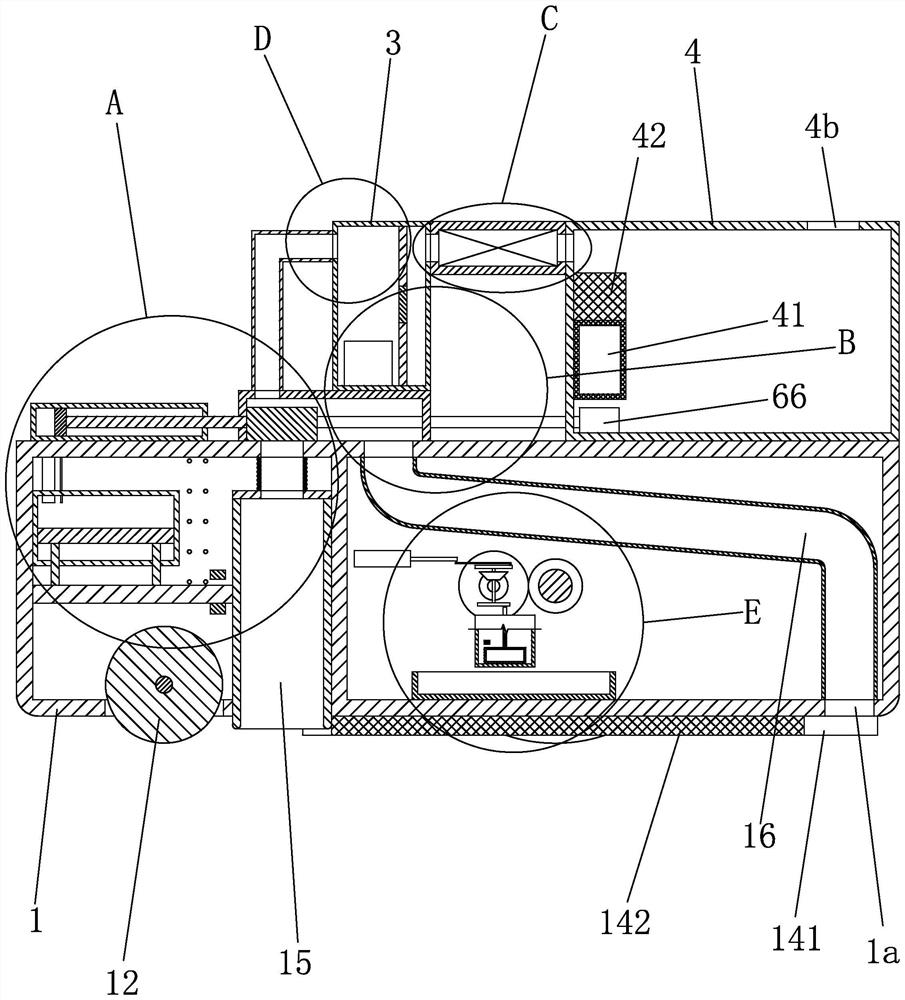

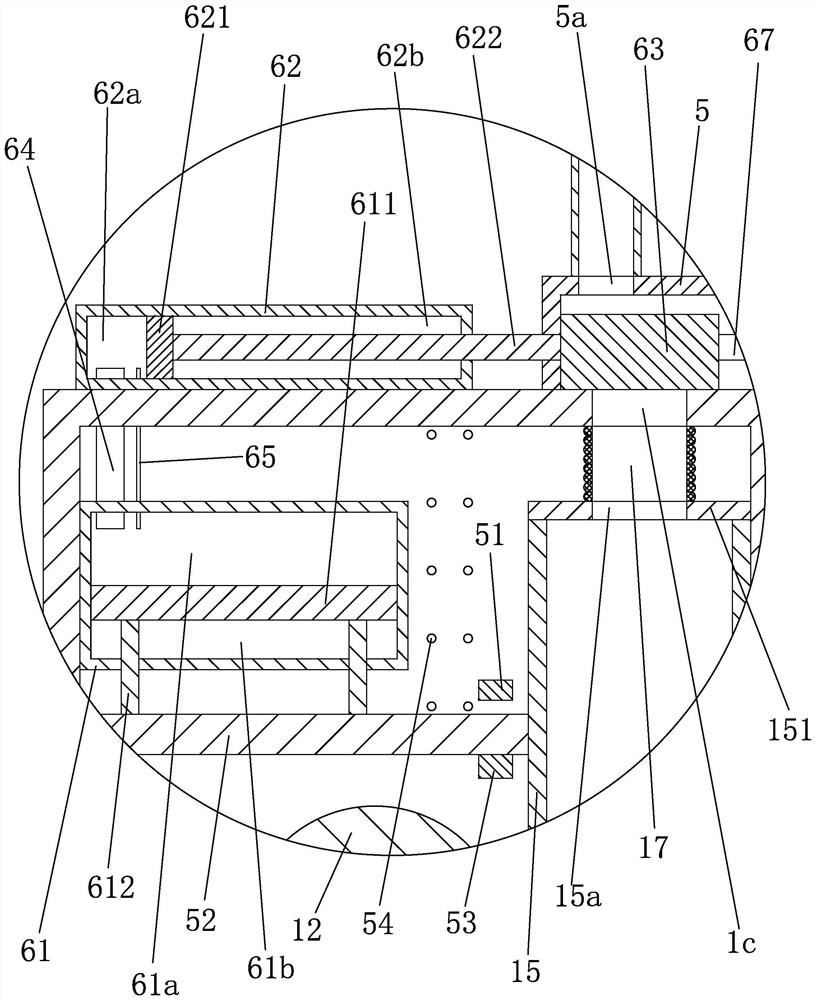

[0032] Such as Figure 1 to Figure 11 as shown,

[0033] An industrial special dust removal equipment, including a main casing 1, two coaxial and symmetrically arranged front wheels 11, a rear wheel 12, a push frame 13, a motor casing 2, a dust collection box 3, a humidification box 4, and a The dust collection motor 21 in the casing, the storage battery for powering the dust collection motor, two symmetrically arranged lower guide plates 141 and a middle guide plate 142 between the two lower guide plates;

[0034] The lower guide plate is arranged vertically, the middle guide plate is vertically arranged, the two front wheels are symmetrically arranged along the middle guide plate, the two lower guide plates are symmetrically arranged along the middle guide plate, the length direction of the main casing is horizontal and parallel to the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com