Turbine hydrodynamic cavitation generator

A hydraulic cavitation and generator technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage treatment equipment, etc., can solve problems such as unsatisfactory cavitation efficiency, reduced cavitation efficiency, and increased energy consumption. Achieve the effects of strengthening the performance of organic sewage treatment, increasing the cavitation degradation area, and increasing the number of cavitation cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

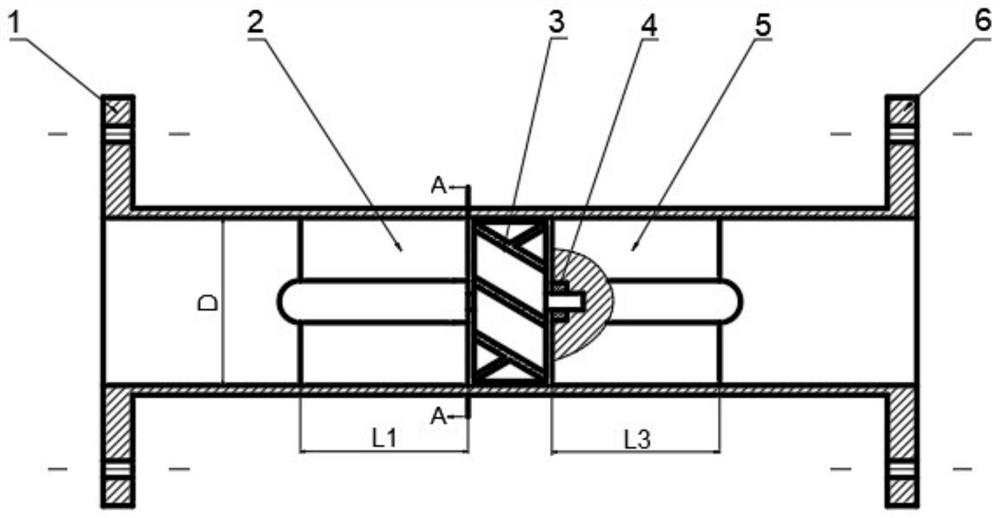

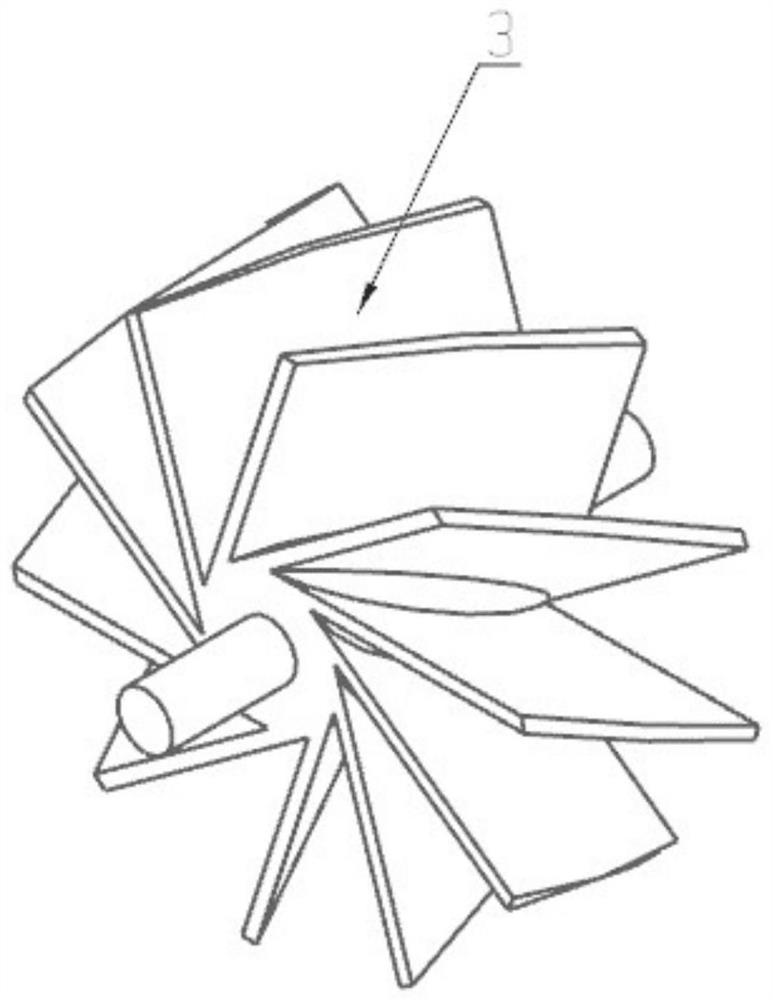

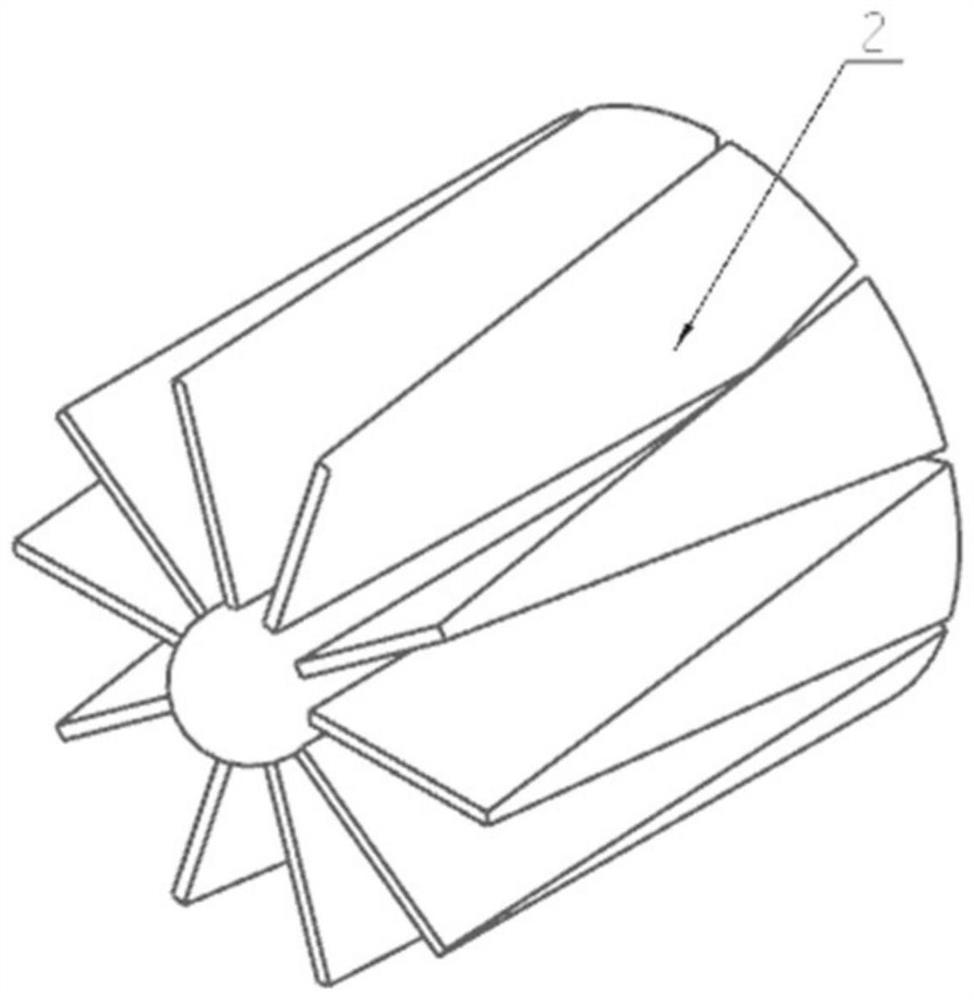

[0027] Such as figure 1 and Figure 4 As shown, the turbine hydrodynamic cavitation generator according to the present invention includes several stages of cavitation units connected in series, and the cavitation units of each stage are connected by flanges, and the cavitation units of each stage include a shell, a left The static blade cascade 2, the right static blade cascade 5 and the turbine rotor 3; the left static blade cascade 2 and the right static blade cascade 5 are symmetrical structures, the left static blade cascade 2 is installed near the shell inlet flange 1, and the right static blade cascade 5 Installed near the casing outlet flange 6, a rotatable turbine rotor 3 is installed between the symmetrically installed left static blade cascade 2 and the right s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com