Concrete mixer

A technology of concrete mixer and mixing bucket, which is applied in the field of concrete, can solve problems such as concrete differences, and achieve the effect of increasing the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] as attached figure 1 to the attached Image 6 shown:

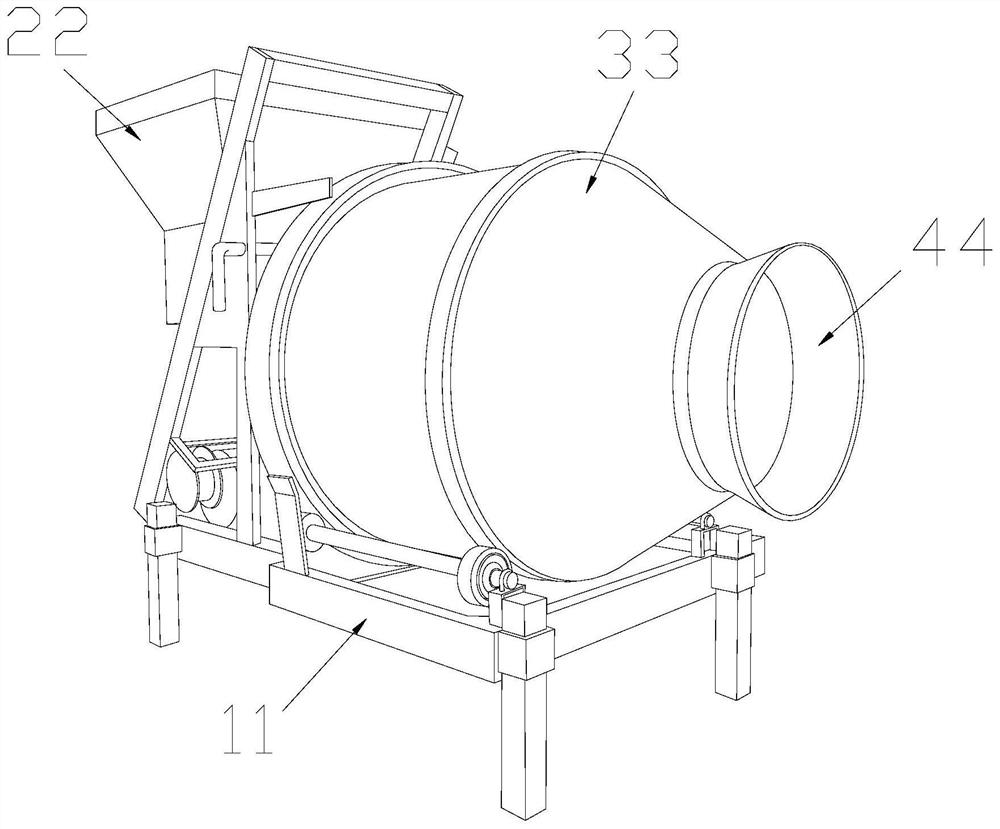

[0033] The present invention provides a concrete mixer, the structure of which includes a support frame 11, an introduction bucket 22, a mixing bucket 33, and an outlet 44, the mixing bucket 33 is welded to the upper surface of the support frame 11, and the outlet 44 and the mixing bucket 33 are In an integrated structure, one end of the mixing bucket 33 away from the lead-out port 44 is connected with the lead-in bucket 22 .

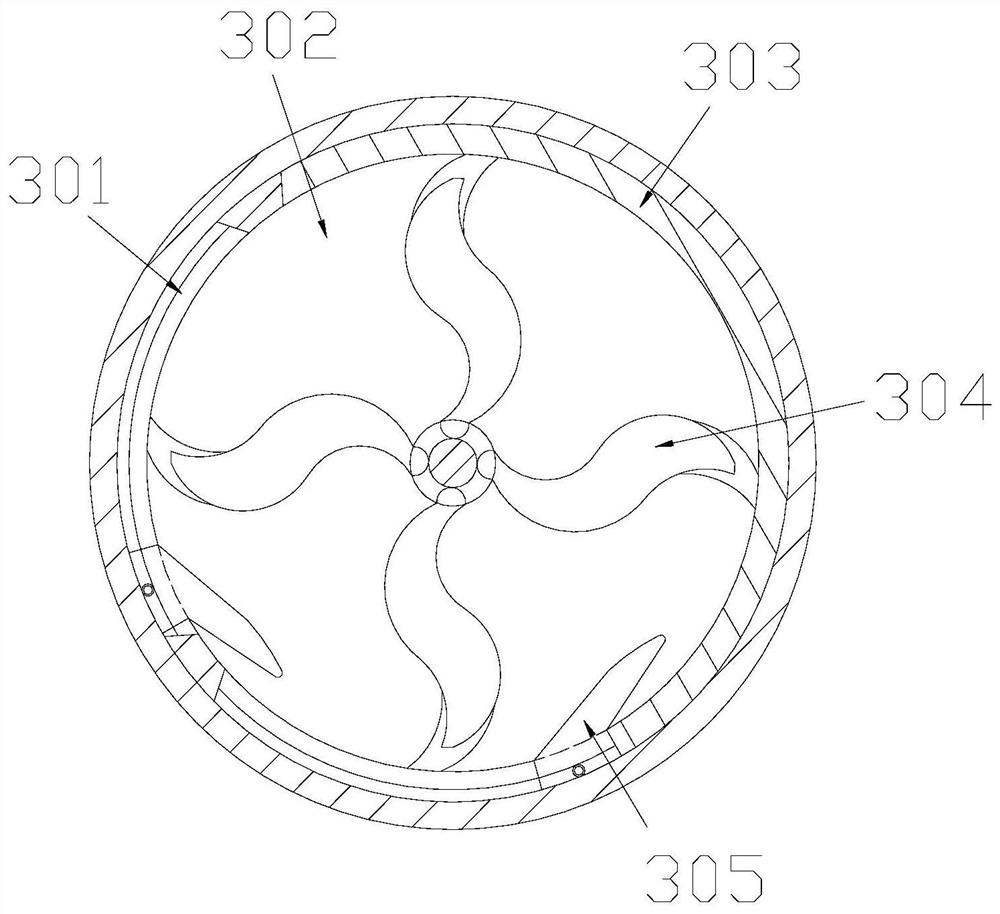

[0034] The mixing bucket 33 includes a ring channel 301, an inner grid 302, a limiting layer 303, a stirring rod 304, and a movable rocker 305. The movable rocker 305 is embedded in the ring channel 301 and is movably connected. The limiting layer 303 is welded, and the stirring rod 304 is installed inside the inner grid 302 .

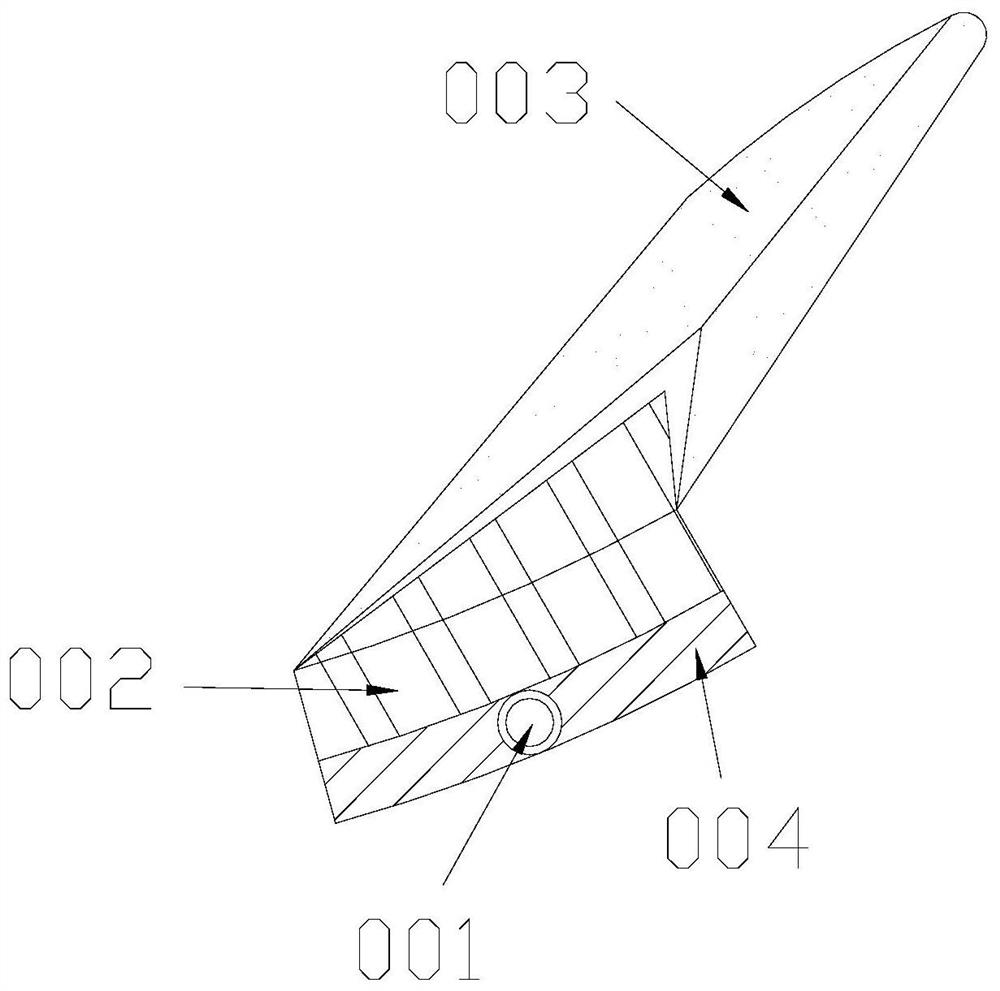

[0035] The movable rocker 305 includes a rolling ball 001, an extension core 002, an extension head 003, and a compliant block 004. The rolling ball 001 is embedde...

Embodiment 2

[0042] as attached Figure 7 to the attached Figure 9 shown:

[0043] The stirring rod 304 includes a front soft head e11, a main block e12, and a forward edge e13, the forward edge e13 and the main block e12 are an integrated structure, and the front soft head e11 is installed on the outer surface of the main block e12 , the main block e12 fixes the overall shape according to its own rigid force, the forward edge e13 extends to the inner range, and the front soft head e11 exerts a certain soft deformation on the object against which it collides.

[0044] The front soft head e11 includes a corner head w1, a soft strip w2, and a guide strip w3, the guide strip w3 is in contact with the soft strip w2, the corner head w1 is embedded in the soft strip w2, and the guide strip w3 is a curvilinear structure, the corner head w1 has a hard point on the outer layer, and the guide strip w3 bears the force from the outside to evenly separate them.

[0045] Wherein, the guide bar w3 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com