construction material transport vehicle

A technology of building materials and transport vehicles, which is applied in the field of construction, can solve problems such as dislocation and jamming, and achieve the effect of evenly dividing nodes to buffer back force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

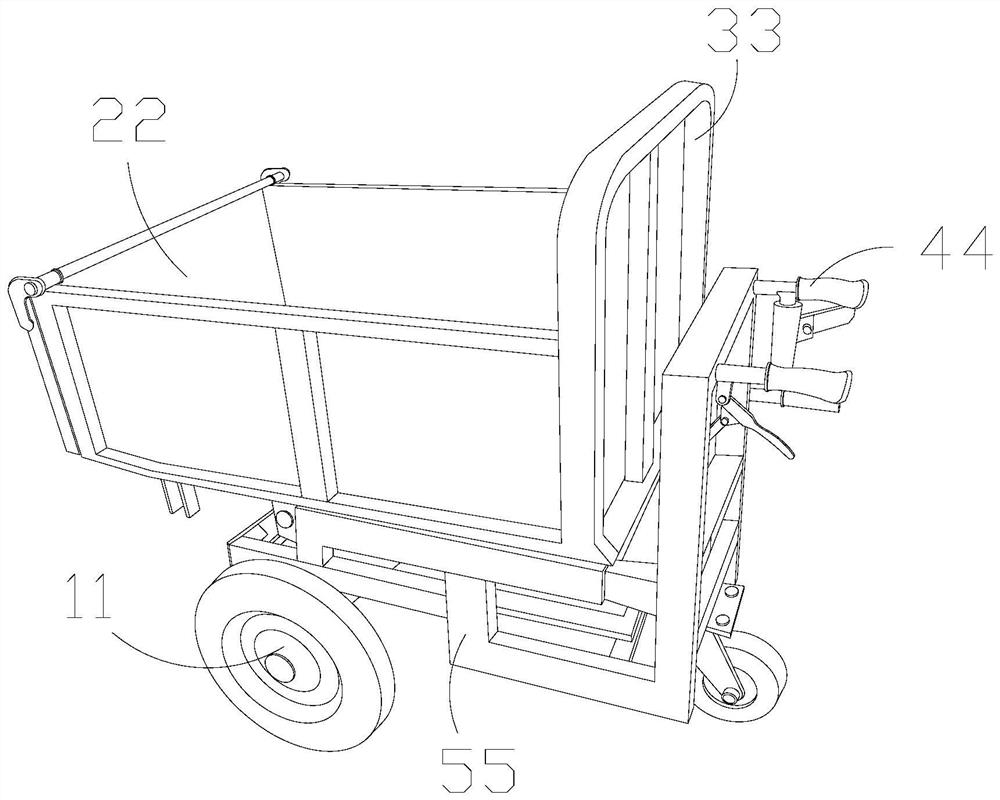

[0032] as attached figure 1 To attach Image 6 Shown:

[0033] The present invention provides a construction material transportation vehicle, the structure of which includes wheels 11, a storage grid 22, a fence 33, a grip frame 44, and a bottom bracket 55, the upper surface of the bottom bracket 55 is welded to the grip frame 44, and the The wheels 11 pass through the inside of the bottom bracket 55 , and the fence 33 is connected with the storage compartment 22 .

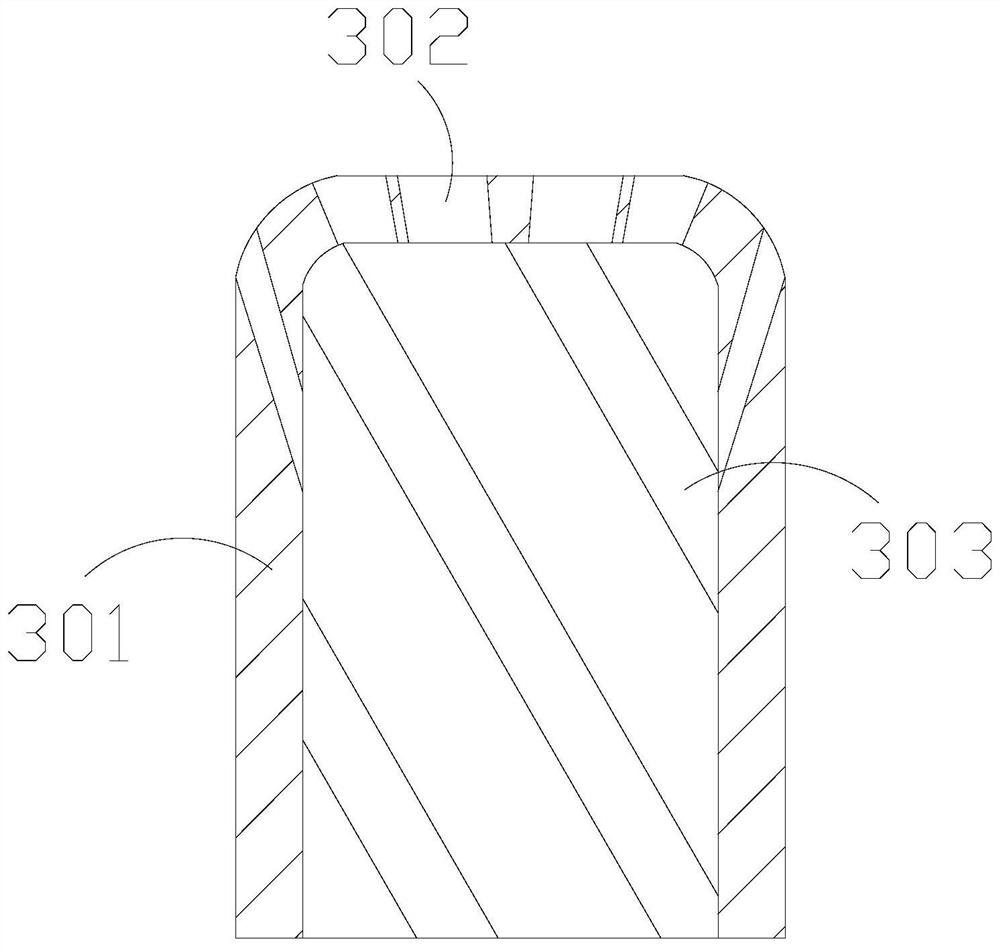

[0034] The fence 33 includes a main rod 301 , a pocket edge 302 , and a main board 303 , the main bar 301 and the main board 303 are an integrated structure, and the pocket edge 302 is connected with the main rod 301 .

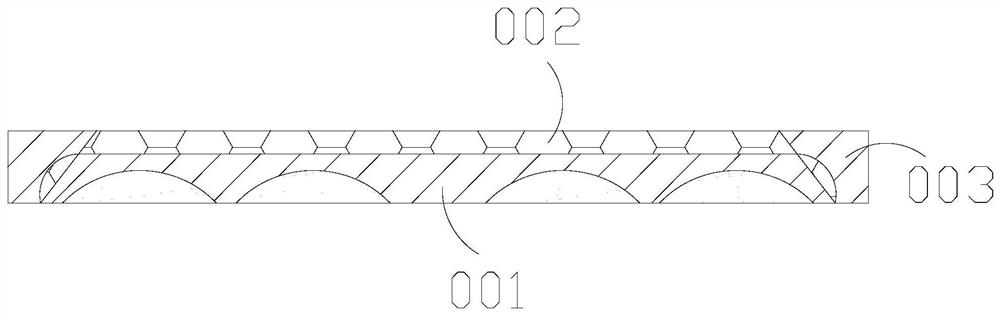

[0035] Wherein, the pocket edge 302 includes a pocket layer 001, a main wrapping layer 002, and a peripheral block 003. The pocket layer 001 is attached to the outer surface of the main wrapping layer 002, and the left and right ends of the main wrapping layer 002 are in contact with the perimet...

Embodiment 2

[0042] as attached Figure 7 To attach Figure 9 Shown:

[0043] Wherein, the telescoping joint e02 includes an extended surface layer x11, a hard core x12, a pressure arc x13, and a space opening x14. The hard core x12 is embedded inside the extended surface layer x11, and the outer surface of the extended surface layer x11 is pasted The arc x13, the space opening x14 and the extended surface layer x11 are an integrated structure, the hard core x12 is a quadrilateral structure, there are two pressing arcs x13, the hard core x12 guides the movable guide on the outside, the When the pressing arc x13 is squeezed on both sides, it acts as a reaction force, and the space opening x14 gives the outer layer a certain space for movement.

[0044]Wherein, the pressing arc x13 includes an adhesive layer w10 and an overlapping angle w11, the overlapping angle w11 is connected with the adhesive layer w10, the overlapping angle w11 is made of rubber material and has a certain pulling eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com