Passenger conveyor

A technology for passenger conveyors and mechanical rooms, which is applied in transportation and packaging, escalators, etc., and can solve problems such as maintenance personnel's wrong inspection and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

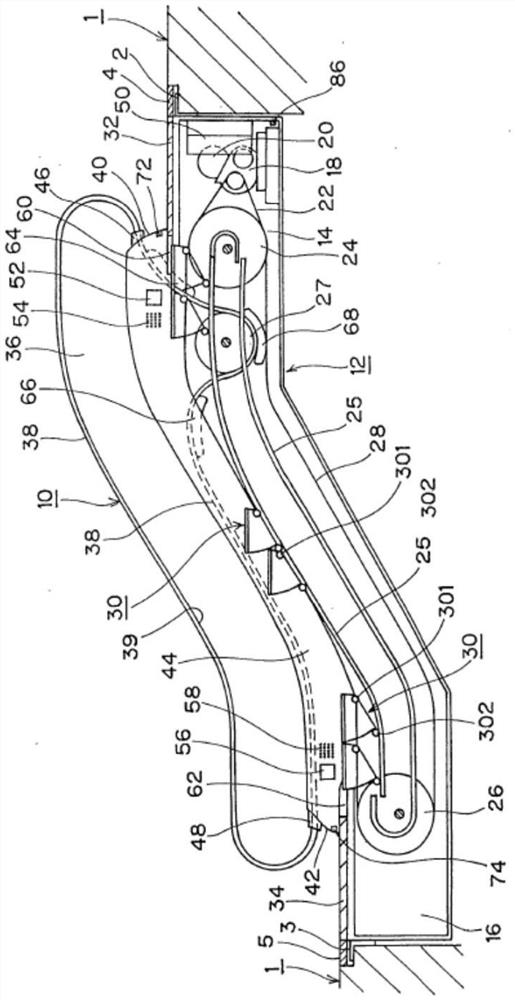

[0017] Below, refer to Figure 1 to Figure 9 The escalator 10 which concerns on one Embodiment of this invention is demonstrated.

[0018] (1) Escalator 10

[0019] refer to figure 1 The structure of the escalator 10 is demonstrated. like figure 1 As shown, a truss 12 which is a frame of the escalator 10 is supported by support angle irons 2 and 3 across the upper and lower floors of the building 1 . The support angle irons 2 and 3 placed on the building 1 are covered with mortars 4 and 5 , and the ground is finished so as to be flush with the ground of the building 1 .

[0020] like figure 1 As shown, in the machine room 14 on the upper side of the upper end of the truss 12, a driving device 18 for advancing the steps 30, a pair of left and right drive sprockets 24, 24, and a pair of left and right pulleys 27, 27 are provided. The drive unit 18 has a motor 20 , a speed reducer, an output sprocket attached to an output shaft of the speed reducer, a drive chain 22 driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com