Emergency ventilation system for nuclear facility master control room

A technology of ventilation system and main control room, applied in ventilation system, auxiliary equipment of nuclear power plant, space heating and ventilation, etc., can solve problems such as power loss of power station, threat to power station safety, inability to activate ventilation system, etc., to improve safety factor and The effect of reliability, improving safety and stability, and improving gas safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

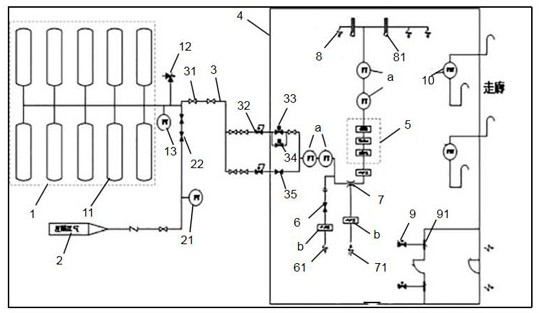

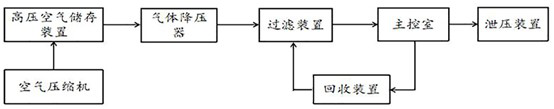

[0039]Example 1, such asfigure 1 As shown, it includes a high-pressure air storage device 1 and a delivery pipe 3. The high-pressure air storage device 1 is used to store high-pressure compressed gas. One end of the delivery pipe 3 is connected to the high-pressure air storage device 1 located outside the main control room 4, and the other end is connected to The air outlet 8 in the main control room 4 is connected, and the conveying pipeline 3 includes a passive valve 33 located in the main control room 4. The emergency ventilation system also includes a pressure relief device for releasing the pressure of the main control room 4. The high-pressure air storage device 1 is connected to the pressure-reducing module. The pressure-reducing module includes a pressure-reducing pipeline and a spare pressure-reducing pipeline connected in parallel with the pressure-reducing pipeline. The gas reduced by the pressure-reducing module passes through the air outlet 8 or the spare air outlet 61 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com