Patents

Literature

49results about How to "Good recoil effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porous non layer boundary gradient metal film pipe and its preparation method

A porous gradient metallic membrane pipe without layer interface is prepared through preparing slurry from basic metallic material, adhesive and carrier, filing it in metallic pipe mould, centrifugal shaping, removing carrier, baking, demoulding and sintering.

Owner:SOUTH CHINA UNIV OF TECH

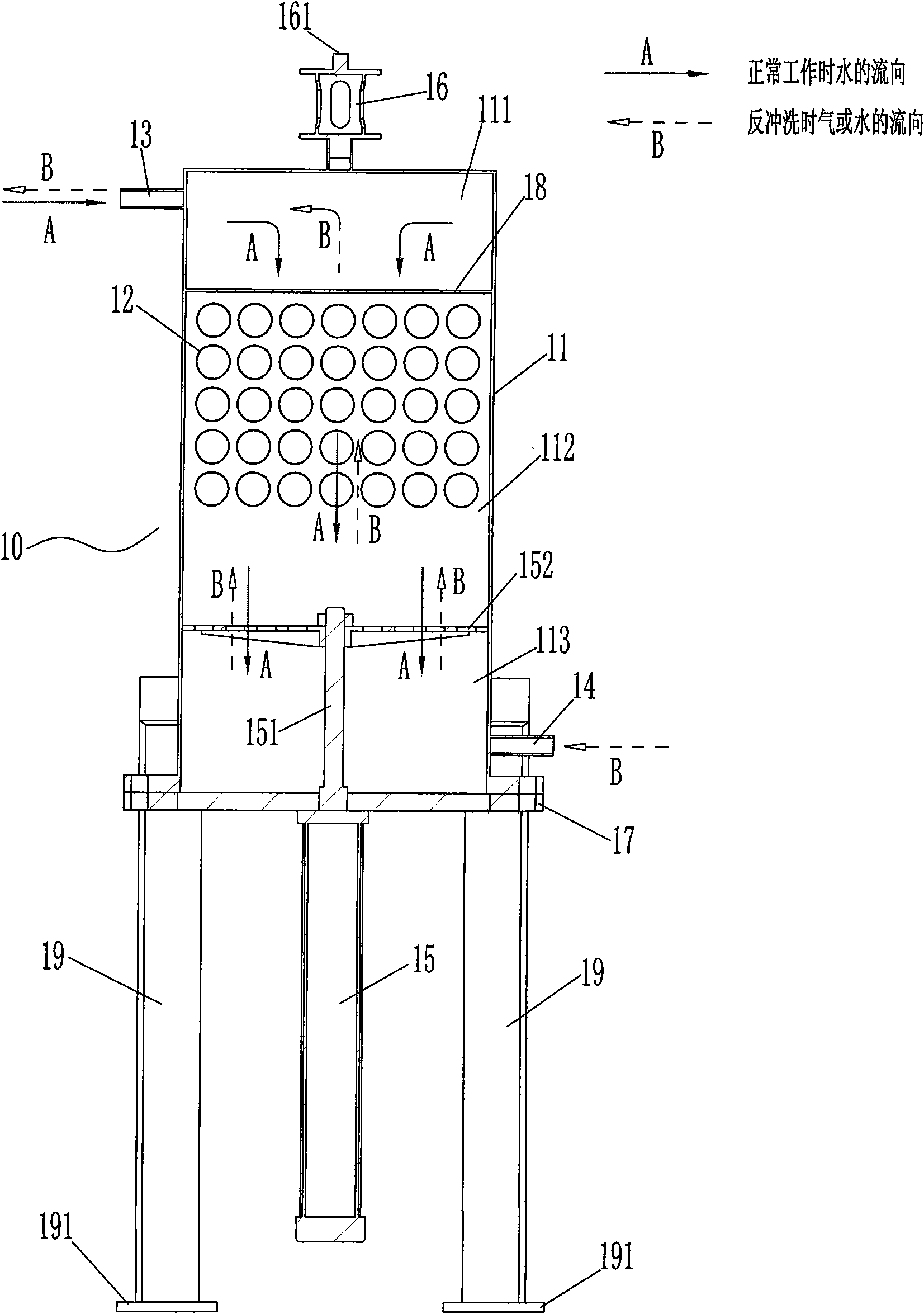

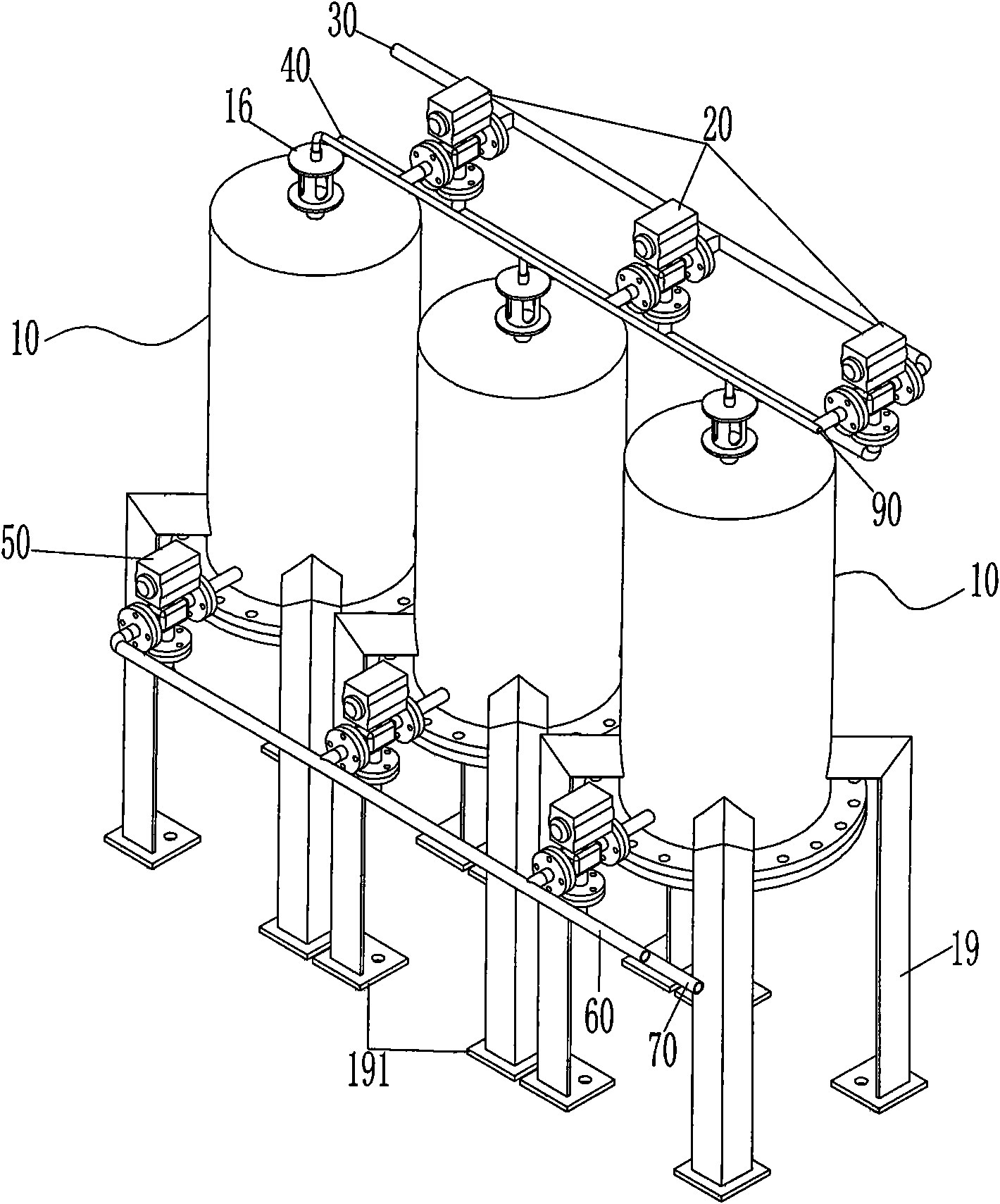

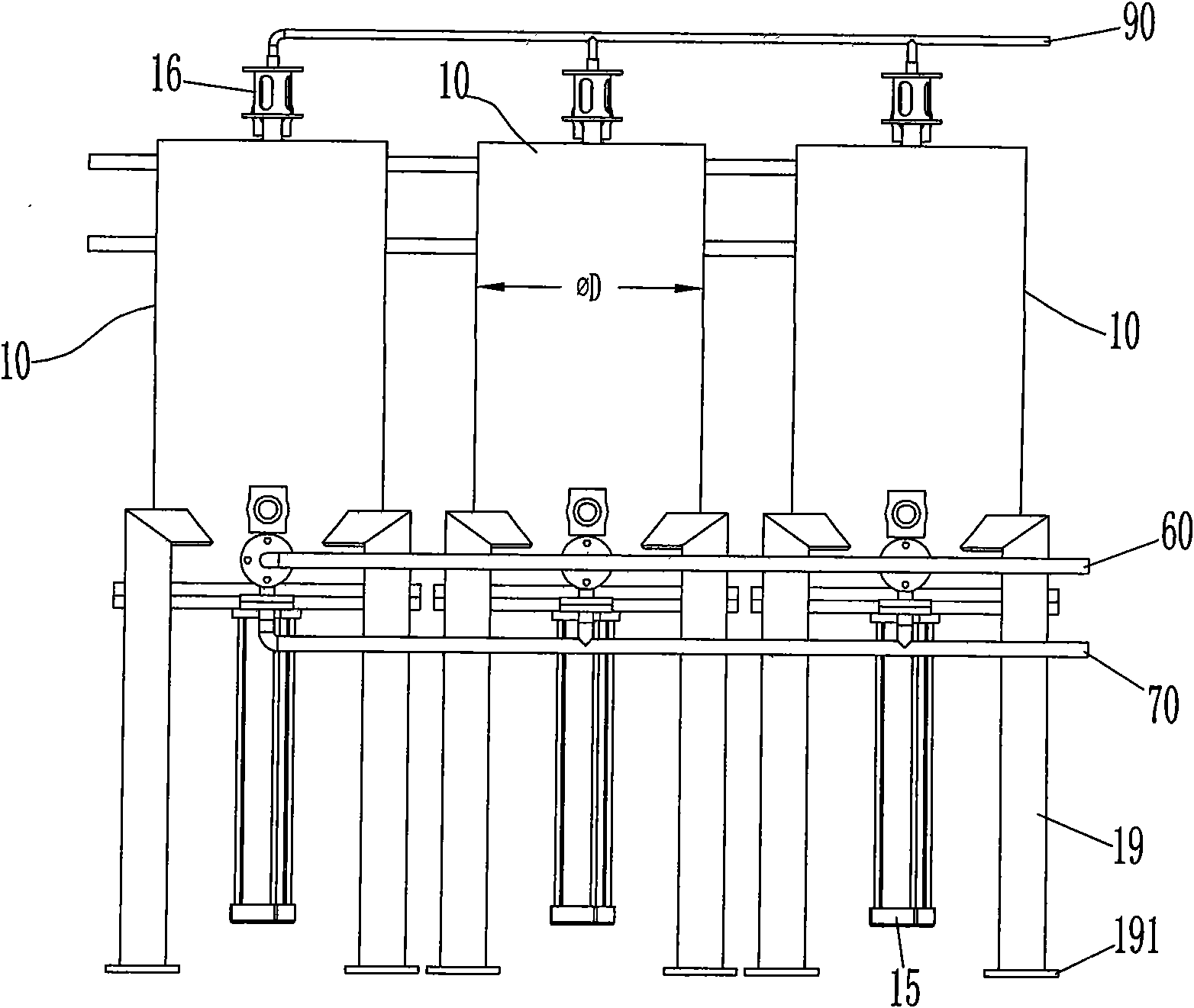

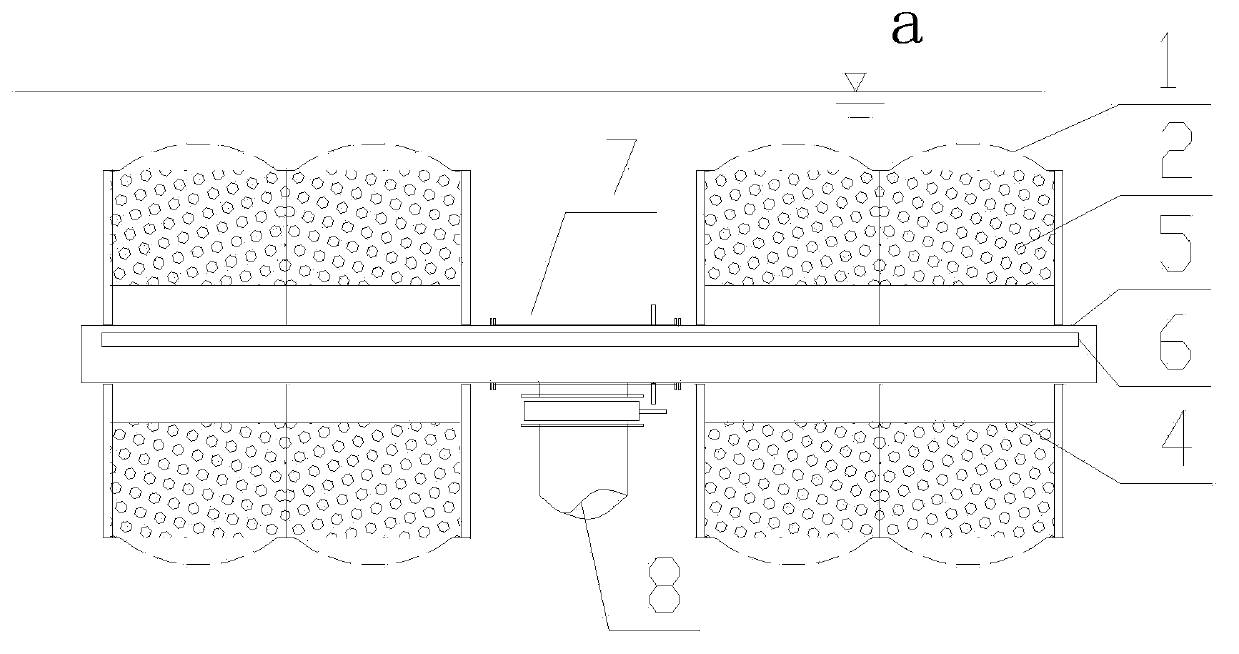

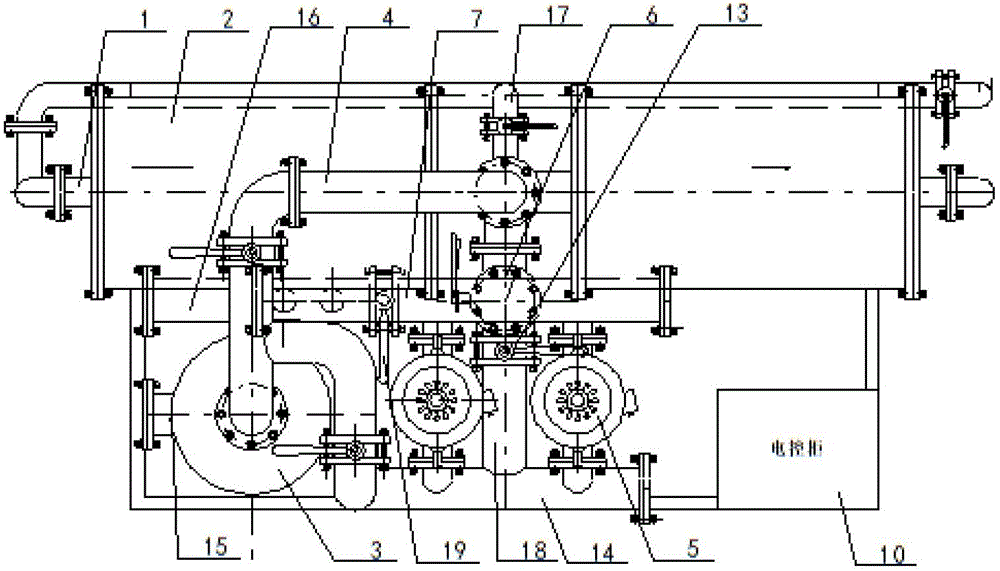

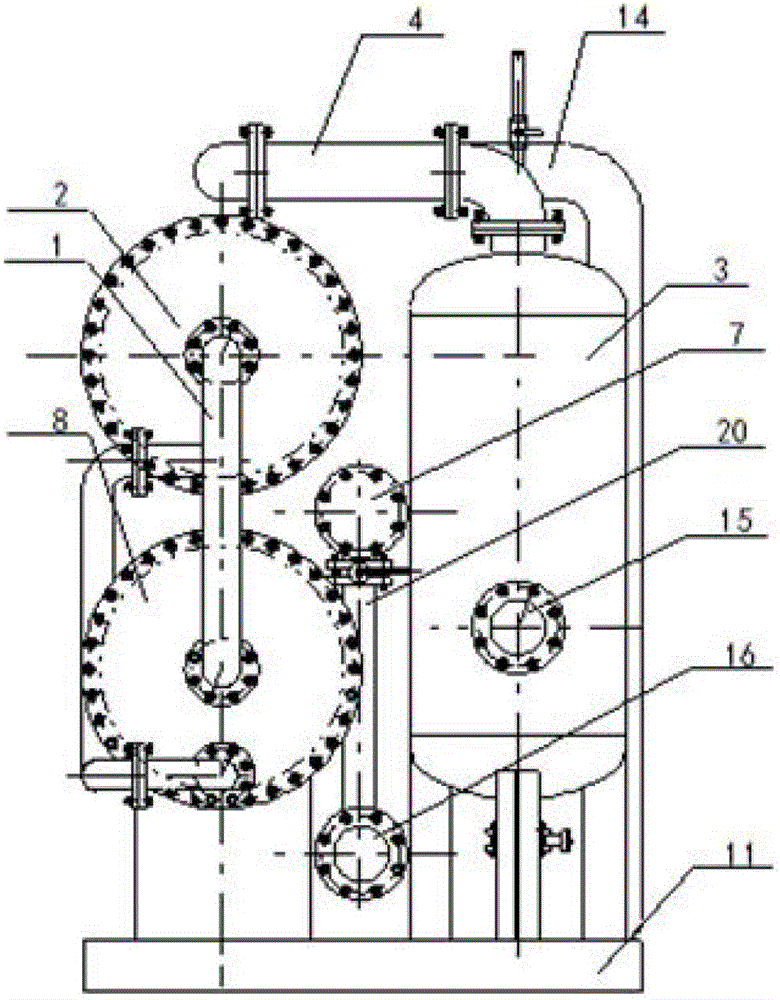

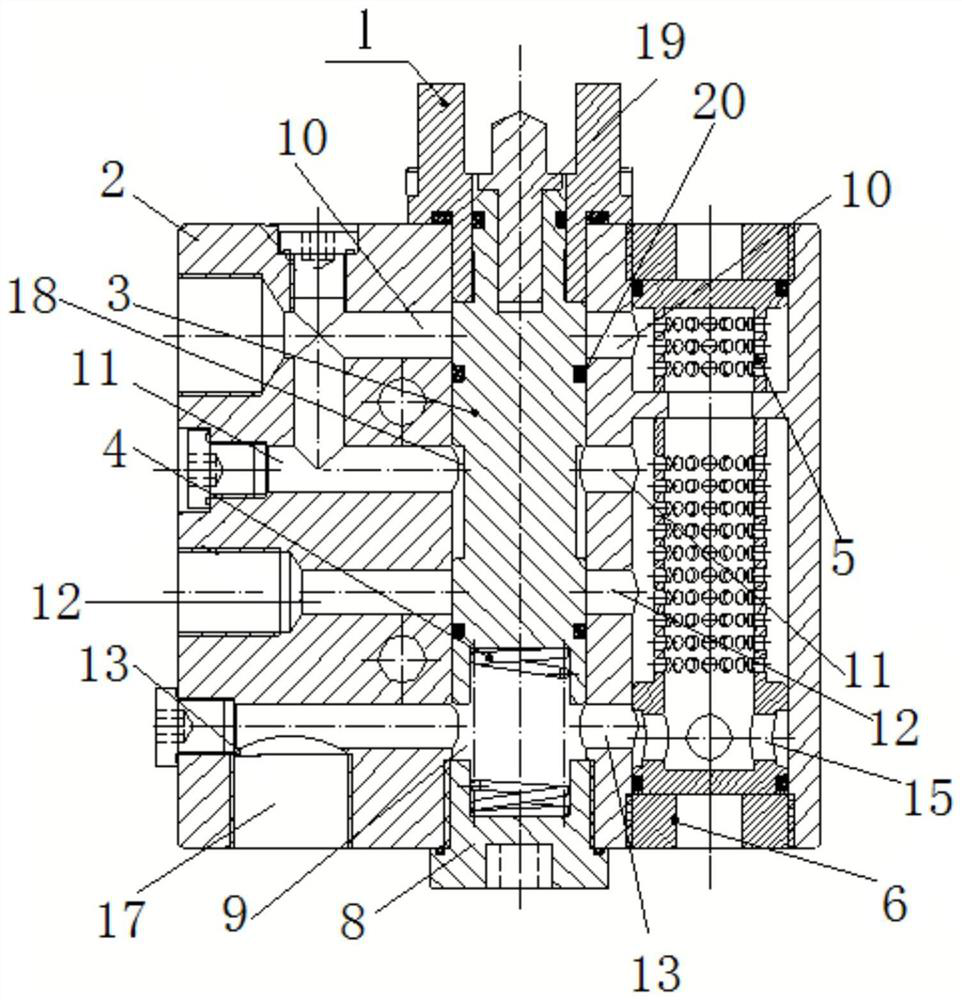

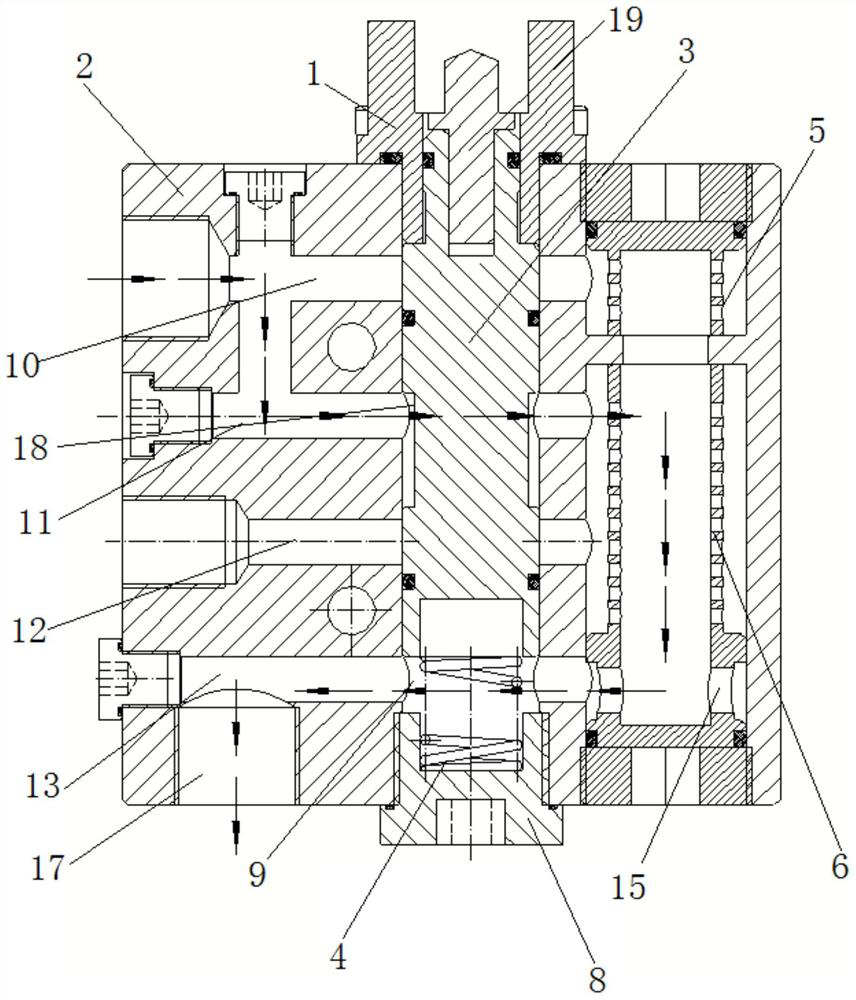

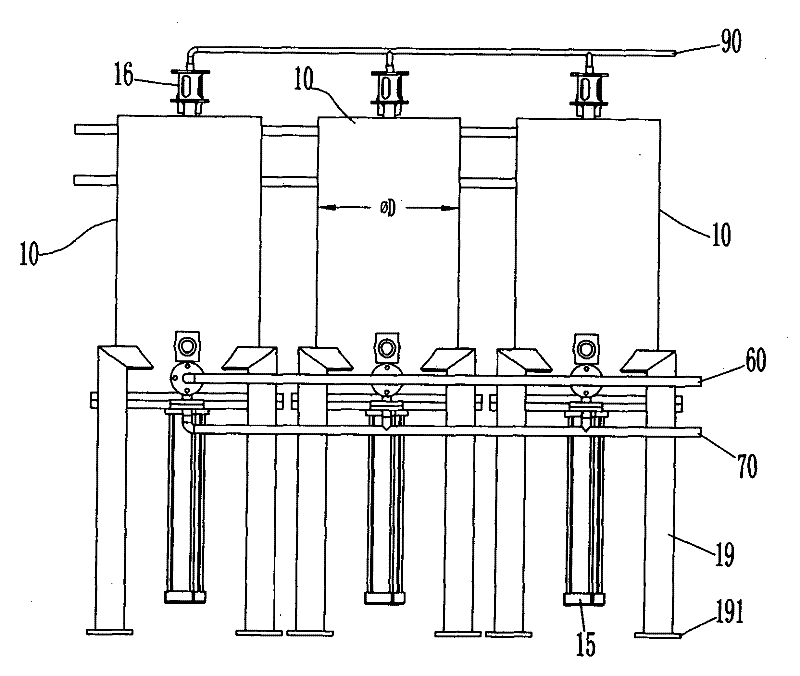

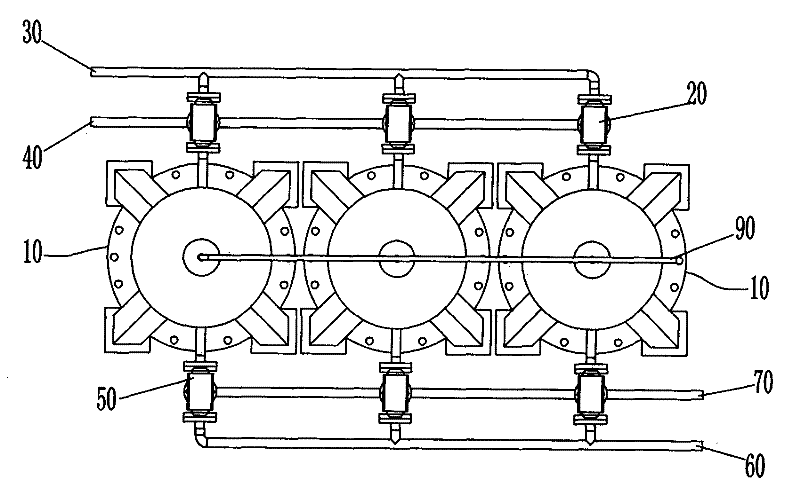

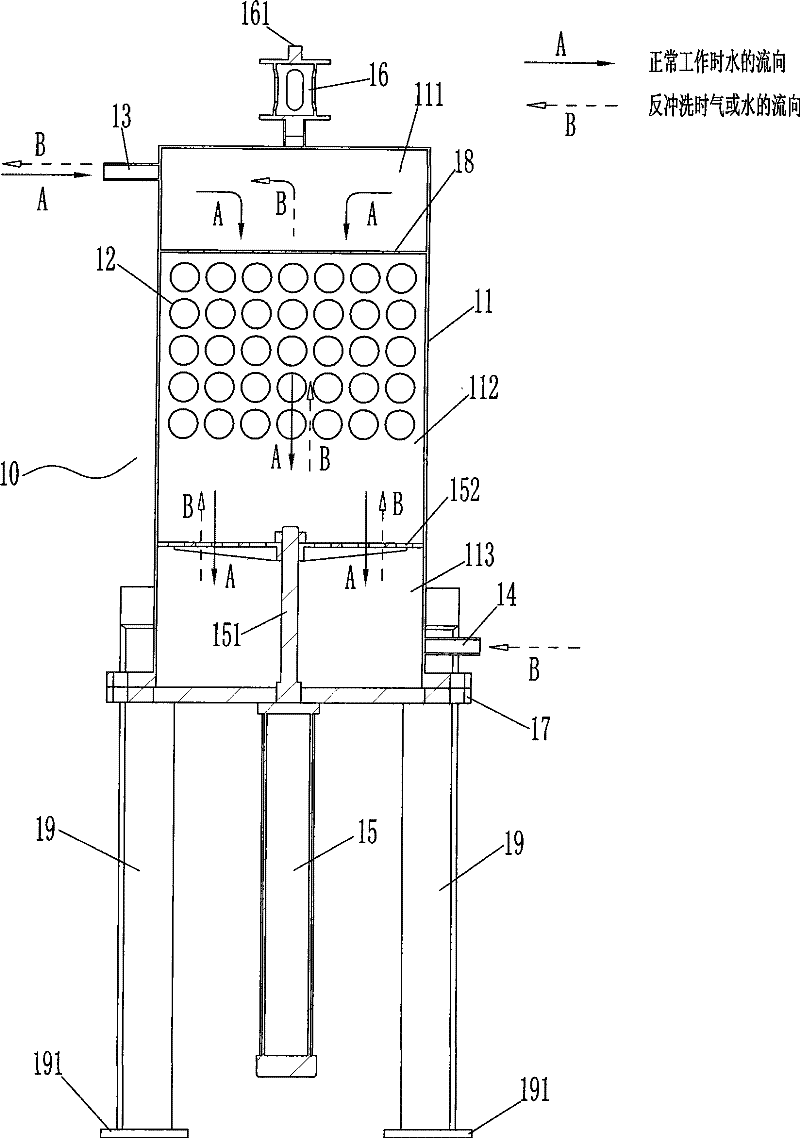

Fully-automatic oily sewage filtration-type separator and separating system

InactiveCN101670194AHigh precision filtrationGood recoil effectLoose filtering material filtersGravity filtersFiltrationOil water

The invention relates to a fully-automatic oily sewage filtration-type separator which comprises a tank body, filter material, a water inlet, a water outlet, a cylinder, a pressure plate, an oil collector, a cylinder fixing cover for fixing the cylinder, and a perforated clapboard; a first chamber is formed between the perforated clapboard and the top wall of an inner cavity of the tank body; thewater inlet and the oil collector are arranged at the upper part of the tank body and both communicated with the first chamber; the perforated clapboard is arranged at the upper part of the inner cavity of the tank body and below the water inlet; the cylinder fixing cover is fixed with the lower end of the tank body, and a piston rod of the cylinder passes through the cylinder fixing cover and then extends into the inner cavity of the tank body; a third chamber is formed between the cylinder fixing cover and the pressure plate; the water outlet is arranged at the lower part of the tank body and communicated with the third chamber; a second chamber is formed between the pressure plate and the perforated clapboard, and a filter core is arranged in the second chamber. The invention also relates to a separating system which adopts the fully-automatic oily sewage filtration-type separator. The invention has small occupying area, is unnecessary to filter oily sewage in advance, can not onlyensure high oil-water separation precision, but also carry out automatic backwash on line.

Owner:深圳市兰科环境技术有限公司

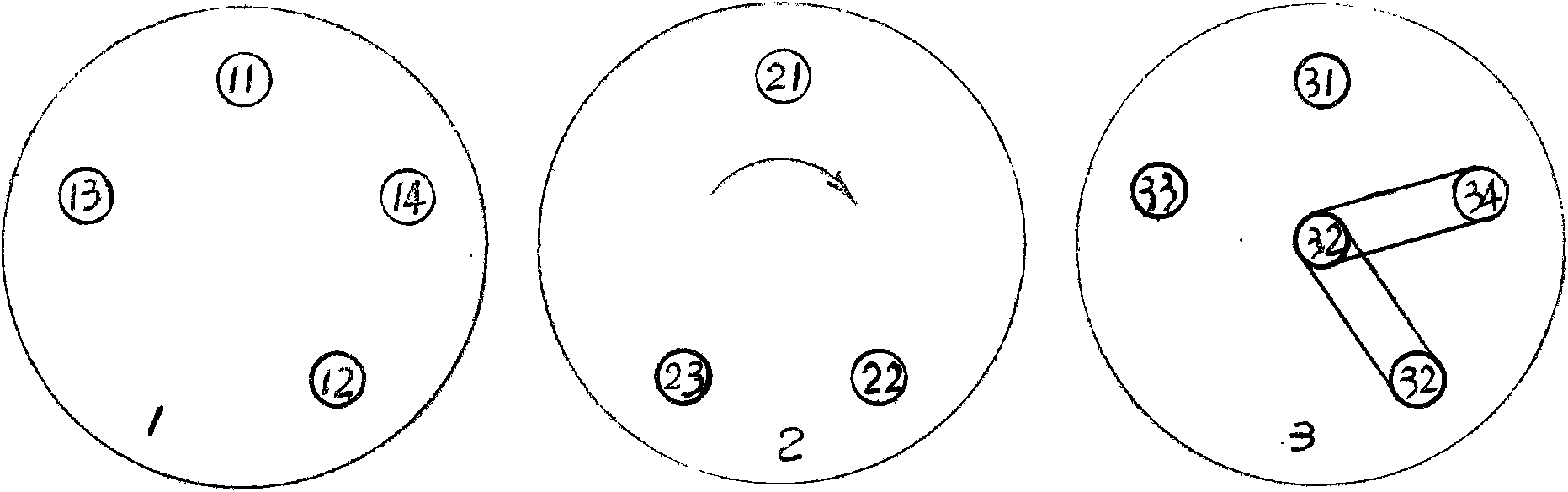

Fresh water treatment machine

InactiveCN102008845AExtend your lifeEasy to installWater/sewage treatmentMultistage water/sewage treatmentPurification aspectsEngineering

The invention relates to the water treatment industry, in particular to the deep filtration and purification aspects of drinking water. The invention discloses a fresh water treatment machine comprising a backflushing filter element, an engine base with a water inlet and a water outlet, a water path switcher and a sealing cover which contacts and is matched with the engine base to form a sealed inner cavity, the built-in water path switcher is provided with a hollow rotating shaft, one end of the hollow rotating shaft is hermetically communicated with a switching water nozzle of a rotary disc of the hollow rotating shaft, the other end of the hollow rotating shaft penetrates through a shaft via hole to form a rotatable water nozzle pipeline, another switching water nozzle of the rotary disc is communicated with another water nozzle pipeline of the engine base through the inner cavity, a fixed disc of the water path switcher is provided with 2-15 water nozzles which correspond to the water nozzles of the rotary disc, are arranged at isotonic included angles as units, correspondingly connected with 1-7 filter elements and form a filter channel, the fixed disc contacts and is matched with the rotary disc, only the water inlet and the water outlet are communicated, and the hollow rotating shaft drives the rotary disc to rotate a switching position by using each isotonic included angle as a unit and form a backflushing channel of the backflushing filter element.

Owner:杜也兵

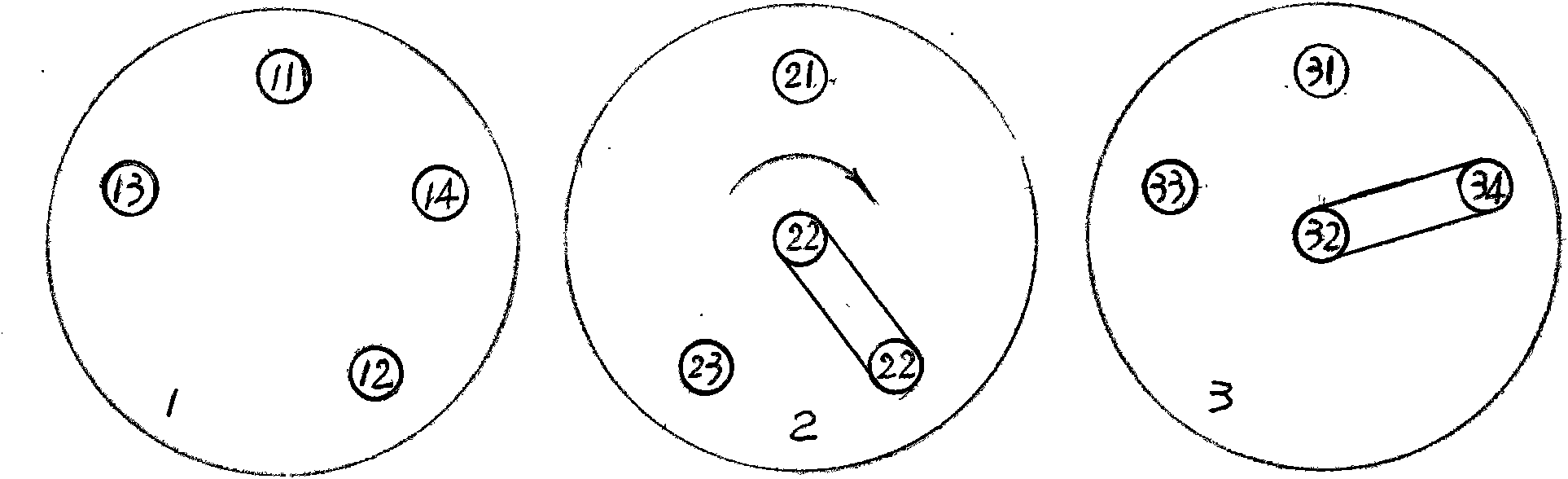

Full back-flushing water purifying treatment device

ActiveCN102019105AExtend your lifeEasy maintenanceStationary filtering element filtersFiltrationEngineering

The invention relates to the water treatment industry, in particular to deep filtration and purification of drinking water. The invention discloses a full back-flushing water purifying treatment device. The device comprises back-flushing filter elements and a base with water inlet and outlet pipelines; the device also comprises a water passage switcher and a sealing cover; the sealing cover is in contact fit with the base through a sealing element to form a sealed cavity; a rotating disc and a fixed disc of the water passage switcher are in contact fit to form a sealed switching interface, and the switching face of the rotating disc of the water passage switcher is provided with three water ports, namely a water inlet bent hole communicated with the water inlet pipelines of the sealed cavity and the base, a water outlet blind hole and a transition blind hole which are mutually communicated; the switching face of the fixed disc of the water passage switcher is provided with a plurality of switching water ports corresponding to the switching water ports of the rotating disc, and the plurality of switching water ports are correspondingly connected at the back-flushing filter elements connected in series; and the fixed disc is butted with the water inlet bent hole of the rotating disc, the water inlet pipeline of the base, the transition blind hole and the water outlet blind hole through the water inlets in front and back of the back-flushing filter elements connected in series and the middle water outlet respectively, and connected with the water outlet pipeline through the water outlet of the fixed disc.

Owner:杜也兵

Method for cleaning filter liners of built-in and combined filter chambers of water purifier

InactiveCN101991988AEliminate the effects ofExtend your lifeWater/sewage treatmentFiltration circuitsFiltrationPermeation

The invention relates to the water treatment industry, in particular to depth type filtration and purification of the drinking water. The invention discloses a method for cleaning filter liners of built-in and combined filter chambers of a water purifier. The device comprises filter elements, a base with water inlet and outlet, a filter channel connecting the filter elements and the water inlet and outlet of the base in series, the combined filter chambers formed by a fixed filter shell, a movable chamber cover and a sealing element and the tubular filter liners, wherein the combined filter chambers form a whole with the base and are provided with two water gaps of the filter liners side by side and two filter liner riding positions; the filter liners are positioned in the combined filter chambers and are connected with the combined filter chambers in series in the filter channel; and forward and reverse single water channels of the filter liners under fixed mode of the water inlet and outlet are respectively formed by translating and changing the riding positions of the filter liners. The invention has simple and practical structure and good filtering and backflushing effects, effectively eliminates the effect of carbon permeation on the drinking water, is convenient and timely in cleaning and replacing the filter liners and ensures the subsequent filter elements to have long service lives.

Owner:杜也兵

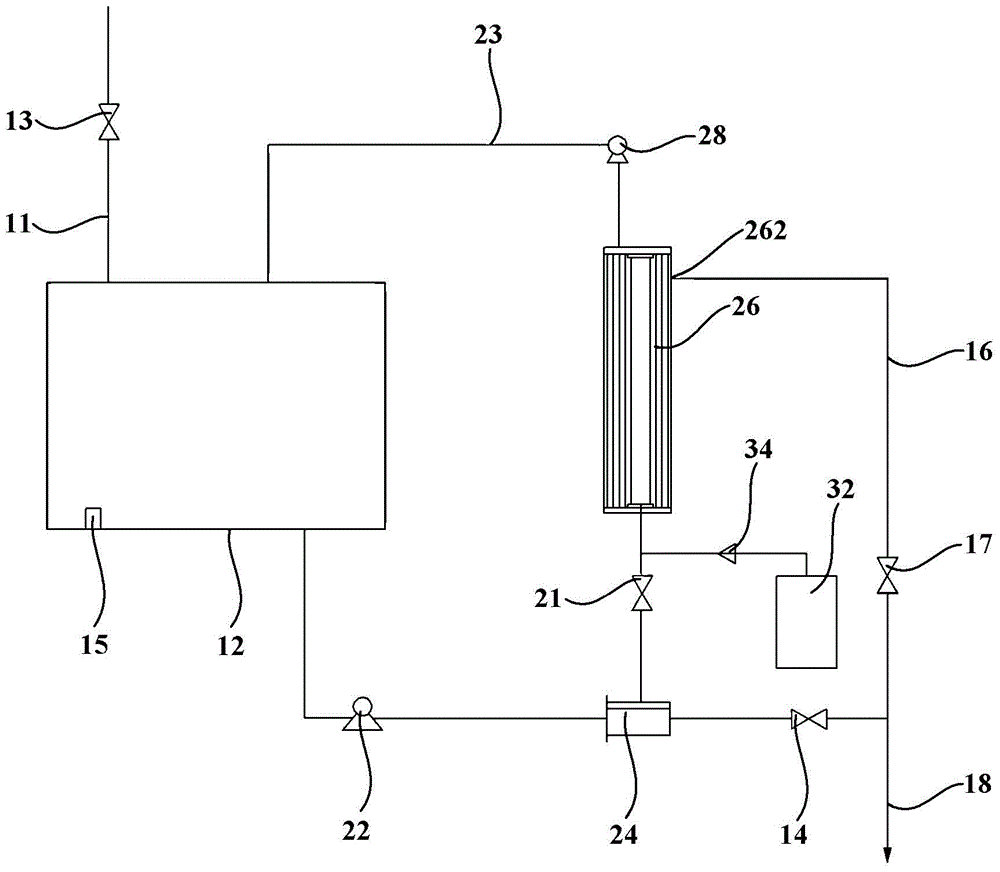

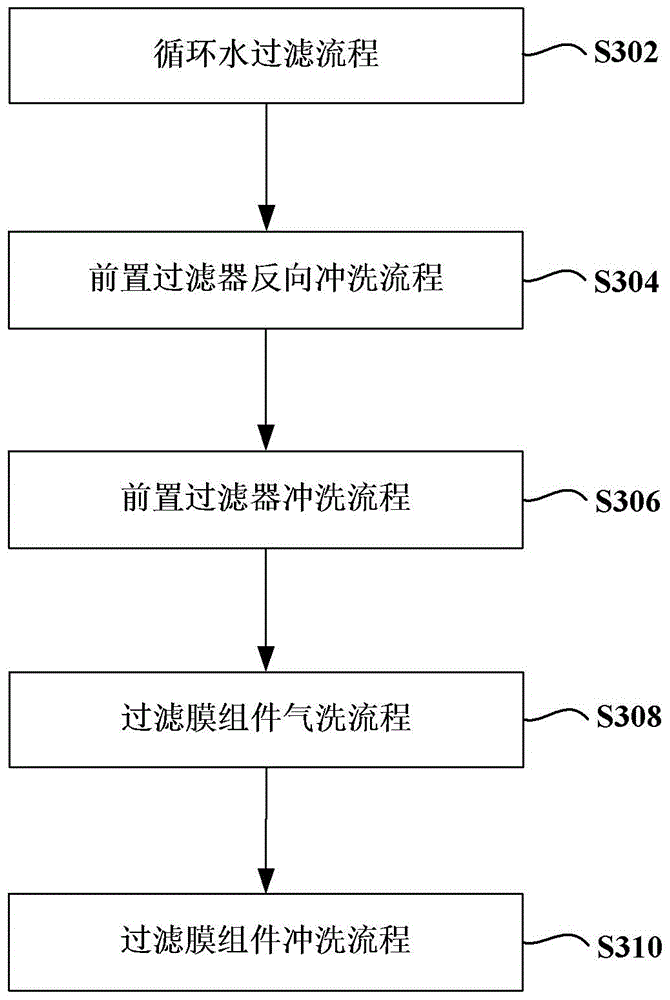

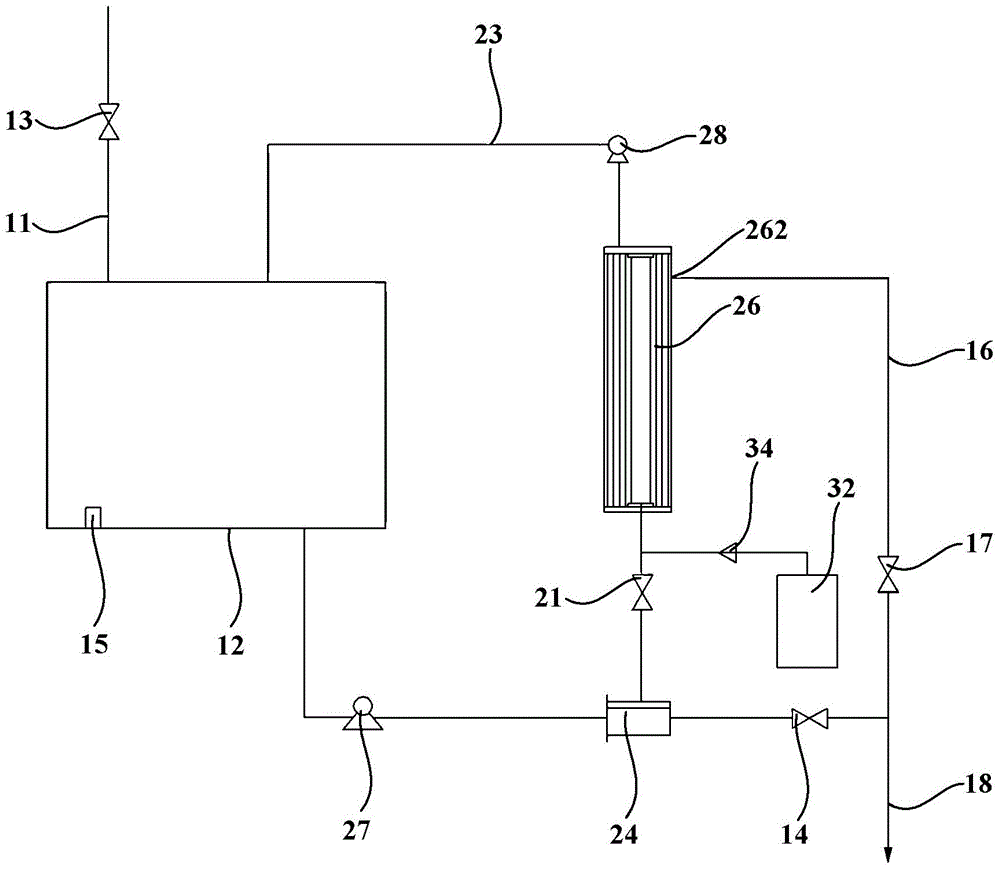

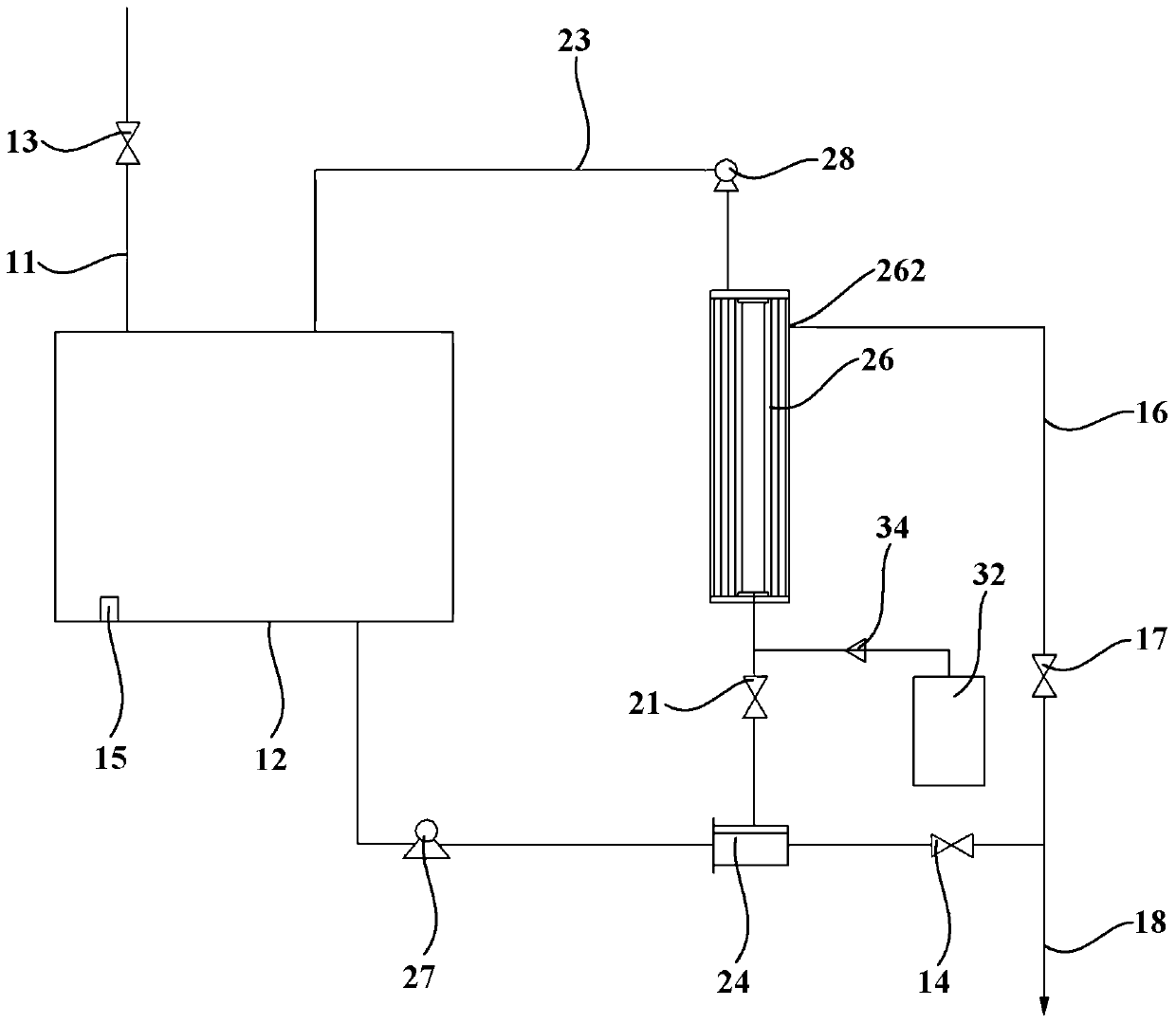

Washing machine and method for back-flushing pre-filter of washing machine

ActiveCN105350266AGood recoil effectImprove stability and longevityOther washing machinesTextiles and paperPre filteringFilter system

The invention provides a washing machine and a method for back-flushing a pre-filter of the washing machine. The washing machine comprises a circulating water filtering system, the circulating water filtering system comprises the pre-filter and a filtering film assembly arranged on a downstream pipeline of the pre-filter, the pre-filter and the filtering film assembly are configured in a way that during the circulating water filtering flow of the washing machine, and water discharged from a washing cylinder of the washing machine is filtered and then is recycled back to the washing cylinder. The filtering film assembly is further configured in a way that after the circulating water filtering flow and / or the filtering film assembly flushing flow, and residual water in the filtering film assembly is reversely discharged to the pre-filter in a controllable manner in order to carry out back-flushing to the pre-filter. According to the invention, after the circulating water filtering flow, residual water in the filtering film assembly carries out back-flushing to the pre-filter, the water source is reasonably utilized, and a filter screen in the pre-filter can be cleaned to a certain extent.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

A novel metal filtration film and preparation method thereof

The invention relates to a metallic filter membrane which can be used in flat filtration, cylinder filtration and folded filtration, etc. Said preparing method uses following materials: nickel, titanium, chrome, stainless steel, molybdenum, cobalt, iron, and copper, etc, that using the powder of one said material or the alloy powder to be mixed with adhesive to be plated on the frameworks (alloy porous base band or spongy base band with same characters of powder) to be sintered. The invention can prepare the filter membrane whose diameter in 0.1 nanometers to 5 micrometers according to the different granularities of powder, with the characters of high-temperature resistance, acid alkali resistance, large flux, small volume, and long service life.

Owner:陈明波

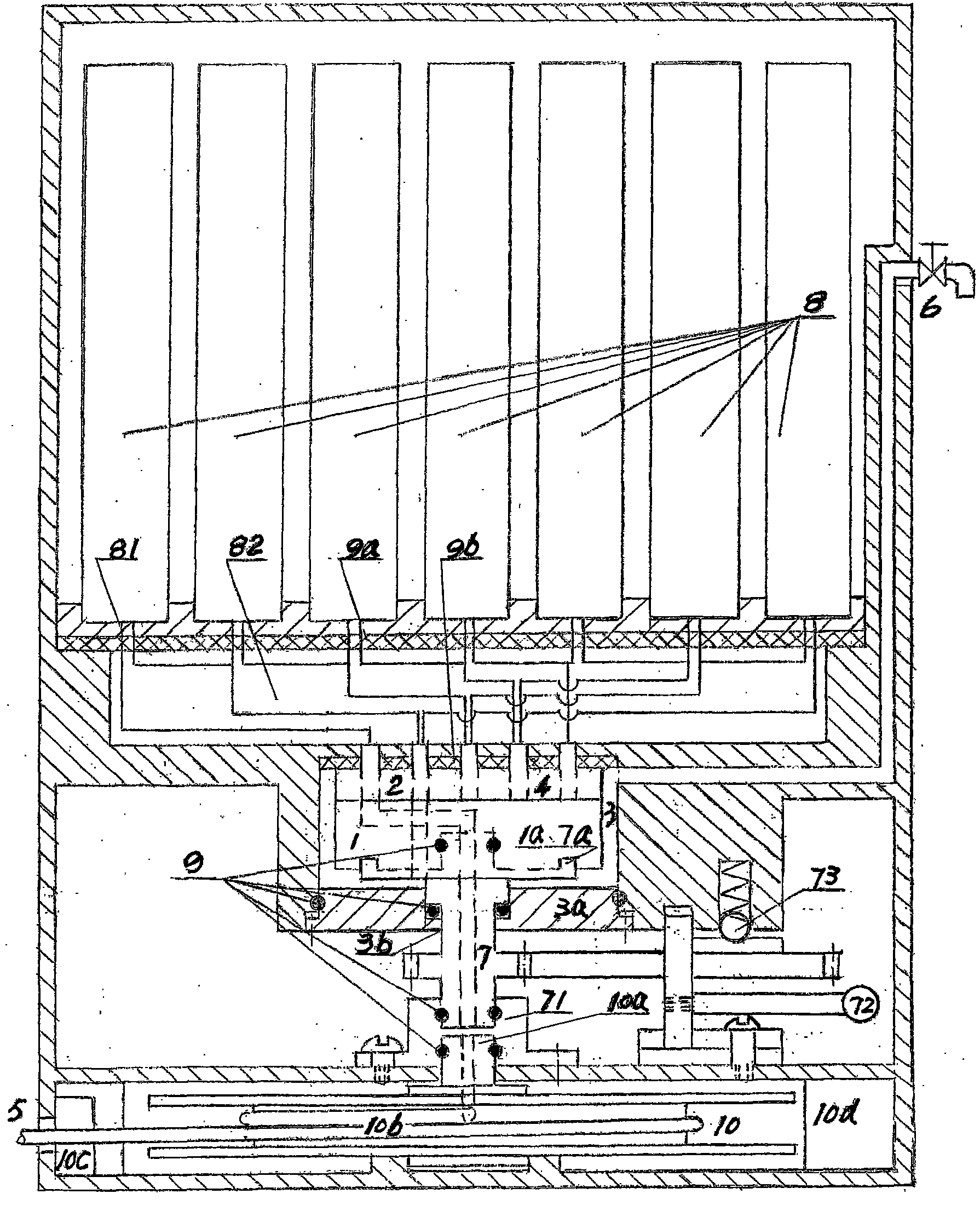

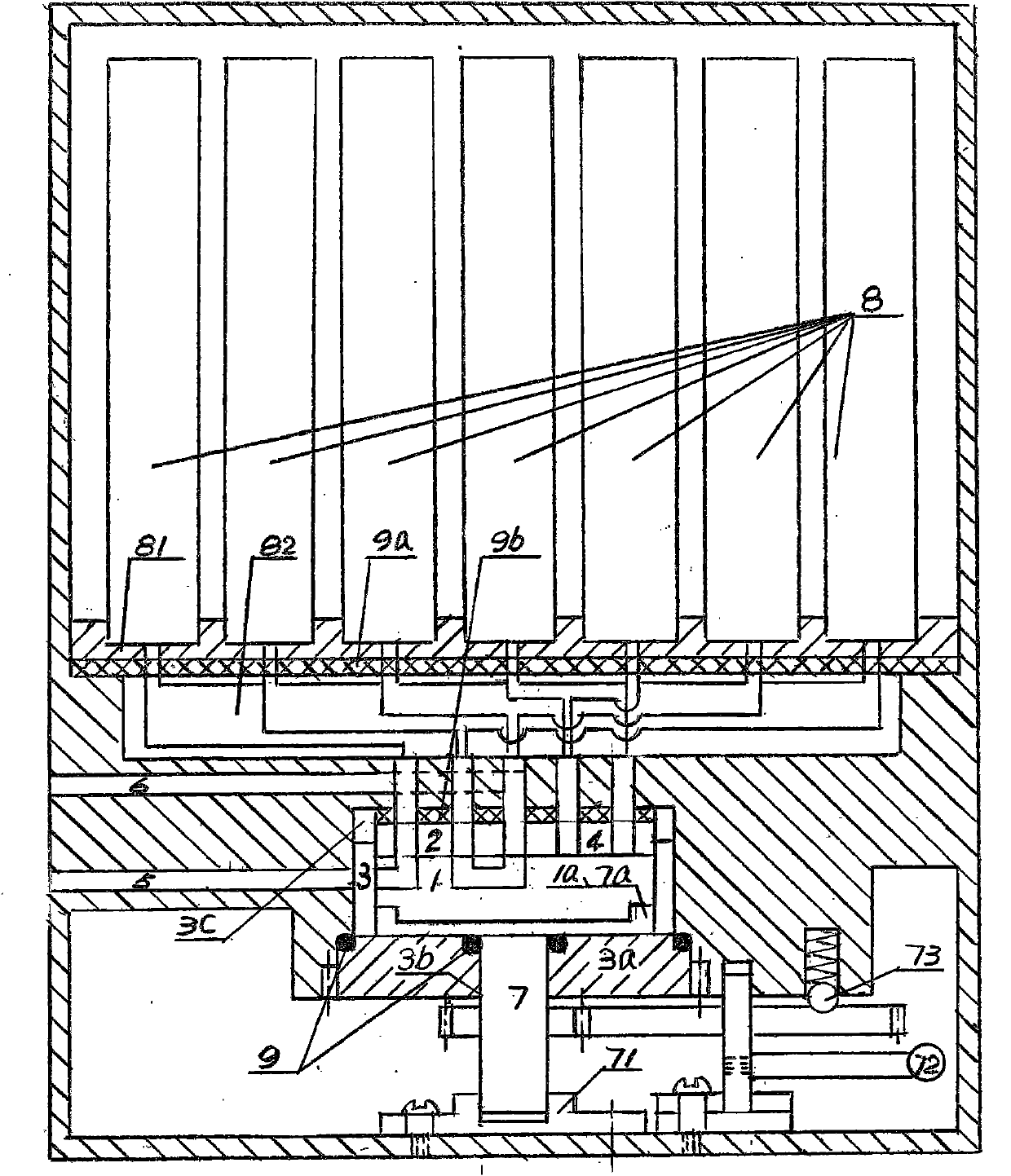

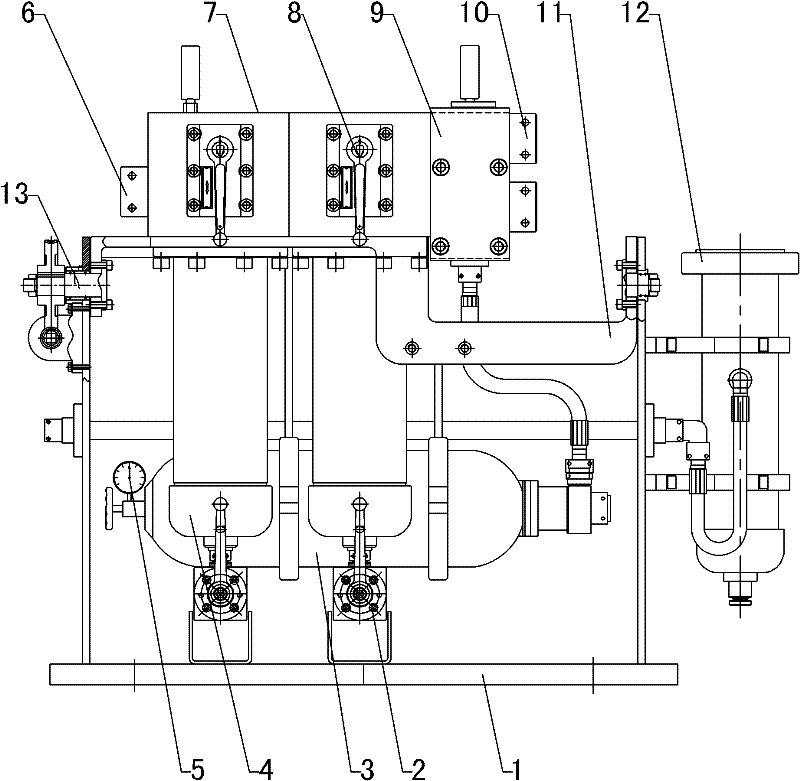

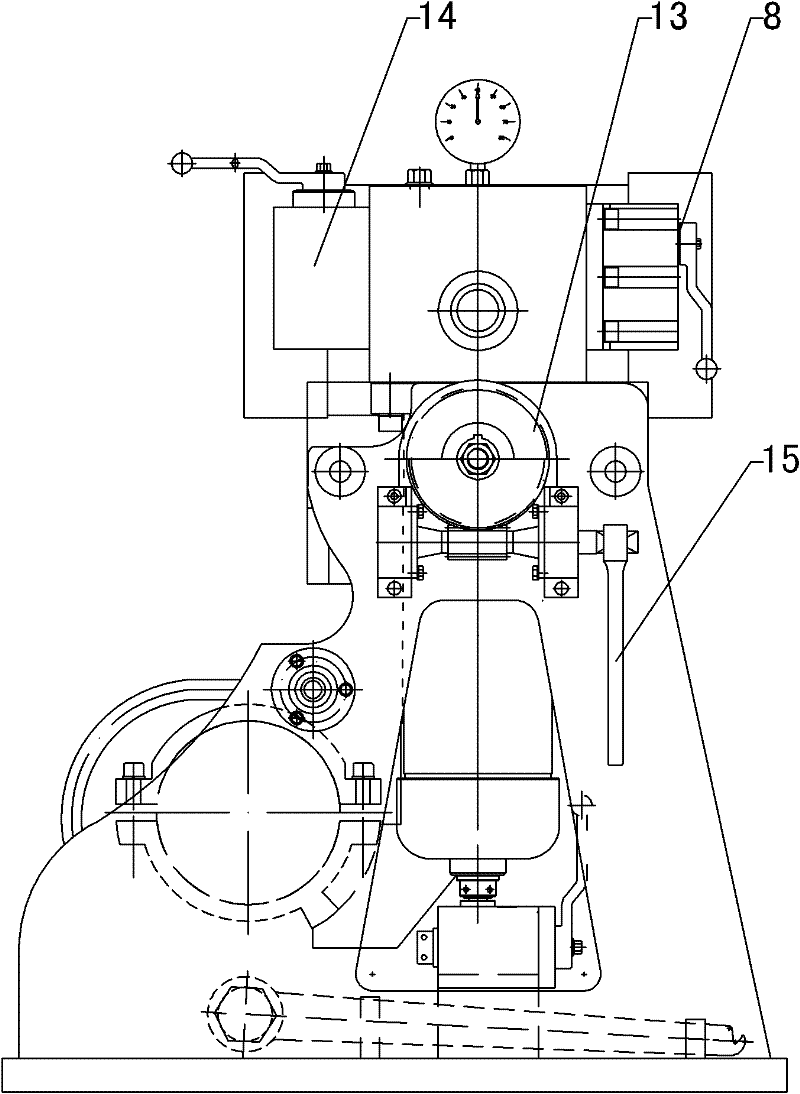

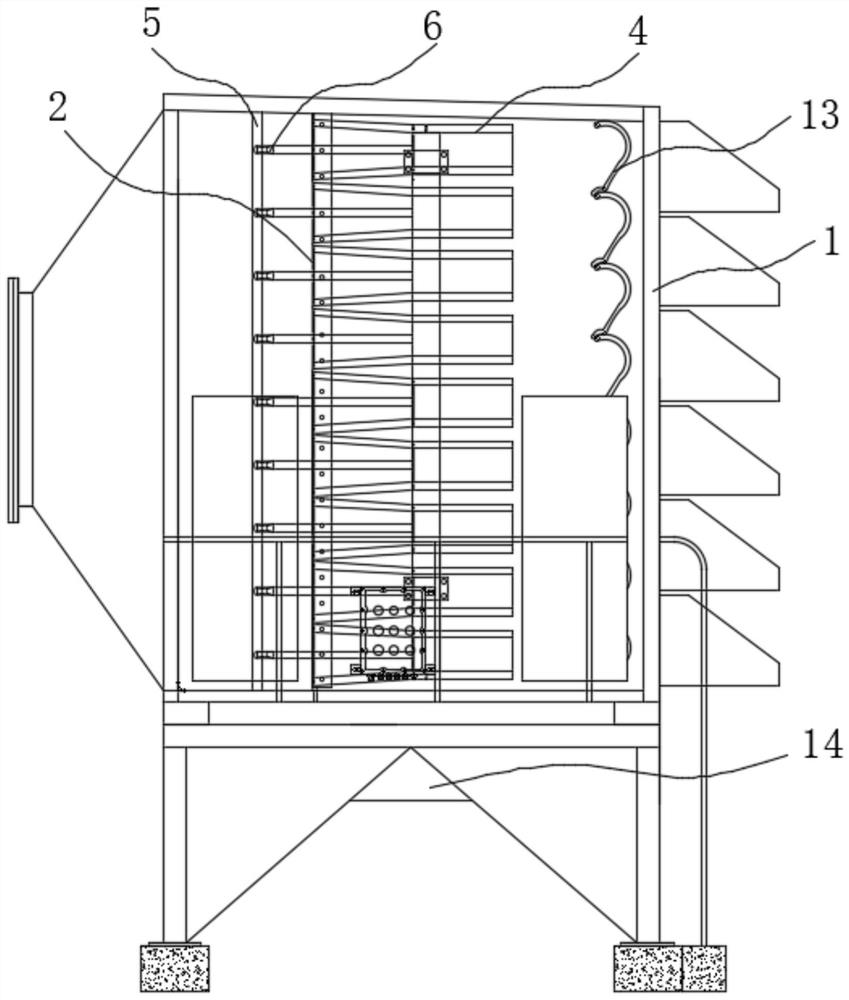

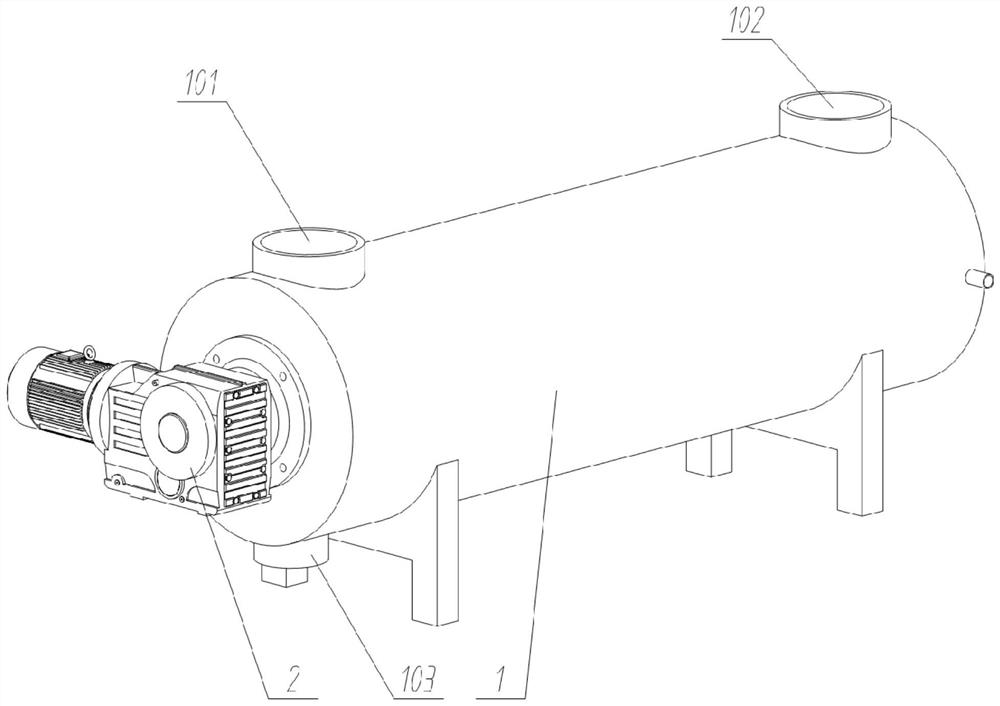

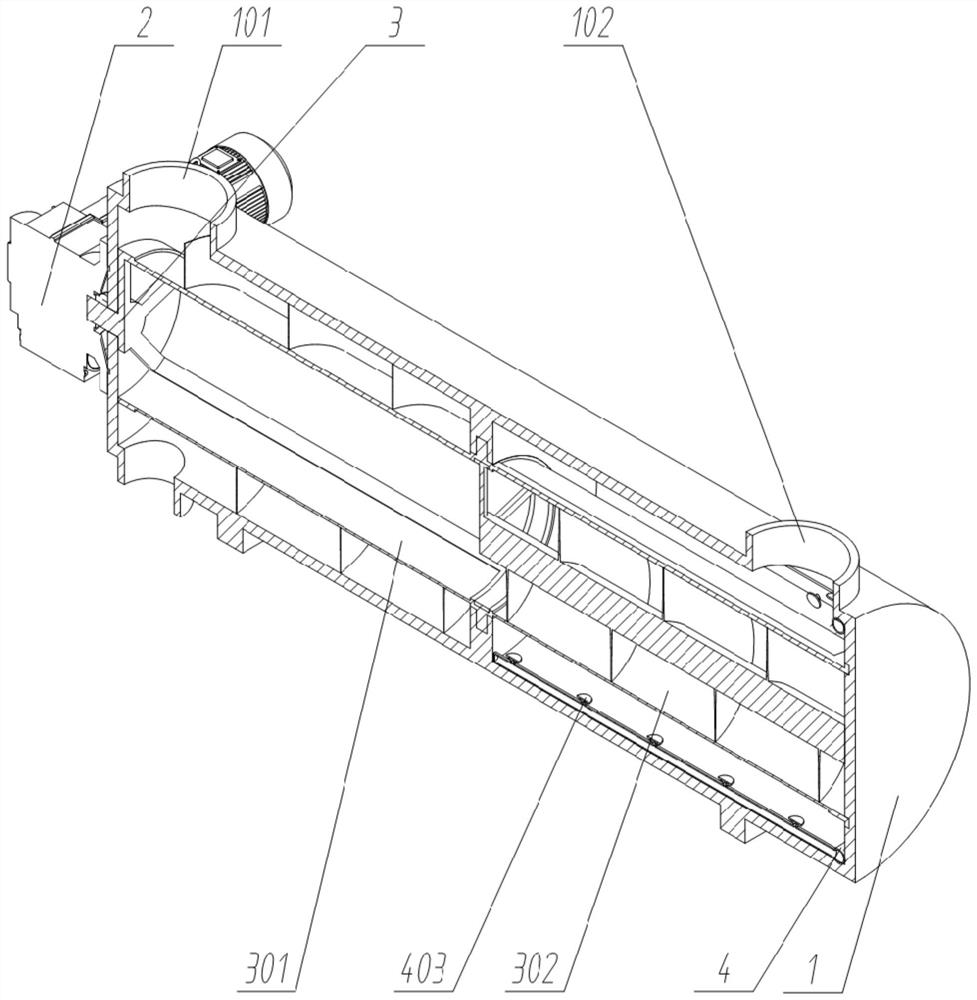

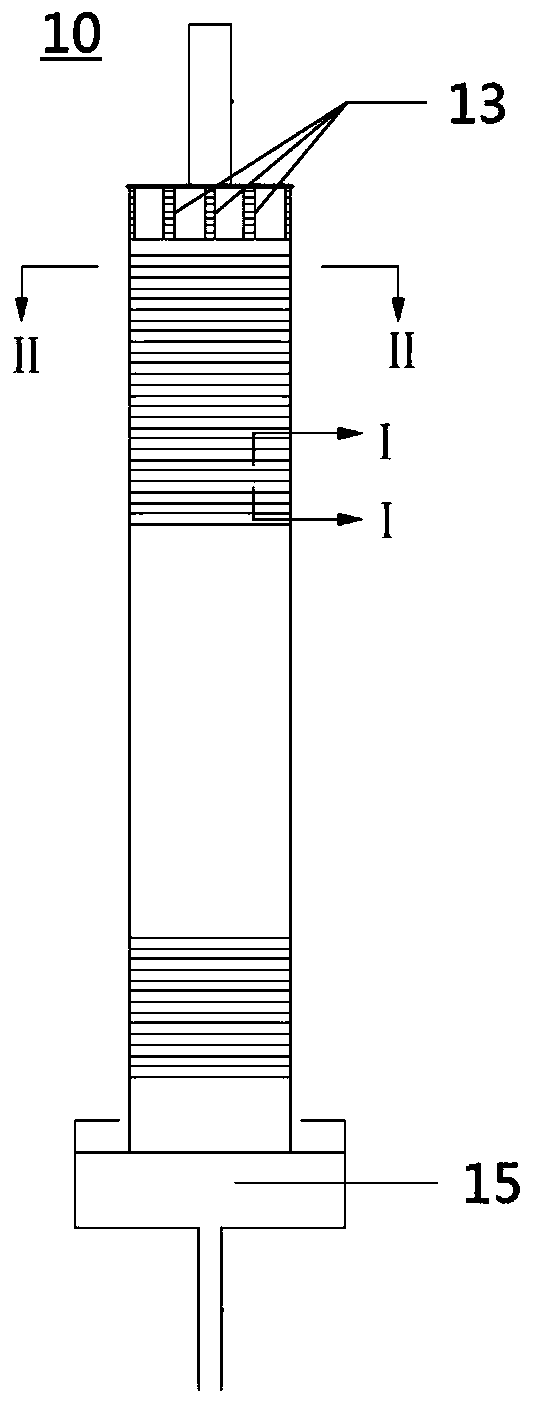

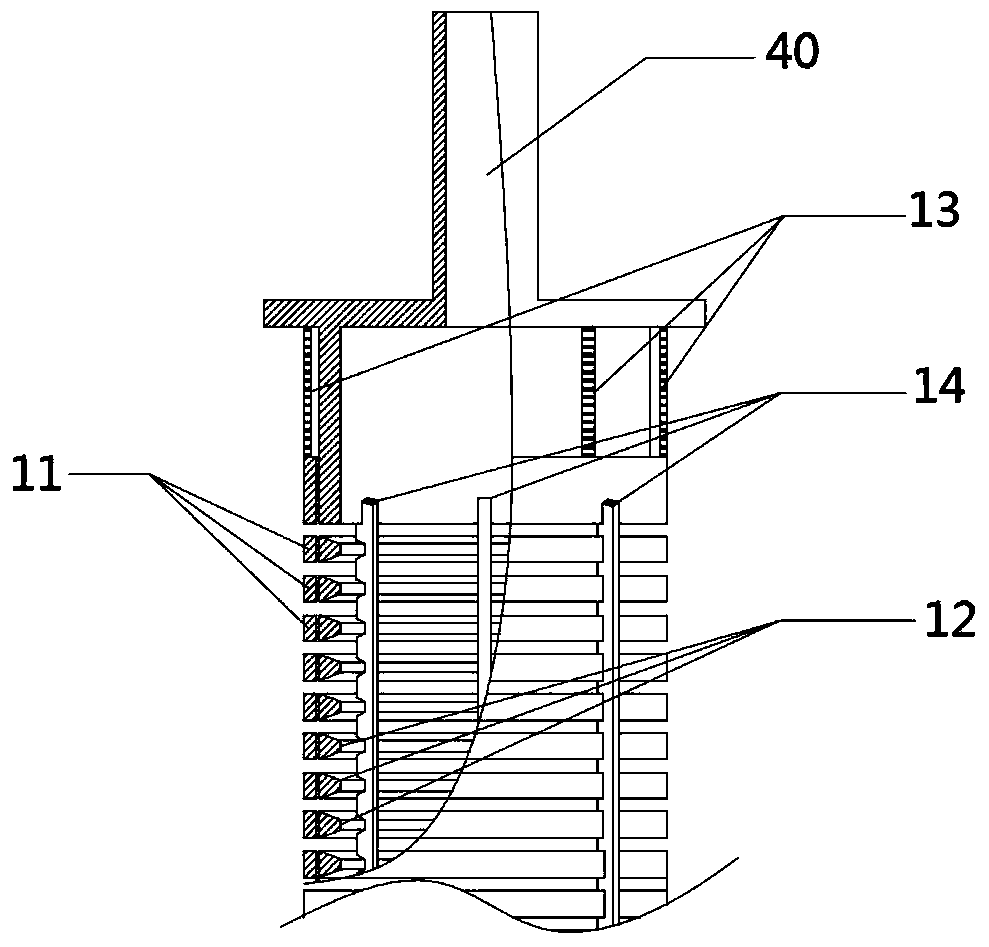

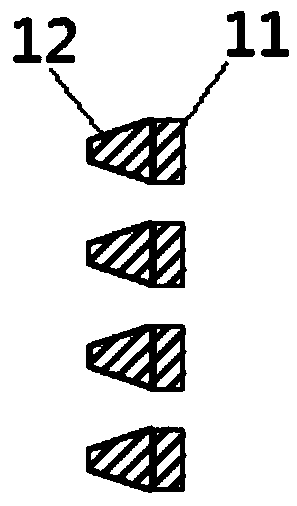

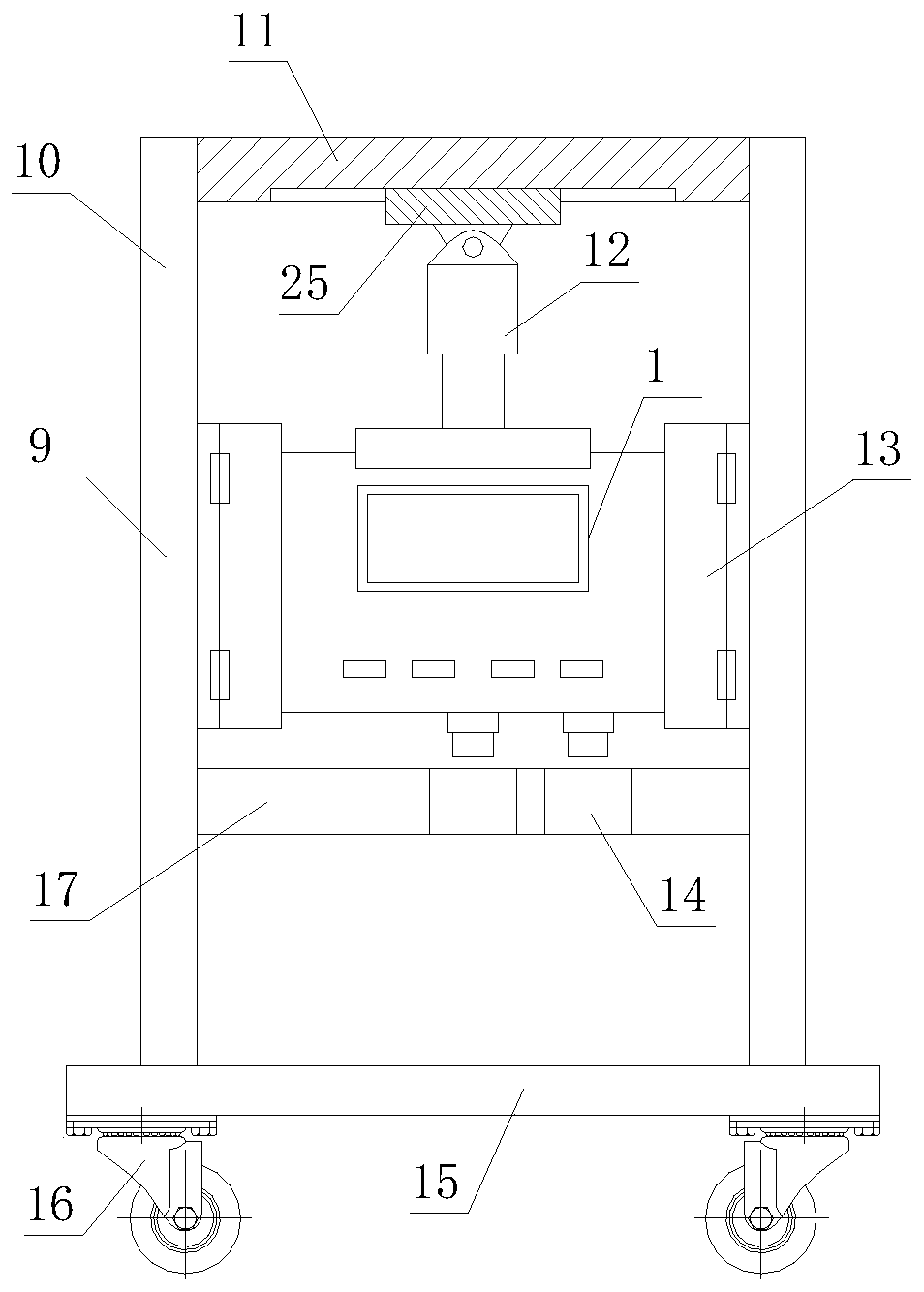

Backwash high pressure filter station

ActiveCN102258910ARealize online recoilDoes not affect production progressFiltration circuitsFluid-pressure actuator componentsEngineeringHigh pressure

The invention discloses a backwashing high-pressure filter station, which belongs to the field of backwashing high-pressure filter devices for hydraulic systems of underground comprehensive mining hydraulic brackets. The backwashing high-pressure filter station comprises a machine seat (1) and a high-pressure filter (4), and is characterized in that: a rotating machine seat (11) is arranged on the upper part of the machine seat (1); an integrated valve seat device (7) is mounted through the rotating machine seat (11); the bottom of the integrated valve seat device (7) is connected with the high-pressure filter (4) and an energy storage device (3); the lower part of the high-pressure filter (4) is connected with a draining valve (2); and a waste liquid recovering device on the lower part of the draining valve (2) is connected with a recovery filter (12). The backwashing high-pressure filter station has the advantages of large flow, high precision, capability of on-line washing, obviouswashing effect, capability of recycling backwashing liquid and the like; and when the backwashing high-pressure filter station is used, the continuous production operation can be ensured, energy conservation and environment protection can be ensured and the cleanness of the working medium can be ensured effectively.

Owner:SHANDONG MINGDUN EXPLOSION PROOF EQUIP TECH CO LTD

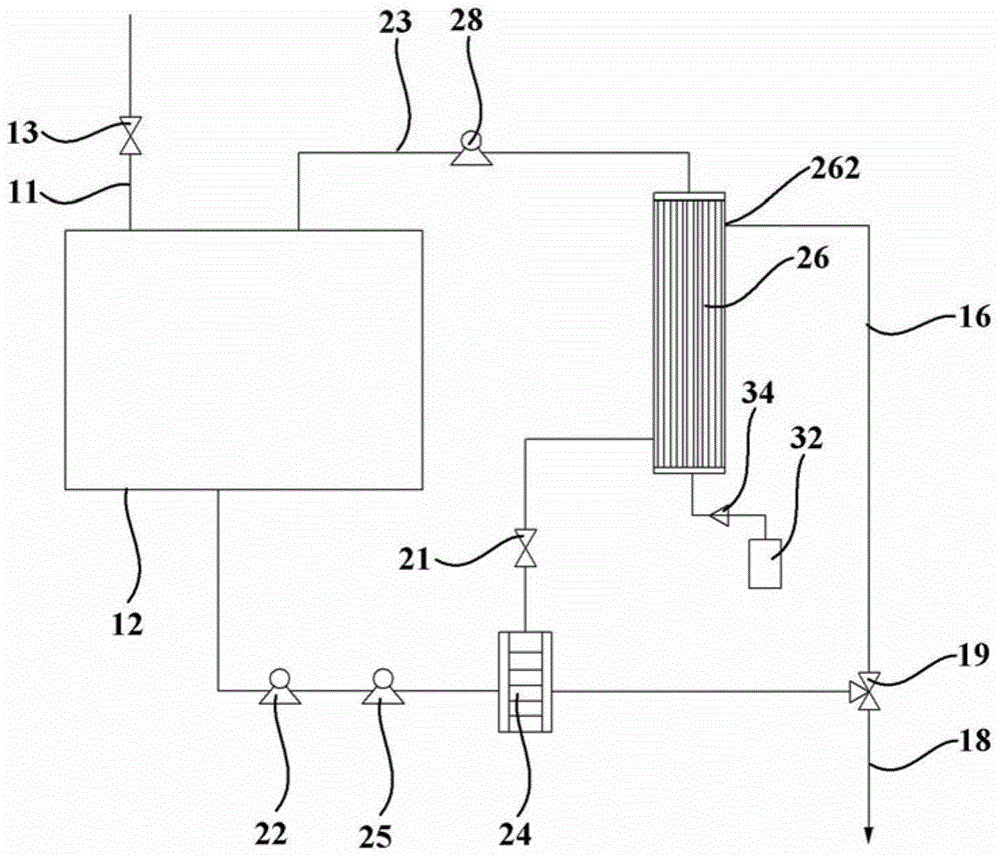

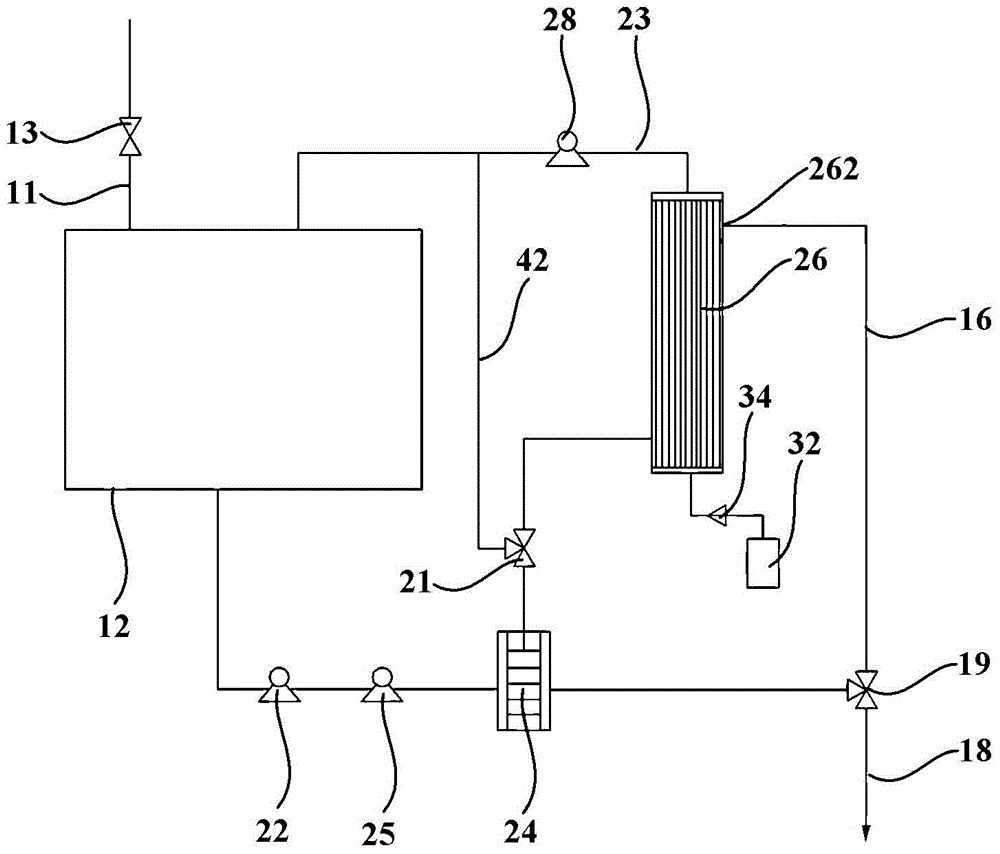

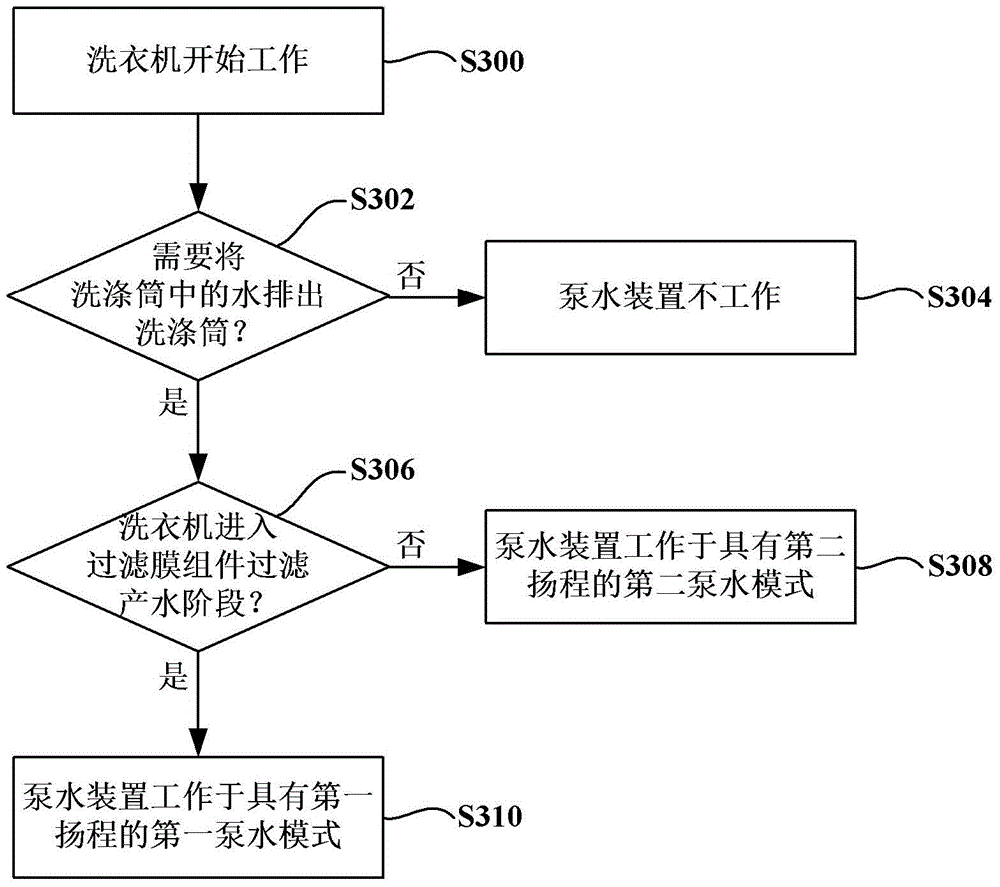

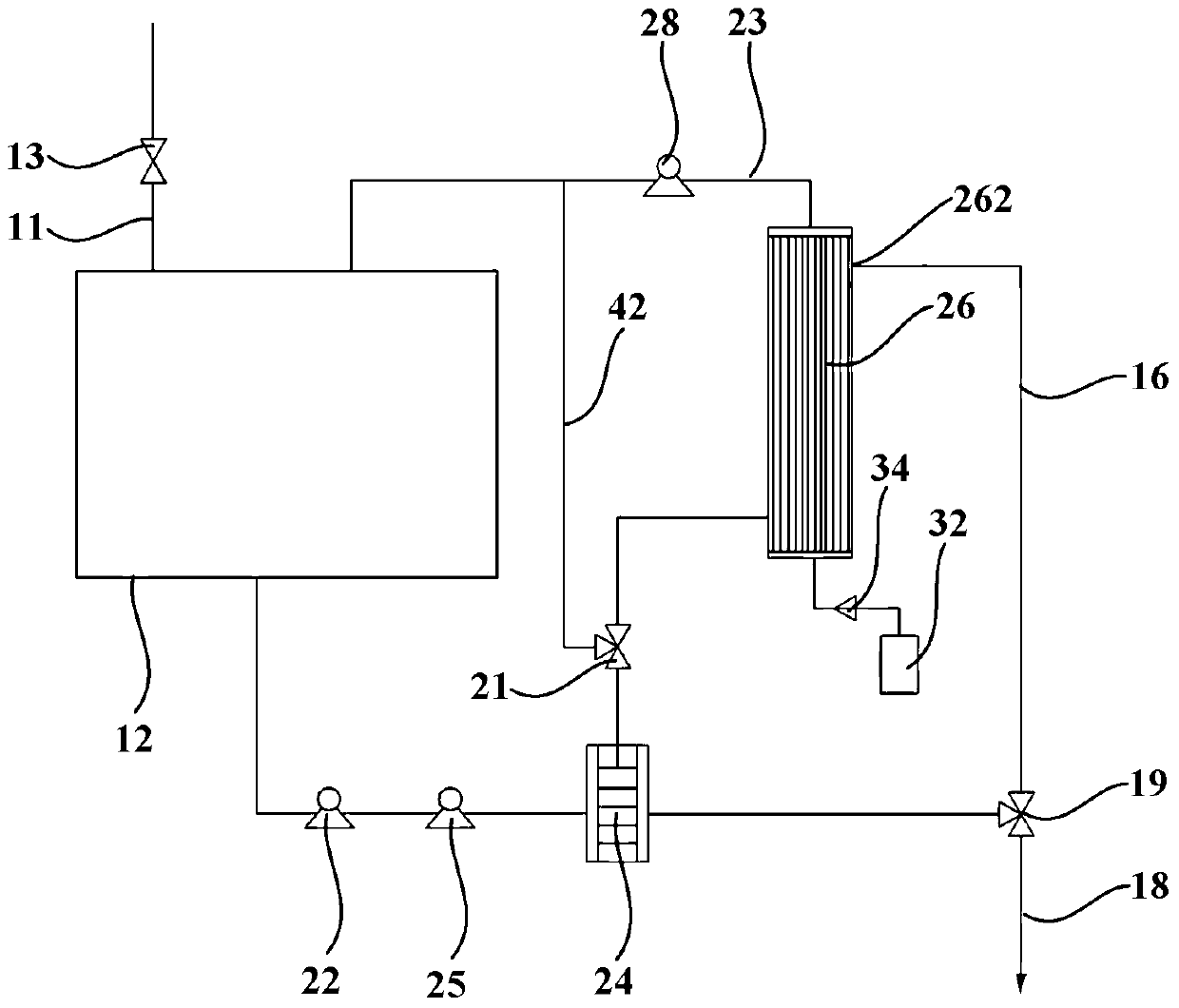

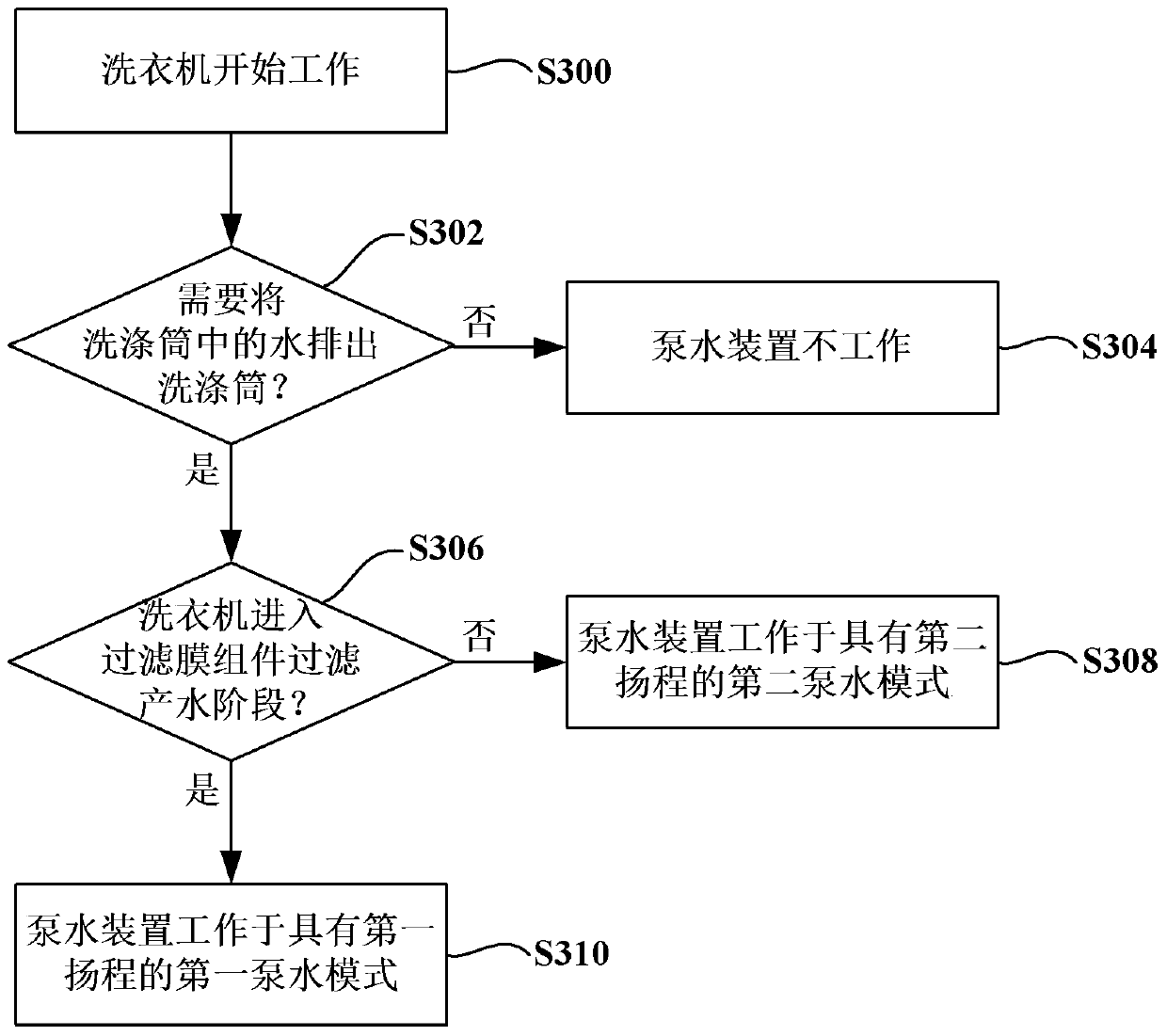

Washing machine and control method thereof

ActiveCN105350267AThe total water volume remains the sameExtend your lifeOther washing machinesControl devices for washing apparatusFiltrationPulp and paper industry

The invention provides a washing machine and a control method thereof. The washing machine comprises a washing cylinder, a filtration film assembly and a pumping device arranged on a pipeline between a water outlet of the washing cylinder and the filtration film assembly. The pumping device is configured in a way that during the filtering and water-producing stage of the filtration film assembly, the pumping device works in a first pumping manner and has first lift in order to pump water in the washing cylinder to the filtration film assembly, and the water level of water in the filtration film assembly is not higher than the lower edge of a discharge opening of the filtration film assembly. By means of different lifts of the pumping device, functions of the washing machine in different working stages are achieved, during the filtering and water-producing stage of the filtration film assembly, the low-lift water pump enables the water level of water in the filtration film assembly to be not higher than the lower edge of the discharge opening of the filtration film assembly, and therefore water from the washing cylinder can be discharged from the discharge opening of the filtration film assembly, and the fact that during the water filtration period, the total water amount of the washing cylinder basically keeps unchanged is guaranteed.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

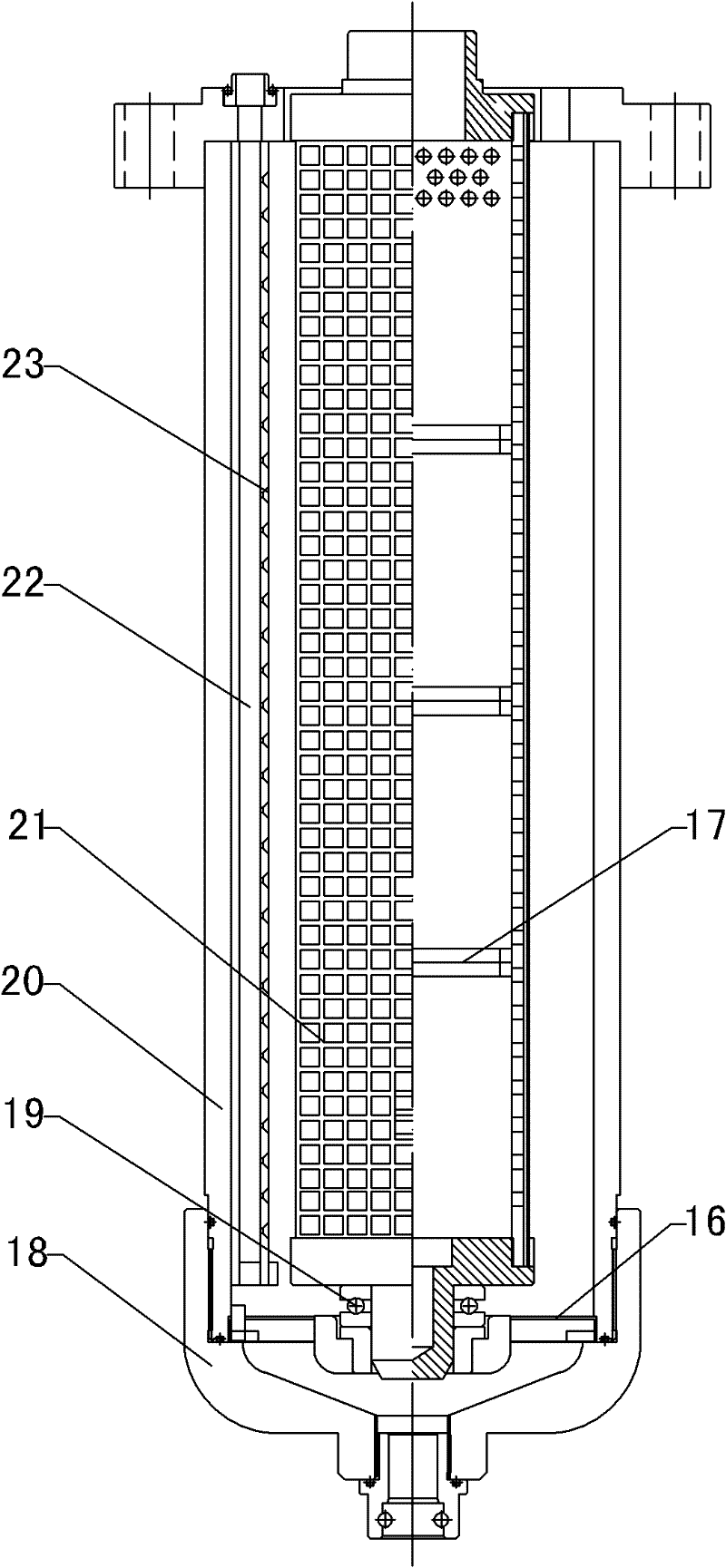

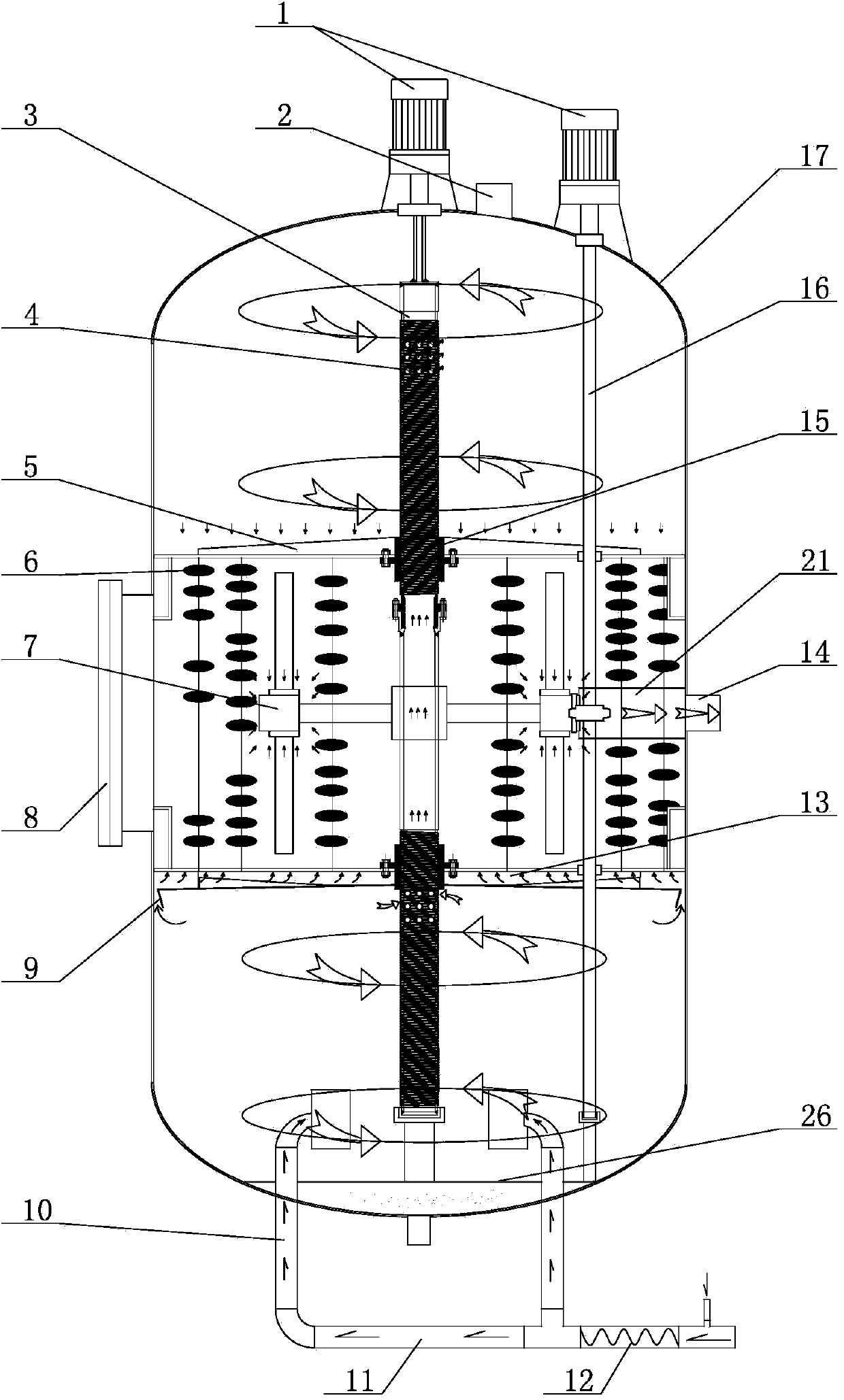

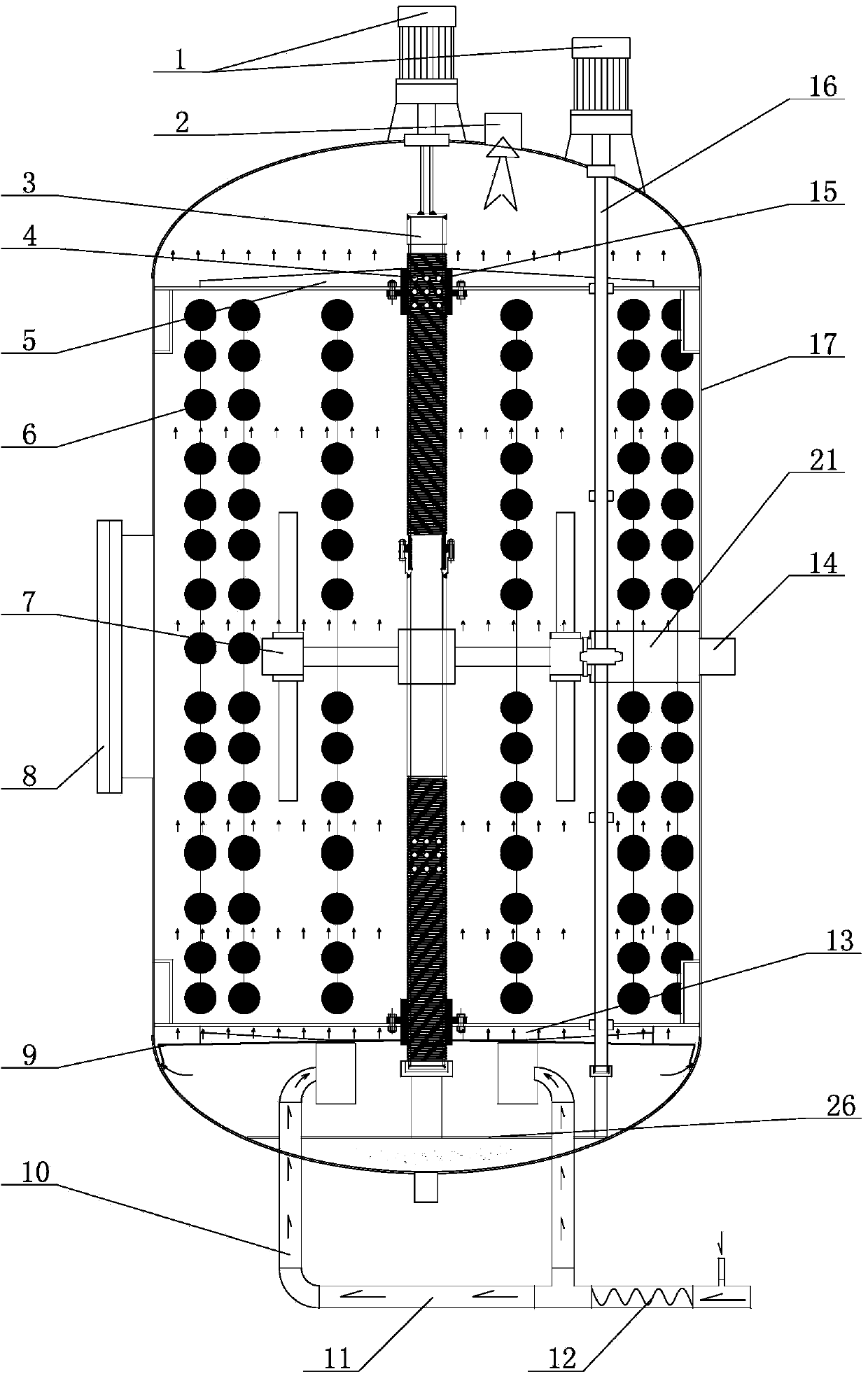

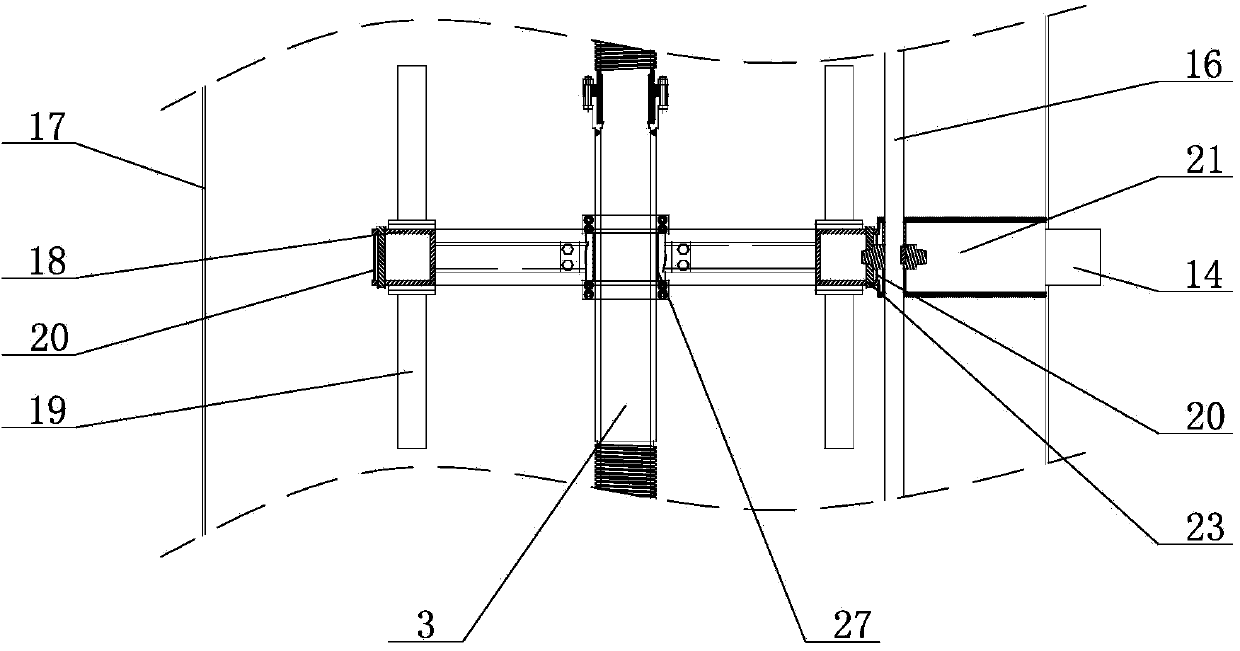

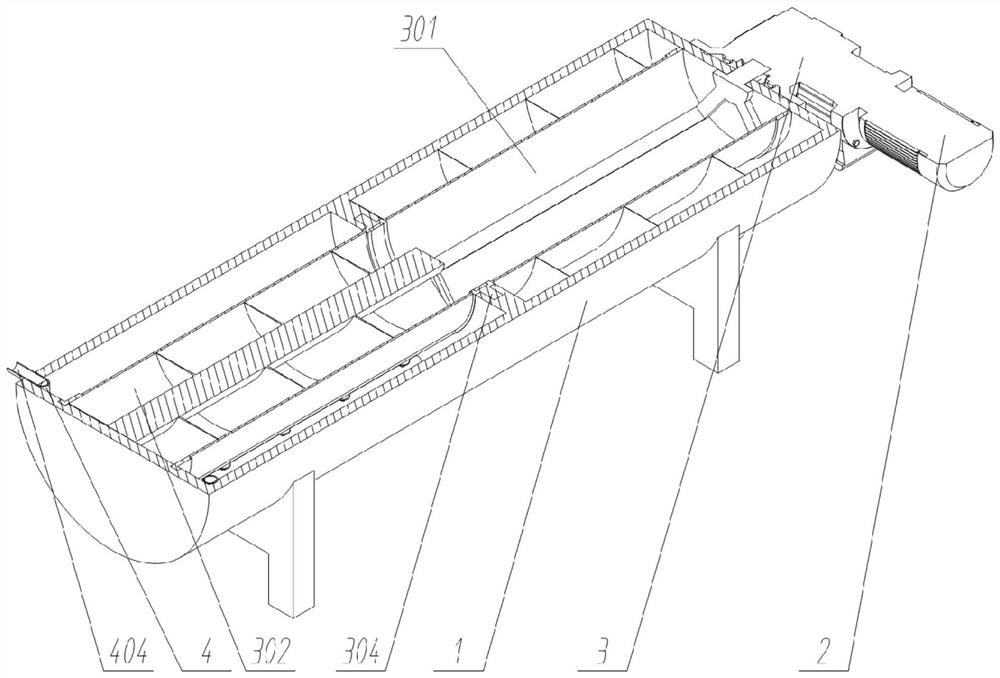

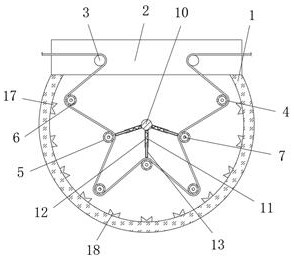

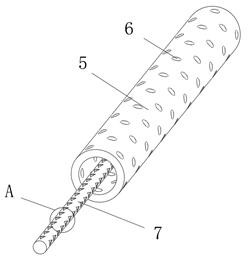

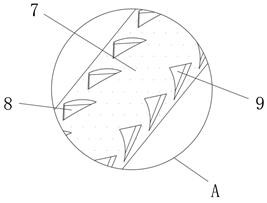

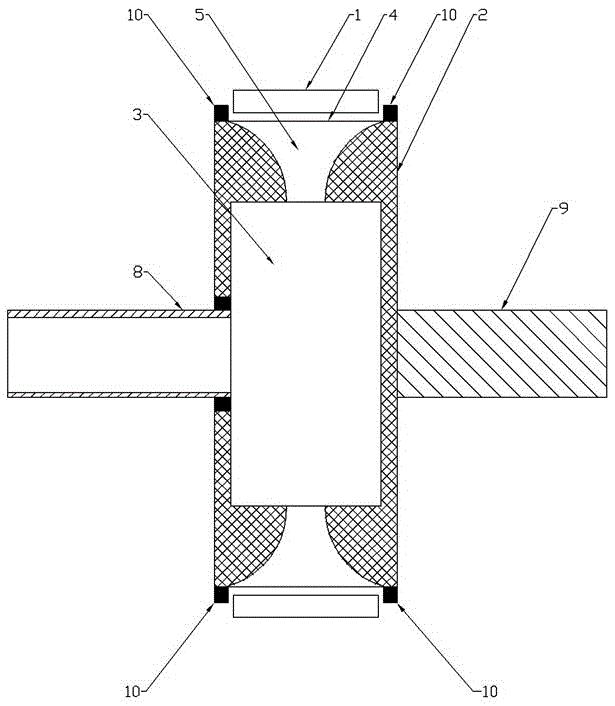

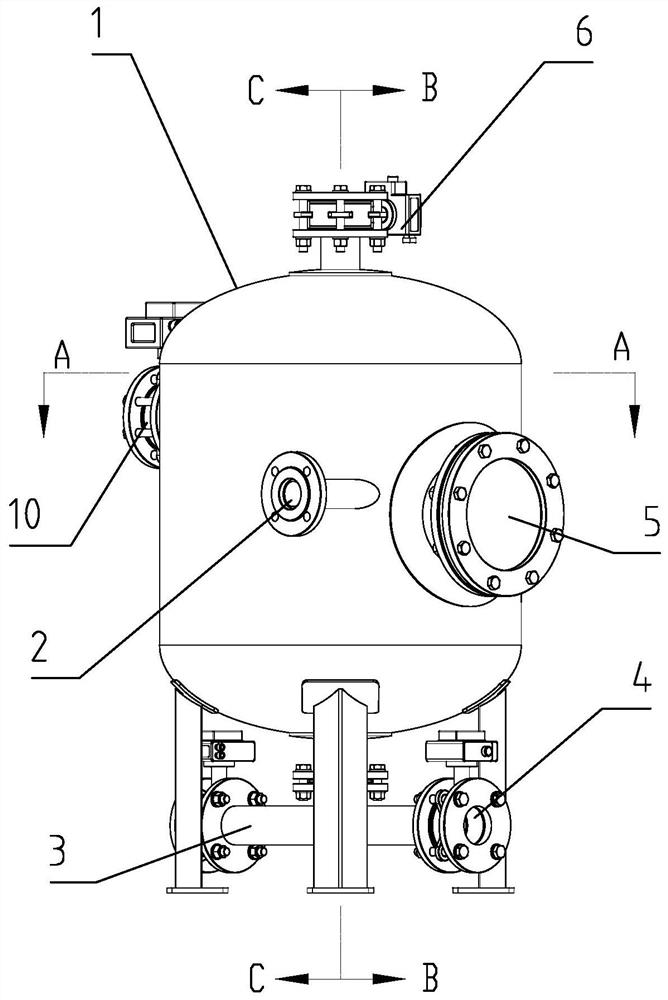

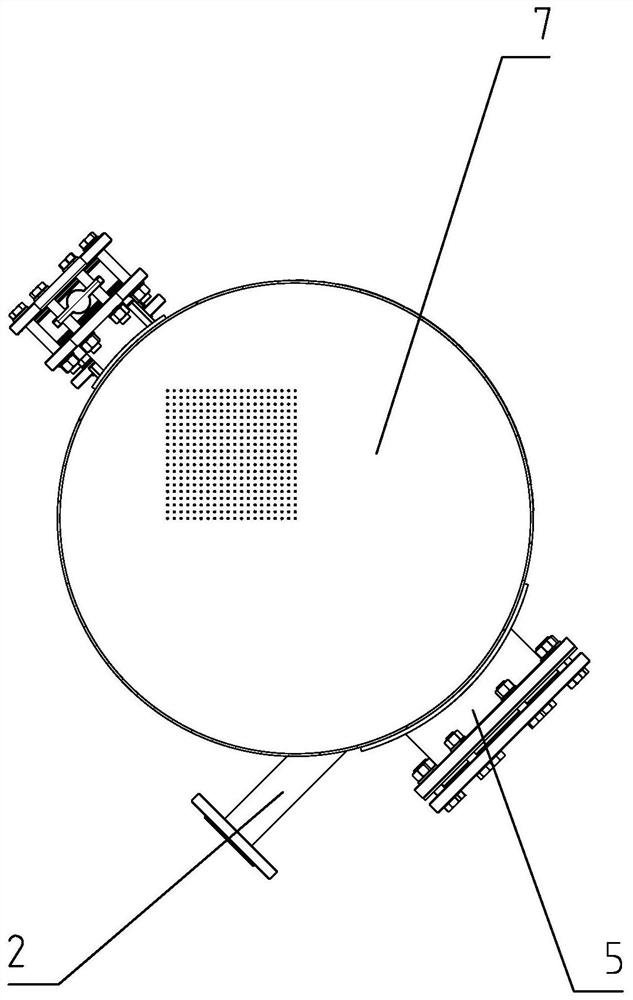

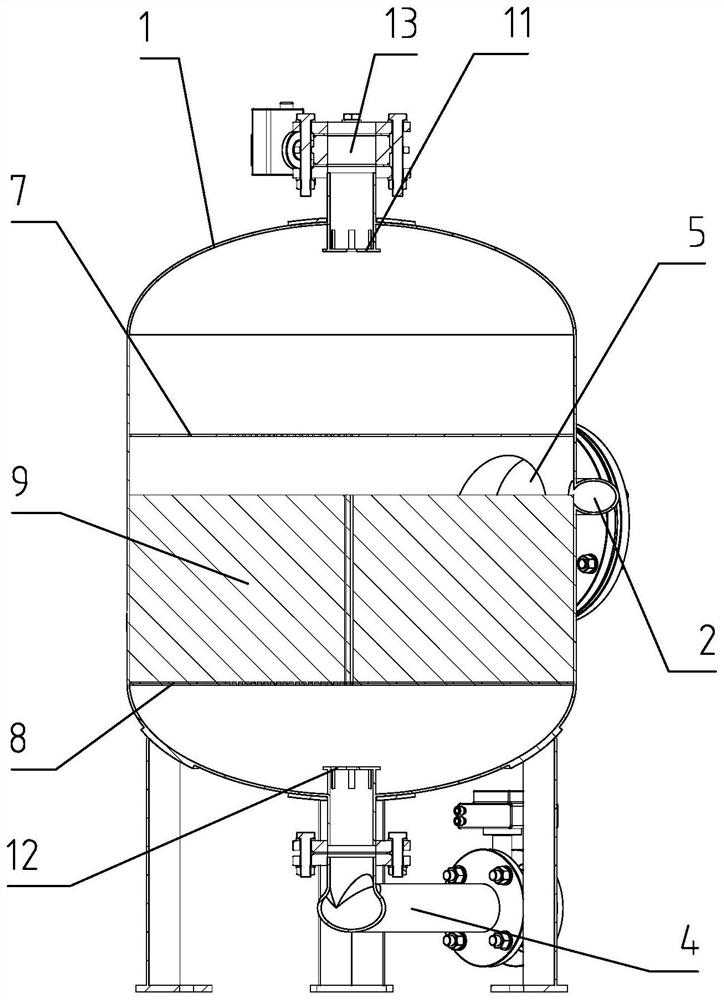

High-precision cyclone separation filter

ActiveCN104190154AImprove processing efficiencyExtend your lifeFiltration circuitsCyclonePulp and paper industry

The invention belongs to the field of water treatment filter equipment, and in particular relates to a high-precision cyclone separation filter. The high-precision cyclone separation filter comprises a cylinder, wherein an upper-end pressure plate and a lower-end pressure plate are arranged in the cylinder body; a filter material is filled between the upper-end pressure plate and the lower-end pressure plate; a hollow screw rod penetrates through a space between the upper-end pressure plate and the lower-end pressure plate; threaded sleeves are arranged at the two ends of the screw rod; the upper-end pressure plate and the lower-end pressure plate are respectively connected with the screw rod through the threaded sleeves; a flow division plate is arranged below the lower-end pressure plate and is arranged on the threaded sleeve which is connected with the lower-end pressure plate, in a sleeving manner; tangent water passage holes are respectively distributed in the upper part and the lower part of the screw rod; a water inlet cyclone device and a sedimentation screen plate are arranged on the bottom of the cylinder body; a backwash water outlet is formed in the top of the cylinder body; the top of the screw rod is connected with a motor; the middle part of the screw rod is connected with a water collecting device; the water collecting device is connected with a water outlet through a water delivery pipe; the water outlet is formed in one side of the cylinder body; a manhole is formed in the other side of the cylinder body. According to the high-precision cyclone separation filter, a backwash pump is not arranged, the number of combination tanks is not required, the high-precision cyclone separation filter can be adjusted and compressed, the filter area is large, the treatment precision is high, the water treatment amount is large, and the occupied area is small.

Owner:山东海钻节能环保科技有限公司

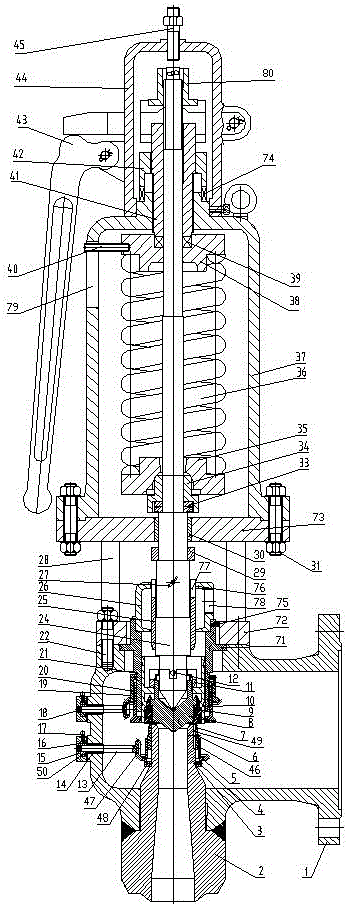

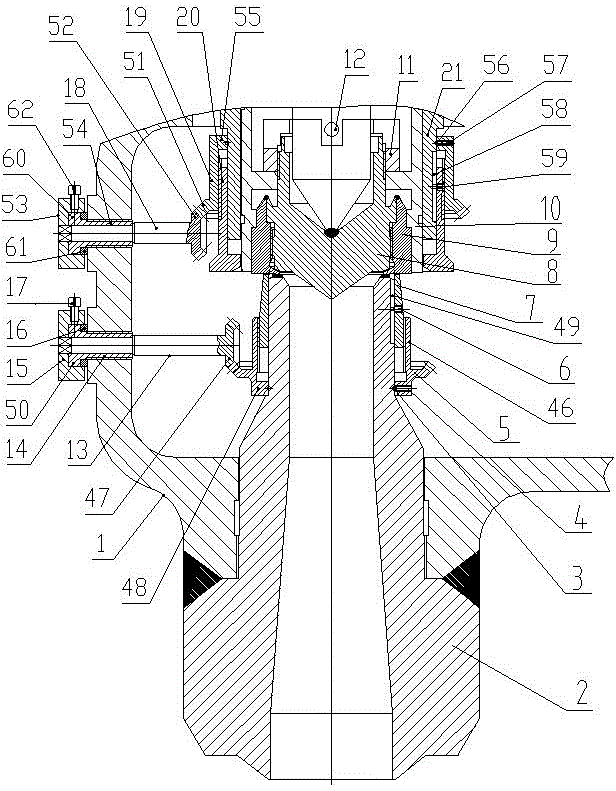

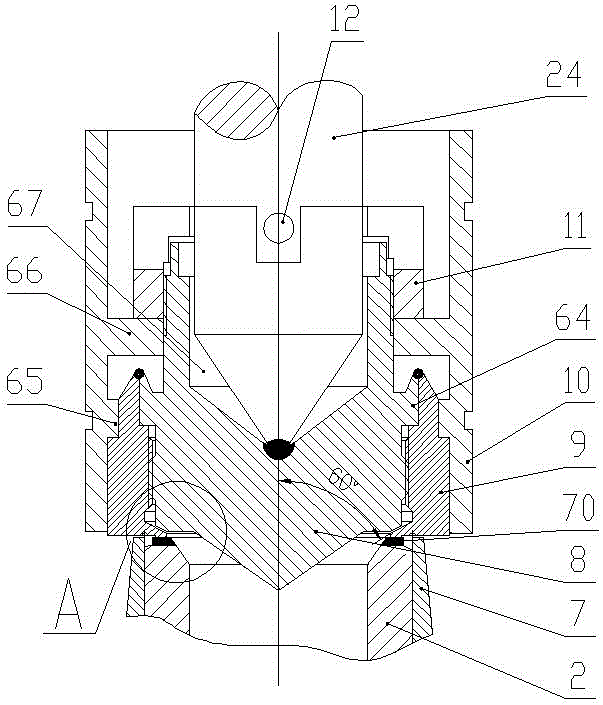

High-temperature high-pressure safety valve with combined adjustable elastic seal disc

ActiveCN106246938AEliminate the regulation of fearEliminates loose factors that change its positionEqualizing valvesSafety valvesEngineeringHigh pressure

A high-temperature high-pressure safety valve with a combined adjustable elastic seal disc comprises a valve body, a valve seat, radiating fins, a valve stem, a bonnet and a hood; the valve body is connected at the top with the lower end of the bonnet through the radiating fins, the bonnet is arranged at the upper end of the hood, the lower end of the valve stem is provided with a combined adjustable disc component that is in crimped hermetic fit with the upper end of the valve seat, the upper portion of the valve stem is provided with a spring compressed anti-loosing anti-torsion structure positioned in the hood, a guide sleeve is arranged in the valve body, the lower portion of the guide sleeve is sleeved with an upper adjusting ring, and the upper portion of the valve seat is sleeved with a lower adjusting ring; the side of the valve body is provided with an upper gear adjusting mechanism for adjusting the upper adjusting ring in vertical motion and a lower gear adjusting mechanism for driving the lower adjusting ring in vertical motion. The action to adjust the safety valve from outside of the valve body is safe, reliable and accurate; the combined adjustable disc component is easy to process and high in assembly precision and provides improved valve sealing reliability and backflushing effect; spring torsion possibly occurring in compression or resilience of the spring is eliminated.

Owner:KAIFENG RUIFA HIGH & MIDDLE PRESSURE VALVE

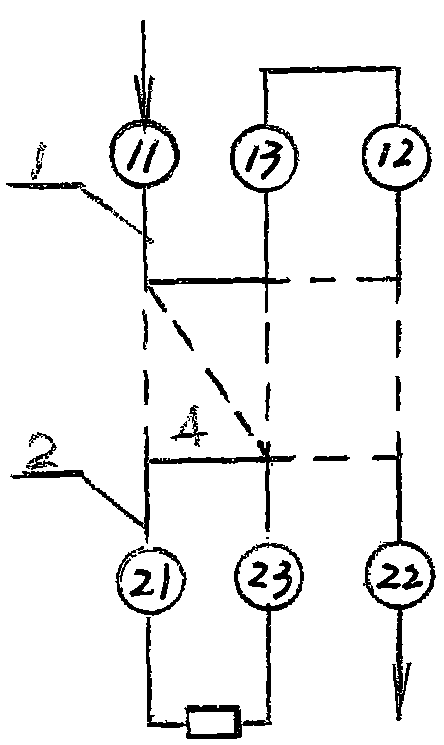

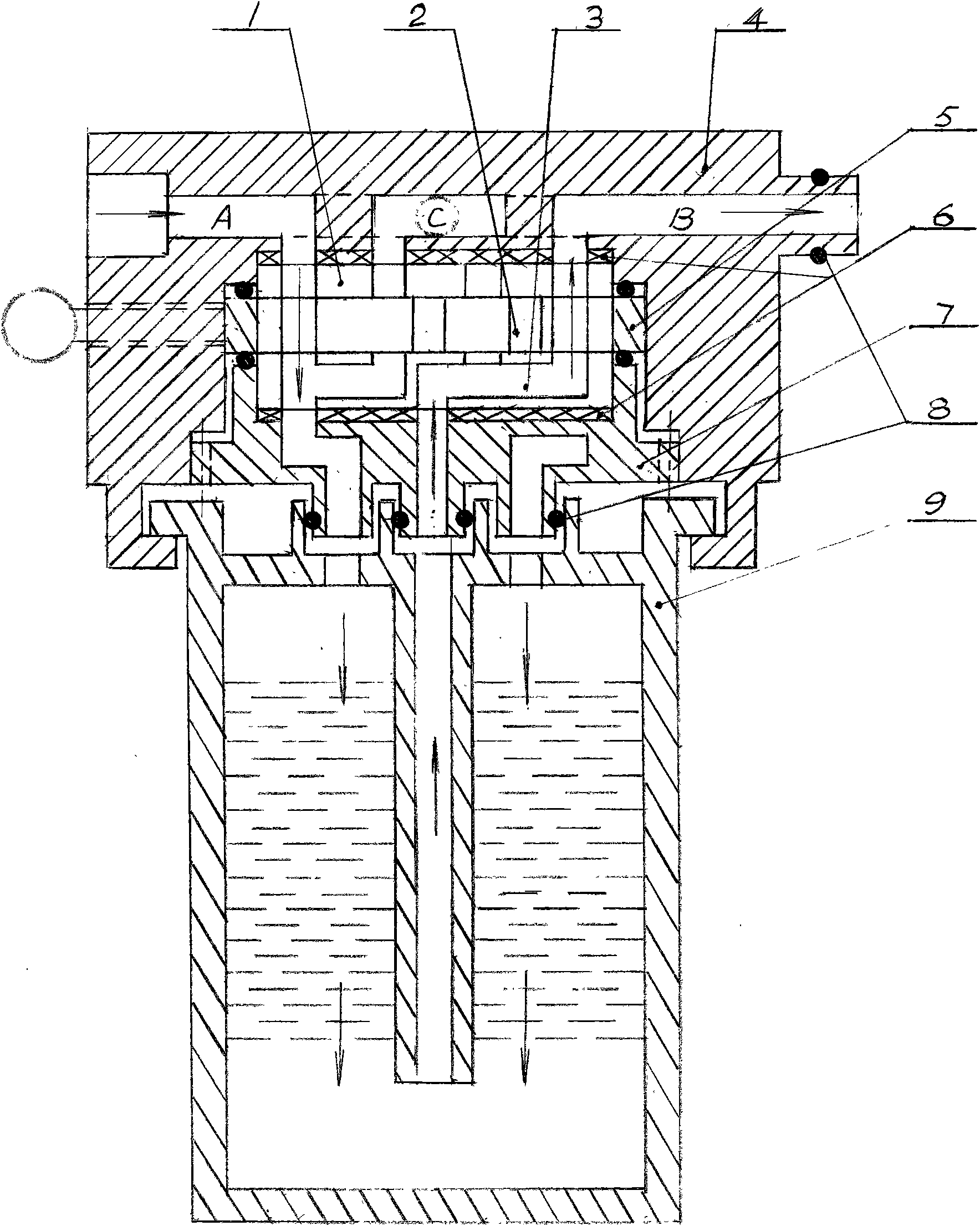

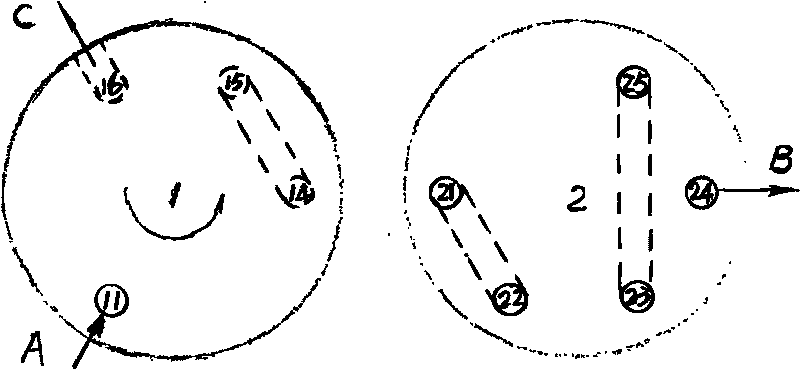

Backwashing water purifier

InactiveCN101564610AEasy to observe directlySimple structureWater/sewage treatmentLoose filtering material filtersFiltrationWater channel

The invention relates to the water treatment industry, in particular to deep filtration and purification of drinking water. The invention discloses a backwashing water purifier which comprises a base and a filter element, wherein a double interface water path switcher and a sealing gland are also arranged in the base; the double interface water path switcher comprises an upper disk, a middle disk and a lower disk which are respectively provided with a switching water slot; the sealing gland is in contact and matched with the upper disk, the middle disk, the lower disk and the base; the water path switcher respectively comprises 5 to 8 pairs of equally divided switching positions; the switching water slot of the upper disk is respectively communicated with independent water channels A, B and C; the water slot of the lower disk is communicated with the water slot of the filter element; the middle disk which is positioned between the upper disk and the lower disk can rotate to simultaneously carry out sealing switching to the two switching interfaces; and the communicated relations among the switching water slots of the three disks can be changed along with the rotation of the middle disk. The invention has the advantages of simple and practical structure, low cost, easy control of the assembling quality, visual backwashing conditions, good effect and good environmental adaptability.

Owner:杜也兵

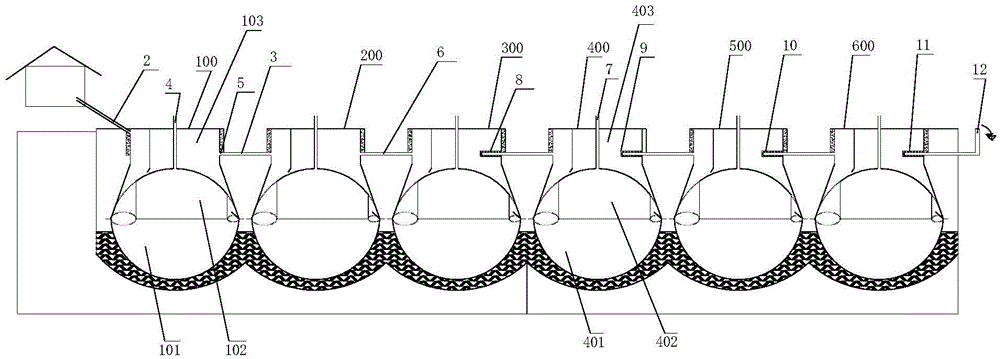

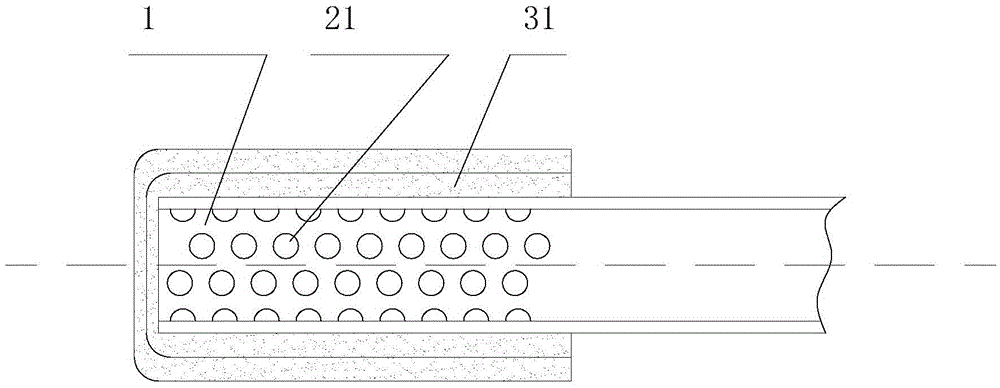

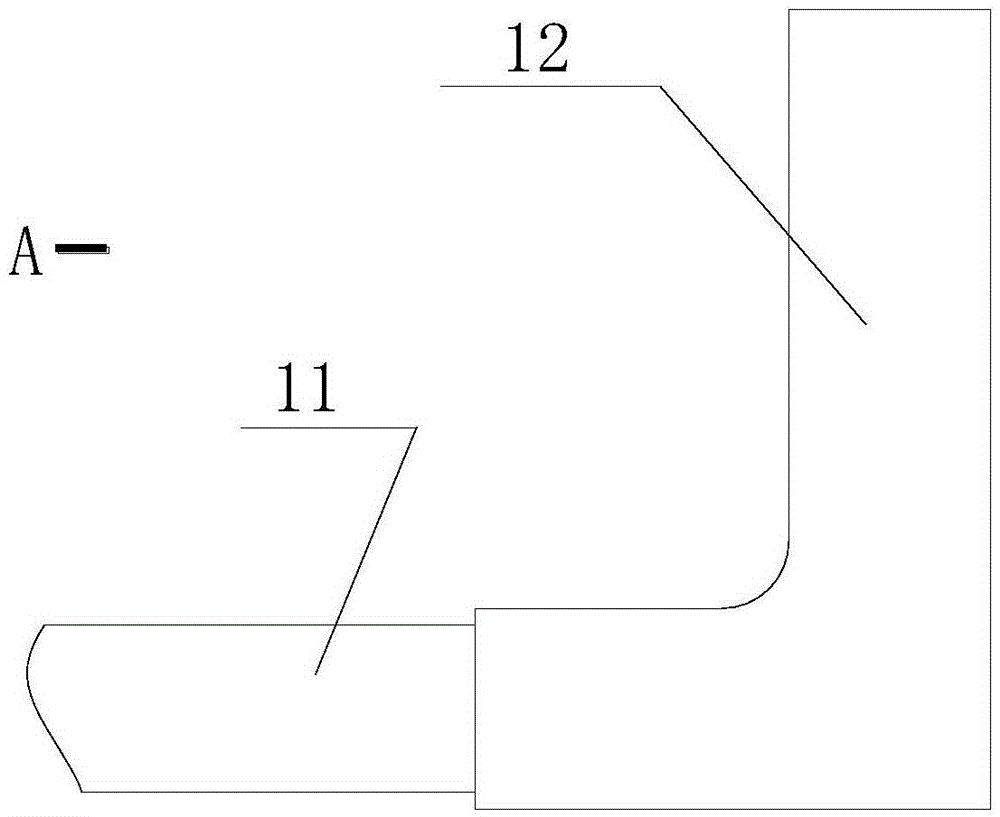

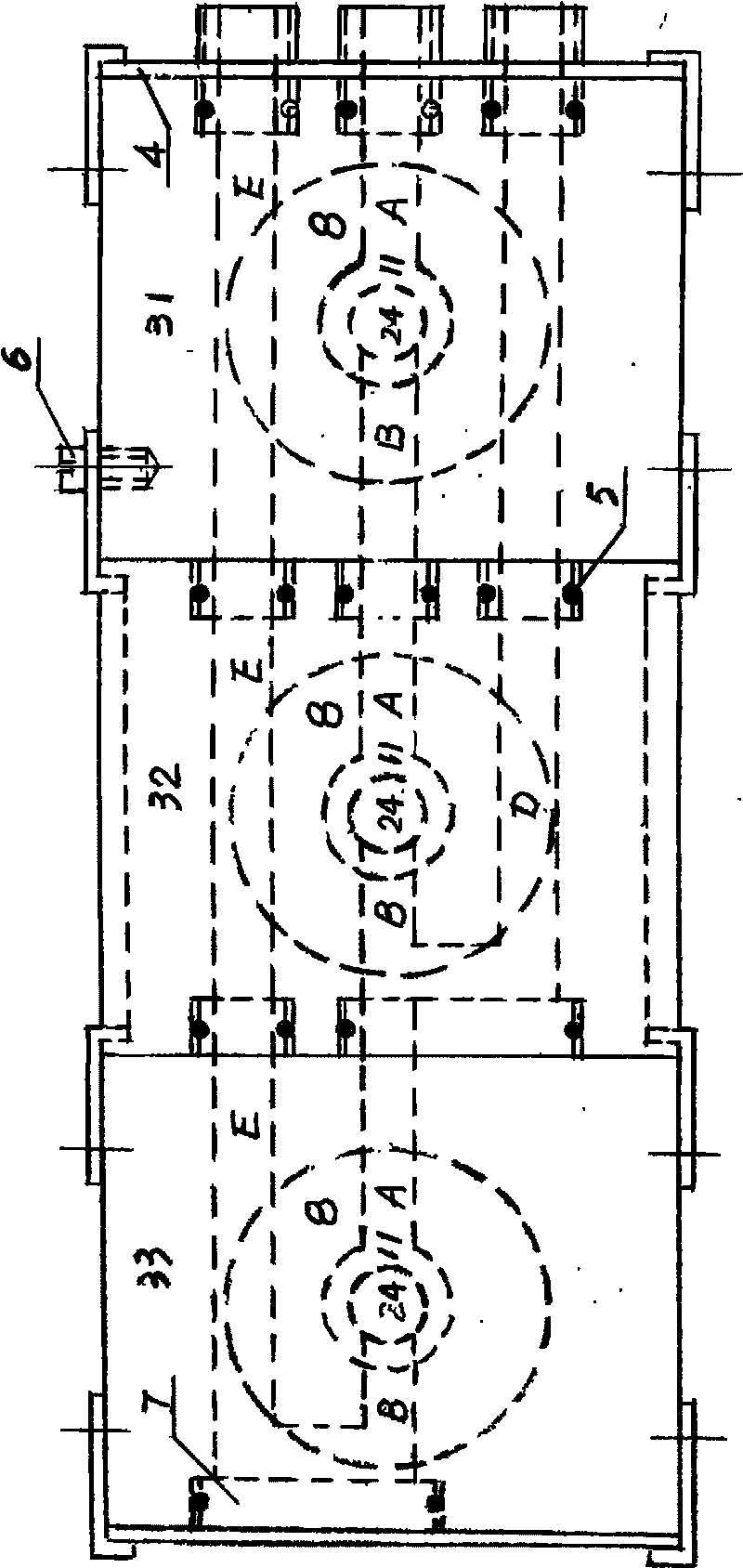

Biogas slurry multistage-fermentation and multistage-filtering purification system

ActiveCN105647792ASave land resourcesIncrease productionBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasWhole systems

The invention discloses a biogas slurry multistage-fermentation and multistage-filtering purification system, which comprises a multistage-fermentation system and a multistage-filtering purification system, wherein the multistage-fermentation system is communicated with the multistage-filtering purification system; the multistage-fermentation system comprises at least three fermentation pool units; the three fermentation pool units are sequentially communicated through a flow guide pipe; the multistage-filtering purification system comprises at least three filtering pool units; the three filtering pool units are sequentially communicated through a filtering pipe; the first fermentation pool unit is connected with a feeding opening; the third filtering pool unit is connected with a water discharge pipe. The biogas slurry multistage-fermentation and multistage-filtering purification system has the advantages that large-batch factory production is convenient; great convenience is brought for transportation and installation; in addition, the whole system is buried under the ground; plants can be planted in gaps above and beside pools; a large number of land resources are saved; independent maintenance can be realized; during maintenance, the operation of other units of the system cannot be influenced; the production of biogas low-carbon biological energy sources is greatly improved; the water pollution is effectively treated.

Owner:CHENGDU SHUNMEI INT TRADE

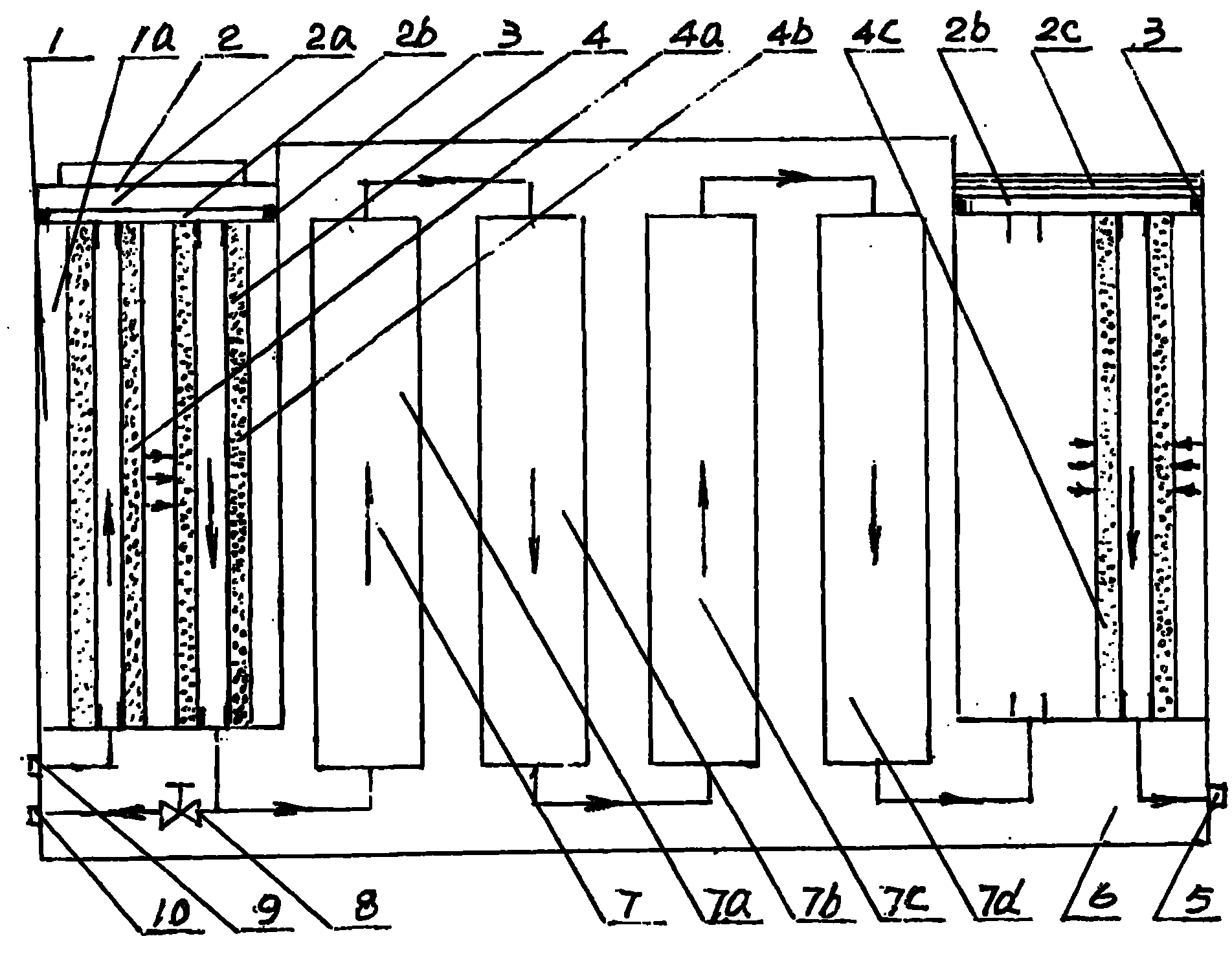

360-degree inflow rotation type underwater filter bed device and filtering method

ActiveCN103272416ALarge filter areaSave filter materialLoose filtering material filtersGravity filtersFilter materialSuspended matter

The invention relates to the technical field of filtering, and in particular relates to a 360-degree inflow rotation type underwater filter bed device and a filtering method; the filter bed device is arranged below the horizontal plane; an air pipe is arranged in a central pipe; the central pipe is connected to a general water outlet pipe; a driving device and a plurality of filtering units are arranged on the central pipe; the driving device drives the filtering units to rotate in 360 degrees by taking the central pipe as the centre; each filtering unit is composed of a filter bed, an outer cover plate of the filter bed and an inner cover plate of the filter bed; the inner cover plate of the filter bed is arranged on the outer ring of the central pipe; the outer cover plate of the filter bed is arranged on the outer ring of the inner cover plate of the filter bed; the filter bed is arranged between the inner cover plate of the filter bed and the outer cover plate of the filter bed; and a shell is arranged outside the outer cover plate of the filter bed. Compared with the prior art, the 360-degree inflow rotation type underwater filter bed device and the filtering method disclosed by the invention have the advantages that on the premise of having the same occupation area, the filtering area of the 360-degree inflow rotation type underwater filter bed device can be increased by multiple times; simultaneously, filter materials are saved; the filter speed is increased; and the 360-degree inflow rotation type underwater filter bed device is low in requirements of the strength of an outer structure and inflow suspended matters, low in loss of a filtering head, centralized in backwash gas, high in strength and good in filtering effect.

Owner:上海复旦水务工程技术有限公司

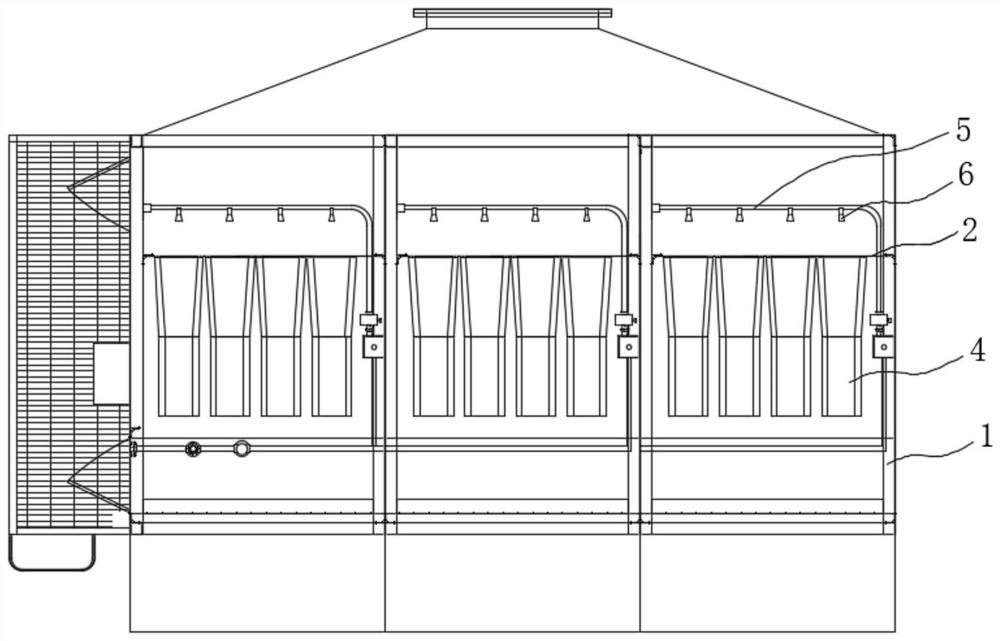

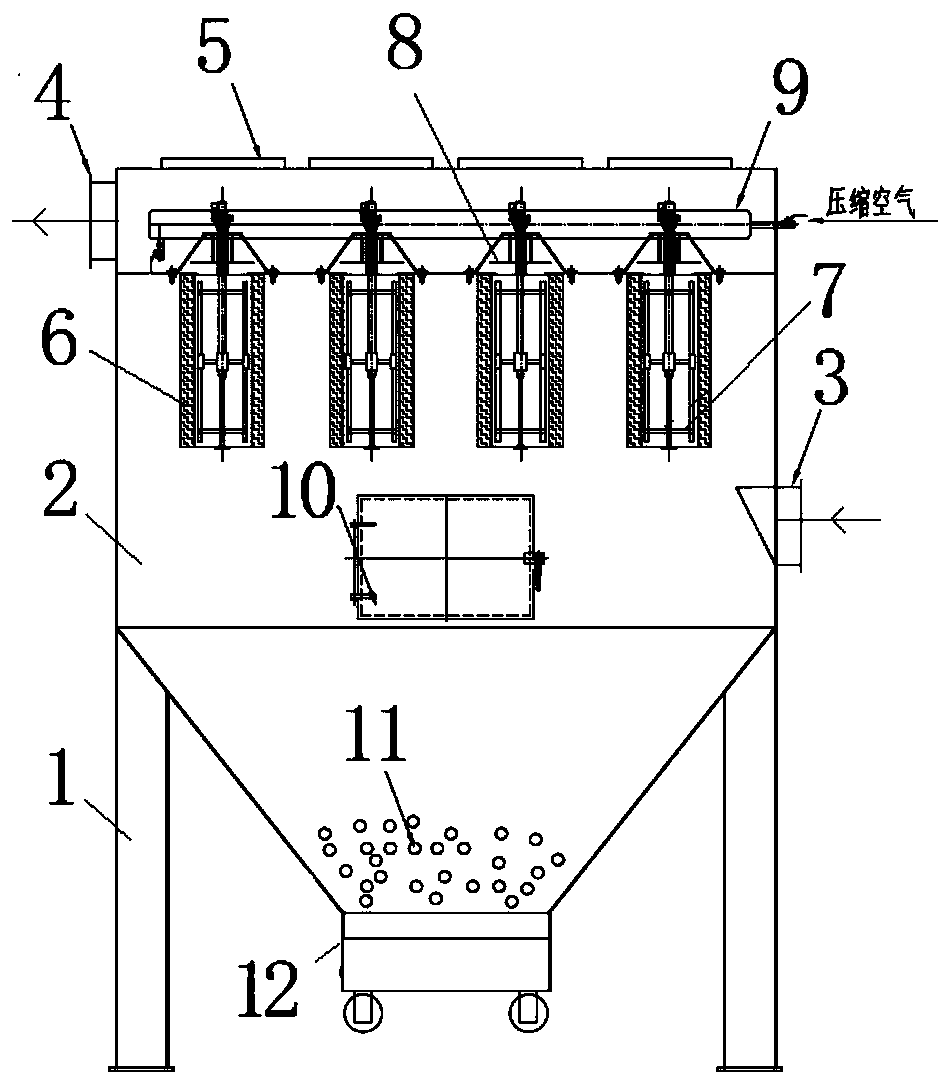

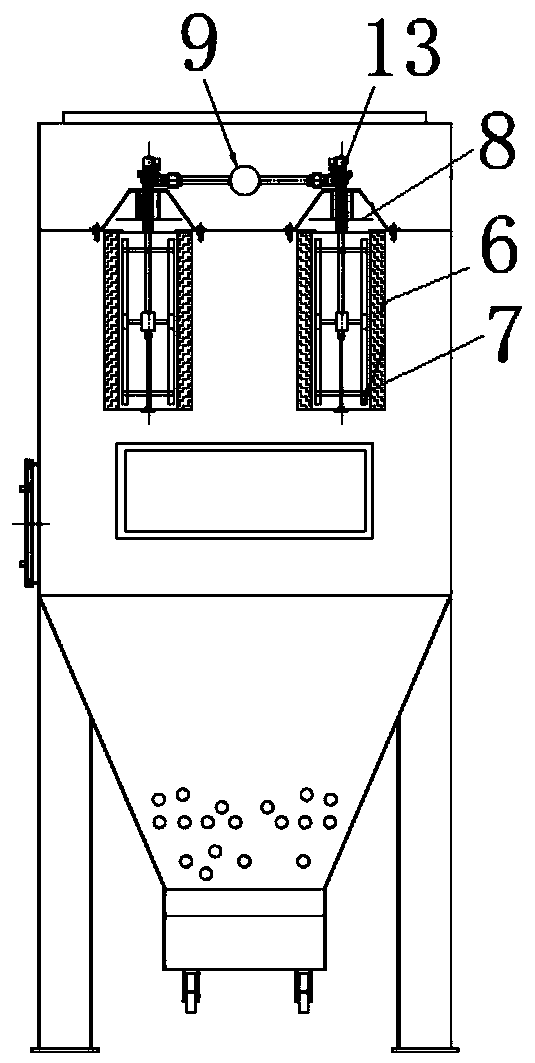

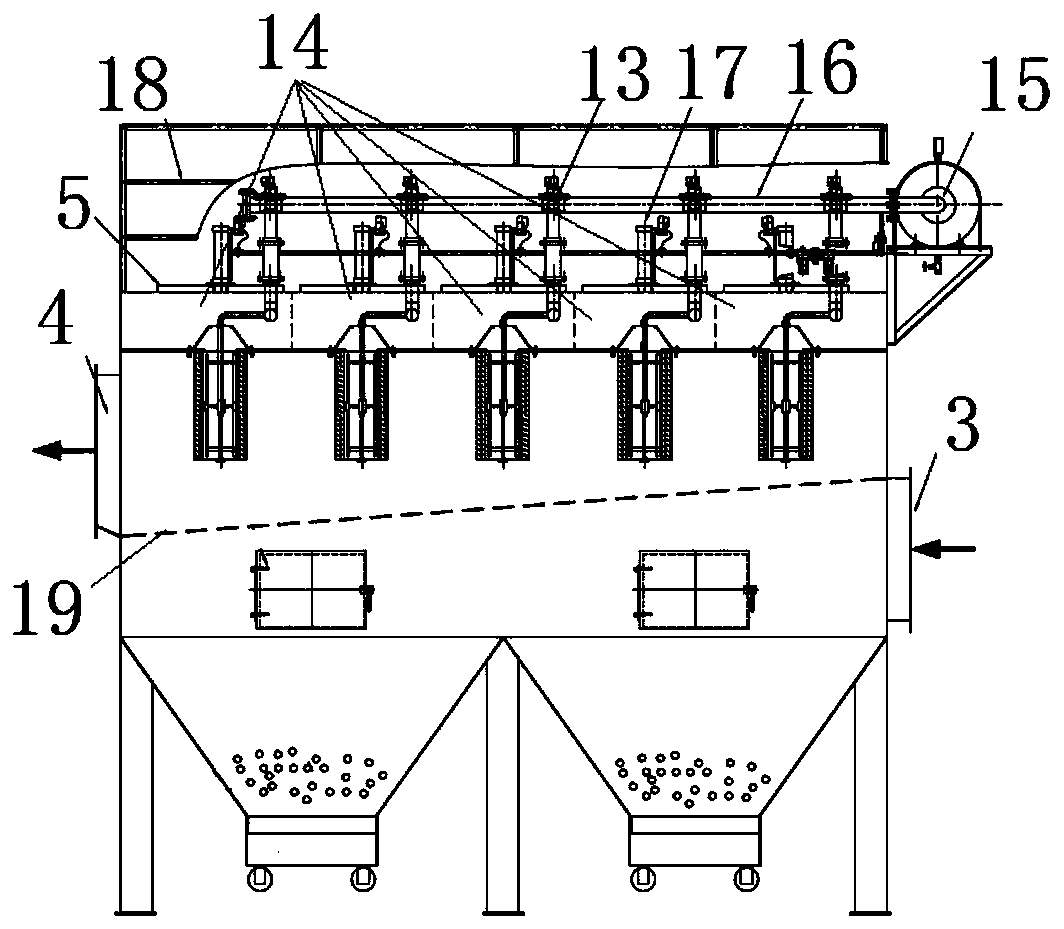

Pulse filtration blowback system for gas turbine

ActiveCN112337202AImproves recoil cleaningIncrease forceDispersed particle filtrationTransportation and packagingFan bladeMechanics

The invention discloses a pulse filtering blowback system for a gas turbine, and belongs to the technical field of filtering blowback. The pulse filtering blowback system for the gas turbine comprisesa rainproof shed; a tube plate is installed in the rainproof shed and close to an air outlet; a filter element support is bolted to the side, away from an outlet of the rainproof shed, of the tube plate; a filter element is fixed on the outside of the filter element support; a drain channel is arranged inside the rainproof shed and below the filter element. According to the pulse filtering blowback system for the gas turbine, high-pressure airflow passes through fan blades in a connecting and fixing cylinder and acts on the fan blades, the fan blades and the connecting and fixing cylinder outside the fan blades can be driven to rotate, and therefore, an inclined nozzle is made to rotate; the air flow can spray the inner part of the filter element in circles. Compared with a mode in whichthe axis direction of the filter element coincides with the axis of the filter element, the above mode makes the air flow generated by the nozzle move closer to the filter element, and therefore, larger acting force can be generated on dust attached to the filter element, and the problem that the backflushing cleaning effect is poor is solved.

Owner:WUXI HUANAN STEEL STRUCTURE ENVIRONMENTAL

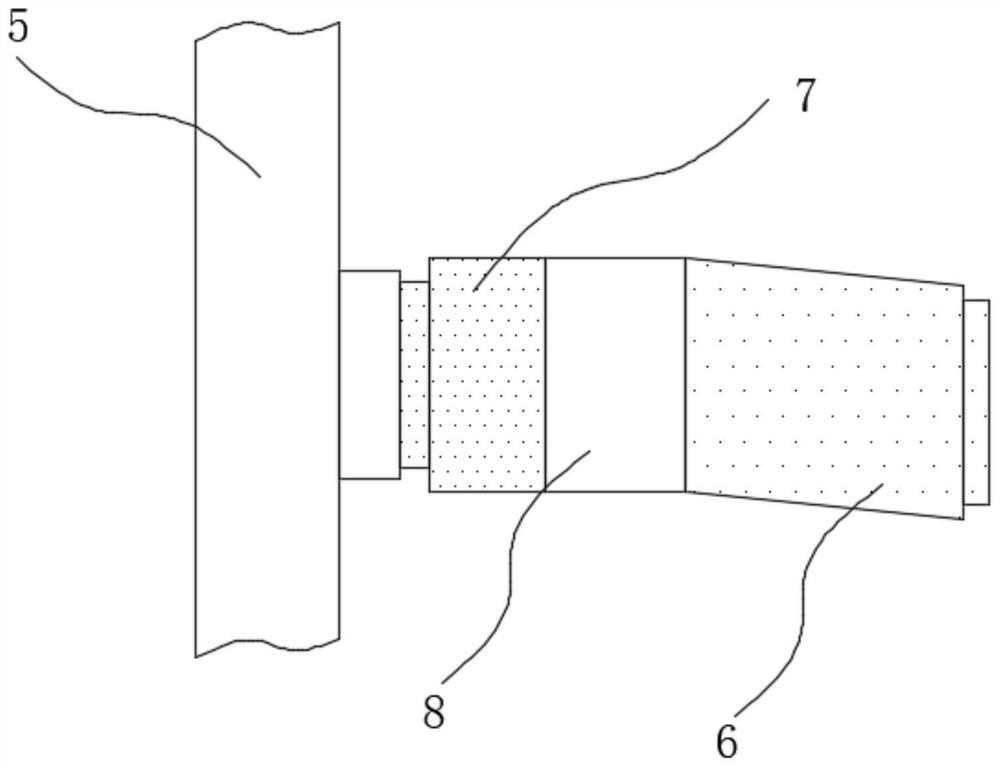

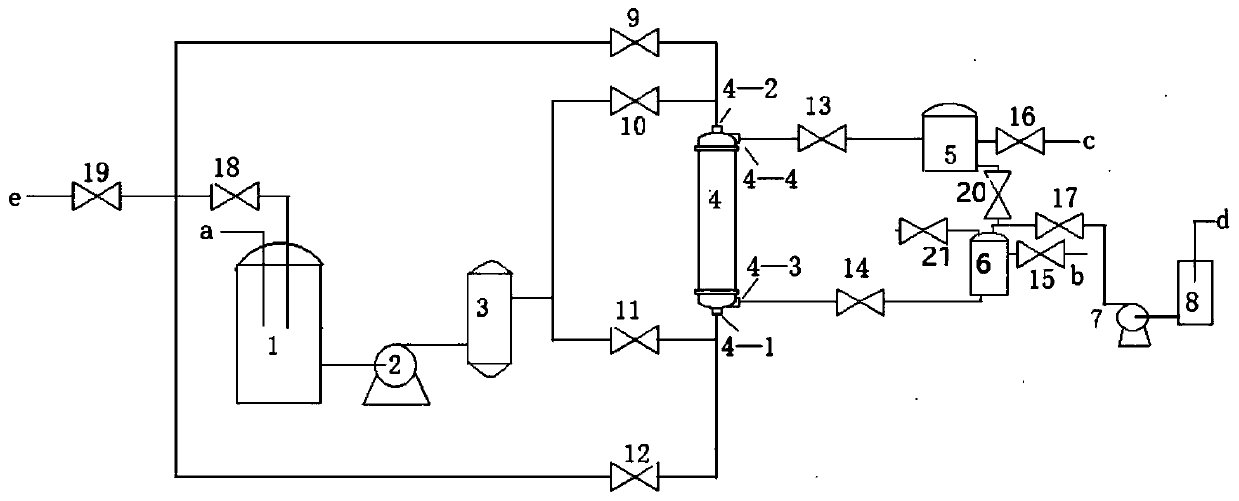

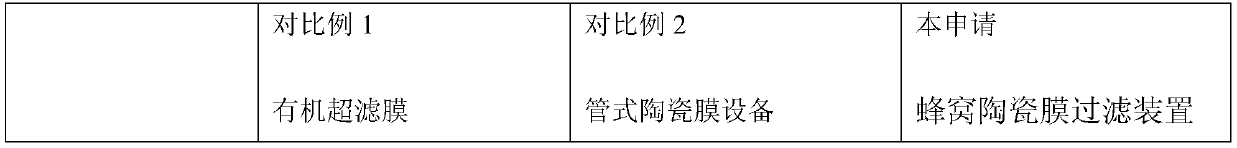

Filtering method and device using honeycomb ceramic membrane

PendingCN110745910AReduce membrane foulingHigh throughputWaste water treatment from quariesSemi-permeable membranesComposite materialEngineering

The invention discloses a filtering method and device using a honeycomb ceramic membrane. The filtering method using the honeycomb ceramic membrane comprises the following steps of feeding a to-be-treated liquid into a honeycomb ceramic membrane assembly for filtering in a bidirectional periodically-changed feeding manner; during filtering, performing periodic back flushing, and performing matchedperiodic forward flushing with the same frequency at the same time. According to the filtering method and device, bidirectional pulsating feeding is adopted, so that turbulence caused by periodic direction conversion is fully utilized to reduce membrane pollution, and light-contaminated membrane portions at inlet and outlet ends are fully utilized to maintain relatively high membrane flux operation. Periodic gas-dissolved mixed liquid is adopted for back flushing, so that a ceramic membrane aeration head and a gas dissolving principle are fully exerted, nano-scale bubbles and liquid-mixed liquid are generated for back flushing, the back flushing effect is enhanced, a back flushing pump is not needed, and energy is saved; periodic forward flushing with the same frequency is carried out while back flushing is carried out, and liquid is adopted as a forward flushing medium, so that contaminants can be brought out of a system in time after back flushing, and flux can be recovered instantly on line.

Owner:南京钛净流体技术有限公司

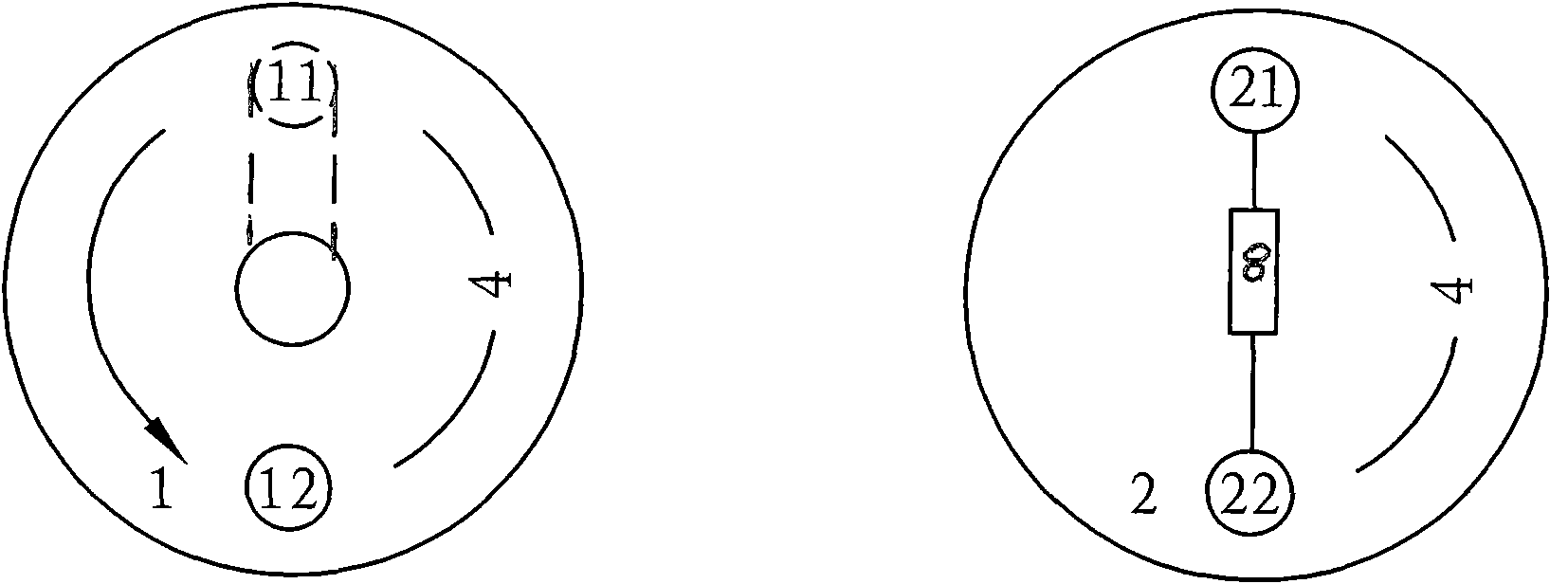

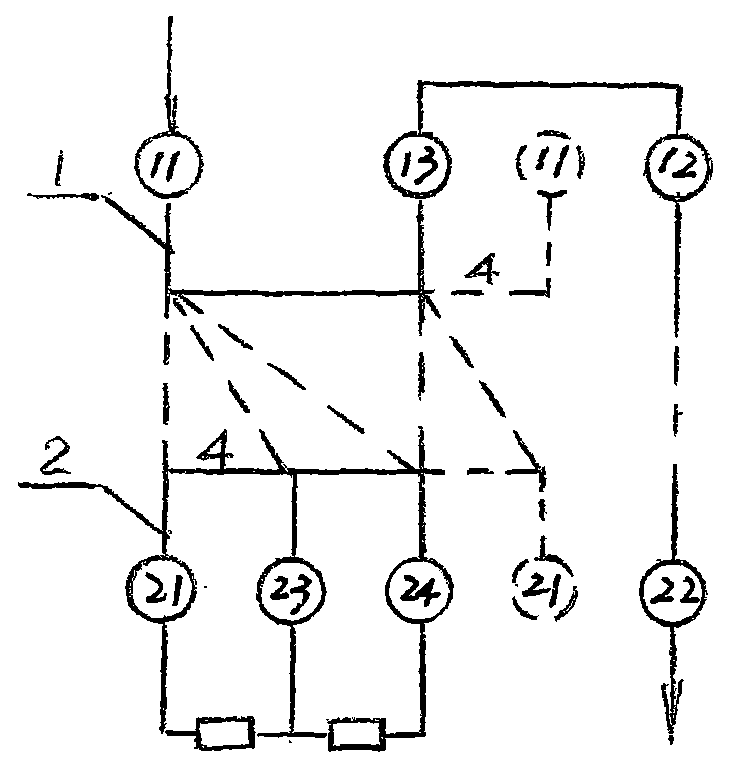

Filtering and back-flushing method of ceramic filter element of water purifier

InactiveCN101954242ALighten the burden of filtrationGuaranteed filtration accuracySemi-permeable membranesWater dischargeFiltration

The invention relates to the water treatment industry, in particular to the aspect of deep filtration and purification of drinking water. The invention discloses a filtering and back-flushing method of a ceramic filter element of a water purifier. The pipeline of a water treatment device comprises a water path switcher and a ceramic filter element device controlled by the water path switcher; the water path switcher is provided with a back-flushing water discharge port; an inflow / outflow water switch port of a connection disk of the water path switcher is serially communicated in the pipeline of the water treatment device; an inflow / outflow water switch port of a controlled disk of the water path switcher is communicated with a water inlet and a water outlet of the controlled ceramic filter element device; a sealed switch interface is formed between the connection disk and the controlled disk, and related water switch ports are formed at corresponding equational switch positions respectively; and a filtering channel and a back-flushing channel of the controlled ceramic filter element device are formed through relative shift of the positions of the water switch ports on the connection disk and the controlled disk respectively. The invention has the advantages of effectively eliminating influence of carbon loss on the drinking water and prolonging the service life of the rear fine filter element, along with simple and practical structure, low cost and good filtering and back-flushing effect.

Owner:杜也兵

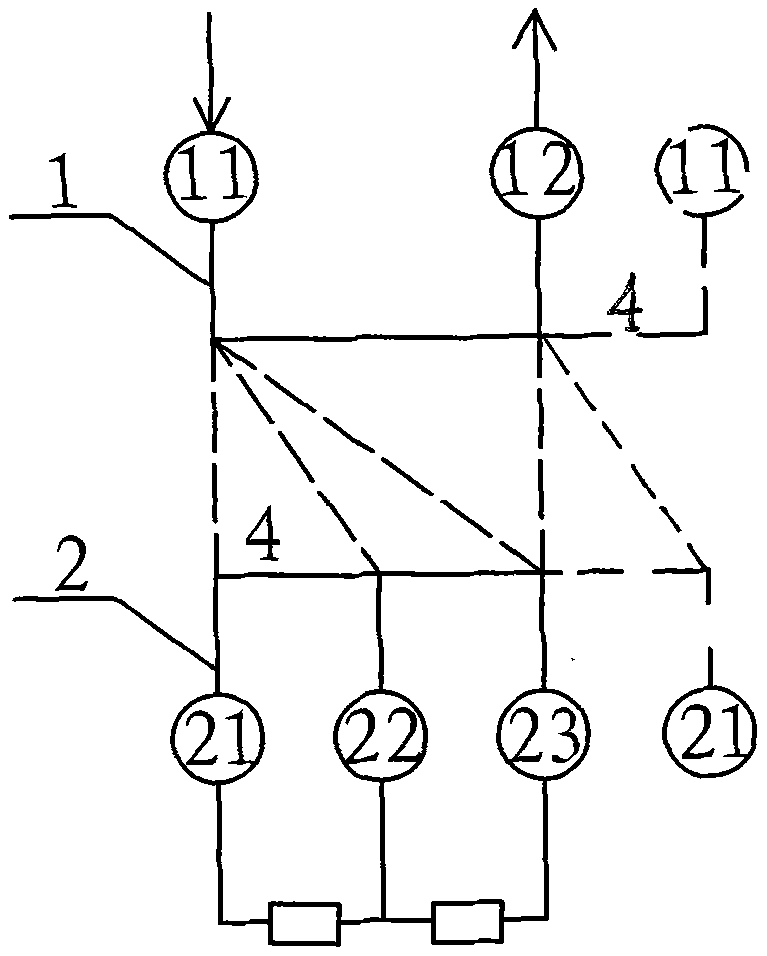

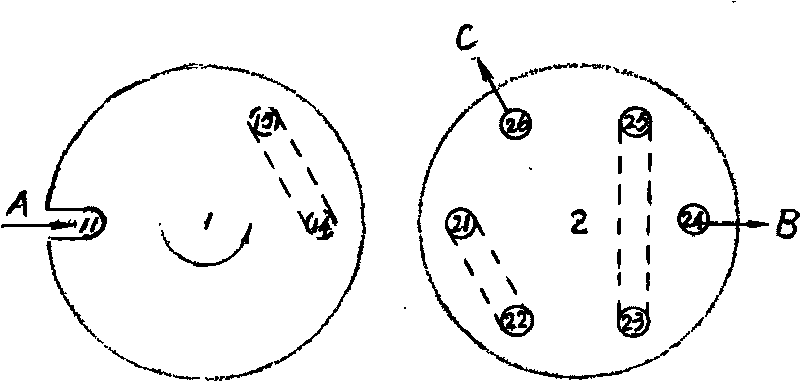

Segment connection method of pipes of multi-machine base water purifier

InactiveCN101734733AGood recoil effectExtended service lifeWater/sewage treatmentMulti machineFiltration

The invention relates to the water processing industry, in particular to depth filtration and purification of drinking water. The invention discloses a segment connection method of pipes of a multi-machine base water purifier. The water purifier comprises a machine base with water inlet and water outlet pipes A, B. The machine base is additionally provided with a water inlet connector and a water outlet connector. The water inlet connector and the water outlet connector communicate filter elements and are connected with the corresponding water inlet and water outlet pipes A, B to form a filtration passage. The invention also comprises independent pipes E arranged on the machine base. The independent pipes E are mutually connected in segment along with the connection between the water inlet and water outlet pipes A, B of each machine base, are connected with related water outlets of the machine bases and extend to the vicinity of the water inlet pipe A of a primary machine base. The water purifier has the following advantages: the structure is simple, the assembly and production efficiency is high and the quality is stable; the filter elements are characterized by thorough backwashing and visual effects; the water purifier meets different demands for drinking water and used water; the service lives of the filter elements are prolonged; and pipe arrangement is neat, the occupied space is small and the product grade is improved.

Owner:杜也兵

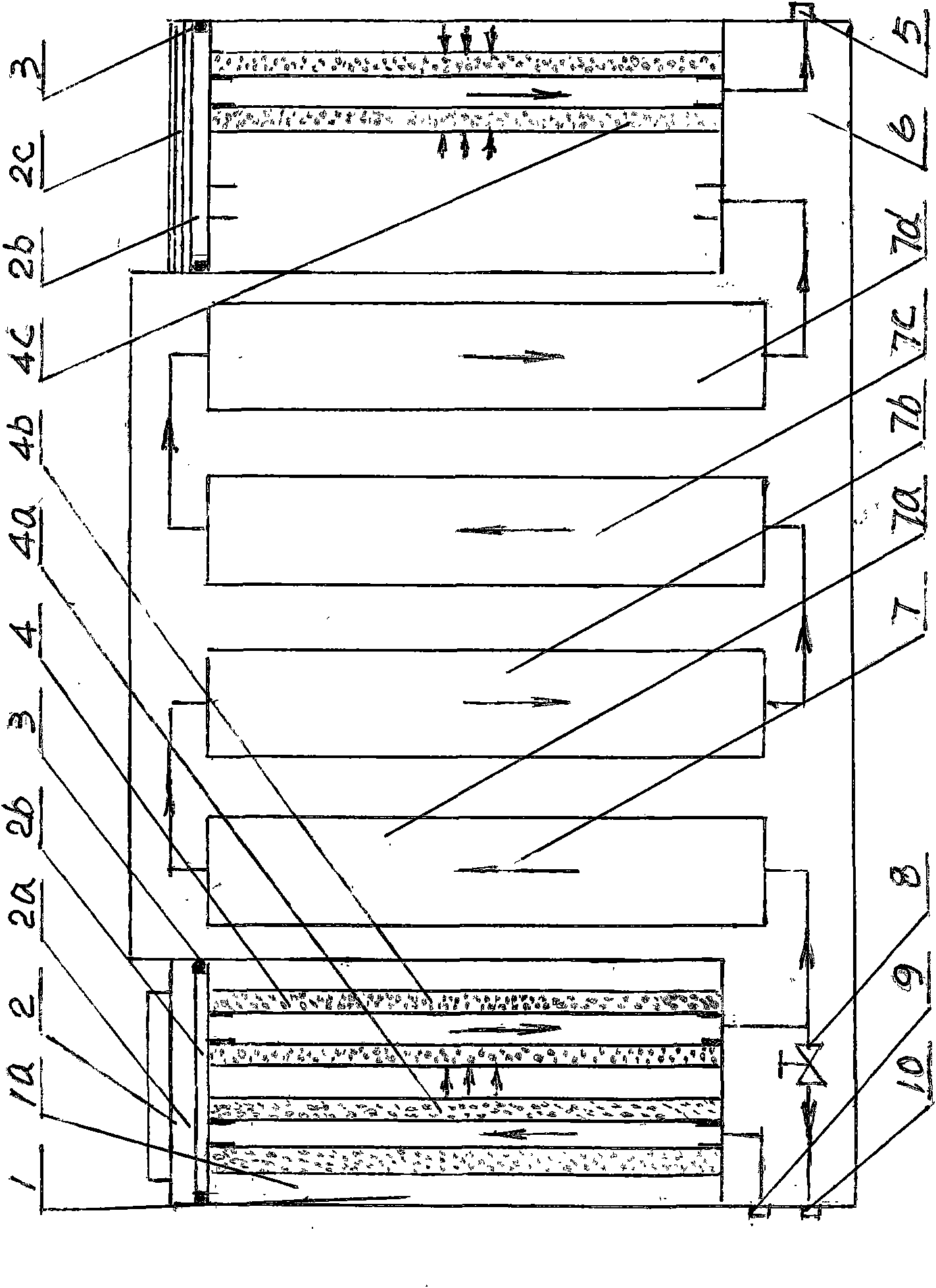

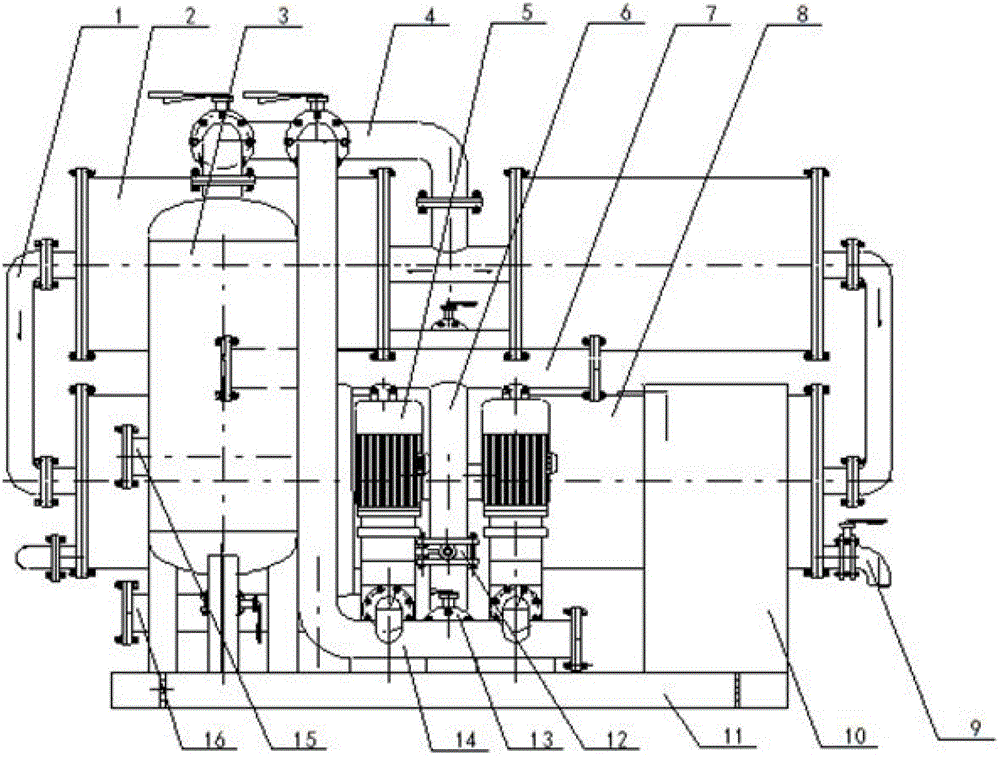

Pressurization back-washing and recharging fine filter unit

The invention relates to a pressurization back-washing and recharging fine filter unit, which comprises a primary filter, one-stage filters and second-stage filters, wherein a main water inlet pipe is arranged on the primary filter; the primary filter is respectively communicated with the one-stage filters through water branch pipes; the water outlet branch pipes of the one-stage filters are communicated with the second-stage filters; the water outlet branch pipes of the second-stage filters are communicated with a main water outlet pipe; the first-stage filters and the second-stage filters are respectively provided with waste water pipes; the first-stage filters and the second-stage filters are all horizontally arranged; a back-washing pipe is communicated near the water branch pipe of the primary filter; and a recharging pipe is arranged at the bottom end of a back-washing vertical pipe forward. Filtering, back-washing and recharging are organically combined together in the filter unit, and the filtering, back-washing and recharging of the unit are realized through scientifically arranged pipelines by adopting only one (or one set of) booster pump, so that the unit is compact in the whole unit structure, small in occupied space and low in cost while multiple functions are realized.

Owner:天津市盛泉潜水电机有限公司

Diversion device based on environment-friendly sewage treatment

InactiveCN111804035AImprove filtering effectImprove passabilityStationary filtering element filtersSewageSewage treatment

The invention discloses a diversion device based on environment-friendly sewage treatment, relates to the technical field of environmental protection equipment, and solves the problem that impuritieson a filter screen cannot be effectively cleaned only through the flushing effect of reverse flowing water when an existing sewage flow dividing device is used, the flow dividing effect is poor, meanwhile, if impurities are not well cleaned for a long time, meshes are prone to being blocked, the filtering capacity of a filtering net is reduced, and the service life of the filtering net is affected. The device comprises an outer shell. The left end face of the outer shell is fixedly connected with a set of driving piece. A set of filtering piece is rotationally connected to the interior of theouter shell; the filtering piece is coaxially and fixedly connected with a rotating shaft of the driving piece; and a set of backflushing piece is fixedly connected to the interior of the right side of the outer shell. The device has a good backflushing effect, good trafficability of the filter element is guaranteed, the filtering effect of the filter element is improved, the service life of the filter element is prolonged, and the device has good diversion capacity.

Owner:陈亚森

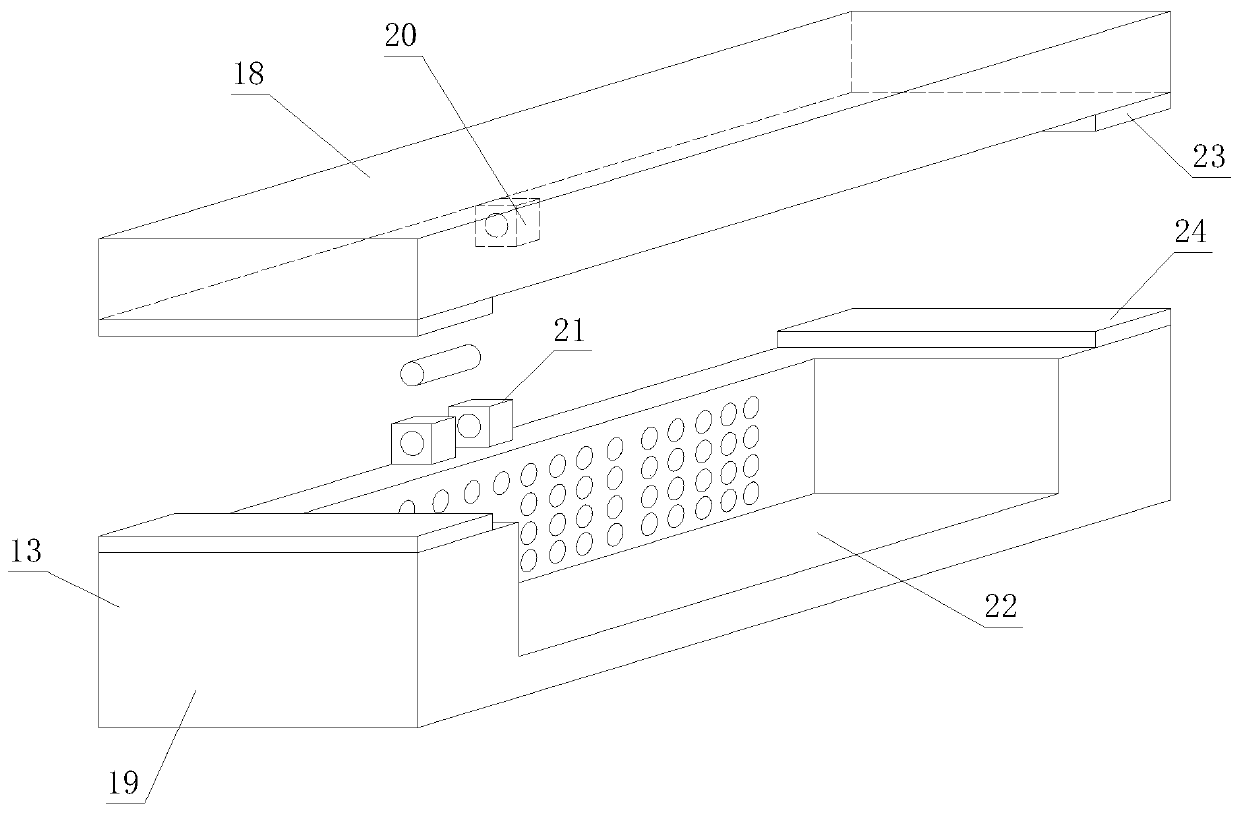

Impregnating device for machining building carbon fiber mesh belt and impregnating method

InactiveCN112337728AImprove impregnation effectImprove impregnation efficiencyLiquid surface applicatorsCoatingsFiberCarbon fibers

The invention discloses an impregnating device for machining a building carbon fiber mesh belt and an impregnating method. The impregnating device comprises an impregnating box, wherein the top of theimpregnating box is open, fixing plates are fixed to the two ends of the outer wall of the top of the impregnating box, feeding rollers are rotatably connected to the two sides between the two fixingplates, and a liquid drain pipe is connected to the bottom end of the impregnating box; and the impregnating box is arranged to be of a horizontally-placed cylinder-like structure, a plurality of annularly-distributed supporting rollers are rotationally connected between the inner walls of the two ends of the impregnating box, and a plurality of annularly-distributed extrusion rollers are rotationally connected between the inner walls of the two ends of the impregnating box. According to the method, the carbon fiber mesh belt drives liquid flow in the impregnating box to flow in the horizontal direction and the vertical direction in the process of moving between the supporting rollers and the extrusion rollers through the interval distribution between the supporting rollers and the extrusion rollers and the distance difference between the supporting rollers and the extrusion rollers and the axis. The impact between the flow of impregnating liquid and the carbon fiber mesh belt is improved, so that the impregnating effect is improved.

Owner:杜亮

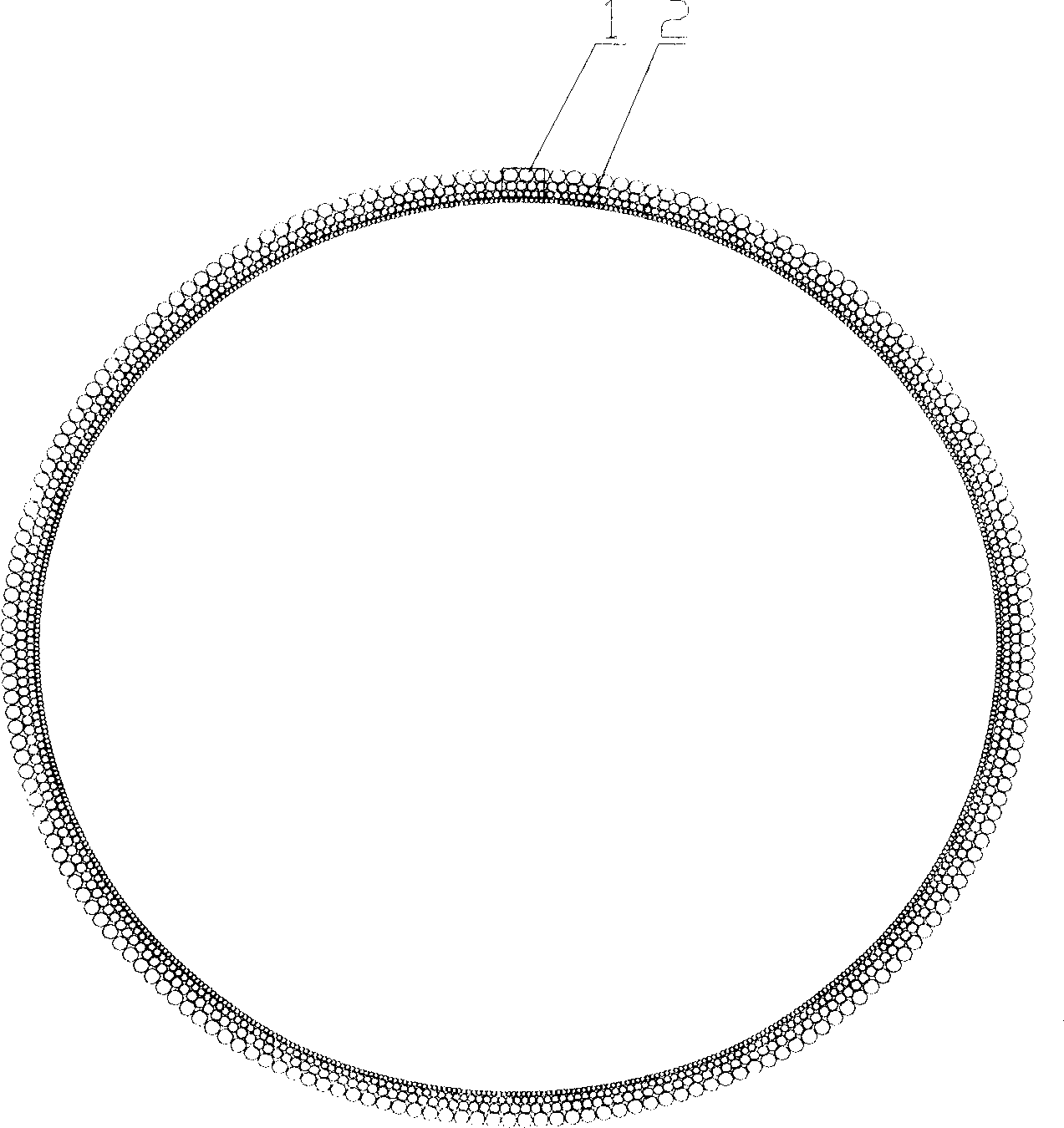

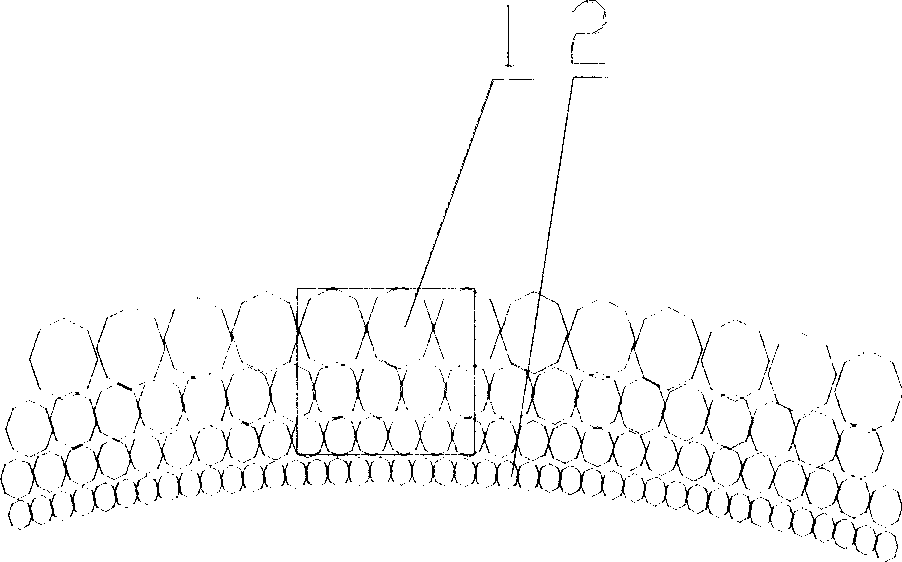

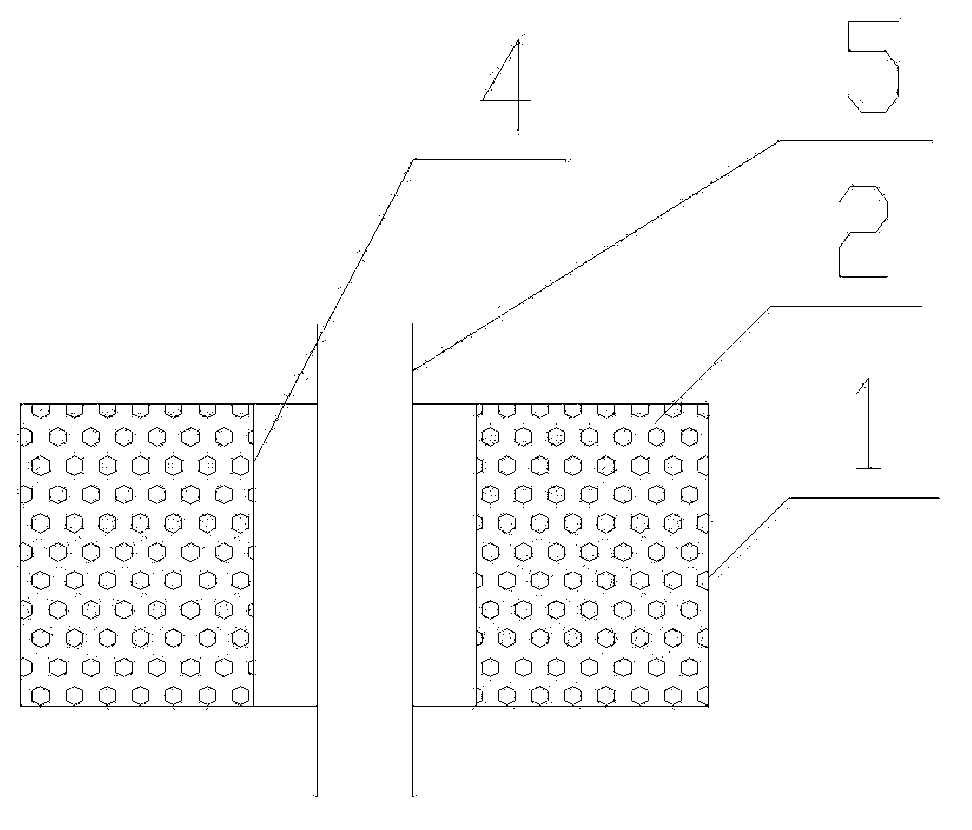

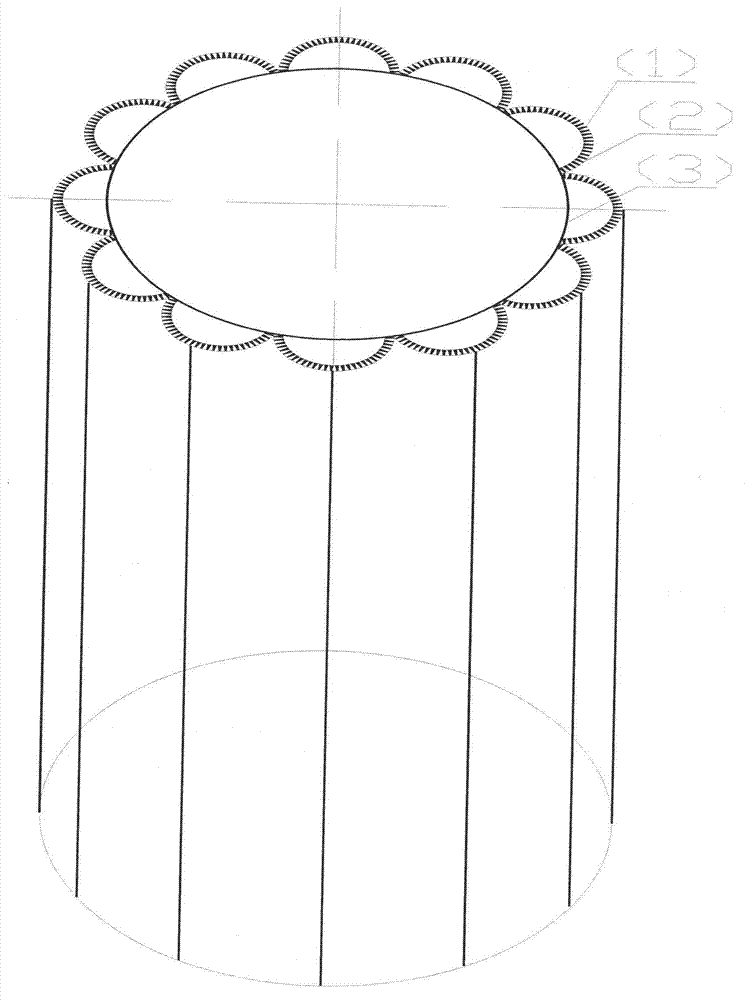

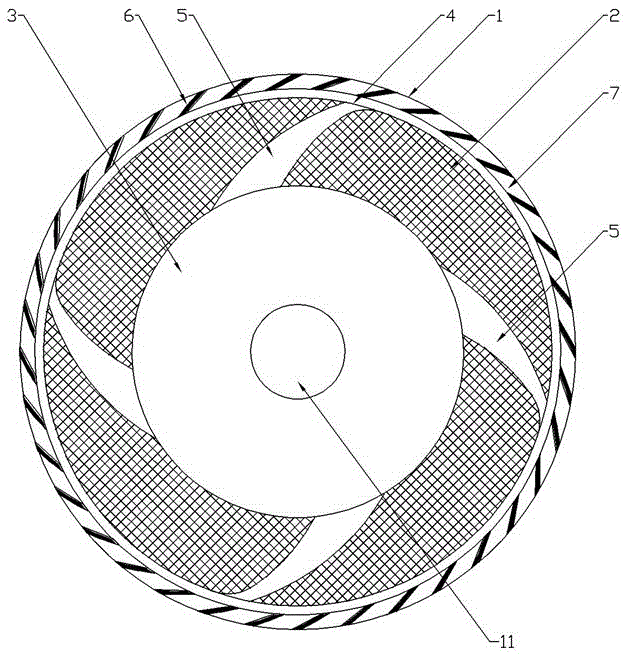

Petal-shaped filter

InactiveCN103585810ALarge amount of water to be treatedLow costStationary filtering element filtersFiltrationPetal

The invention discloses a petal-shaped filter, relates to a water treatment device, and specifically relates to the petal-shaped filter. The petal-shaped filter comprises mesh cylinders (1), vertical ribs (2) arranged between adjacent mesh cylinders, and horizontal ribs (3) arranged between the mesh cylinders. The petal-shaped filter is formed by a plurality of non-closed filter cores and reinforcing ribs, and has the characteristics of smooth surface, uniform gaps, too large filter area, little filtration interference and good backflushing effect.

Owner:杨志江

Chemical reaction system and its filter unit and filter system

ActiveCN106914052BSmall sizeAvoid cloggingChemical/physical processesStationary filtering element filtersChemical reactionFiltration

The invention relates to the field of raw material processing, and discloses a filtering unit, a filtering system and a chemical reaction system. The filtering unit comprises two walls which are oppositely arranged at intervals, a first filtering layer and a second filtering layer, wherein the first filtering layer and the second filtering layer extend between the two walls in the length direction, when the filtering unit performs filtering operation, a deformable device can deform to enable the size of the facing portion of each pair of filtering holes to be smaller than the size of the facing portion of each pair of the filtering holes when the filtering unit is in a natural state; when the filtering unit performs back flushing operation, the deformable device can deform to enable the size of the facing portion of each pair of the filtering holes to be larger than or equal to the size of the facing portion of each pair of the filtering holes when the filtering unit is in a natural state. According to the technical scheme, when the filtering unit performs the filtering operation, the size of the facing portion of each pair of the filtering holes can be reduced, and therefore the effect of fluid filtering is guaranteed, and when the filtering unit performs the back flushing operation, the size of the facing portion of each pair of the filtering holes is increased, so that the effect of back flushing is improved, and blockage of the filtering holes is effectively prevented.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

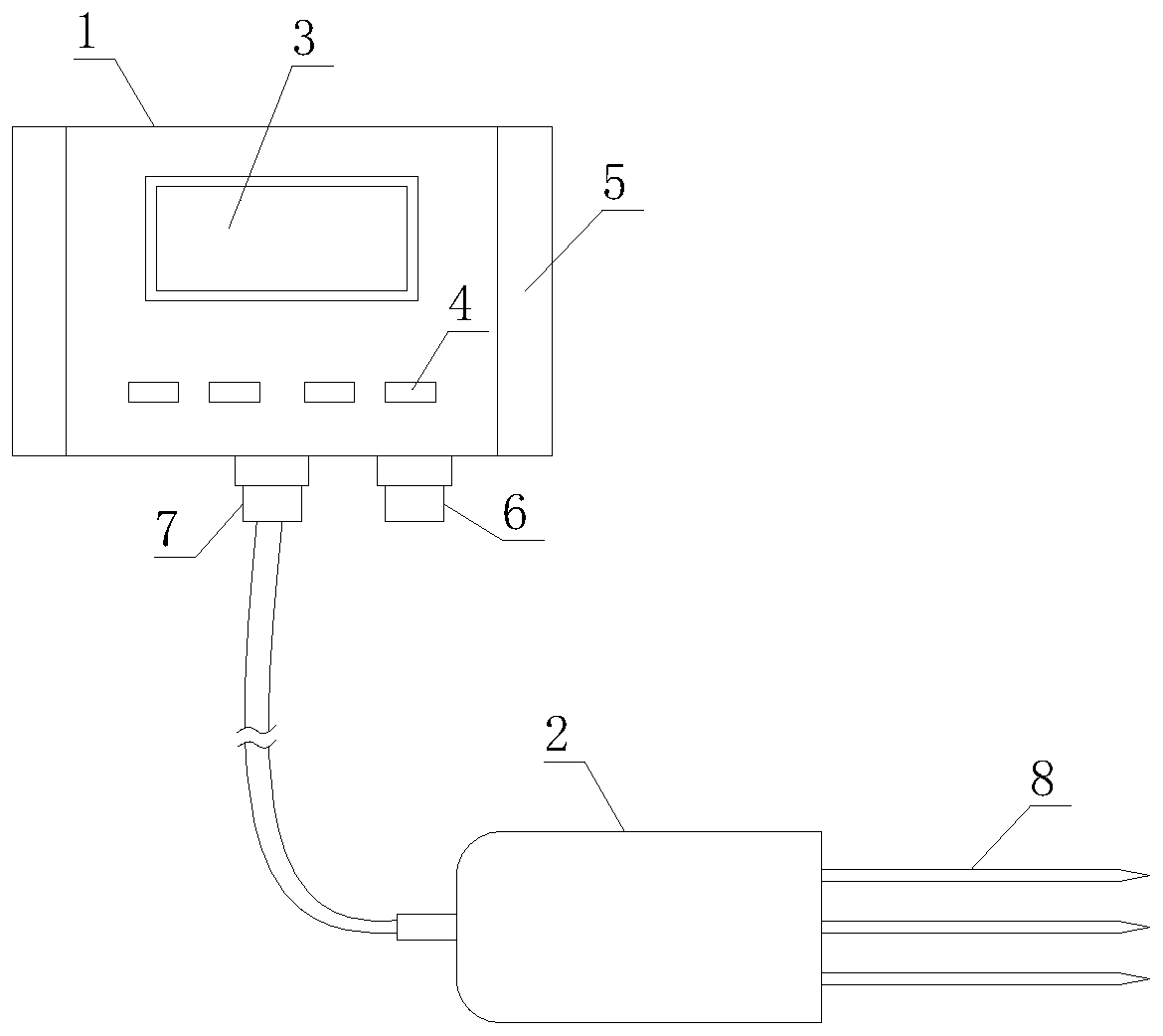

Portable humidity sensor

InactiveCN110231368AImplement bufferingDriving safetyEarth material testingMaterial resistanceEngineeringMoisture sensor

The invention belongs to the technical field of sensors and particularly relates to a portable humidity sensor. The portable humidity sensor comprises a sensor main body and a detection head main body, the portable humidity sensor further comprises a safety protection movable support assembly, the safety protection movable support assembly comprises a bottom plate, side vertical plates and a fixedtop plate; supporting plates are further fixed on the inner sides of the two side vertical plates; mounting strips are respectively fixed at the left end and the right end of the sensor main body, and a bracket assembly is fixed on the opposite surfaces of the side vertical plates respectively; and the lower surface of the top plate is fixedly provided with a pressing assembly. According to the portable humidity sensor in the invention, an adjusting screw rod longitudinally and rotationally mounted on an inner supporting plate is arranged so as to adjust the longitudinal position of an adjusting supporting block, and then the kickback effect of the roller on the sensor main body is improved to the largest extent; a damping tube is communicated with two buffer air bags below the mounting strips, so that the buffering effect of the buffer air bags on the shaking process of the sensor main body is further increased, and the service life of the sensor main body is further prolonged.

Owner:姜超

Backwash filtering equipment and backwash filtering method thereof

PendingCN113181697AEasy to operateGood recoil effectStationary filtering element filtersEngineeringOil intake

The invention discloses backwashing filtering equipment which comprises a valve body, a valve rod is arranged in the valve body in the vertical direction, a compression spring is arranged at the lower end of the valve rod, the upper end of the compression spring is clamped with the valve rod, and a spring clamping seat is arranged at the lower end of the compression spring; an oil guide gap is formed between the lower end of the valve rod and the spring clamping seat; an oil port A, an oil port B, an oil port C and an oil port D are sequentially formed in the valve body from top to bottom in the horizontal direction; an oil inlet and a filter element A are further arranged at the two ends of the valve body respectively, a filter element B is arranged below the filter element A, and an oil guide port is formed in the lower end of the filter element B and communicates with one end of the oil port D; and an oil outlet is formed in the bottom of the valve body and communicates with the other end of the oil port D. The invention further discloses a backwash filtering method, the problem that a handle of an existing backwash filtering device is difficult to shift in a high-pressure system is solved, and the problem that an existing backwash device is poor in backwashing effect in a low-pressure system is also solved.

Owner:SHAANXI RUN TOP TRANSMISSION TECH CORP

Fully-automatic oily sewage filtration-type separator and separating system

InactiveCN101670194BHigh precision filtrationGood recoil effectLoose filtering material filtersGravity filtersFiltrationSewage

The invention relates to a fully-automatic oily sewage filtration-type separator which comprises a tank body, filter material, a water inlet, a water outlet, a cylinder, a pressure plate, an oil collector, a cylinder fixing cover for fixing the cylinder, and a perforated clapboard; a first chamber is formed between the perforated clapboard and the top wall of an inner cavity of the tank body; thewater inlet and the oil collector are arranged at the upper part of the tank body and both communicated with the first chamber; the perforated clapboard is arranged at the upper part of the inner cavity of the tank body and below the water inlet; the cylinder fixing cover is fixed with the lower end of the tank body, and a piston rod of the cylinder passes through the cylinder fixing cover and then extends into the inner cavity of the tank body; a third chamber is formed between the cylinder fixing cover and the pressure plate; the water outlet is arranged at the lower part of the tank body and communicated with the third chamber; a second chamber is formed between the pressure plate and the perforated clapboard, and a filter core is arranged in the second chamber. The invention also relates to a separating system which adopts the fully-automatic oily sewage filtration-type separator. The invention has small occupying area, is unnecessary to filter oily sewage in advance, can not onlyensure high oil-water separation precision, but also carry out automatic backwash on line.

Owner:深圳市兰科环境技术有限公司

Self-cleaning universal filtering device

PendingCN111420489AReasonable structural designCompact structureDispersed particle filtrationTransportation and packagingEnvironmental engineeringMechanical engineering

The invention discloses a self-cleaning universal filtering device, which comprises a filtering box body, the filtering box body is provided with an air inlet pipe for waste gas to enter and an air outlet pipe for filtered gas to be discharged, the device also comprises a filtering barrel which is arranged in the filtering box body, wherein the filtering barrel is of a hollow structure with an opening in one end, the filtering barrel comprises a back-flushing air pipe arranged inside and a metal filtering structure arranged outside the back-flushing air pipe, an air inlet cavity communicated with the air inlet pipe and an air outlet cavity communicated with the air outlet pipe are formed in the filtering box body, an opening in one end of the filtering barrel is communicated with the air outlet cavity, and the metal filtering structure is located in the air inlet cavity. The filtering structure can be in contact with an internal backflushing gas pipe, the backflushing effect is good, waste gas containing oil and water can be filtered, and accumulated ash is efficiently removed. One group of filtering structures are arranged side by side, one filtering structure is closed for backflushing cleaning, other filtering structures operate normally, and the filtering structures do not need to be taken out and production does not need to be stopped during cleaning.

Owner:安徽朝祯环保科技有限公司

Washing machine and control method thereof

ActiveCN105350267BThe total water volume remains the sameExtend your lifeOther washing machinesControl devices for washing apparatusFiltrationPulp and paper industry

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

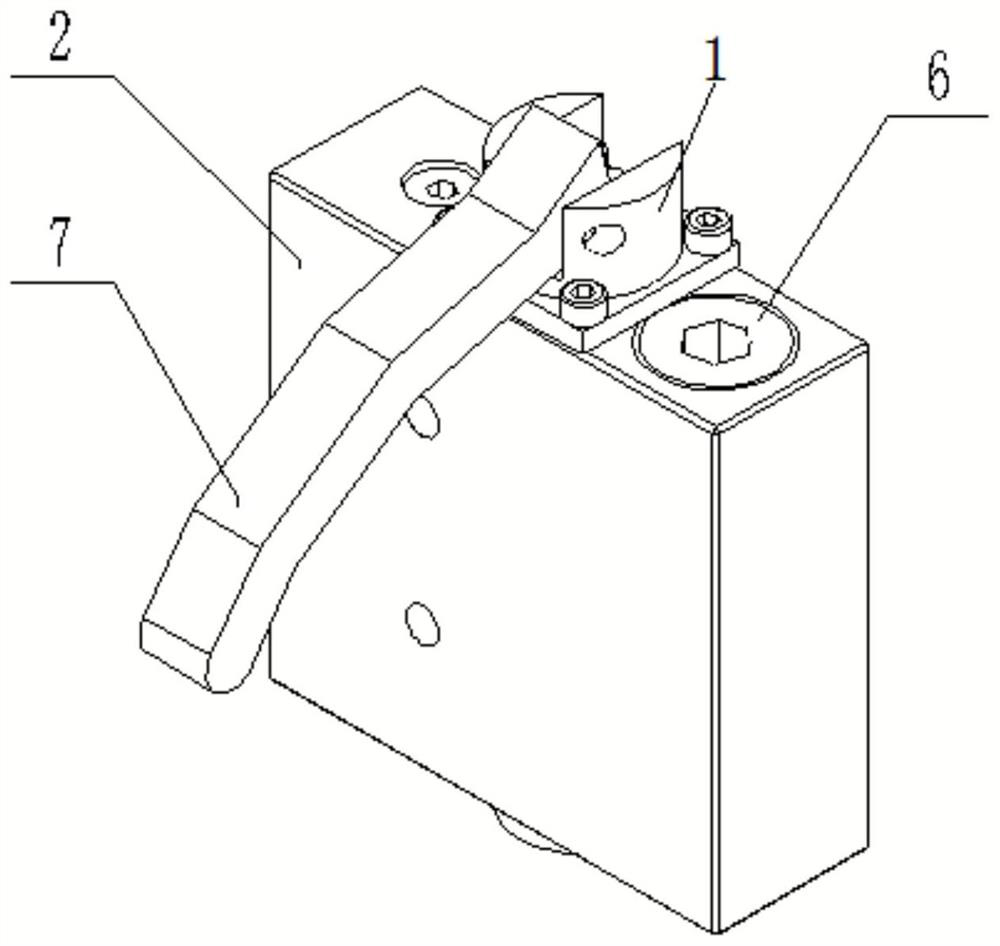

Rotary Jet Stator Recoil Turbine

InactiveCN103758580BDon't spray aroundImprove energy conversion efficiencyStatorsMachines/enginesTurbineEnergy conversion efficiency

The invention discloses a turbine, and aims to provide a rotary spraying stator backflushing turbine which is simple in structure, high in energy conversion efficiency and safe and stable in operation. The rotary spraying stator backflushing turbine comprises a stator (1) and a rotor (2), wherein an expansion flow-splitting chamber (3) is arranged inside the rotor (2), at least one nozzle (4) is arranged on the outer circumference of the rotor (2), a spraying channel (5) communicated with the expansion flow-splitting chamber (3) and the nozzle (4) is further arranged inside the rotor (2), a plurality of bent teeth (6) matched with the spraying direction of the nozzle (4) are evenly arranged on the inner side of the stator (1), a tooth groove (7) matched with the nozzle (4) is formed between every two adjacent bent teeth (6), a flow guiding pipe communicated with the expansion flow-splitting chamber (3) is coaxially rotationally arranged on one side of the rotor (2) in a sealed mode, and a rotor transmission shaft is coaxially fixedly arranged on the other side of the rotor (2). The rotary spraying stator backflushing turbine is applied to the technical field of turbines.

Owner:石智勇

Maintenance-free filter

PendingCN113082798ANot stickyNo need to replace frequentlyLoose filtering material filtersGravity filtersFiberPhysical chemistry

The invention provides a maintenance-free filter which is provided with a shell, a backflushing opening is formed in the shell, a water inlet is formed in the upper portion of the shell, a water outlet is formed in the lower portion of the shell, an upper pore plate and a lower pore plate are arranged in the shell, a filter material is arranged on the lower pore plate, and the pore diameter of the upper pore plate and the pore diameter of the lower pore plate are both smaller than the boundary dimension of the filter material. And the upper part of the shell at the upper part of the upper pore plate is also provided with a drain outlet. The filter solves the technical problems that an existing filter is easy to block when being used for treating sewage containing impurities such as plush and fibers discharged in industries such as printing and dyeing, bathing and the like, the maintenance cost of the filter is higher, and the sewage treatment efficiency is influenced. The device and the method can be widely applied to treatment of sewage containing fine impurities.

Owner:山东双合节能环保技术股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com