Fully-automatic oily sewage filtration-type separator and separating system

A separator, oily sewage technology, applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., can solve the problems of equipment investment, increased floor space, uneconomical water treatment, etc. More thorough cleaning and better recoil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with each accompanying drawing.

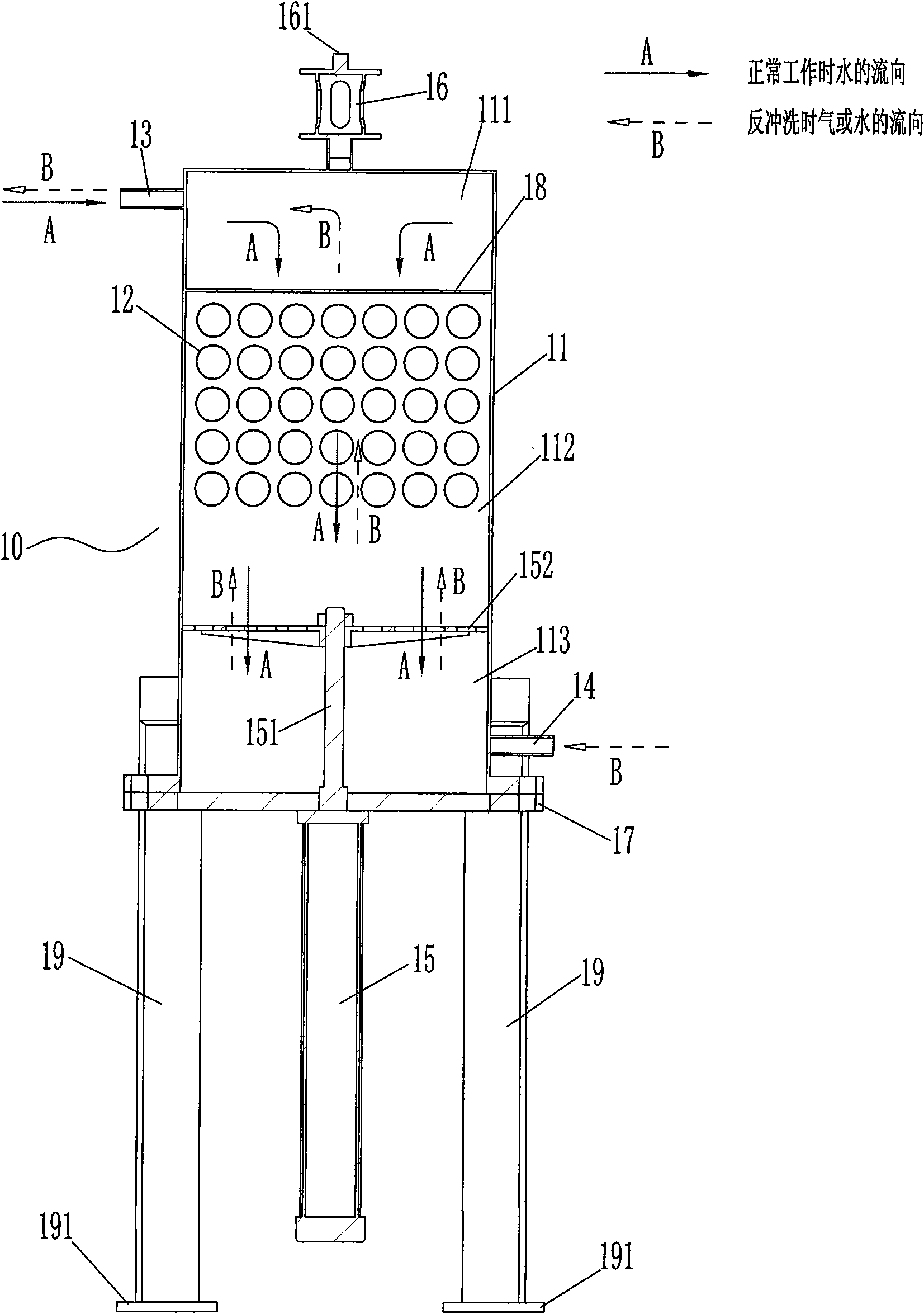

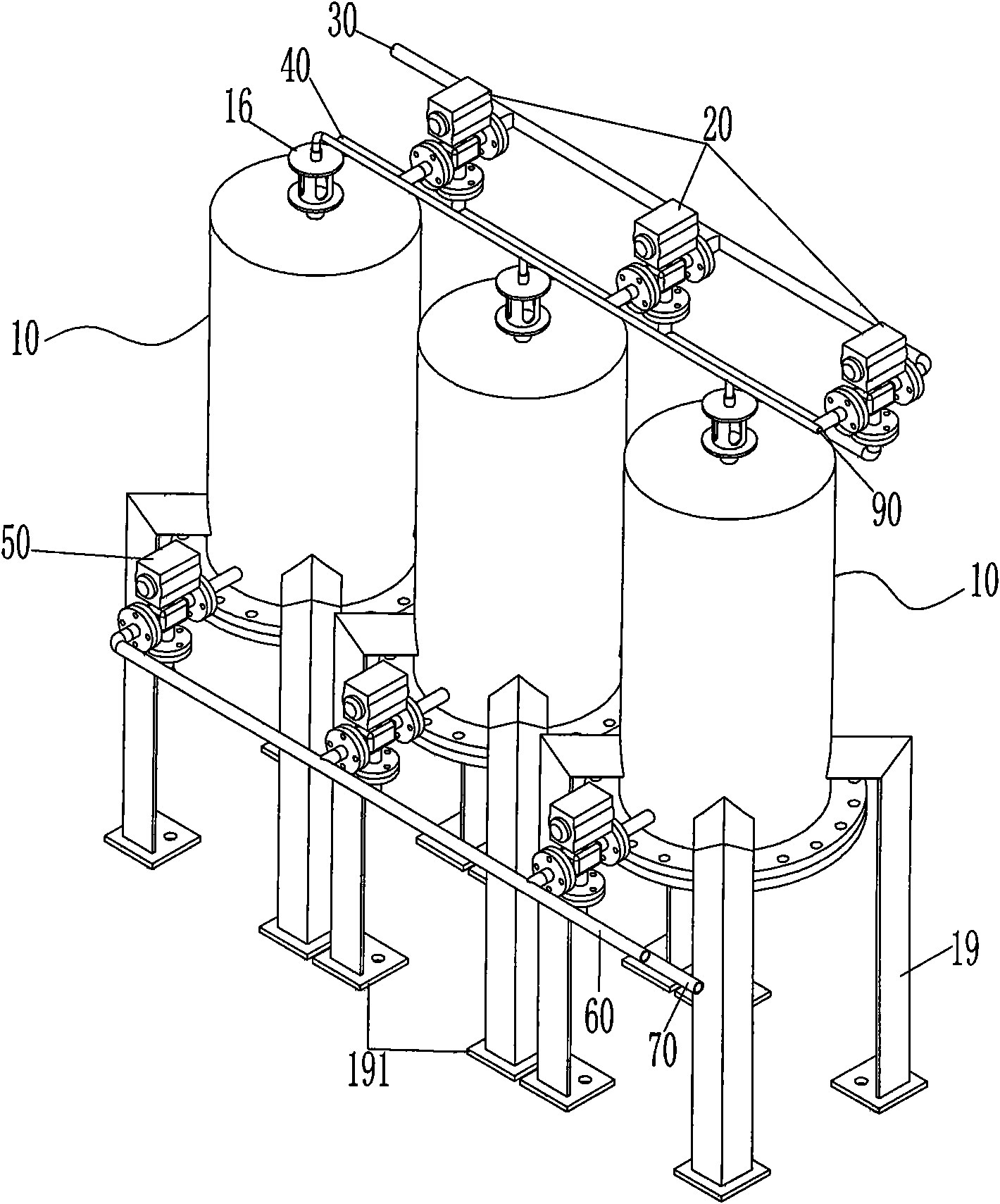

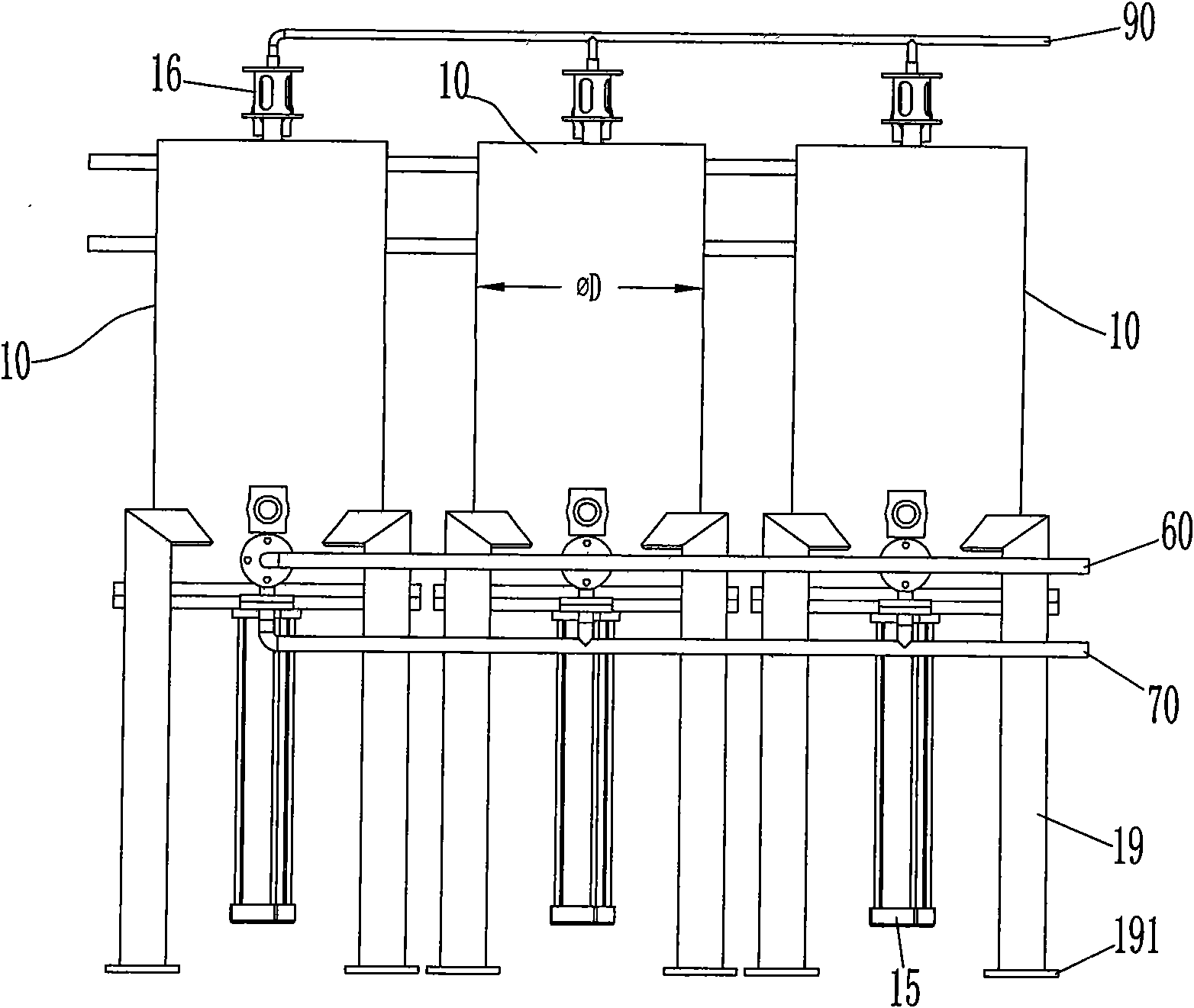

[0034] see figure 1 , a fully automatic oily sewage filter separator 10, comprising a tank body 11 and a filter material 12 in it, a water inlet 13, a water outlet 14, a cylinder 15, a pressure plate 152 fixed on the front end of the cylinder 15 piston rod 151, a device There are oil collector 16 of oil discharge port 161, cylinder fixed cover 17 and perforated partition 18, and this perforated partition 18 is provided with a plurality of through holes that allow oily sewage to flow through, and the size of each through hole must ensure that oily sewage Sewage and oil drop particles can pass through smoothly; the inner cavity of the tank body 11 includes a first chamber 111, a second chamber 112 and a third chamber 113; the water inlet 13 and the oil collector 16 are located in the The upper part of the tank body 11 is in communication with the first chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com