Rotary Jet Stator Recoil Turbine

A technology of spraying the stator and penetrating, applied in the field of turbines, can solve the problems of slow rotation speed of compressed air turbines, difficult to obtain effective application, unable to meet industrial production, etc., and achieves simple structure, stable operation, and energy conversion. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below with regard to specific embodiment:

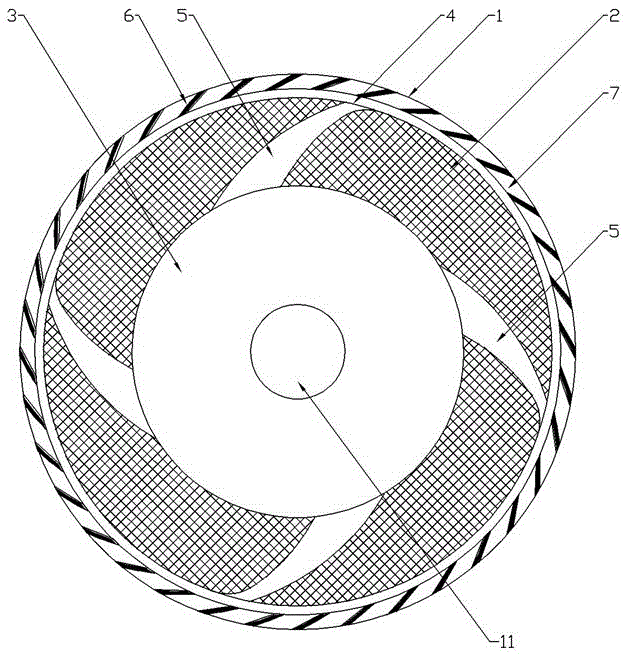

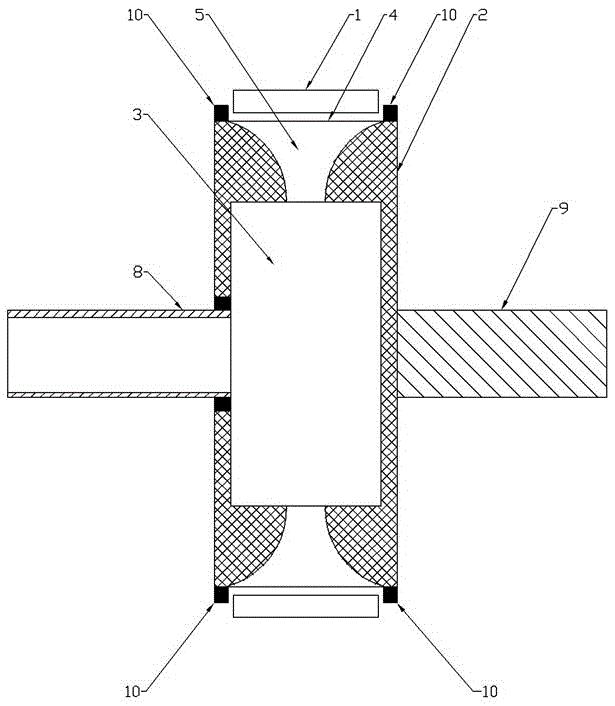

[0018] like figure 1 and figure 2 As shown, the present invention includes a stator 1 and a rotor 2 arranged in the stator 1, the rotor 2 is provided with an expansion split chamber 3, and at least one nozzle 4 is provided on the outer circumference of the rotor 2. The rotor 2 is also provided with a spout 5 that communicates with the expansion split chamber 3 and the spout 4, and the inner circumferential surface of the stator 1 is evenly provided with a number of curved teeth 6 that match the spray direction of the spout 4 Between the adjacent curved teeth 6 there is a tooth groove 7 that is compatible with the nozzle 4, and one side of the rotor 2 rotates coaxially and is sealed with a guide that communicates with the expansion split chamber 3. The other side of the flow pipe 8 and the rotor 2 is coaxially fixed with a rotor transmission shaft 9 . In this embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com