Biogas slurry multistage-fermentation and multistage-filtering purification system

A technology of purification system and fermentation system, which is applied in bioreactor/fermentation tank combination, special-purpose bioreactor/fermentation tank, biochemical equipment, etc., and can solve problems such as high pool construction cost, environmental hazards, and difficult management , to achieve the effects of saving land resources, controlling water pollution, and increasing gas production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0026] Any feature disclosed in this specification (including any appended claims, abstract and drawings), unless expressly stated otherwise, may be replaced by alternative features which are equivalent or serve a similar purpose. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

[0027] The specific implementation manners of the present invention will be described in detail below in conjunction with the drawings and embodiments.

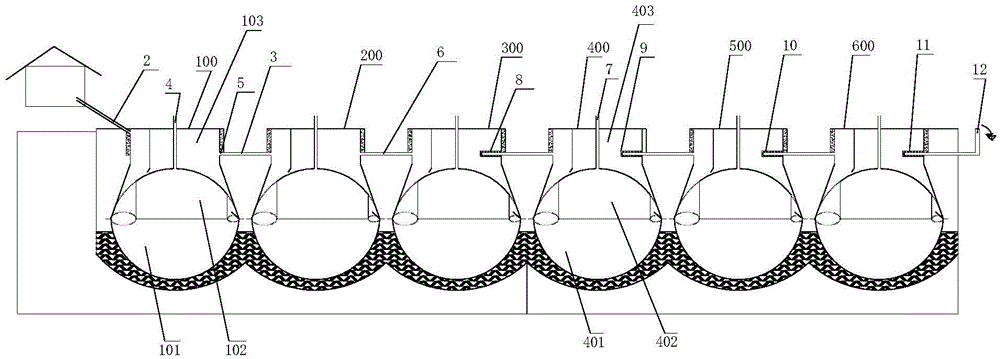

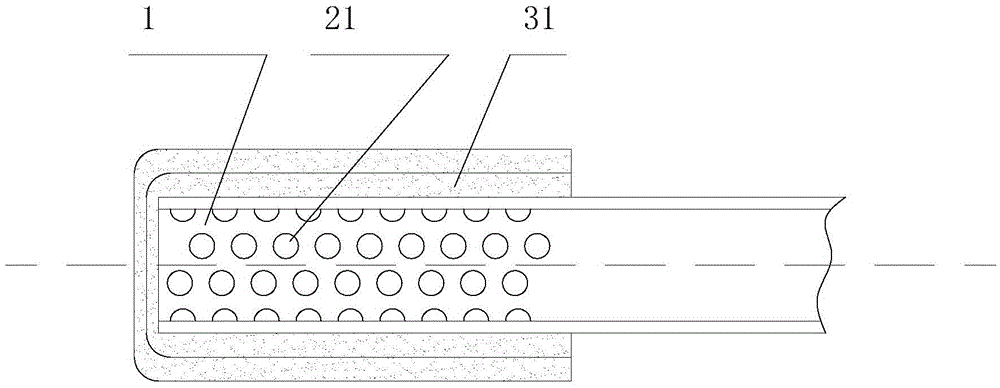

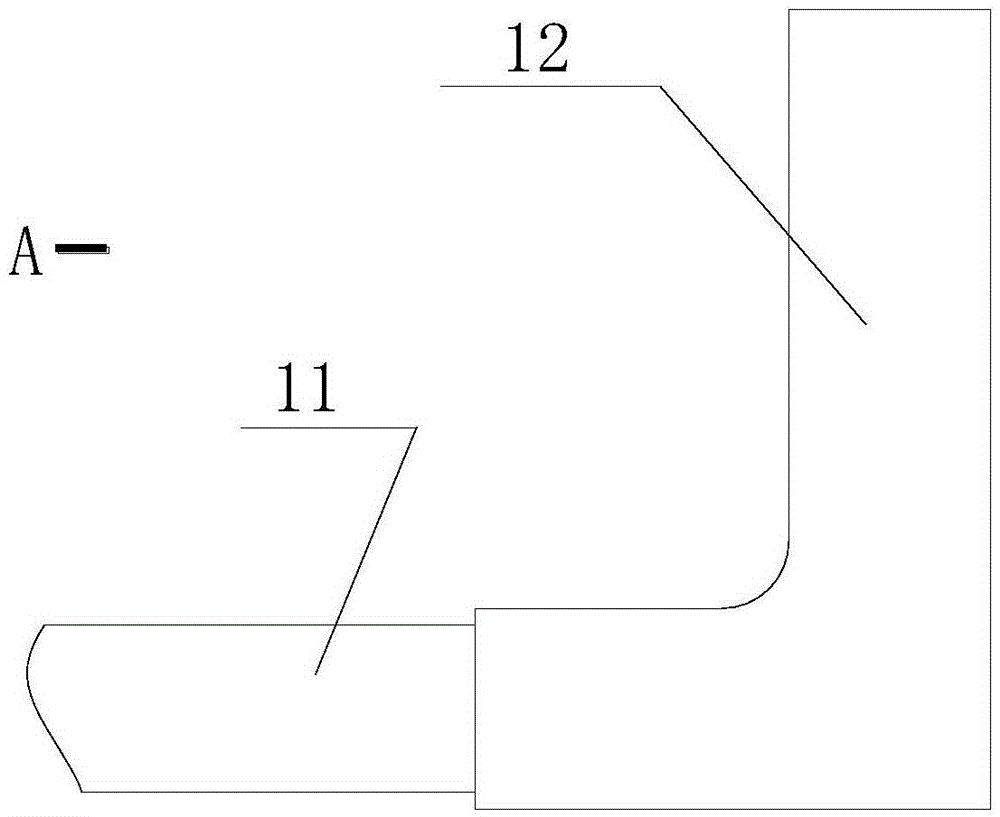

[0028] Such as Figure 1 to Figure 4 As shown, according to an embodiment of the present invention, this embodiment discloses a biogas slurry multi-stage fermentation multi-stage filtration purification system, which includes a multi-stage fermentation system and a multi-stage filtration pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com