Method for cleaning filter liners of built-in and combined filter chambers of water purifier

A technology of water purifiers and filter chambers, which is applied in the field of filter gall cleaning with built-in combined filter chambers in water purifiers. It can solve the problems of affecting the quality of drinking water, the difficulty of wider popularization of water purifiers, and running out of charcoal. Good recoil effect, convenient and timely replacement of filter tubes, simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

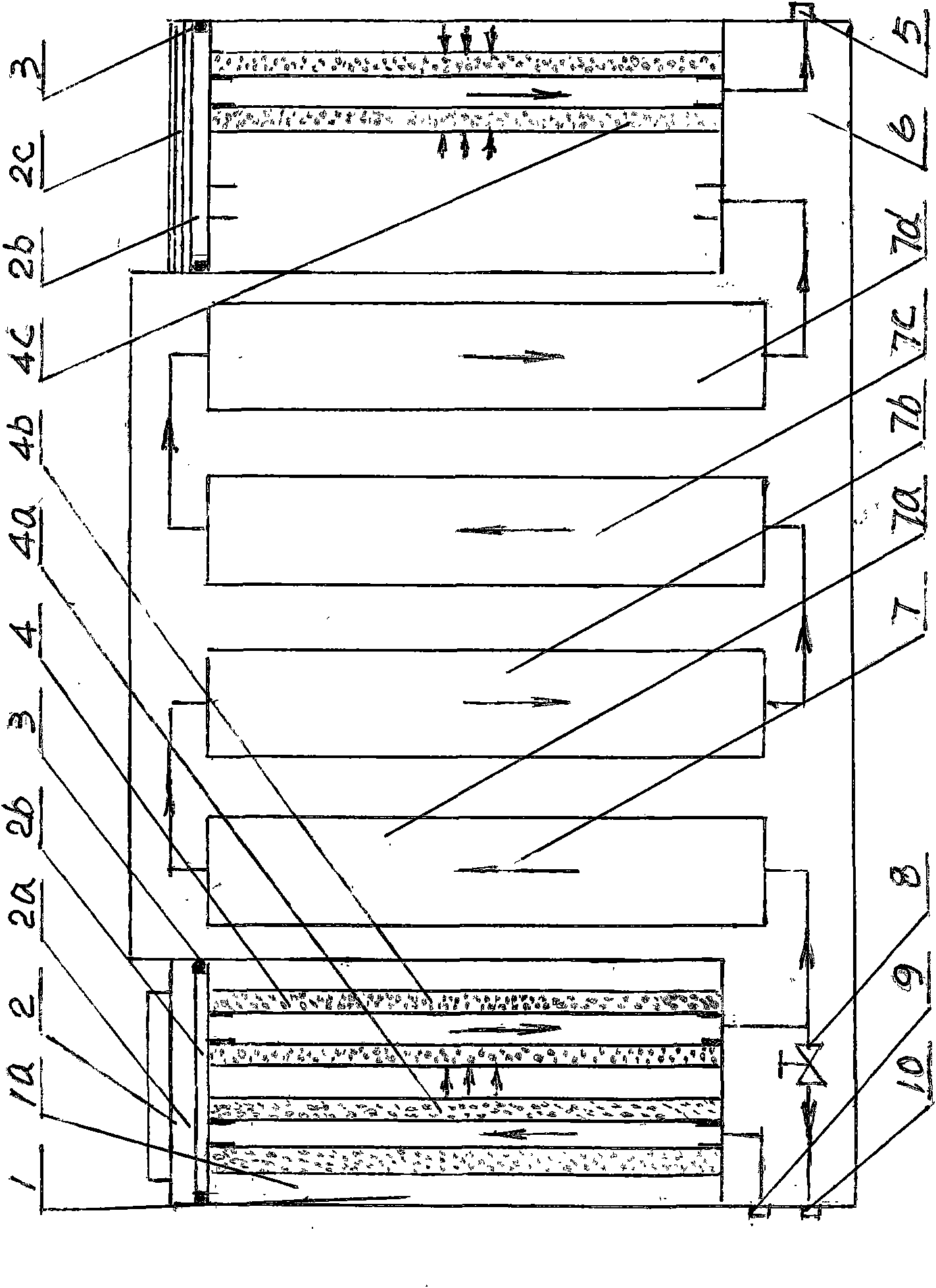

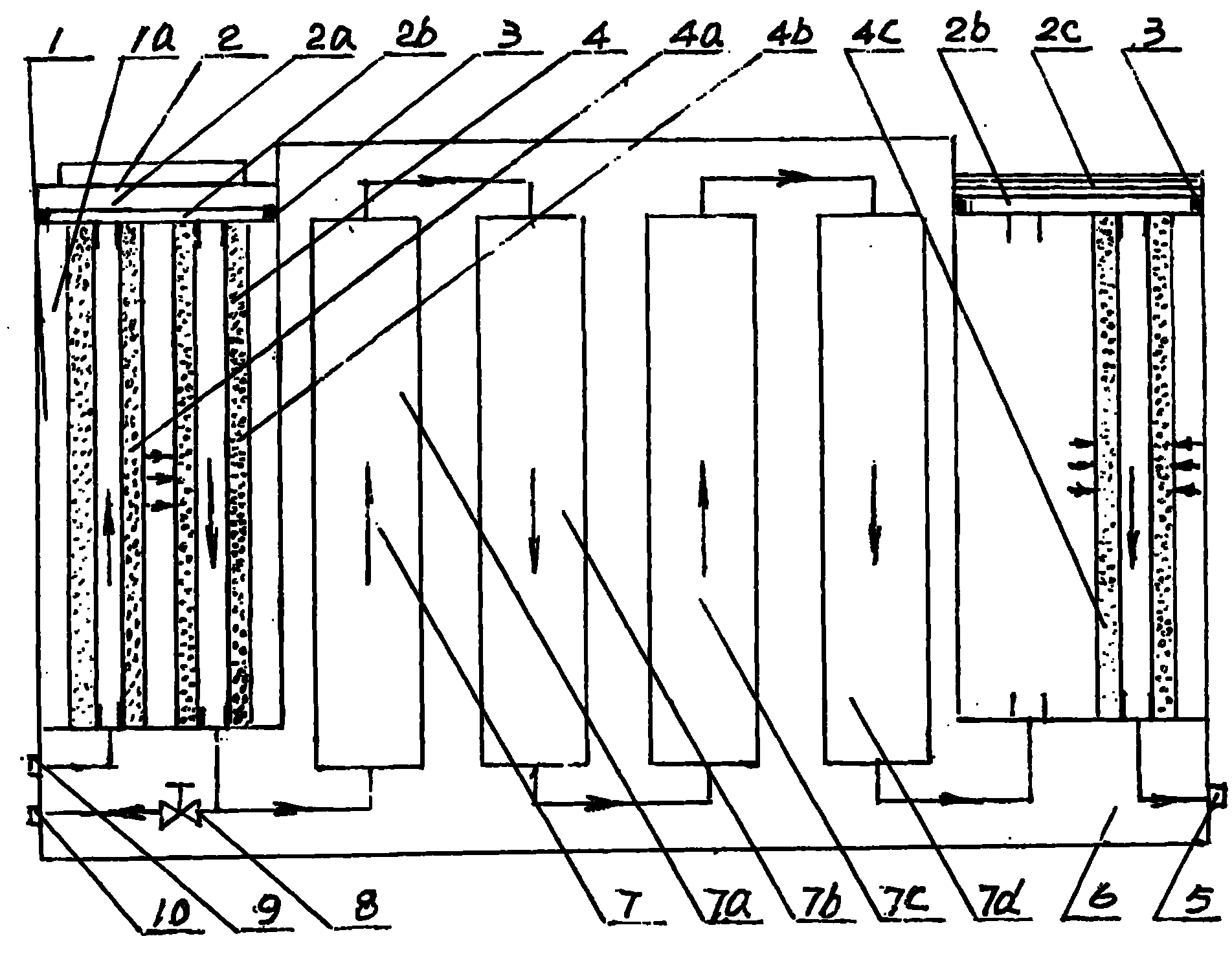

[0031] The accompanying drawings show the best implementation of the present invention. The tap water of the pipeline enters from the water inlet 9 of the box-type machine base 6, and the water inlet of the fixed filter case 1a, the pipe walls of the front and rear fiber filters 4a, 4b, 4c are fixed through the combined filter chamber 1, and the other water port of the fixed filter case 1a is fixed. And the second, third, fourth, fifth stage filter element 7a, 7b, 7c, 7d, finally flow out by the water outlet 5. In the rear combination filter cavity 1, water enters the inside through the pipe wall from the outside of the tubular filter gall 4c and flows out from another water port of the fixed filter housing 1a, the machine water outlet 5. After the machine has been running in the filtering mode for a period of time, impurities are accumulated on the inner and outer sides of the two filter galls 4a, 4b in the front combined filter cavity, and on the outer side of the filter gal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com