Segment connection method of pipes of multi-machine base water purifier

A base water purifier and connection method technology, which is applied in the field of multi-base water purifier pipeline segment connection, can solve the problems of large water purifier installation, inconvenient machine installation, fast consumption of filter elements, etc., and achieve pipeline Neat layout, prolong service life and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

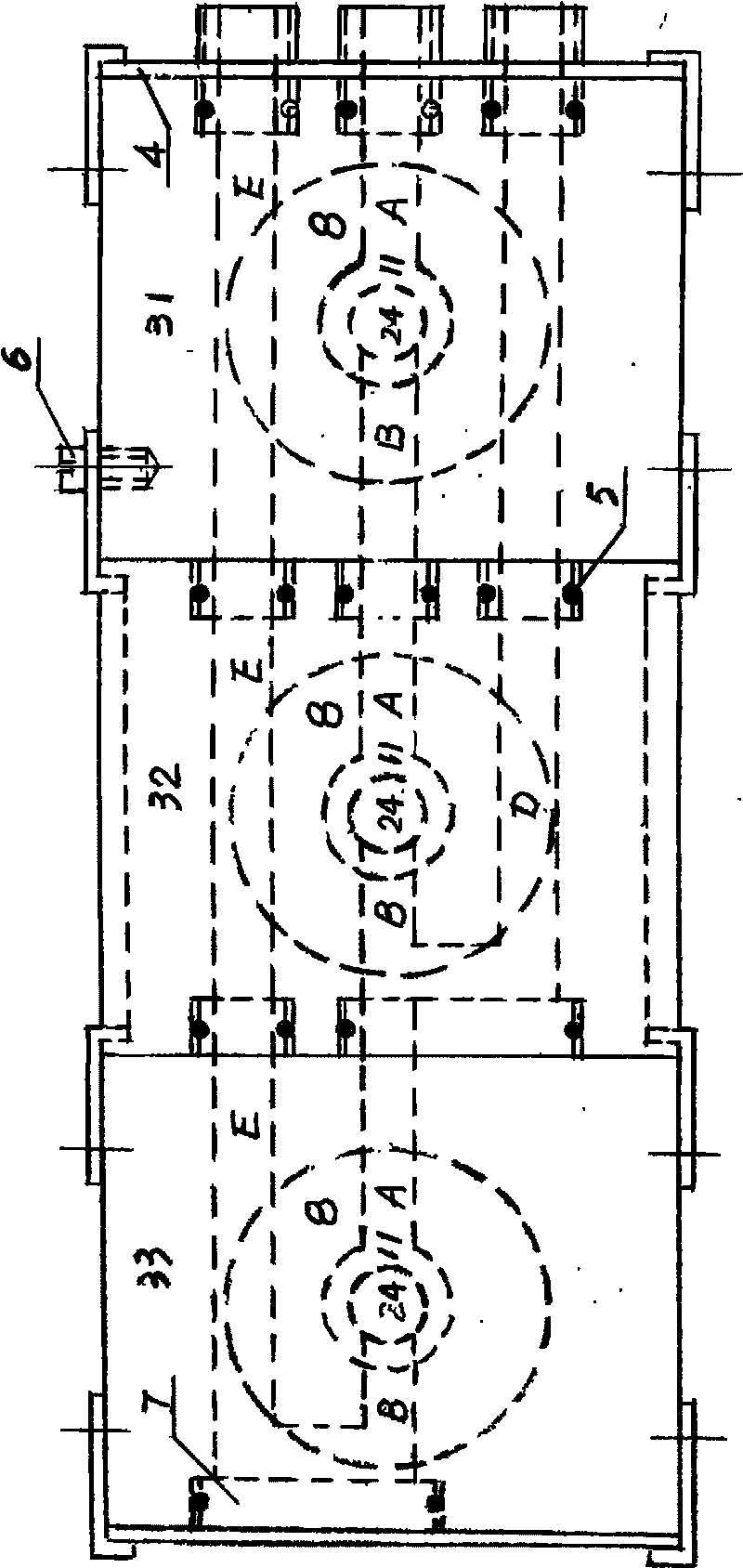

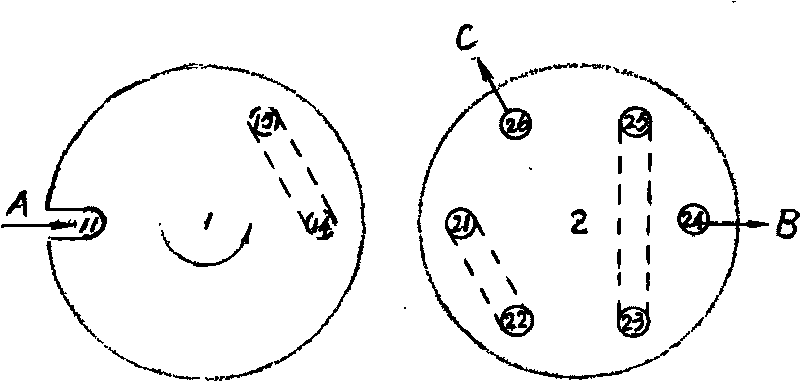

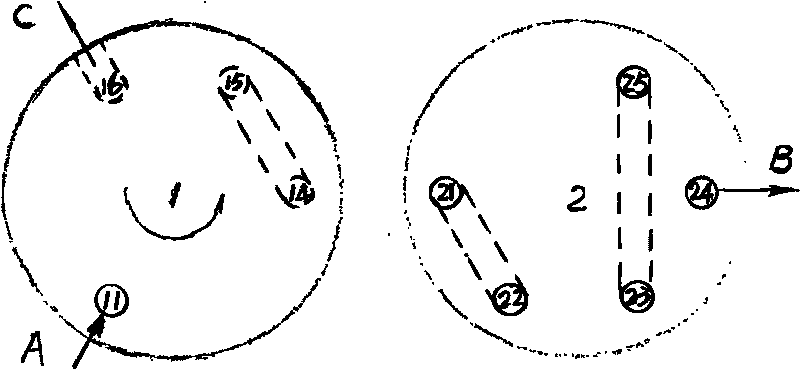

[0024] figure 1 It is the best embodiment of the present invention. The base 3 includes primary, front and final bases 31 , 32 , 33 provided with water inlet and outlet ports connected to the water inlet and outlet pipelines A and B to connect with the filter element 8 . Independent water purification pipelines E are additionally arranged on the three machine bases. While connecting the water inlet and outlet pipelines A and B of the machine base 3, the water purification pipeline E is also connected to each other in sections to form a water purification pipeline E that runs through the three machine bases and is connected to the water outlet pipe of the final machine base 33. The road B is connected, thereby extending the water outlet of the multi-stage water purifier to the vicinity of the water inlet pipe A of the primary machine base 31 .

[0025] As an improvement, it is also possible to connect the segmental purification pipelines D arranged on the primary and front ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com