Self-cleaning universal filtering device

A filtration device and self-cleaning technology, applied in the filtration of dispersed particles, transportation and packaging, separation of dispersed particles, etc., can solve the problems of poor backflushing effect, affecting production continuity, inability to filter waste gas, etc., and achieve good backflushing effect. , Easy to arrange and install, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

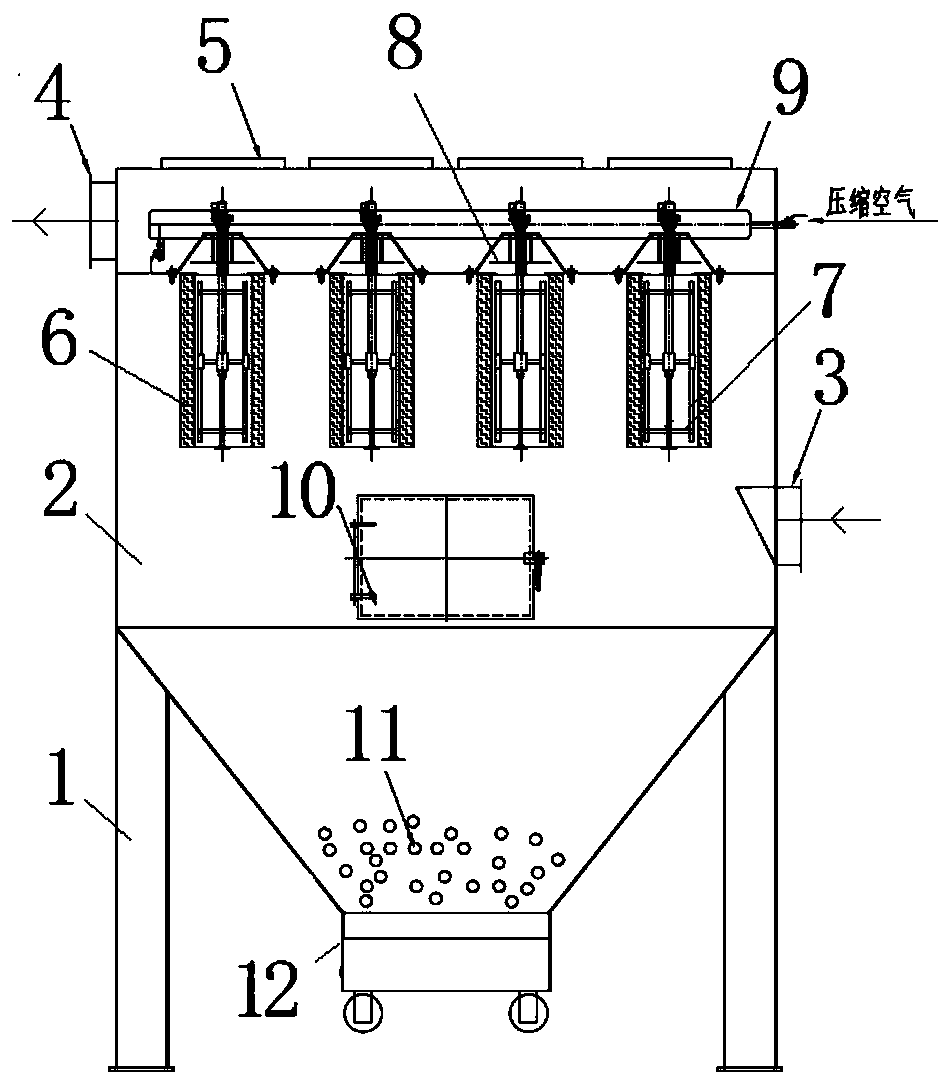

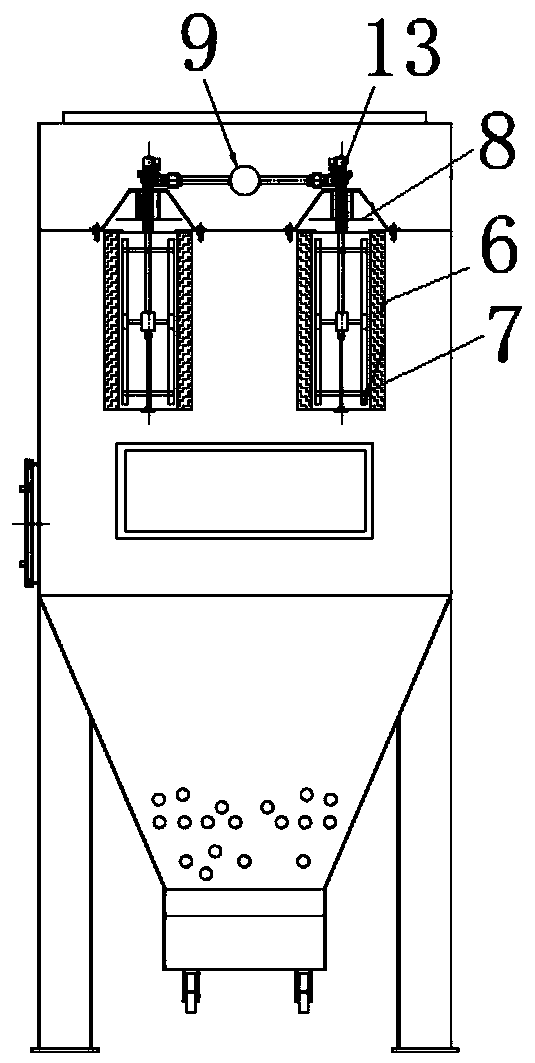

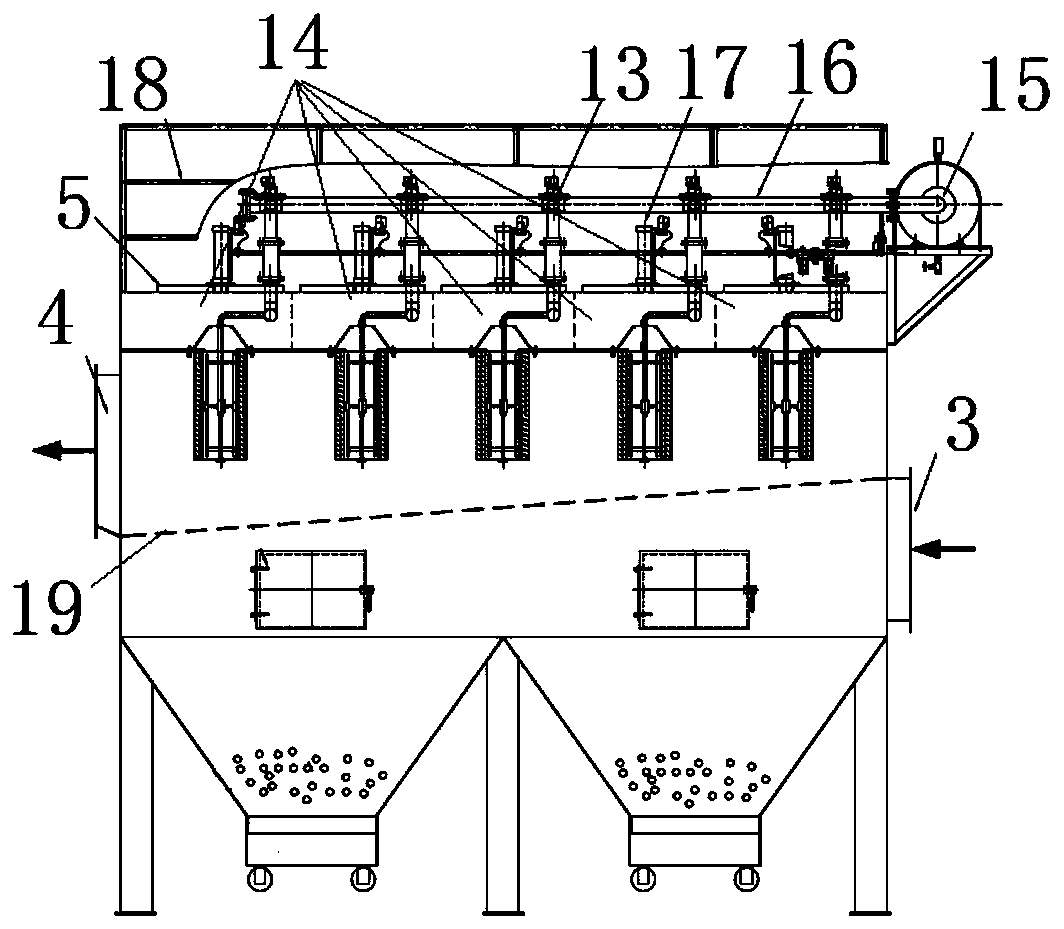

[0037] The filter box is divided into an air inlet cavity at the bottom and an air outlet cavity at the top through a partition. The partition is provided with a through hole corresponding to each opening and closing plate. The filter barrel is located in the intake cavity and the upper end The openings correspond to the through holes.

[0038] The filter barrels 6 are a group, and the recoil air pipe in each filter barrel is connected with the compressed air pipeline through an independent pulse valve 13, and the opening end of the corresponding filter barrel is provided with a switch to control the opening and closing of the opening end of the filter barrel Plate 8 is provided with a lifting cylinder corresponding to the opening and closing plate, and the opening and closing plate is driven to move up and down by the lifting cylinder, thereby controlling the opening and closing of the upper opening of the filter barrel, and the opening and closing plate is also controlled by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com