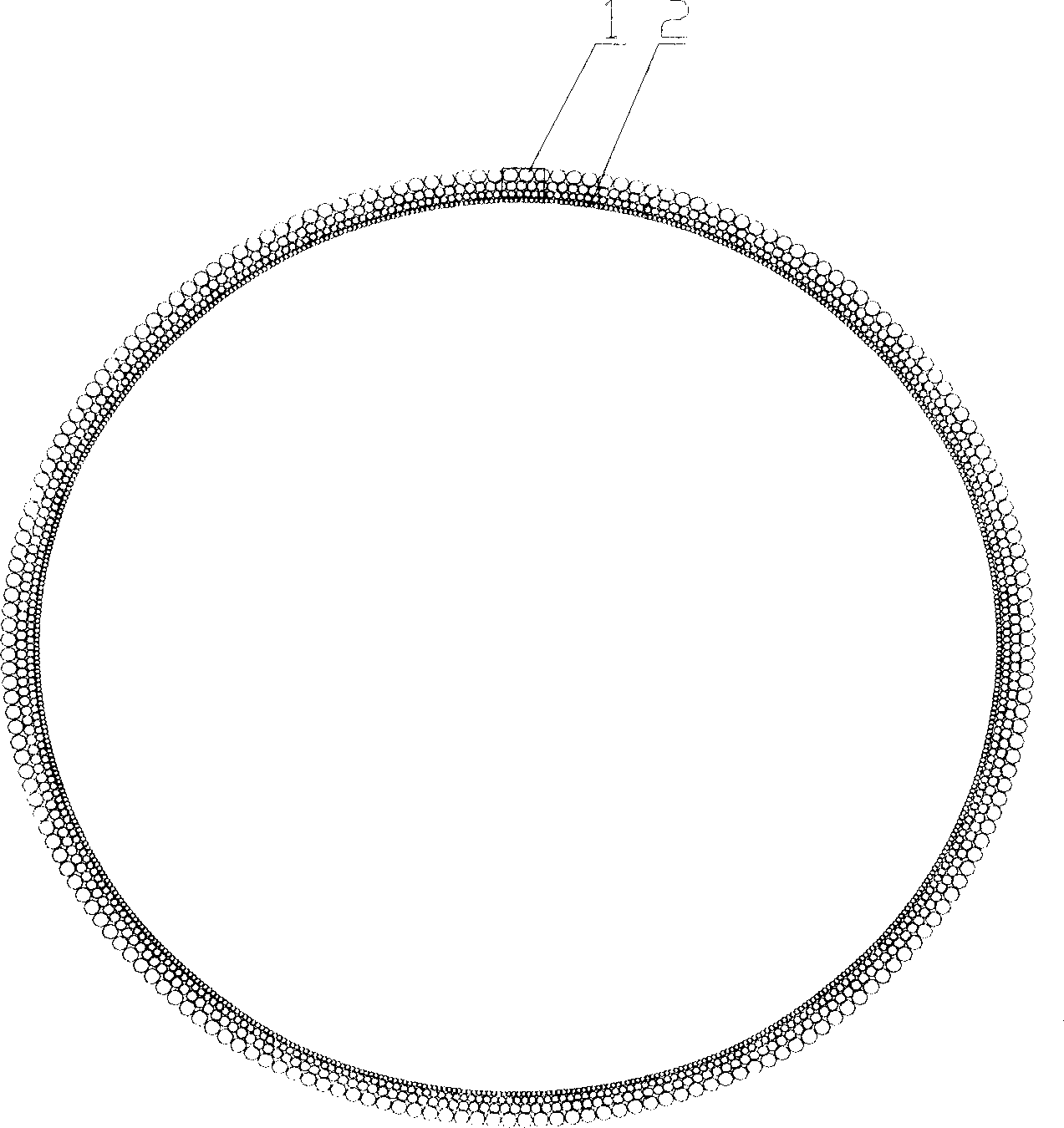

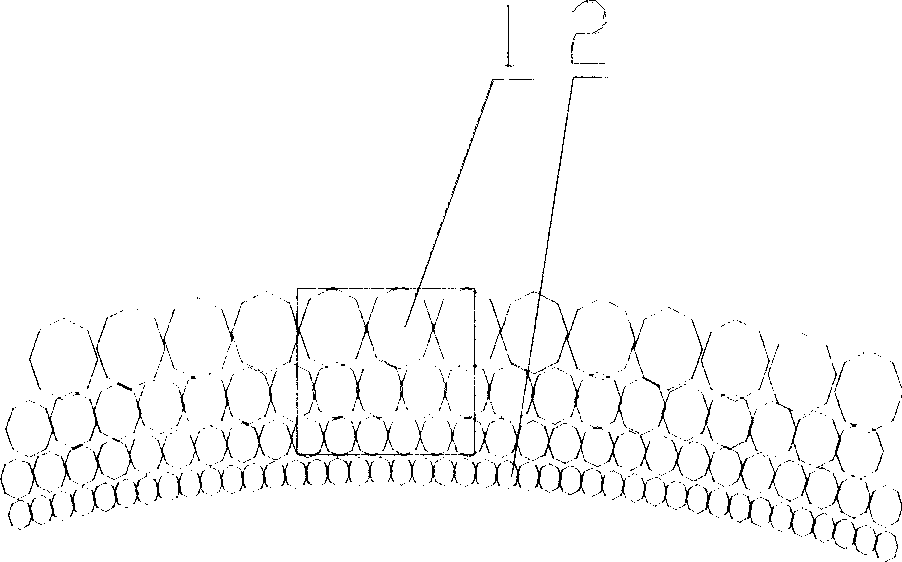

Porous non layer boundary gradient metal film pipe and its preparation method

A metal membrane tube and gradient technology, applied in the composition and preparation, the structure of porous non-layer boundary gradient metal membrane tube, and the field of inorganic membrane preparation, can solve the problem of the inability to prepare porous non-layer boundary gradient metal membrane tube and gradient ceramic membrane tube Strength, sealing performance brittleness, thermal conductivity weakness and other issues, to achieve the effect of high porosity, good recoil and uniform pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]60 parts by weight, an average particle size of 3 μm metal nickel powder base material, 40 parts by weight of carrier water and 0.2 parts by weight of polyacrylamide binder are mixed to prepare a composite slurry, After 3 hours of mechanical stirring, a uniform slurry was made. Start the centrifugal forming metal film tube machine, inject the composite slurry into the high-speed rotating stainless steel tube, the tube speed is 10000rpm, under the action of centrifugal force, the metal nickel powder particles will migrate in the carrier slurry, and the powder Due to their large mass, the large particles will segregate toward the inner surface of the tube, that is, the closer to the outer surface of the metal film tube, the larger the particles; while the smallest particles are concentrated on the inner surface of the metal film tube, due to its powder particles The smallest, the formed membrane pore size is also the smallest, then the inner surface layer is the control la...

Embodiment 2

[0029] 70 parts by weight, the average particle size is 40 μm metal titanium powder base material, 30 parts by weight of carrier water and 0.1 part by weight of sodium carboxymethyl cellulose binder are mixed to prepare a composite The slurry was mechanically stirred for 2 hours to make a uniform slurry. Start the centrifugal forming metal film tube machine, inject the composite slurry into the high-speed rotating stainless steel tube, and the tube speed is 8000rpm. Under the action of centrifugal force, the metal titanium powder particles will migrate in the carrier slurry, and the large particles in the powder will segregate toward the inner surface of the tube due to their larger mass, that is, the closer to the outer surface of the metal film tube, the particles The larger; and the smallest particles are concentrated in the inner surface of the metal membrane tube, because the powder particles are the smallest, the formed membrane pore size is also the smallest, so the inn...

Embodiment 3

[0031] The parts by weight are 50 parts, the average particle size is 80 μm stainless steel powder, the carrier ethanol of 50 parts by weight and the polyvinyl alcohol binder of 0.1 part by weight are mixed, and the composite slurry is prepared, and after 2 Hours of mechanical stirring to make a uniform slurry. Start the centrifugal forming metal film tube machine, inject the composite slurry into the high-speed rotating stainless steel tube, and the tube speed is 2000rpm. Under the action of centrifugal force, the stainless steel powder particles will migrate in the carrier slurry, and the large particles in the powder will segregate toward the inner surface of the tube due to their larger mass, that is, the closer the particles are to the outer surface of the metal film tube, the closer the particles will be. Large; while the smallest particles are concentrated in the inner surface layer of the metal membrane tube. Because the powder particles are the smallest, the formed me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com