Impregnating device for machining building carbon fiber mesh belt and impregnating method

A carbon fiber mesh and impregnation device technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of poor impregnation treatment effect and low efficiency of carbon fiber mesh belt, and achieve improved contact impregnation effect, increased impact effect, Increased effect of dispersing flow effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

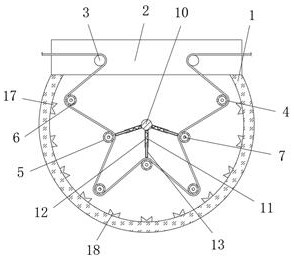

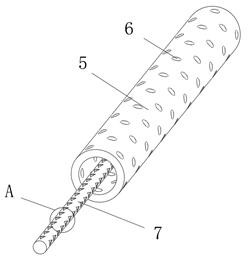

[0028] refer to Figure 1-3 , a kind of impregnation device for building carbon fiber mesh belt processing, including a dipping box 1, the top of the dipping box 1 is open, and the two ends of the top outer wall of the dipping box 1 are fixed with a fixed plate 2, and the two fixed plates 2 between Both sides are rotatably connected with feeding rollers 3, and the bottom of the dipping tank 1 is connected with a drain pipe. A plurality of annularly distributed support rollers 4 are connected, and a plurality of annularly distributed squeeze rollers 5 are connected between the inner walls of both ends of the dipping tank 1. The distance between the squeeze rollers 5 and the axis of the dipping tank 1 Less than the distance between the support roll 4 and the axis of the dipping tank 1, the support roll 4 and the squeeze roll 5 are arranged in an interval distribution;

[0029] The device uses the feed roller 3, the support roller 4 and the squeeze roller 5 to send the carbon fi...

Embodiment 2

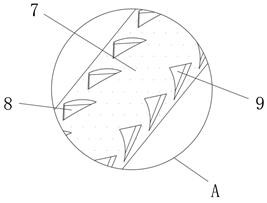

[0033] refer to Figure 1-5 , an impregnating device for building carbon fiber mesh belt processing, a fixed rod 10 placed horizontally is fixed at a position corresponding to the axis center between the inner walls of the two ends of the impregnated box 1, and the outer wall of the fixed rod 10 is fixed at a position corresponding to the extrusion roller 5 There is a connecting seat 11, the connecting seat 11 is open away from one end of the fixed rod 10, the inner wall of the connecting seat 11 is slidably connected with a connecting plate 13, and the end of the connecting plate 13 close to the fixed rod 10 is connected with the inner wall of one end of the connecting seat 11. Spring 12, the middle position of connecting plate 13 is provided with cavity, and utilizes spring 12 to make connecting plate 13 carry out extruding operation to the carbon fiber mesh belt of extrusion roller 5 outer wall, by the working effect of extruding and relaxing mesh belt again, and Improve th...

Embodiment 3

[0039] refer to Figure 1-5 , an impregnation method of an impregnation device for processing a construction carbon fiber mesh belt, comprising an impregnation box 1, a feeding roller 3, a support roller 4, a squeeze roller 5, a through hole and an auxiliary rod 7, utilizing the feed roller 3, the support roller 4 and the extrusion The pressure roller 5 sends the carbon fiber mesh belt into the impregnation box 1 to move and impregnate along the inner wall of the arc-shaped structure, and through the distribution of the interval between the support roller 4 and the squeeze roller 5 and the distance between the two and the axis In the process of moving the carbon fiber mesh belt between the support roll 4 and the squeeze roll 5, it drives the flow effect of the liquid flow in the impregnation tank 1 in the horizontal and vertical directions, so that through multi-directional movement and impregnation The flow of the liquid improves the actual impregnation effect and impregnatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com