Tire grabbing and mounting mechanism for mounting multi-scale round nut

An installation mechanism and indexing circle technology, applied in tire installation, tire parts, transportation and packaging, etc., can solve the problems of time-consuming and laborious, increase production cost, etc., to ensure synchronization and accuracy, improve tightening efficiency and equipment The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

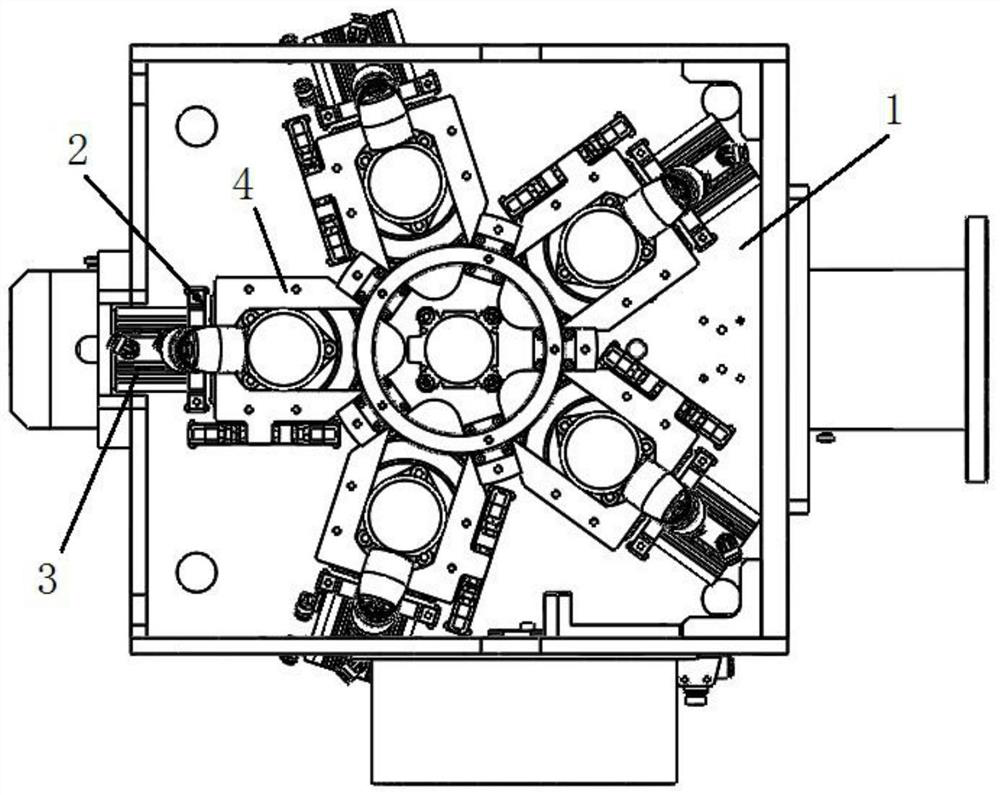

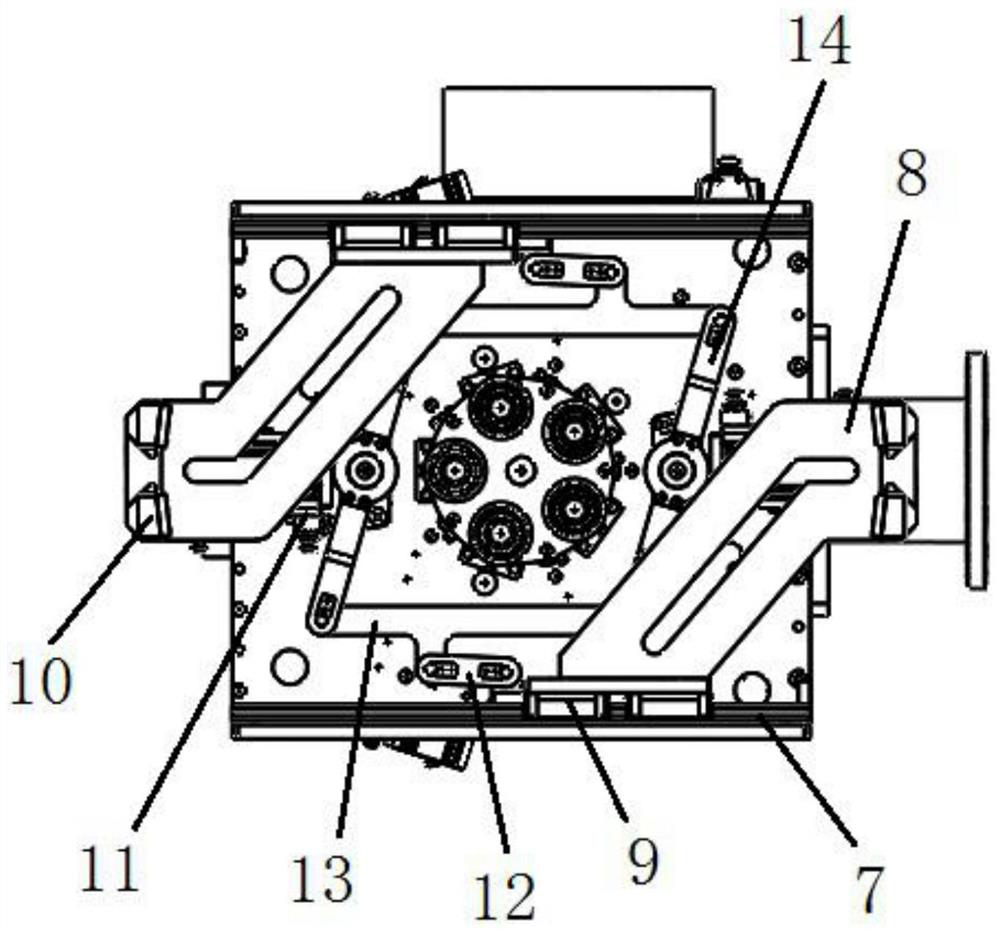

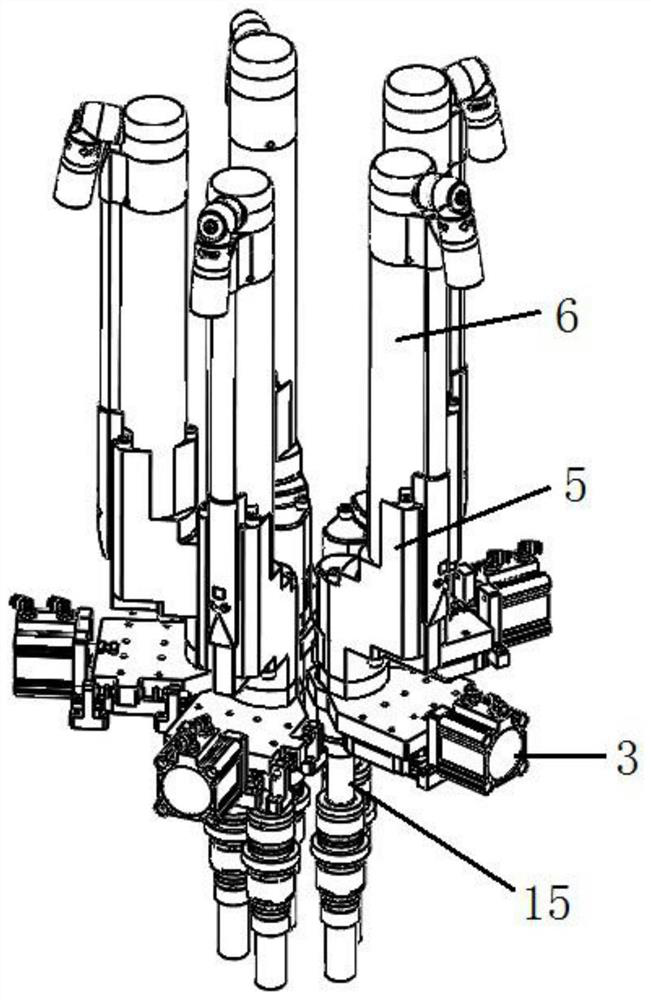

[0016] Attached below Figure 1-6 The present invention is described further:

[0017] A tire grabbing installation mechanism installed with multi-indexing round nuts, a vertical plate 2 is fixed on the base plate 1, a segmental cylinder 3 is fixed on the base plate 1 through the vertical plate 2, and the output end of the segmental cylinder 3 is connected to the segmental fork plate 4, The section fork plate 4 is slidably connected to the base plate 1, and the section fork plate 4 is connected to the mounting frame 5. A tightening motor 6 is installed on the mounting frame 5, and the tightening motor 6 is connected to a plurality of tightening shafts 15. The base plate 1 is provided with a tightening shaft 15. The upper and lower ends of the base plate 1 are provided with relative guide rails 7 through the through holes, and the slider 9 slidably connected to the guide rail 7 is connected to the connecting plate 8. The end of the connecting plate 8 is connected to the jaw 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com