Dry type edge washing system for ceramics

A dry and edge washing technology, which is applied in the mechanical field, can solve the problems that the edge is easy to touch external objects, get dirty, waste water resources and energy, and achieve the effect of saving water and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

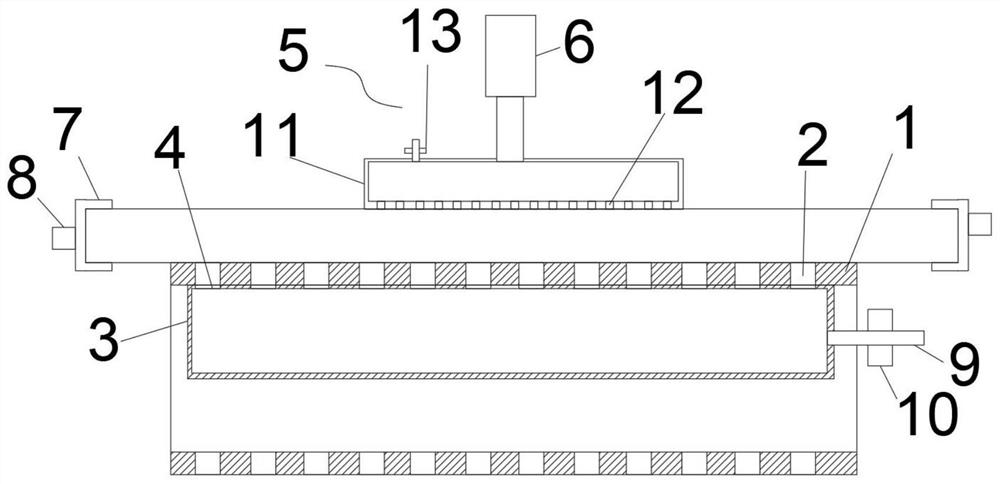

[0015] Such as figure 1 The shown ceramic dry-type edge washing system includes a conveyor belt 1 formed with a number of first through holes 2; the bottom of the conveyor belt 1 is sequentially installed along the transmission direction with two adsorption boxes 3, and the top of the adsorption box 3 is A strip-shaped hole 4 is formed to cooperate with the first through hole 2; a turning area is formed between the two adsorption boxes 3; an adsorption device 5 is installed above the turning area, and the adsorption device 5 is connected to a rotating device 6; the corresponding transmission of the adsorption box 3 Both sides of the belt are equipped with U-shaped grinding blocks 7 connected with telescopic devices 8; the adsorption box 3 is connected with a first negative pressure device 10 through a first communication pipe 9.

[0016] The adsorption device 5 includes an adsorption box body 11 , a number of adsorption holes 12 are formed on the top of the adsorption box body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com