Method for judging furnace protection effect of blast furnace hearth

A technology of blast furnace and blast furnace, which is applied in the evaluation model of titanium ore protection effect, prediction of furnace protection titanium load, and evaluation of blast furnace hearth protection effect. Guidance and evaluation methods cannot truly and real-time reflect problems such as the effect of hearth protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A specific embodiment of the invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

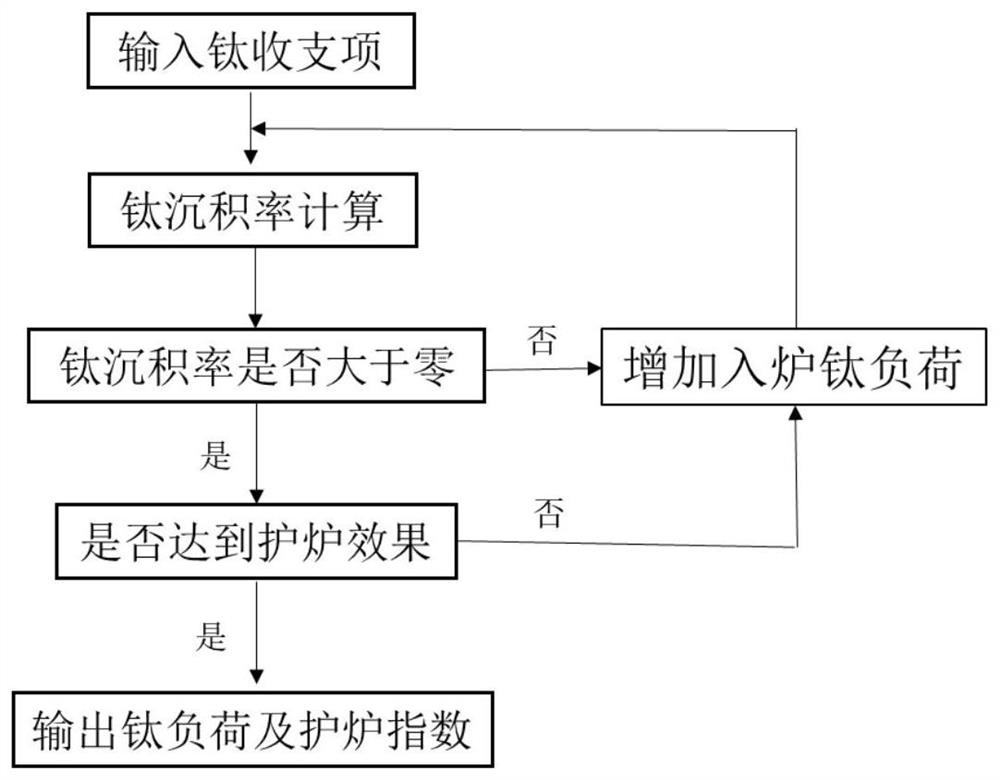

[0020] Such as figure 1 Shown:

[0021] Step 1: According to the evaluation requirements of titanium furnace protection effect, input dynamic TiO in titanium 2 Income items, recorded as a and TiO in titanium 2 Expenditure item, recorded as b, and measuring the residual thickness of the hearth side wall carbon brick at the same time, recorded as d; the purpose is to calculate the titanium deposition rate of the blast furnace hearth, clarify the current titanium income and expenditure of the blast furnace hearth and the blast furnace hearth security status.

[0022] Step 2: Calculate the titanium deposition rate in the hearth of the blast furnace through the formula for the sorted titanium data: deposit TiO in the furnace 2 Amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com