Polishing equipment with clamping function for hardware product machining

A kind of equipment and hardware technology, which is applied in the field of polishing equipment for hardware processing, can solve the problems of not being able to meet production and life, affecting the working efficiency of polishing equipment, and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

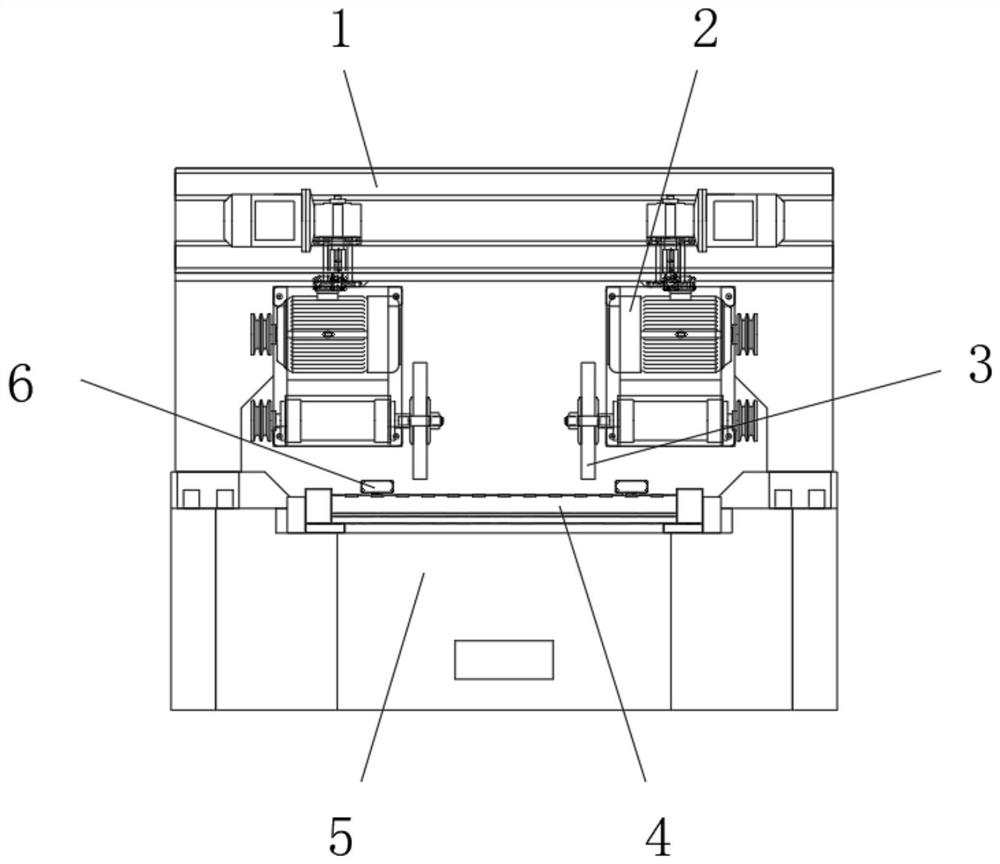

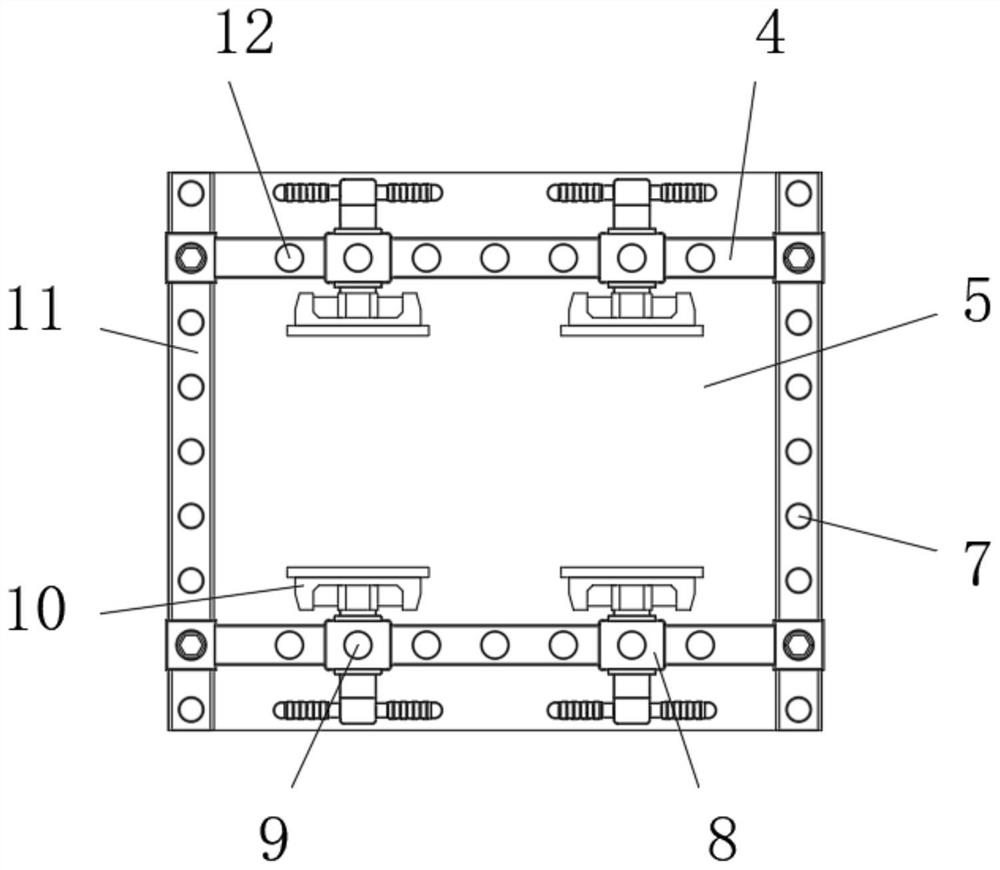

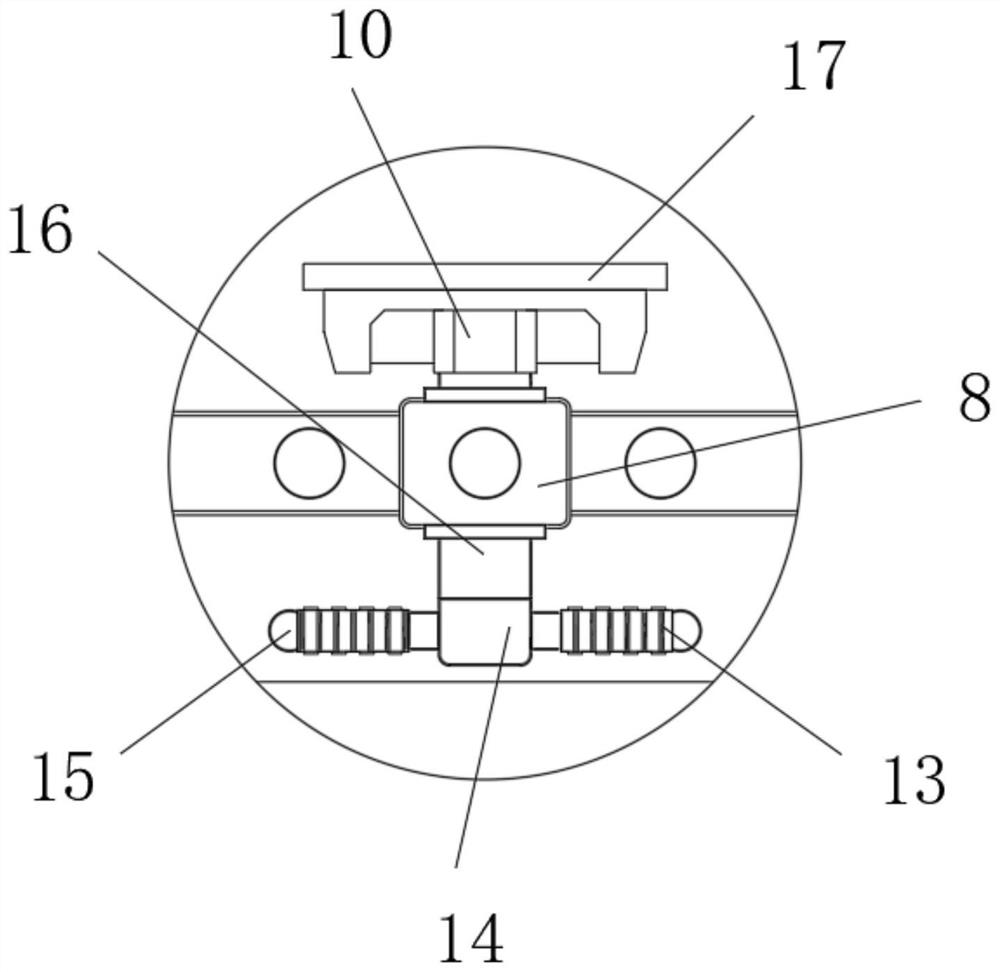

[0024] Please refer to figure 1 , figure 2 and image 3 As shown, the present invention provides a polishing device for processing hardware products with a clamping function, which includes a frame 1, a polishing device body 2 is fixedly connected to the top of the front end of the frame 1, and a polishing device body 2 is fixedly connected to the end of the polishing device body 2. The wheel 3 is fixedly connected with the working table 5 at the bottom of the front end of the frame 1, and the polishing wheel 3 is installed on the top of the working table 5, and the two ends of the top of the working table 5 are provided with guide rail rods 4, and the top of the guide rail rod 4 is provided with a movable seat 8. The inside of the movable seat 8 is provided with a threaded rod 16, the end of the threaded rod 16 is fixedly connected with a splint 10, and the surface of the end of the splint 10 is covered and fixed with a rubber pad 17. The seat 8 slides to the appropriate p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap