Polishing method for precision hole

A processing method and fine polishing technology, applied in the field of high-precision hole processing of metal parts, can solve the problems of substandard fatigue life of parts and products, low processing quality stability, low processing efficiency, etc. The effect of stable product quality and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

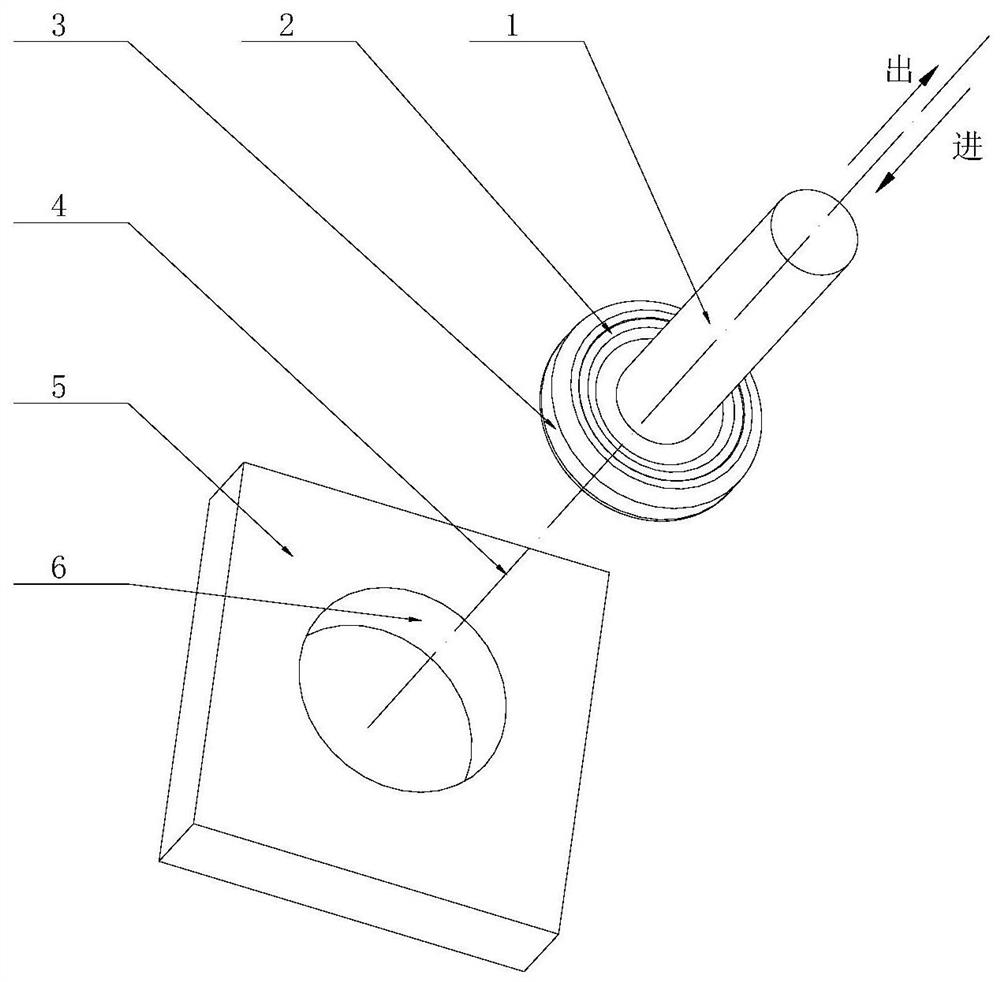

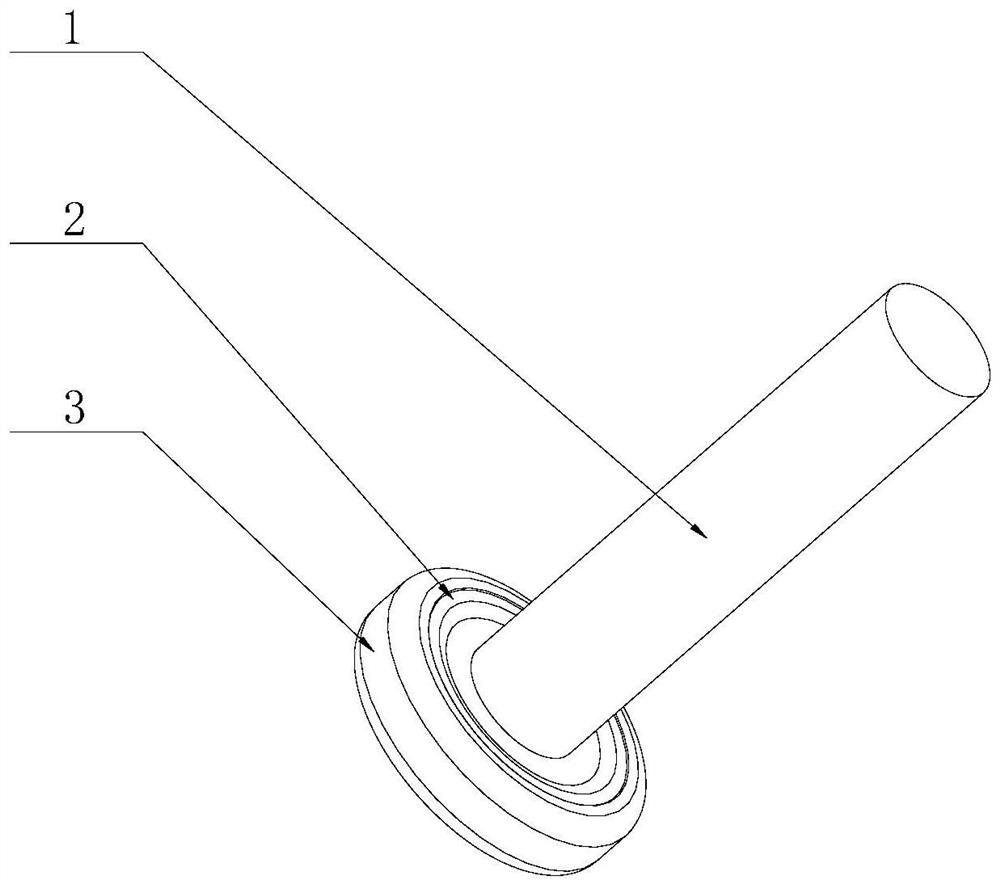

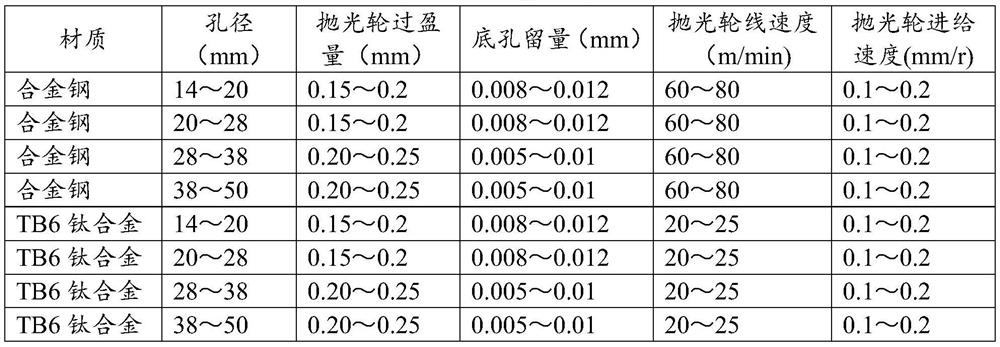

[0036] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

[0037] It has been explained in the above background technology that in the processing technology of precision holes, there are generally problems of low processing efficiency and high cost, due to the influence of factors such as equipment positioning accuracy, the problem of low stability of processing quality, and due to local out-of-tolerance or Factors such as out-of-tolerance roundness lead to poor product consistency and have a greater impact on the fatigue life of parts and products.

[0038] In view of the above-mentioned various problems, the embodiment of the prese...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap