A Parallel Actuation Structure Based on Intelligent Flexible Bending Deformation Actuation Material

A technology of bending deformation and driving structure, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., to achieve the effect of improving force transmission state, improving efficiency and flexible mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

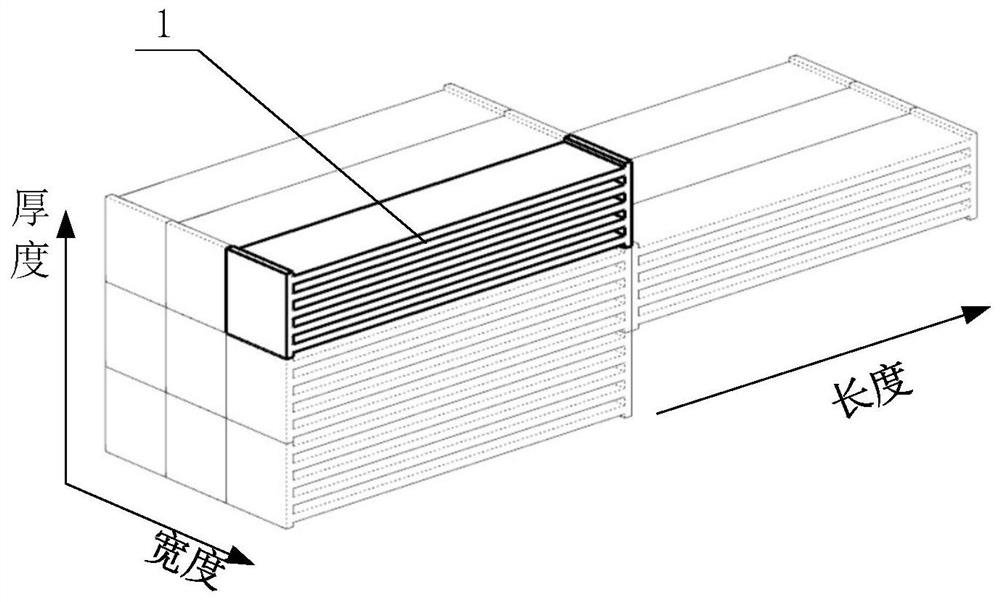

[0052] see figure 1 , this embodiment 1 is an overall structure based on intelligent flexible bending deformation driven materials formed by superimposing basic parallel units in the three directions of length, width and thickness. Two layers of basic parallel units are superimposed in the length direction, and superimposed in the width and thickness directions A three-layer basic parallel unit is proposed, which can increase the bending deformation range and output force of the overall parallel structure.

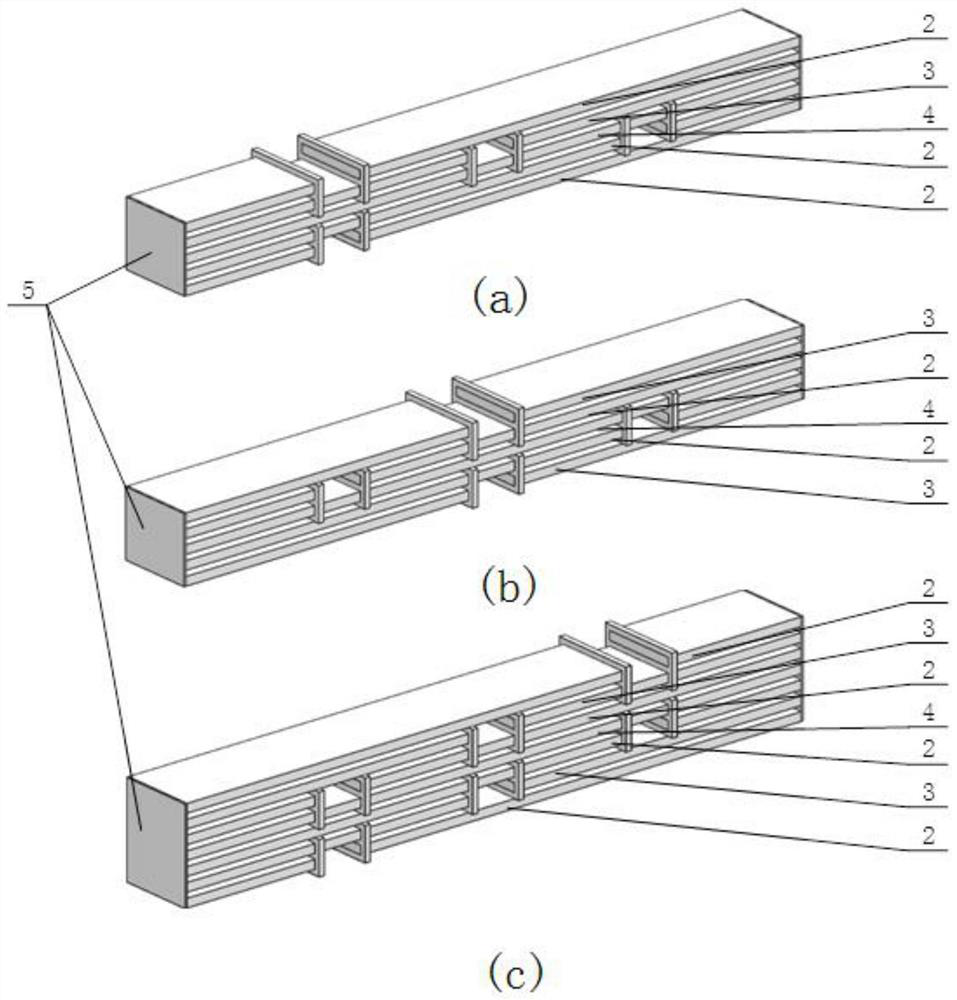

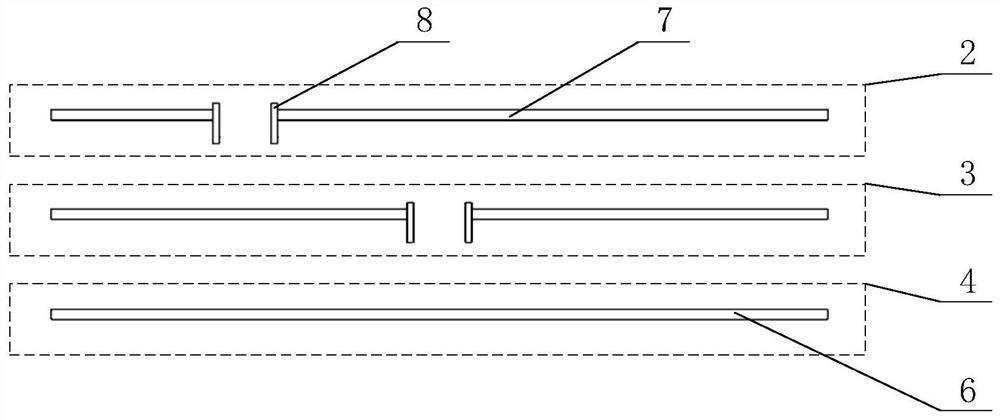

[0053] see figure 2 , the basic parallel unit 1 is flexibly composed of subunits of different structural forms. figure 1 The basic parallel unit in the figure 2 The basic parallel unit in the structure can also be composed of other reasonable basic parallel unit structures. The connectors 5 arranged on both sides of the basic parallel unit 1 are directly connected to each subunit structure by bonding, interference fit, magnetic link, etc. to form a fixed connection, w...

Embodiment 2

[0057] This embodiment is a comparative test of the output force of the single-layer drive structure and the parallel drive structure. In the test, the bending deformation driving material is unified with IPMC material with a width and thickness of 5mm*1mm, and the overall length of the driving structure is 60mm. Among them, the parallel driving structure is figure 2 A single basic parallel unit 1 shown in (a) constitutes. By applying the same voltage to the overall structure, one obtains Figure 5 Output force results shown.

[0058] see Figure 5 , the output force of the single-layer drive structure is 24mN, and the output force of the parallel drive structure can reach 95mN, which is about 4 times the output force of the single-layer drive structure. The test shows that the parallel driving structure can obviously improve the output force of the driving structure. Its overall driving efficiency is about 80%, indicating that Figure 4 The empty sleeve connection stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com