A kind of packaging equipment and packaging method of air-sensitive two-dimensional material device

A two-dimensional material and packaging equipment technology, applied in electrical components, devices for coating liquid on surfaces, coatings, etc., can solve problems such as orbital hybridization, and achieve the effect of ensuring reliability and protecting the gas environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

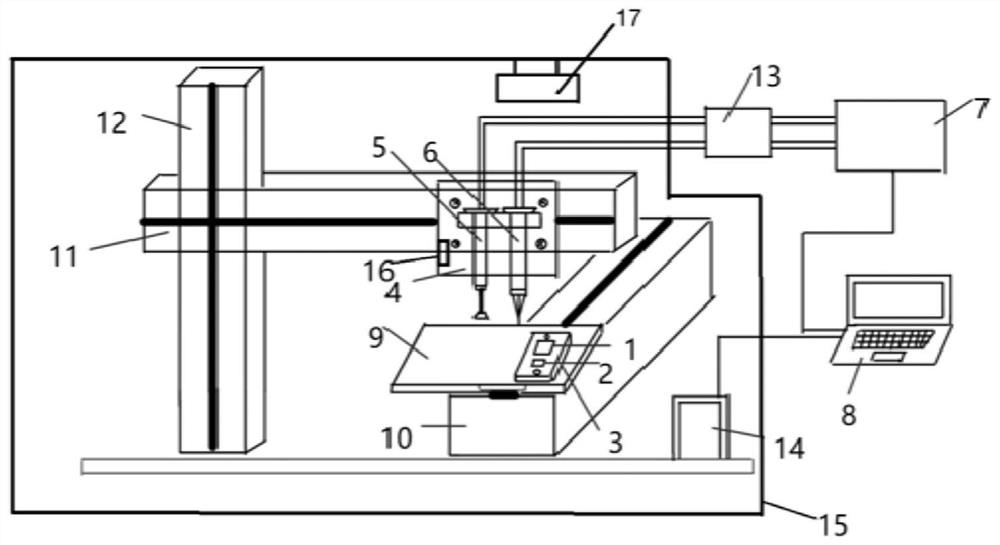

[0042] Equipment structure and connection method:

[0043] This embodiment provides a packaging device for an air-sensitive two-dimensional material device, including a glue supply device, a fixing device, and an operating device placed inside an integrated cavity; a Raman spectrometer is built in the packaging device, and the operating device is used to control the feeding device. The glue device moves and is placed in the integrated chamber after assembly.

[0044] The fixing device includes a base 3 fixed inside the packaging device for placing the sample base 1 and the cover glass 2 . The operating device is a CNC linear guide rail linear sliding table module composed of a precision stepping cross motor and a ball screw guide rail, which can precisely control the movement of the sliding table by writing G codes. The dispensing device includes a dispensing needle 6, an air pump 7 and an air flow controller 13 are connected to the dispensing needle 6, the air pump 7 extrude...

Embodiment 2

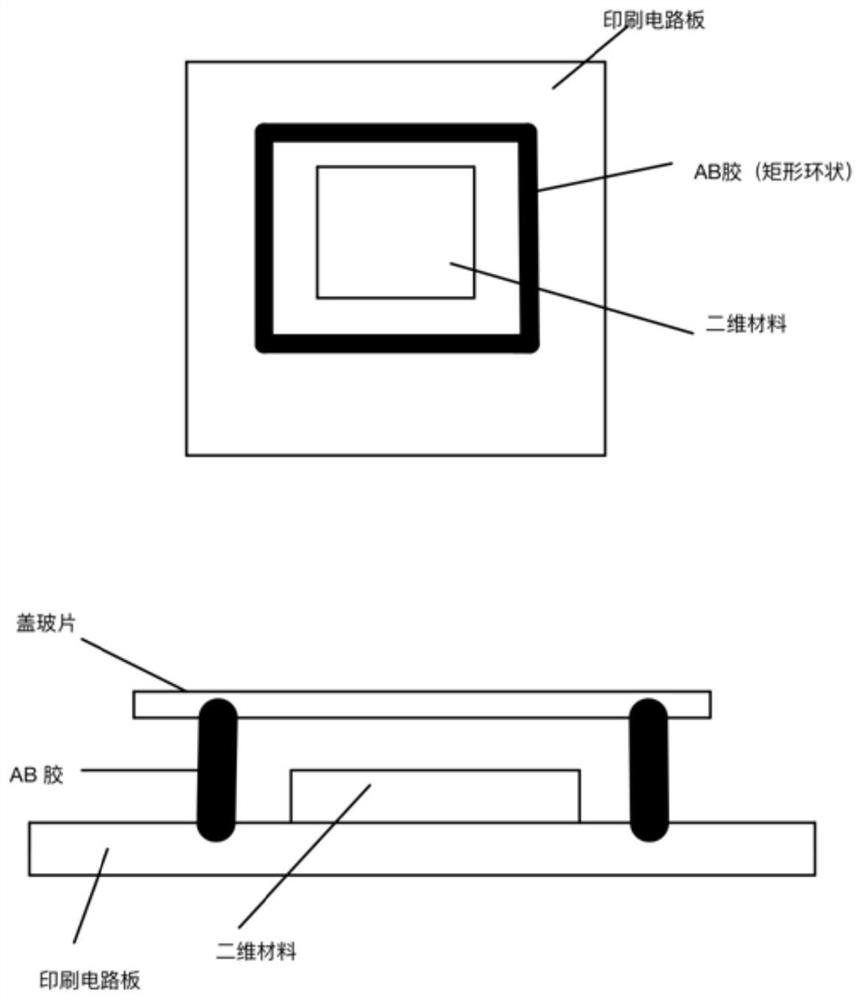

[0059] The packaging method of the air-sensitive two-dimensional material device in this embodiment is carried out by using the air-sensitive two-dimensional material device packaging equipment in Example 1.

[0060] Wherein, the base 3 is fixed on the right edge of the packaging system platform 9, which is convenient for the two steps of glue dispensing and capping.

[0061] The bracket 4 has two circular grooves for fixing the dispensing needle tube 6 and the suction cup needle tube 5, and is fixed on the numerical control mechanical arm of the packaging system by screws. The dispensing needle tube 6 is placed on the suction cup needle tube 5 right sides, five centimeters apart. When the dispensing needle tube 6 is dispensing glue (encapsulation glue) on the sample base 1, the suction cup needle tube 6 is suspended outside the base 3; when the suction cup needle tube 6 picks up the cover glass 2 and hovers over the two-dimensional material, the The needle tube 6 is suspende...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com