Assembling tool and method for box-packed mechanical seal

A mechanical seal, box-packed technology, applied in hand-held tools, manufacturing tools, etc., can solve problems such as damage to the sealing surface, achieve the effects of easy installation, simple structure, and improved work quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

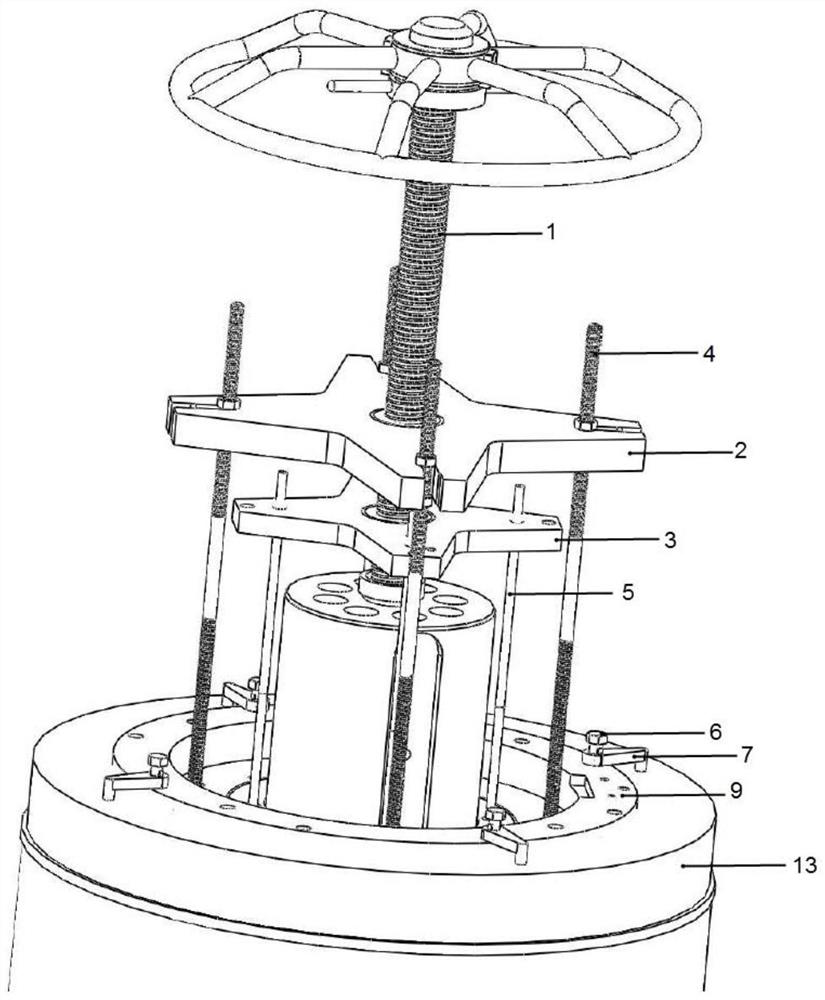

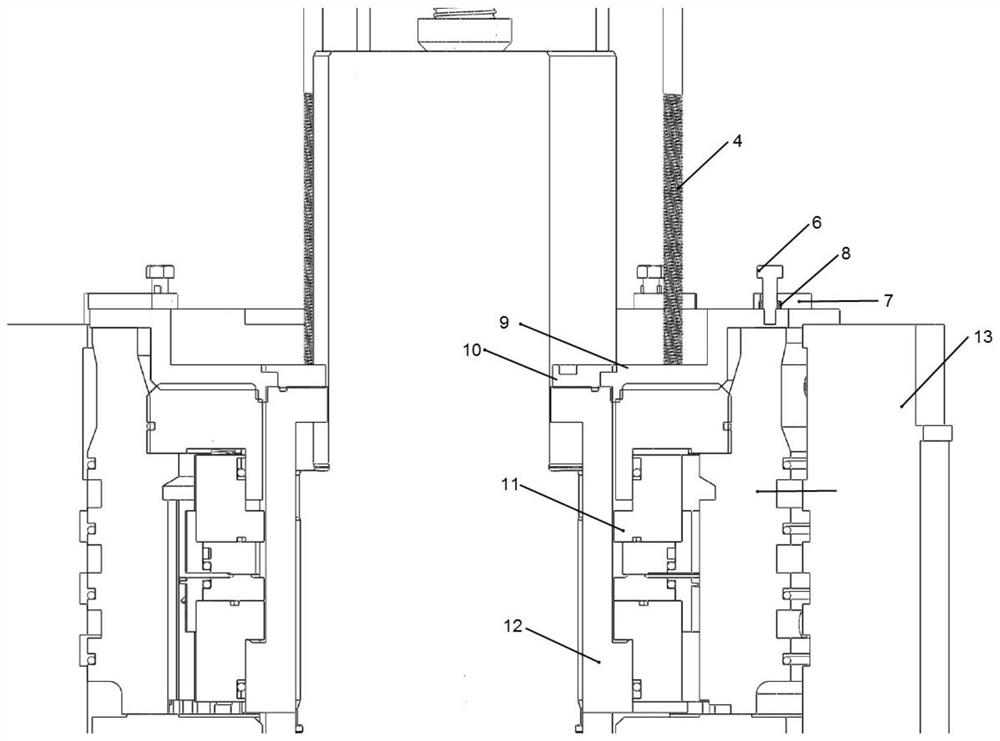

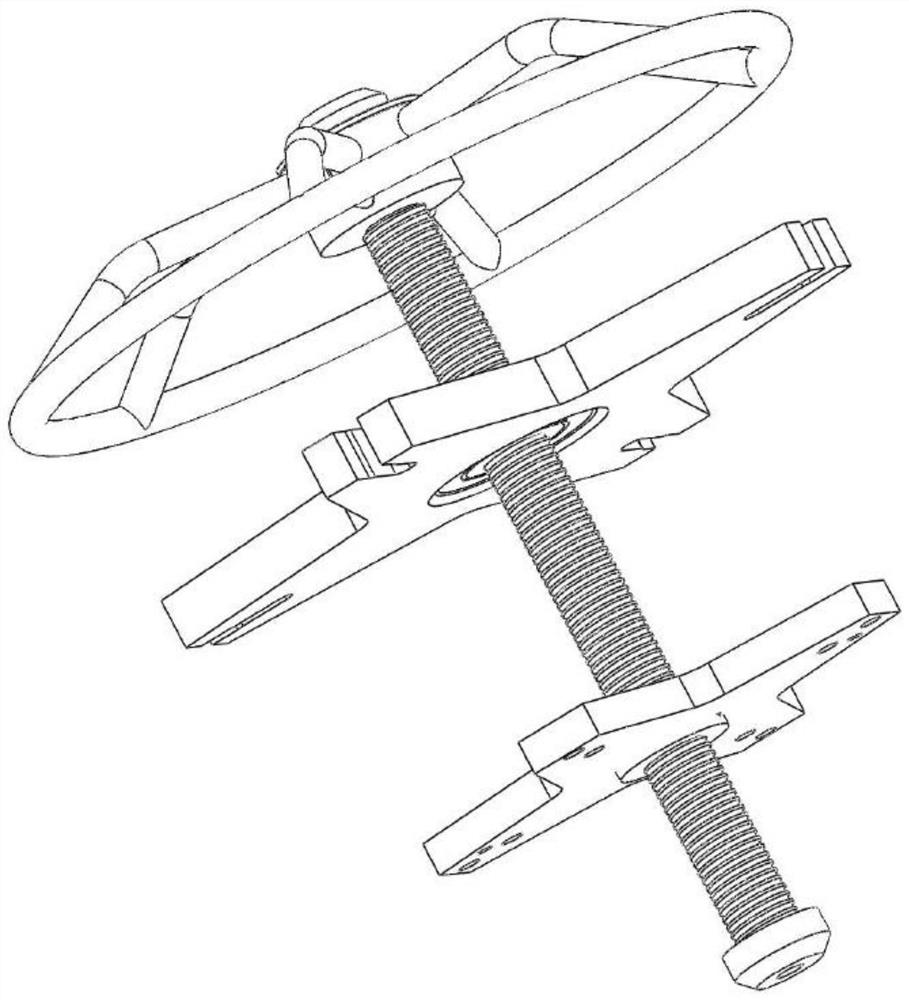

[0038] As shown in the figure, the present invention is a tooling for box-mounted mechanical seal assembly, including a screw-up mechanism 1, a star plate A2, a star plate B3, 4 screws A4, 4 screws B5, 4 Special-shaped bolts 6, 4 support rods 7, 4 springs 8, outer ring 9, inner ring 10, mechanical seal static ring assembly 11, mechanical seal dynamic ring assembly 12, mechanical seal chamber 13;

[0039] The mechanical seal static ring assembly 11 is arranged in the mechanical seal chamber 13;

[0040] The adapter ring assembly includes an inner adapter ring 10 and an outer adapter ring 9, and a support rod assembly;

[0041] The outer ring 9 is connected to the mechanical seal static ring assembly 11 by bolts, and is linked to the star disk A2 by four screws A4 evenly arranged around the circle; the inner ring 10 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com