Ultrasonic atomization piece, manufacturing process thereof and ultrasonic electronic cigarette

A production process, ultrasonic technology, applied in the fields of tobacco, smoker supplies, food science, etc., can solve the influence of the oil conduction smoothness of the atomizer at the operation level, affect the atomization effect and suction experience, and the time-consuming assembly of the oil conduction medium Power consumption and other issues, to achieve the effect of ensuring the suction experience, avoiding inconsistency, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

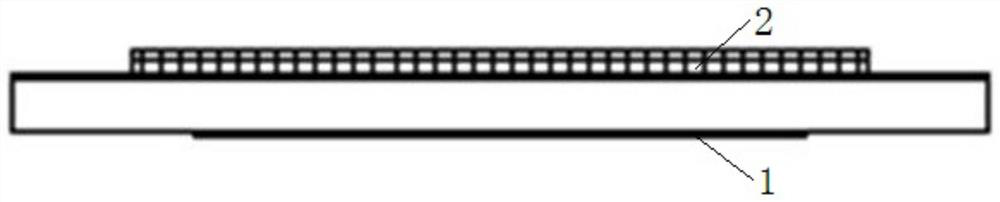

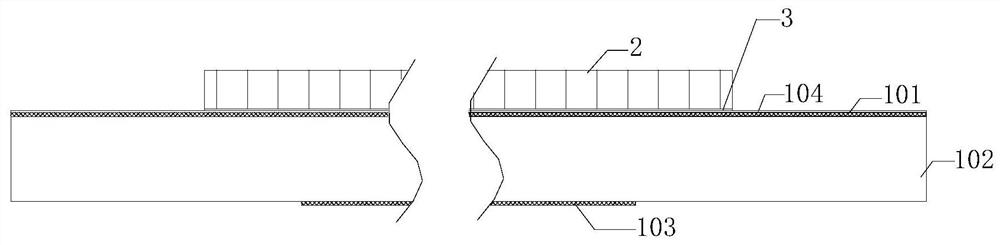

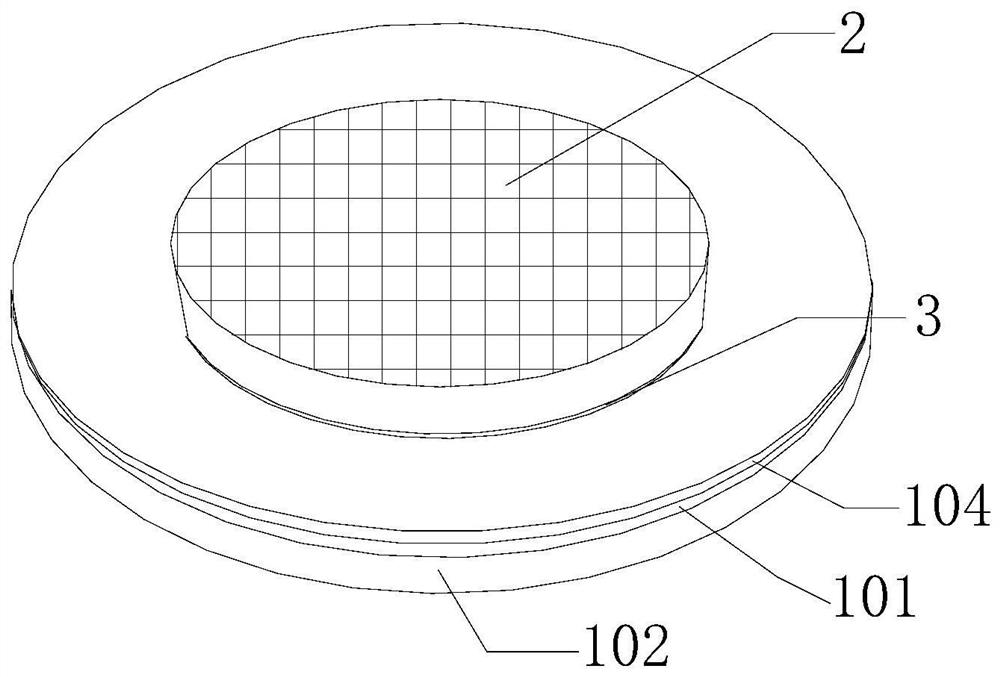

[0057] Such as Figure 1 to Figure 4 As shown, the first embodiment of the ultrasonic atomizing sheet includes a piezoelectric vibrator 1 , and a porous oil-conducting layer 2 is fixed on the upper surface of the piezoelectric vibrator 1 . The porous oil-conducting layer 2 is fixed on the upper surface of the piezoelectric vibrator 1 through the adhesive layer 3 .

[0058] The piezoelectric vibrator 1 includes a glaze layer 104 , an upper electrode layer 101 , a piezoelectric ceramic sheet 102 , and a lower electrode layer 103 arranged in sequence from top to bottom. The driving control circuit generates a driving voltage consistent with the resonance frequency of the piezoelectric vibrator 1 and applies it to the piezoelectric vibrator 1, the piezoelectric vibrator 1 will generate high-frequency resonance, thereby breaking up and atomizing the liquid e-liquid to generate smoke.

[0059] Figure 5 shows various structures of the cross-section of the porous oil-conducting lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com