Oil lubrication stern shaft bearing sealing device

A technology of bearing sealing and oil lubrication, which is applied in the direction of propulsion transmission, engine sealing, and transmission with synchronous propulsion components, etc. It can solve the problem of pressure resistance changes and sealing rings that do not have a good sealing effect on the sealing end cover , elastic pressure reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

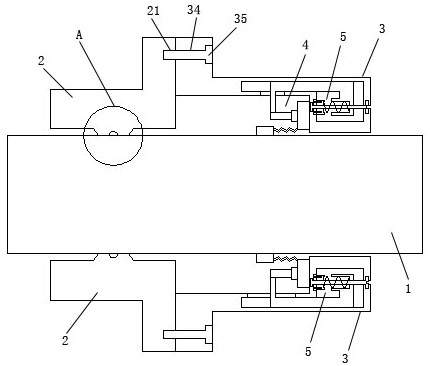

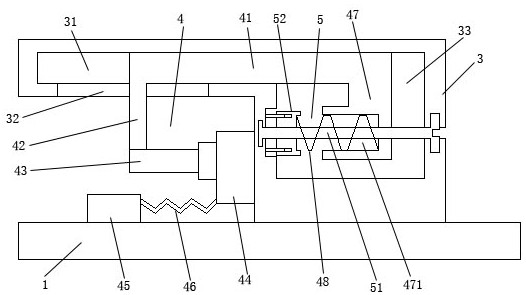

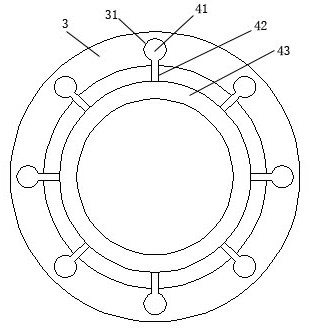

[0020] like Figures 1 to 5 As shown, an oil-lubricated stern shaft bearing sealing device includes a stern shaft 1, a front end cover 2, a rear end cover 3, a sealing assembly 4, an adjustment mechanism 5, and an abutting lubricating ring body 6; the front end cover 2 and the rear end The cover 3 is connected end-to-end; the stern shaft 1 is installed between the front end cover 2 and the rear end cover 3; the sealing assembly 4 includes a fastening sealing ring 45, a pressing sealing ring 44, a telescopic hose 46, Squeeze ring 43, piercing rod 42, guide sliding rod 41, driving ring 47, pressing elastic body 48; the inside of the rear end cover 3 is provided with a plurality of guide channels 31 along its length direction; the rear end cover 3 is provided with an annular drive groove 33 inside the outer end surface; the outer ends of the plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com