Radial and axial double-seal pressing type stern shaft sealing piece

A double-seal and compression technology, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problem of changes in the pressure resistance of the sealing ring and the sealing end cover, the reduction of the elastic resistance pressure, and the impact of the sealing ring on the sealing end cover. There are no problems such as a good sealing effect, so as to improve the sealing performance and achieve the effect of abutment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The contents of the present invention will be further described in detail below with reference to the accompanying drawings.

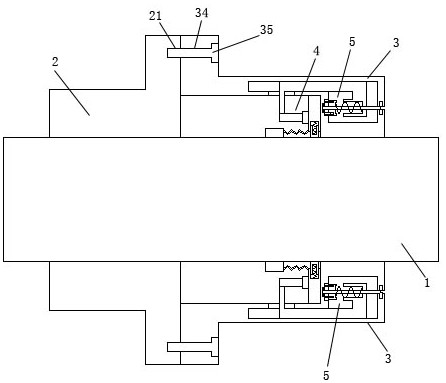

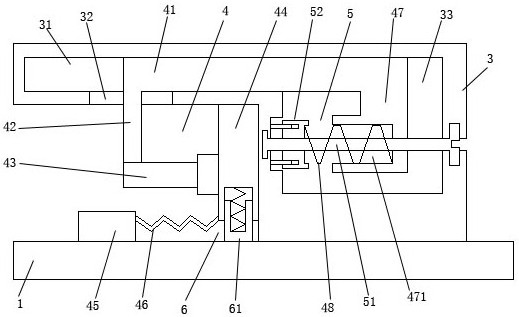

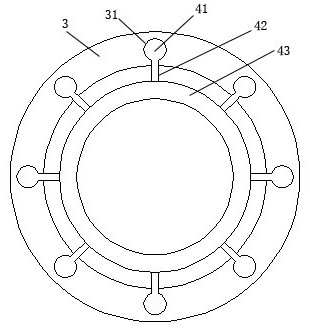

[0020] Such as Figure 1 to 5 As shown, a radial and axial double-sealed pressed axial seal, including the shaft 1, the front end cover 2, the rear end cover 3, sealing assembly 4, regulating mechanism 5, radial abutting mechanism 6; The front end cover 2 and the rear end cap 3 end are connected to the end connection; the shaft shaft 1 is coupled between the front end cover 2 and the rear end cap 3; the sealing assembly 4 includes a fastening seal ring 45, a pressure seal ring 44, the telescopic hose 46, the extrusion ring 43, the passing rod 42, the guide slider 41, the drive ring 47, pressure elastomer 48; the rear end cover 3 four weeks, there is a plurality of guide channels in its longitudinal direction 31; The outer end surface of the rear end cap 3 is provided with an annular driving groove 33; the outer end of the plurality of guide channels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com