Transmission device for a hybrid vehicle

A motor vehicle and torque transmission technology, which is applied in the direction of hybrid vehicles, power devices, air pressure power devices, etc., can solve problems such as the complexity of transmission device installation, achieve radial and axial compactness, reduce floor space, and effectively Contributes to the effect of axial and radial compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

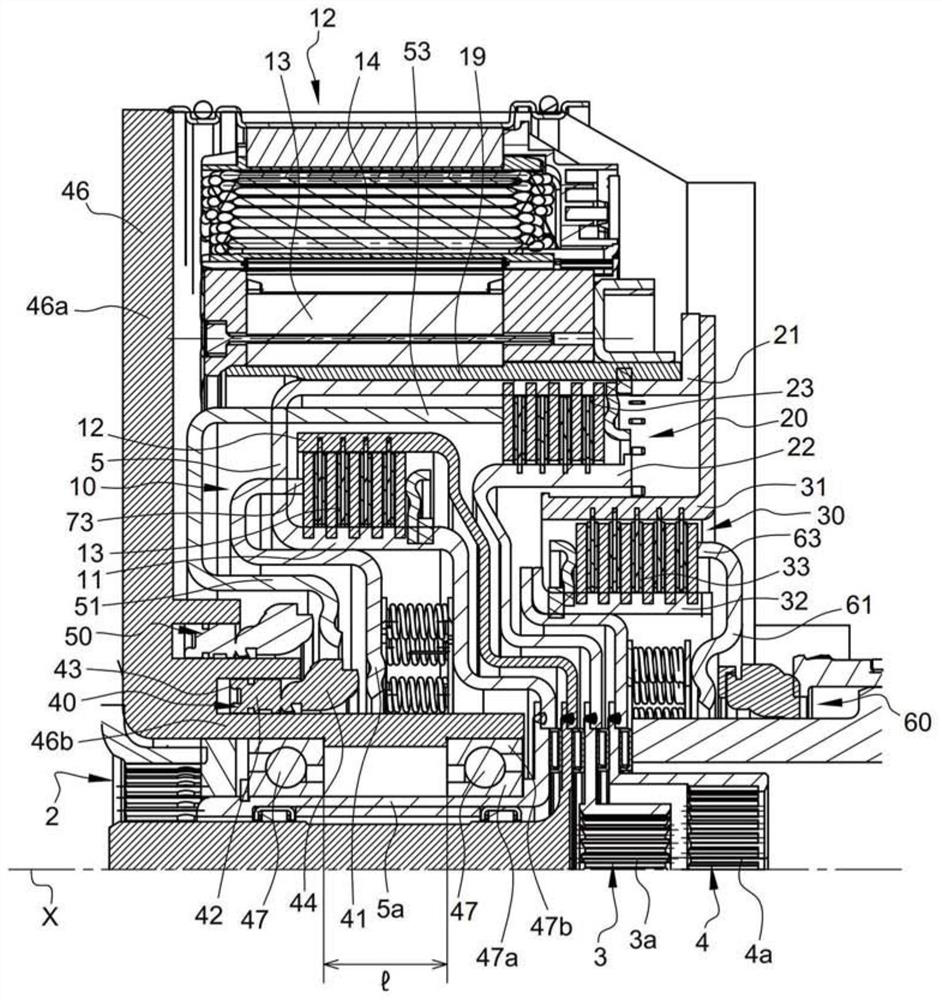

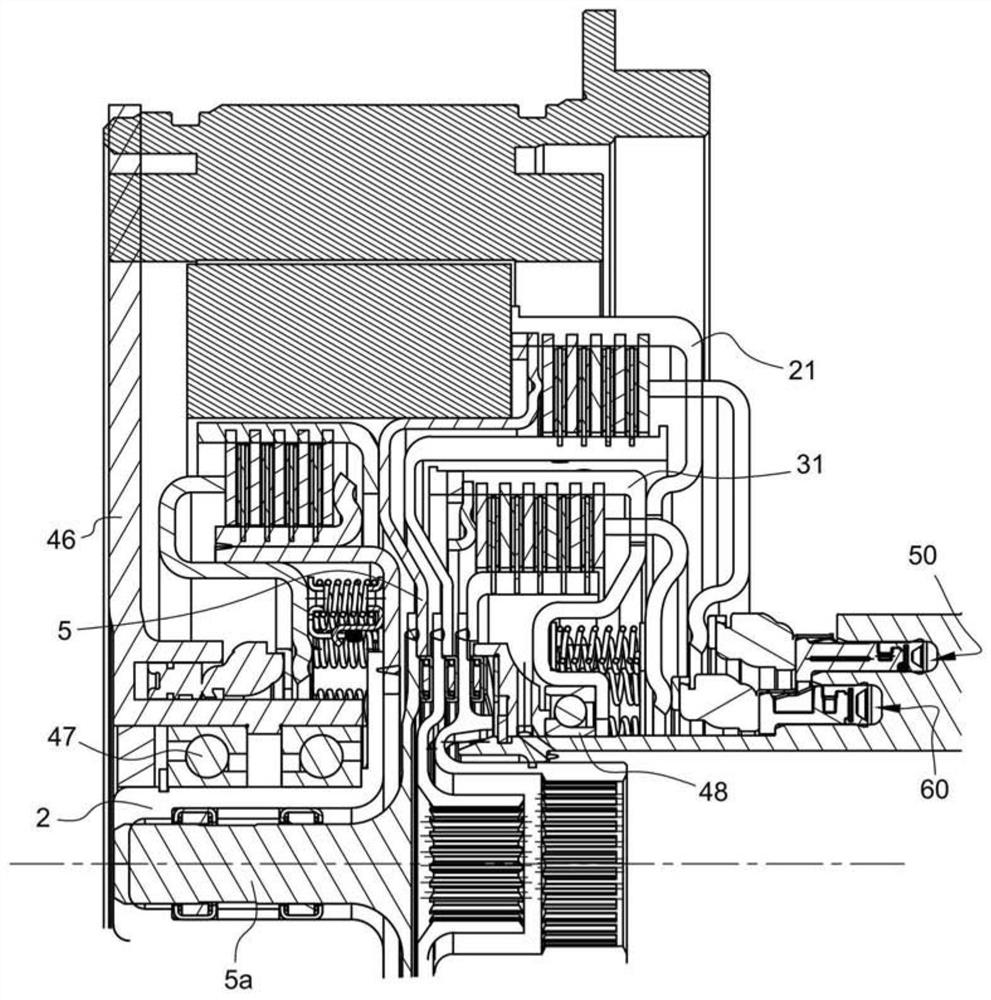

[0062] refer to figure 1 , shows a torque transmission device 1 comprising:

[0063] - a torque input element 2 which rotates about an axis of rotation X and is rotatably coupled to the crankshaft of an internal combustion engine (not shown),

[0064] - a first torque output member 3, rotatably coupled to a first input shaft of a gearbox (not shown),

[0065] - second torque output member 4, rotatably coupled to the second input shaft of the gearbox (not shown), and

[0066] In the example considered, the second output element 4 is arranged parallel to the first output element 3 in the direction of torque transmission. Each of these elements rotates about the axis of rotation X of the device.

[0067] The first output element 3 and the second output element 4 respectively include a first output interface 3a and a second output interface 4a, and the inner circumferences of the first output interface 3a and the second output interface 4a are splined and can be connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com