Non-single incident angle unequal-intensity laser shock processing method

A technology of laser shock and incident angle, which is applied in the field of laser shock, can solve the problems of low processing technology, achieve the effects of improving strengthening efficiency, facilitating operation, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

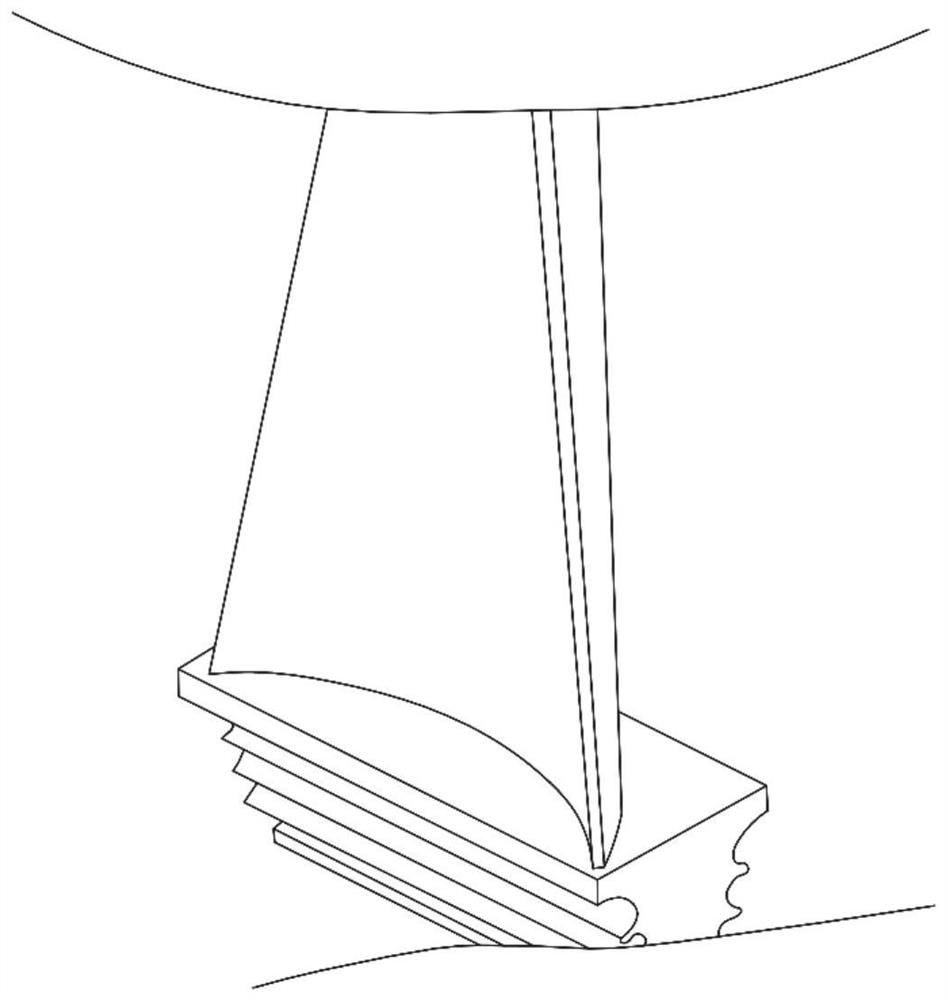

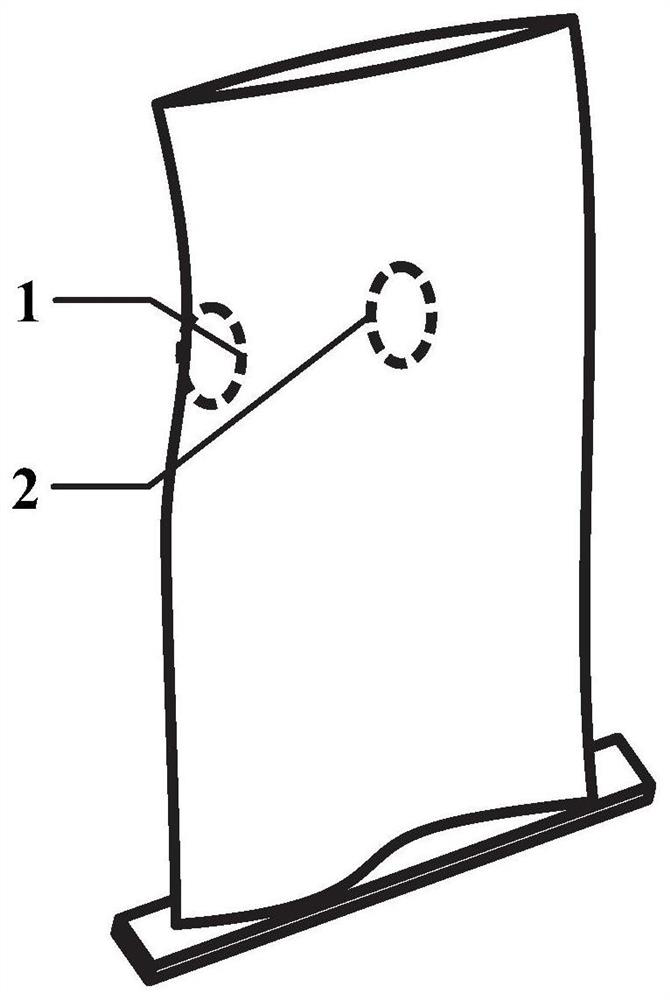

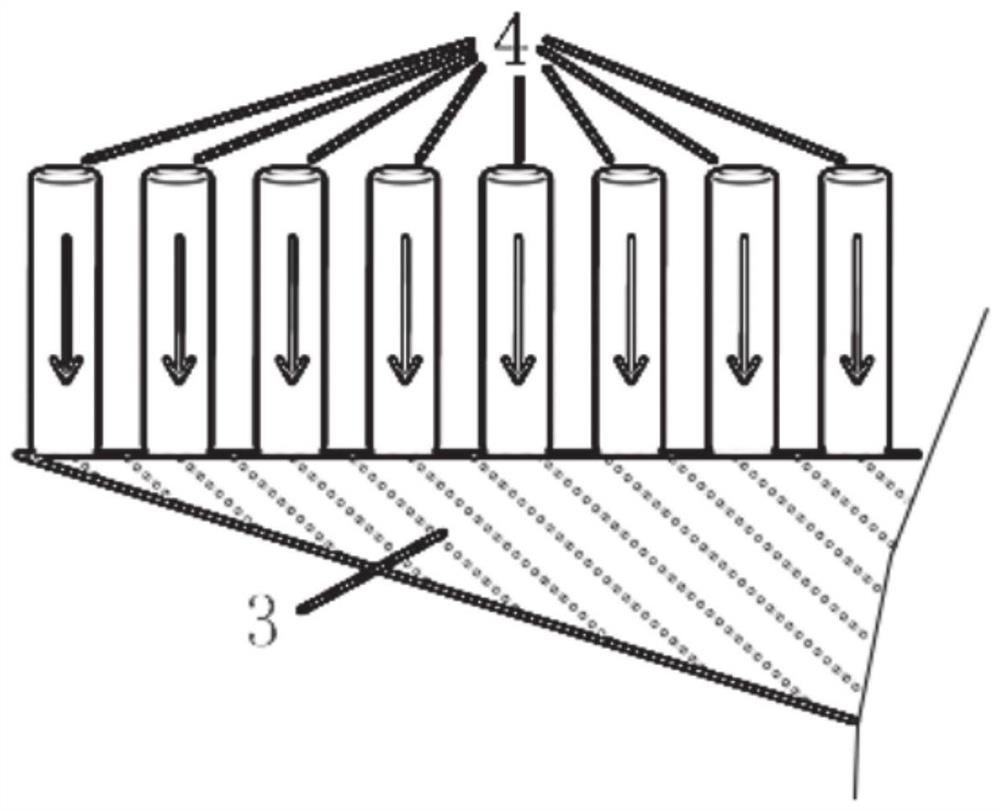

[0032] In a typical implementation of the present invention, this embodiment discloses a non-single incident angle and unequal intensity laser shock processing method, including the following steps:

[0033] According to the thickness, the component to be processed is divided into the area whose thickness is greater than or equal to the set value and the area whose thickness is less than the set value;

[0034] According to the target processing effect of each area, determine the laser processing parameters of each area;

[0035] Through the adjustment of the spatial position of the component to be processed and the incident direction of the laser, the unequal intensity processing of different processing regions of the component to be processed can be realized.

[0036] Specifically, in this embodiment, it can be divided into the following specific steps:

[0037] (1) Determine the insensitive area of the component to be processed to laser shock.

[0038] The laser shock i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com