Nonwoven fabric laminate, stretchable nonwoven fabric laminate, fiber product, absorbent article and hygienic mask

A non-woven fabric, spunbond non-woven fabric technology, applied in non-woven fabrics, absorbent pads, layered products, etc., can solve the problems of reduced sealing strength, hardened sealing parts, shortened sealing time, etc., and achieve good expansion and contraction characteristics , The effect of good low temperature heat sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

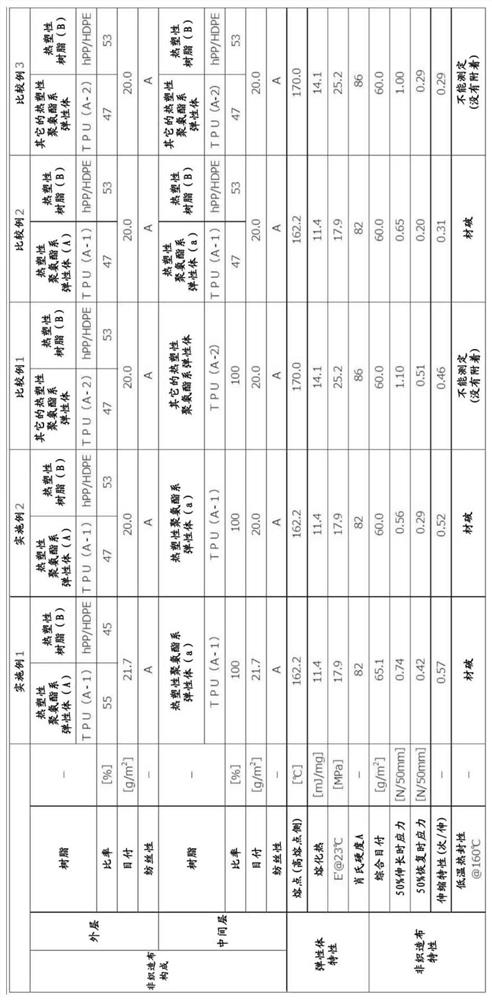

Embodiment 1

[0188]

[0189] Use TPU (A-1) and thermoplastic resin composition (B-1) each independently extruder and After the extruder is melted, use a spunbonded nonwoven fabric forming machine with a spinneret, with the resin temperature and die temperature both at 210°C, the cooling air temperature at 20°C, and the stretching air speed at 3160m / min. Carry out melt spinning by spunbonding method, make the long fiber A that is formed by TPU (A-1) and the long fiber B that is formed by thermoplastic resin composition (B-1) The mixed fiber mass ratio is the net of 55:45 ( web) accumulate on the capture surface.

[0190] In addition, the above-mentioned spinneret has a nozzle pattern in which the discharge holes of A-1 (long fiber A) and the discharge holes of B-1 (long fiber B) are arranged alternately, and the diameter of the nozzle of long fiber A is The nozzle diameter of long fiber B is The pitch of the nozzles is 8 mm in the vertical direction and 11 mm in the horizontal dire...

Embodiment 2

[0198]

[0199] Use TPU (A-1) and thermoplastic resin composition (B-1) each independently extruder and After the extruder is melted, use a spunbonded nonwoven fabric forming machine with a spinneret, with the resin temperature and die temperature both at 210°C, the cooling air temperature at 20°C, and the stretching air speed at 3160m / min. Melt spinning by a spunbonding method, and a web in which the mixed fiber mass ratio of long fibers A made of TPU (A-1) and long fibers B made of thermoplastic resin composition (B-1) is 47:53 is deposited on the capture surface. In addition, the above-mentioned spinneret has a nozzle pattern in which the discharge holes of A-1 (long fiber A) and the discharge holes of B-1 (long fiber B) are arranged alternately, and the diameter of the nozzle of long fiber A is The nozzle diameter of long fiber B is The pitch of the nozzles is 8 mm in the vertical direction and 11 mm in the horizontal direction, and the ratio of the number of nozz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com