Automatic fire extinguishing system and method for cable tunnel

An automatic fire extinguishing system and cable tunnel technology, which is applied in the field of cable tunnel fire prevention, can solve the problems of inconvenient maintenance, high cost, long cable tunnel inspection route, etc., and achieve the effect of quick pick-and-place and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

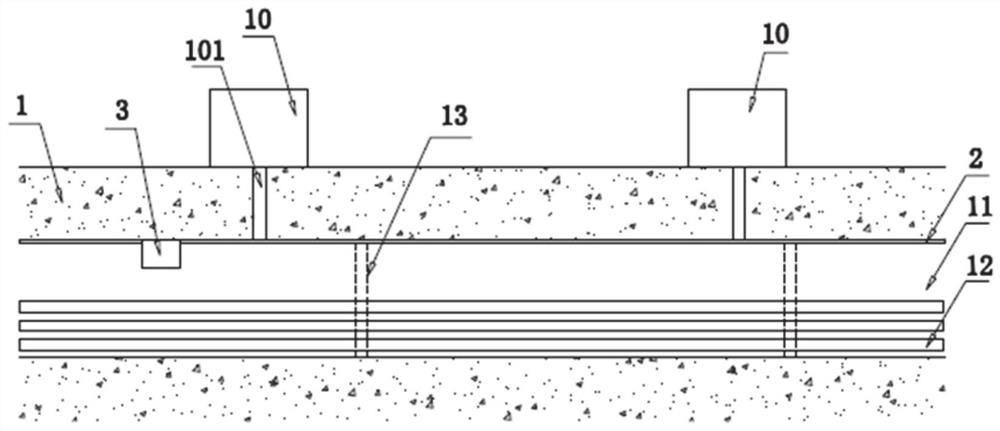

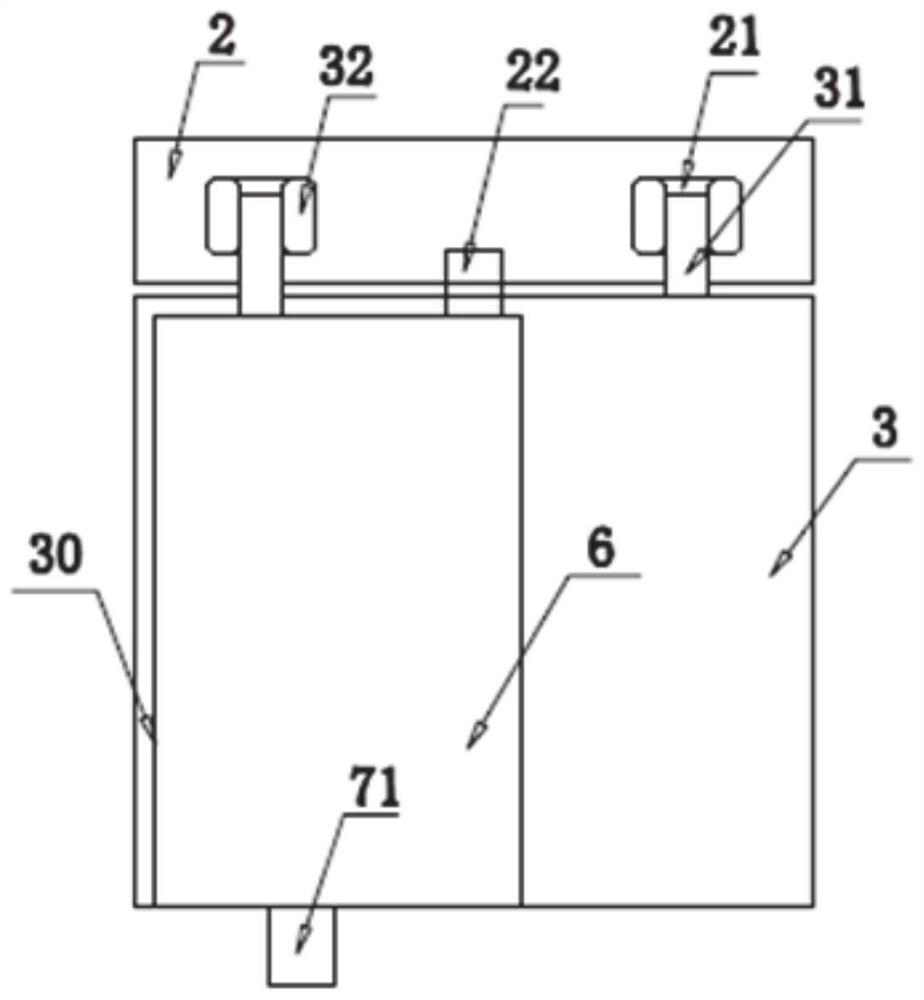

[0061] Embodiment 1 of the present disclosure provides an automatic fire extinguishing system for a cable tunnel, which includes:

[0062] guide rail, which is fixed on top of the cable tunnel;

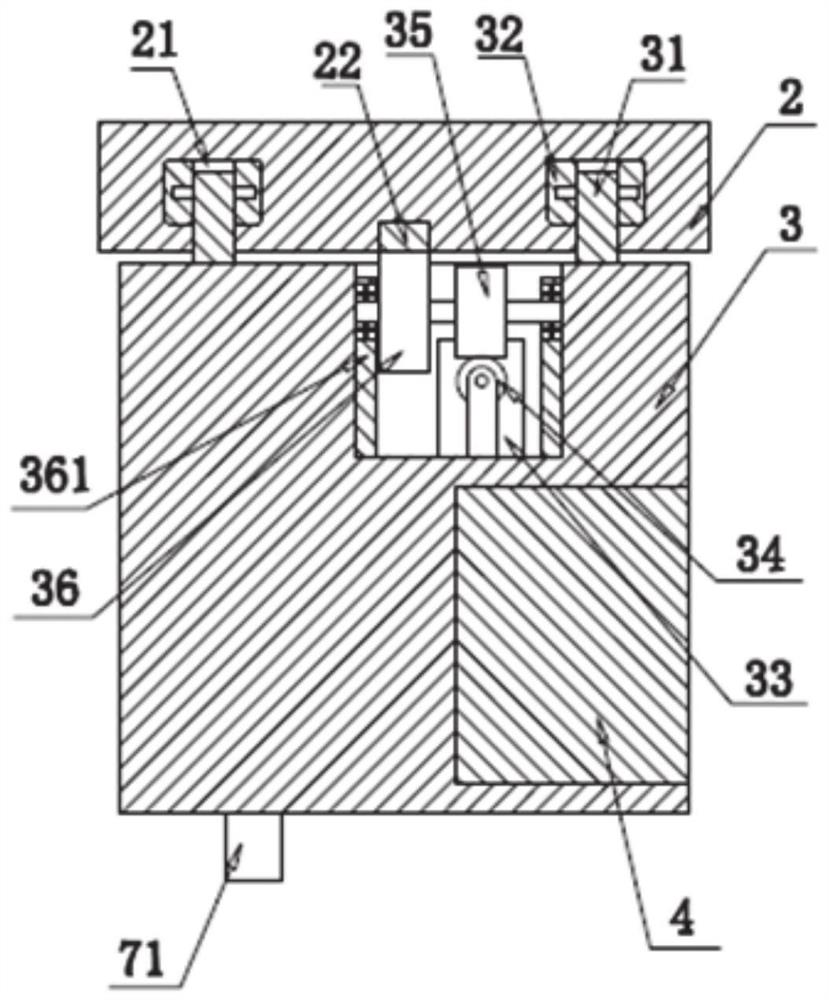

[0063] An inspection robot is arranged to move along the guide rail, and a first driving mechanism is arranged on the inspection robot, and the inspection robot walks along the guide rail under the action of the first driving mechanism;

[0064] The battery is arranged in the battery slot on the inspection robot, and the inspection robot is provided with a first locking mechanism for locking the battery;

[0065] A charging unit, which is arranged on the side wall of the cable tunnel, is used to charge the battery;

[0066] A positioning robot, which is arranged on the inner side of the inspection robot, is provided with a second driving mechanism on the mobile robot, and the positioning robot moves along the guide rail under the action of the second driving mechanism, and is provide...

Embodiment 2

[0093] Embodiment 2 of the present disclosure provides an automatic fire extinguishing method for a cable tunnel, including the following steps:

[0094] Step 1: Monitor the fire in the cable tunnel through the inspection robot installed in the cable tunnel;

[0095] Step 2: When a fire is found, the inspection robot quickly moves to the fire source and moves to the nearest docking pipe;

[0096] Step 3: The fire extinguishing mechanism is connected with the docking pipe to realize the connection between the fire extinguishing pipeline and the fire extinguishing mechanism;

[0097] Step 4: The positioning robot moves out of the inspection robot until it moves to the place closest to the fire source;

[0098] Step 5: Extinguish the fire source through the fire extinguishing mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com