Plate turnover machine with plate protection function

A protection function, the technology of turning machine, applied in the field of turning machine, can solve the problems of inability to turn the board, occupy a large space, and high cost of the cylinder, and achieve the effects of flexible and ingenious methods, reasonable and effective structure, and stable and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

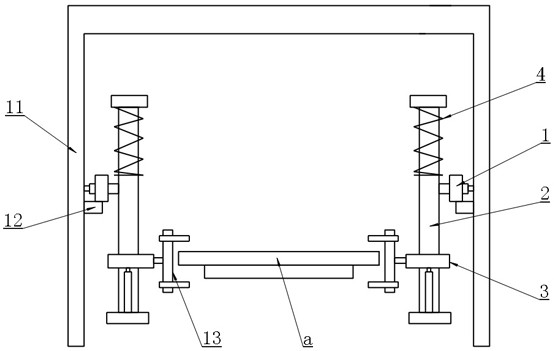

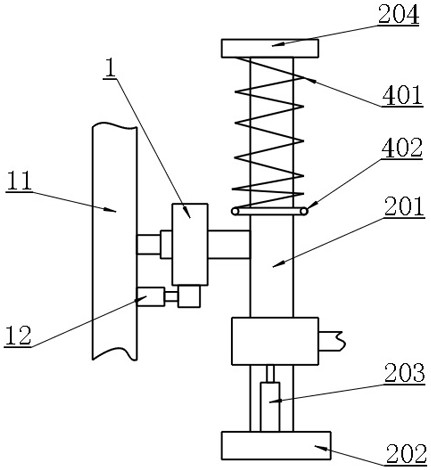

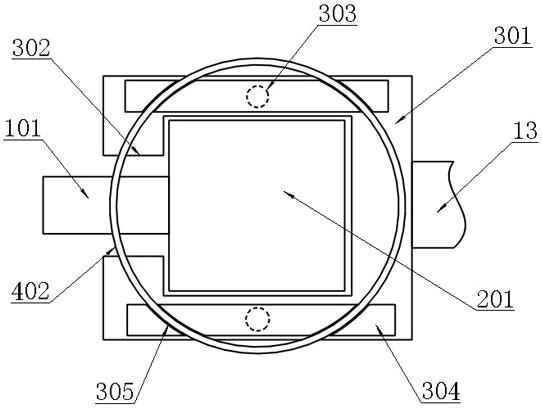

[0024] Example: as attached figure 1 , 2, 3, 4 and attached Figure 5 As shown, the turnover machine with plate protection function includes a stand 11, a drive motor 12 arranged on the stand 11, and a pick-and-place clamp 13 connected to the drive motor 12 and used to pick and place the plate a, It also includes a rotating unit 1 arranged on the stand 11 and connected to the driving motor 12, a rotating plate unit 2 arranged on the rotating unit 1, arranged on the rotating plate unit 2 and equipped with the The sliding block unit 3 of the pick-and-place folder 13, and the elastic buffer unit 4 arranged on the rotating plate unit 2 and used for elastically protecting the sliding block unit 3.

[0025] In this embodiment, the rotating unit 1 and the pick-and-place folder 13 are in an idle state initially, and the number of the pick-and-place folder 13 is two, and the pick-and-place folder 13 is distributed on both sides of the roller table for conveying the plate to avoid Col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com