Improved plate turnover machine with quick turnover function

An improved, flipping machine technology, applied in the field of sheet metal processing, can solve the problems of loud noise, falling, impact, damage to the sheet, etc., and achieve the effects of safe and reliable action, not easy to break, and reasonable and effective rotating structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

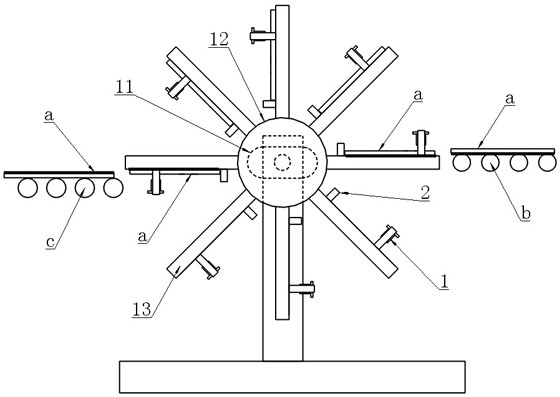

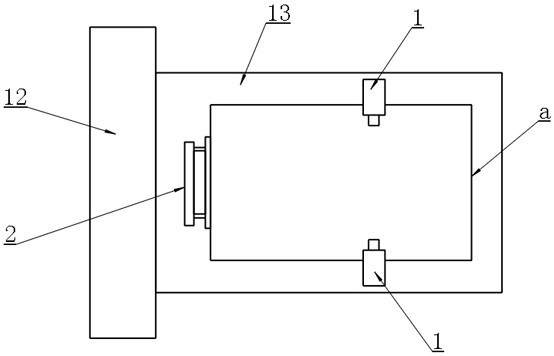

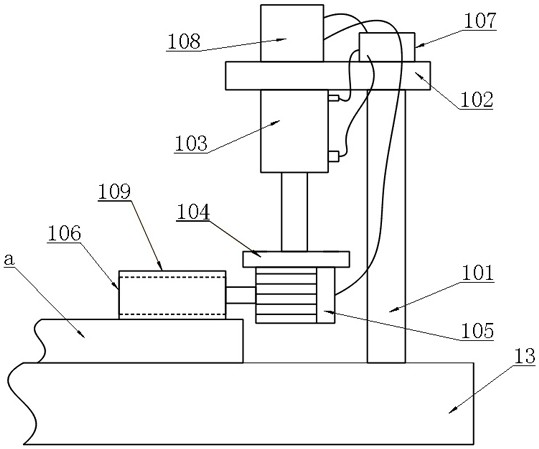

[0025] Example: as attached figure 1 , 2 , 3, 4 and attached Figure 5 As shown, an improved plate turning machine with a quick turning function includes a driving motor 11, a rotating shaft 12 arranged on the driving motor 11, and a rotating shaft 12 arranged on the rotating shaft 12 for supporting the plate The rotating plate 13 also includes a side of the rotating plate 13 that is located in the direction of rotation and is located on both sides of the plate a, and is used to push the plate a toward the direction of the rotating shaft 12 and away from the rotating shaft. The motor pressing unit 1 that pushes the plate a to be discharged in the direction of 12, and the elastic plate unit 2 that is arranged on the side of the rotating plate 13 and is used to elastically lift the plate a outward when the plate a is discharged.

[0026] In this embodiment, initially the motor pressing unit 1 is in an idle state, and the number of the rotating plates 13 is 8, when one of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com