Clamp mechanism for steel plate conveying trolley

A technology for conveying trolleys and clamps, which is applied to the details of milling machine equipment, metal processing, and metal processing equipment. It can solve problems such as complex mechanisms, clamps that cannot be lifted up and down, and high manufacturing costs. It achieves safe and reliable actions, simple structure, and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

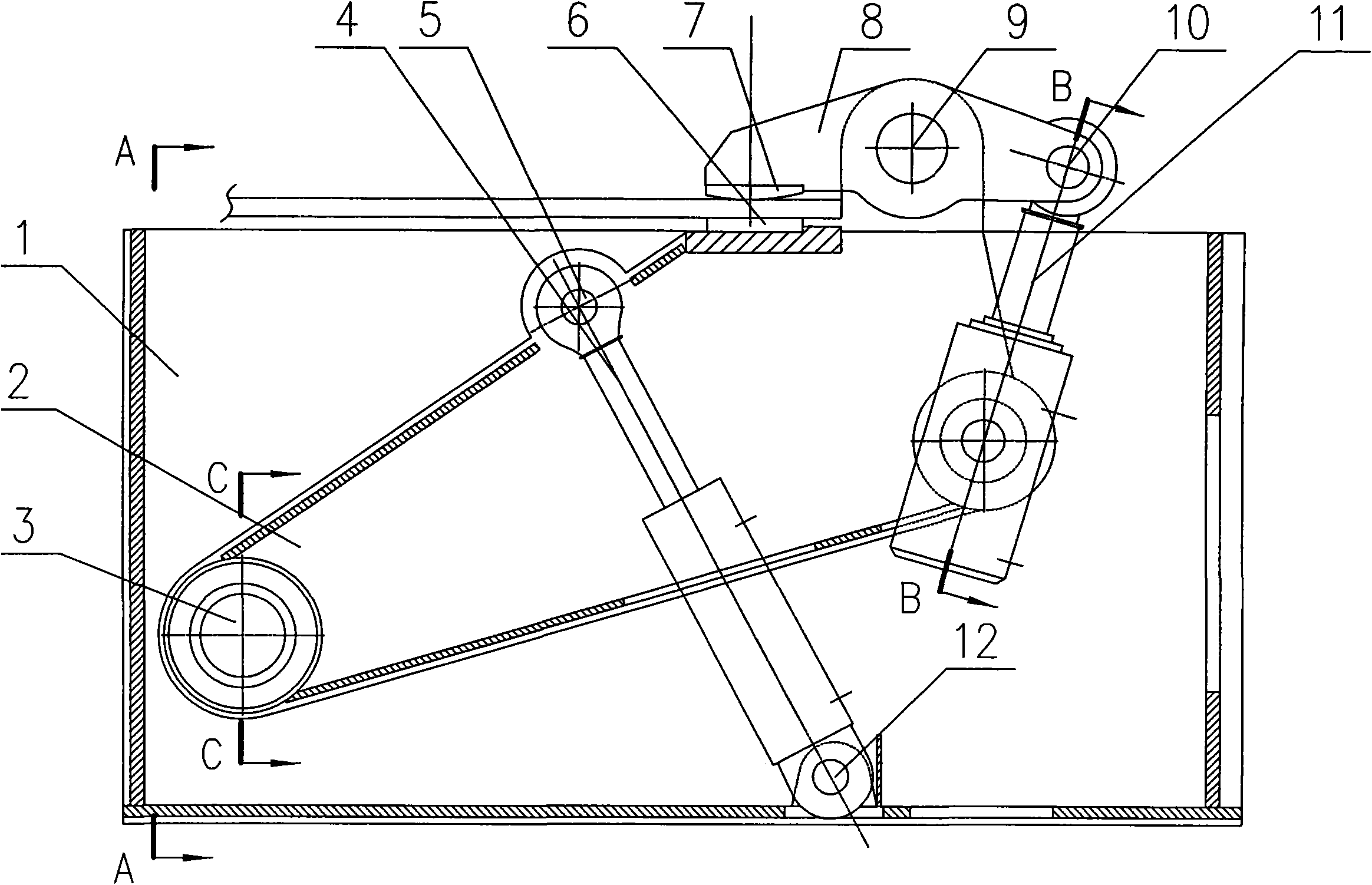

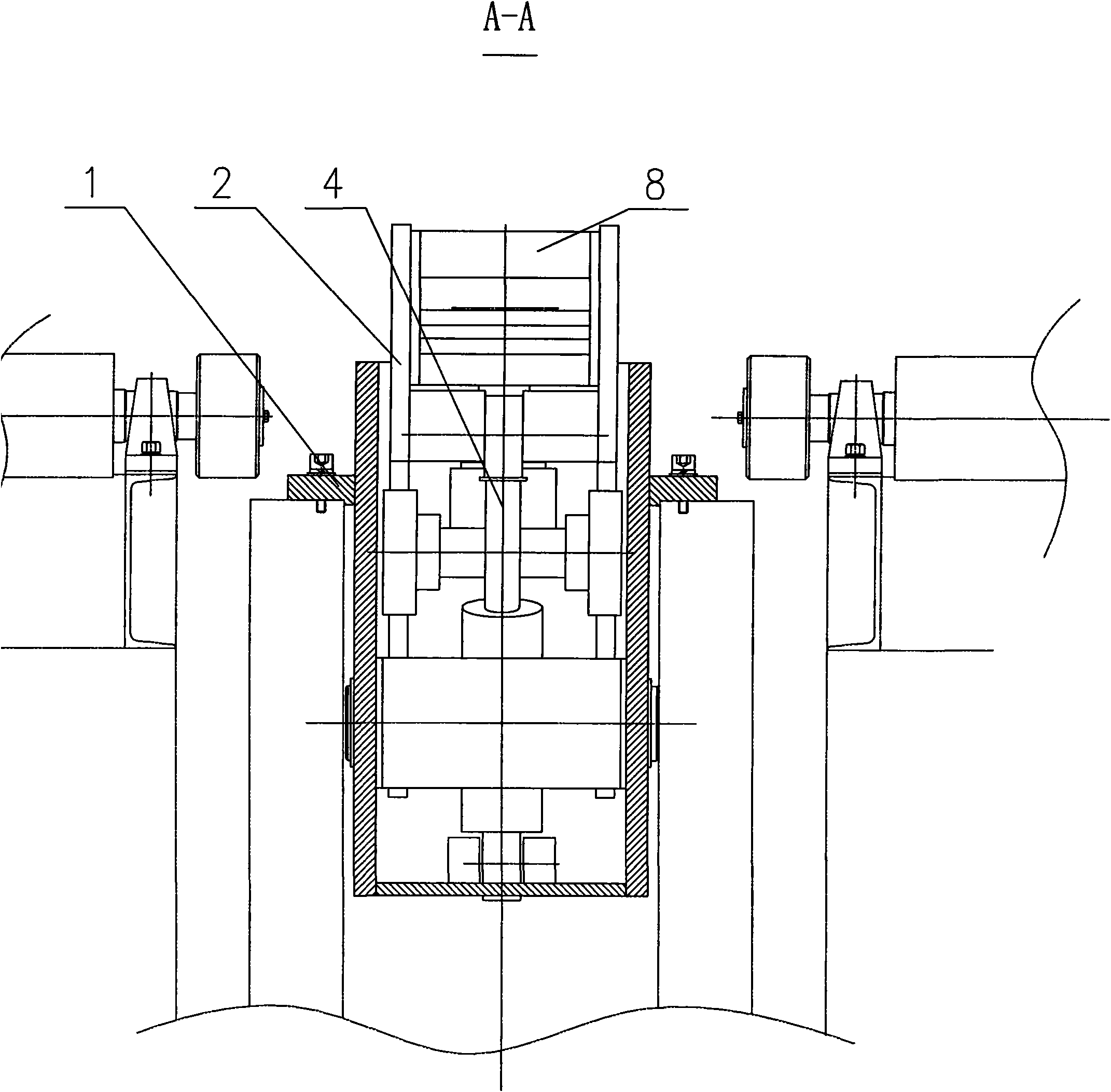

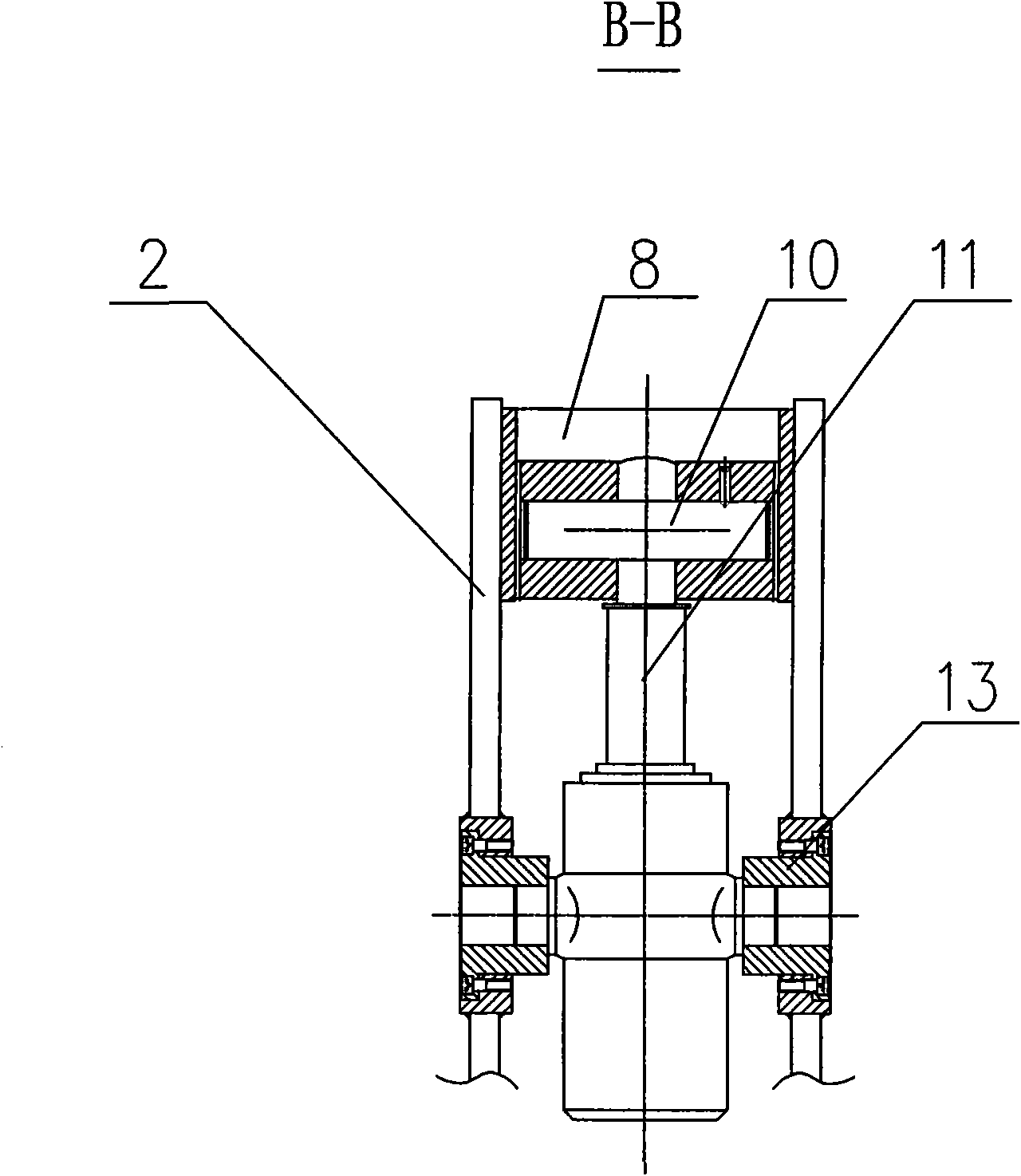

[0013] like Figure 1 ~ Figure 4 As shown, the present invention mainly includes a frame body 1, a swing arm 2, a first pin shaft 3, a swing hydraulic cylinder 4, a second pin shaft 5, a lower jaw 6, an upper jaw 7, a jaw body 8, and a third pin shaft 9. The fourth pin shaft 10, the clamping hydraulic cylinder 11, the fifth pin shaft 12, the oil cylinder mounting seat 13, the copper sleeve 14, and the pressure plate 15. The swing arm 2 is connected to the frame body 1 by the first pin shaft 3, the pressure plate 15 is fixed on both ends of the first pin shaft 3 by bolts, and the copper sleeve 14 is installed in the shaft hole of the swing arm 2. One end of the swing hydraulic cylinder 4 is connected to the swing arm 2 by the second pin shaft 5, the other end is connected to the frame body 1 by the fifth pin shaft 12, and the middle part of the clamp b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com