Motor train unit single carriage brake debugging method and debugging equipment

A debugging method and technology for EMUs, which are applied in software testing/debugging, instruments, electrical digital data processing, etc., can solve problems such as affecting the braking debugging efficiency of EMUs, spending a lot of time and energy, and taking a long time for brake debugging tests.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

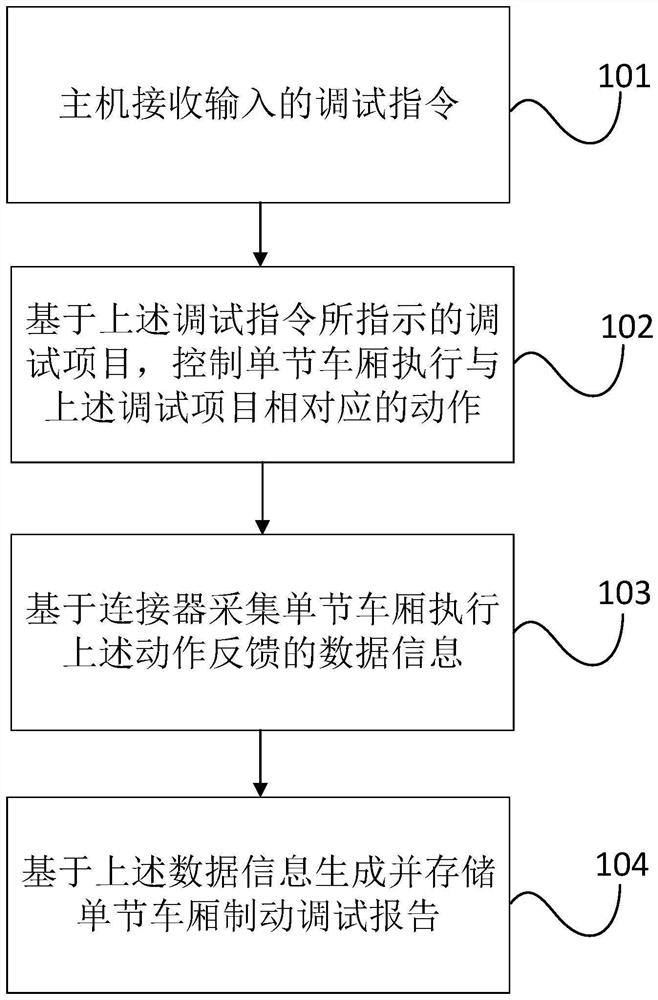

[0052] This application provides a method for debugging the brake of a single compartment of an EMU, such as figure 1 As shown, the EMU single-car brake debugging method provided by the application can improve the efficiency of EMU brake debugging. The above-mentioned EMU single-car brake debugging equipment includes: a host and a connection for connecting to a single car to be debugged. device;

[0053] The above EMU single car brake debugging method includes:

[0054] Step 101, the host receives an input debugging instruction;

[0055] Step 102, based on the debugging items indicated by the above-mentioned debugging instructions, control the single carriage to perform actions corresponding to the above-mentioned debugging items;

[0056] Step 103, based on the connector, collect the data information of the above-mentioned action feedback in a single carriage;

[0057] Step 104, generating and storing a single car brake debugging report based on the above data information....

Embodiment 2

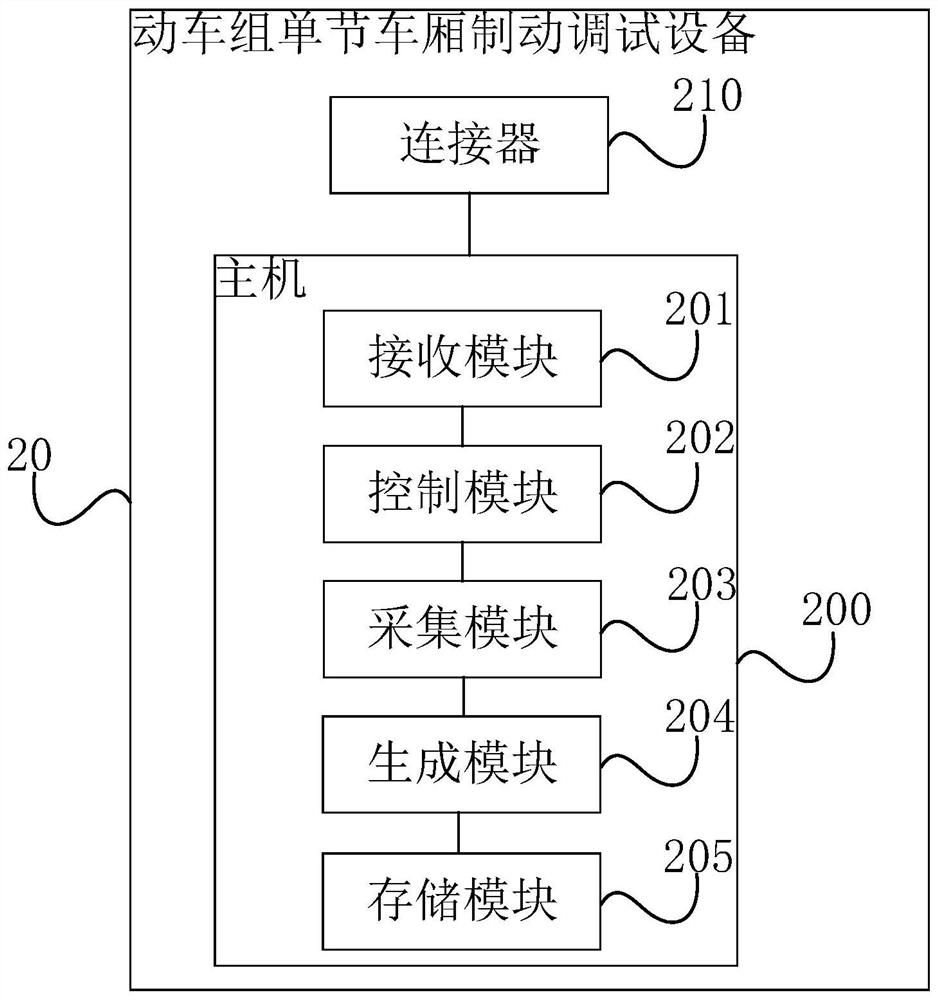

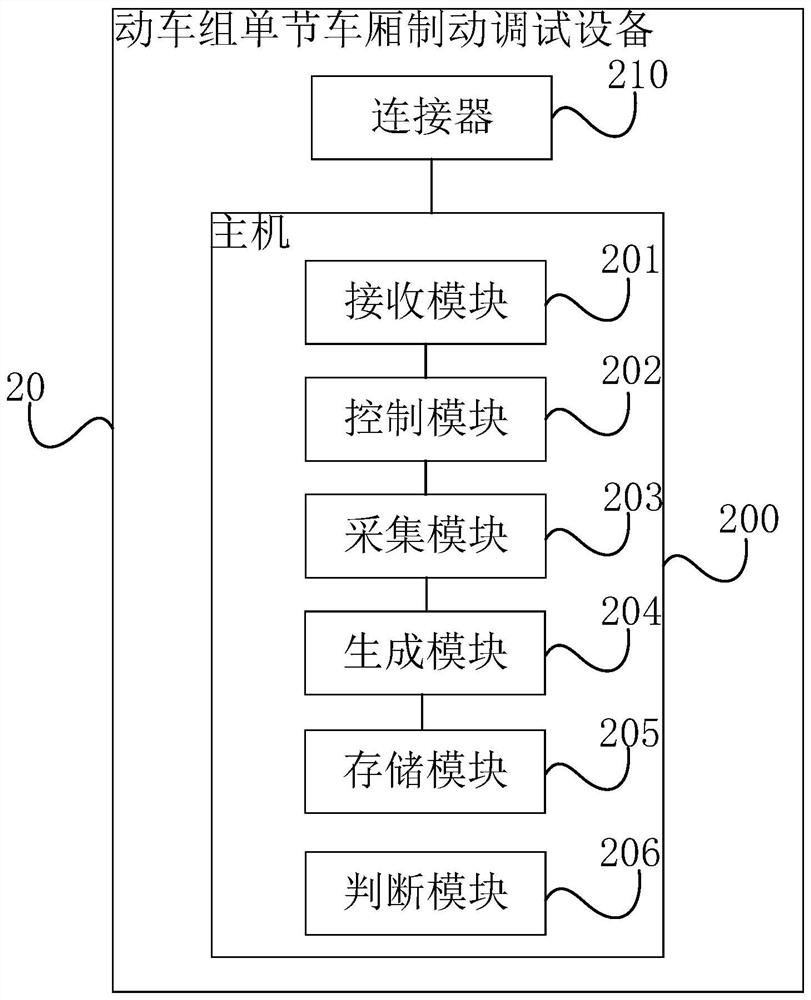

[0080] The embodiment of the present application also provides a train brake debugging equipment, figure 2 The train brake debugging equipment provided by the embodiment of the present application is shown, and for the convenience of description, only the parts related to this embodiment are shown.

[0081] Specifically, see figure 2 , the above-mentioned EMU single-car brake debugging equipment 20 includes: a host 200 and a connector 210 for connecting to a single car to be debugged;

[0082] The above-mentioned host 200 includes:

[0083] A receiving module 201, configured to receive an input debugging instruction;

[0084] The control module 202 is configured to control the above-mentioned single car to perform corresponding actions based on the debugging items indicated by the above-mentioned debugging instructions;

[0085] A collection module 203, configured to collect the data information of the above-mentioned action feedback performed by the above-mentioned singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com