Gas turbine radial air inlet complex distortion digital twinning test device and control method

A gas turbine and test device technology, applied in gas turbine engine testing, jet engine testing, measuring devices, etc., can solve the problem of the inability to establish a real-time mapping relationship between field operation test data and flow field simulation data, and the inability to accurately evaluate the complexity of the intake filter Inlet distortion characteristics and flow field simulation accuracy need to be further improved to reduce the risk of deep surge, save manpower and material costs, and reduce the number of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

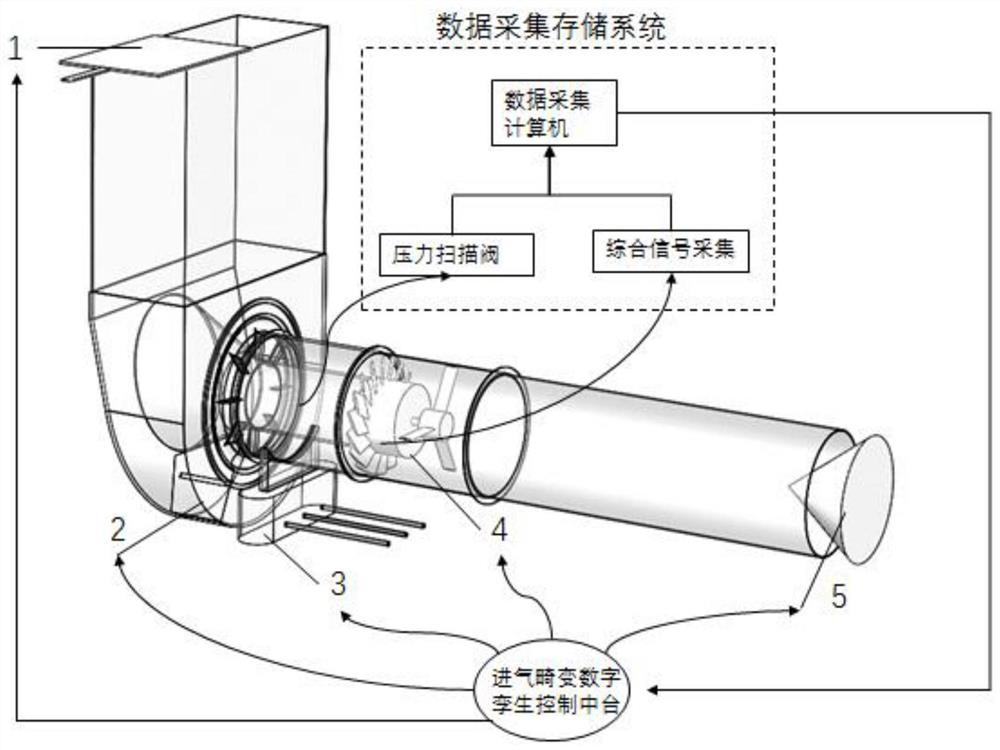

[0088] Such as figure 1 As shown, the digital twin test device includes a radial air intake chamber, a lubricating oil mist generator 3, an axial compressor 4, an electric valve 5, a performance sensor, a data acquisition and storage system, and a digital twin control center for intake distortion;

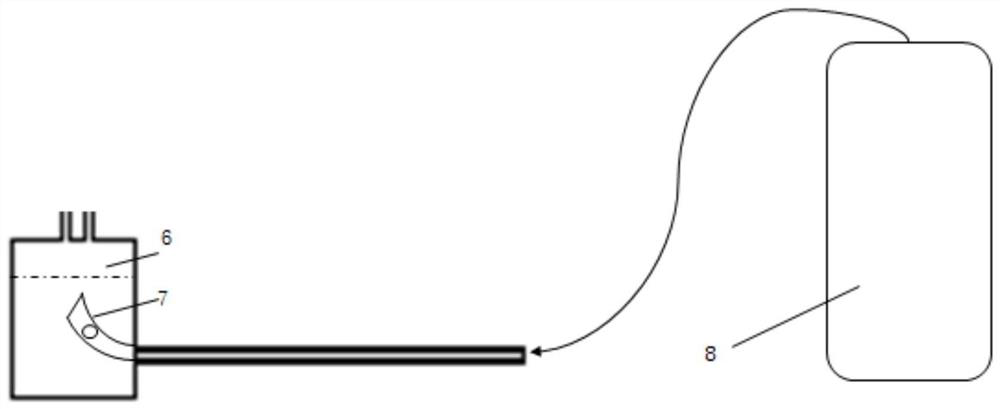

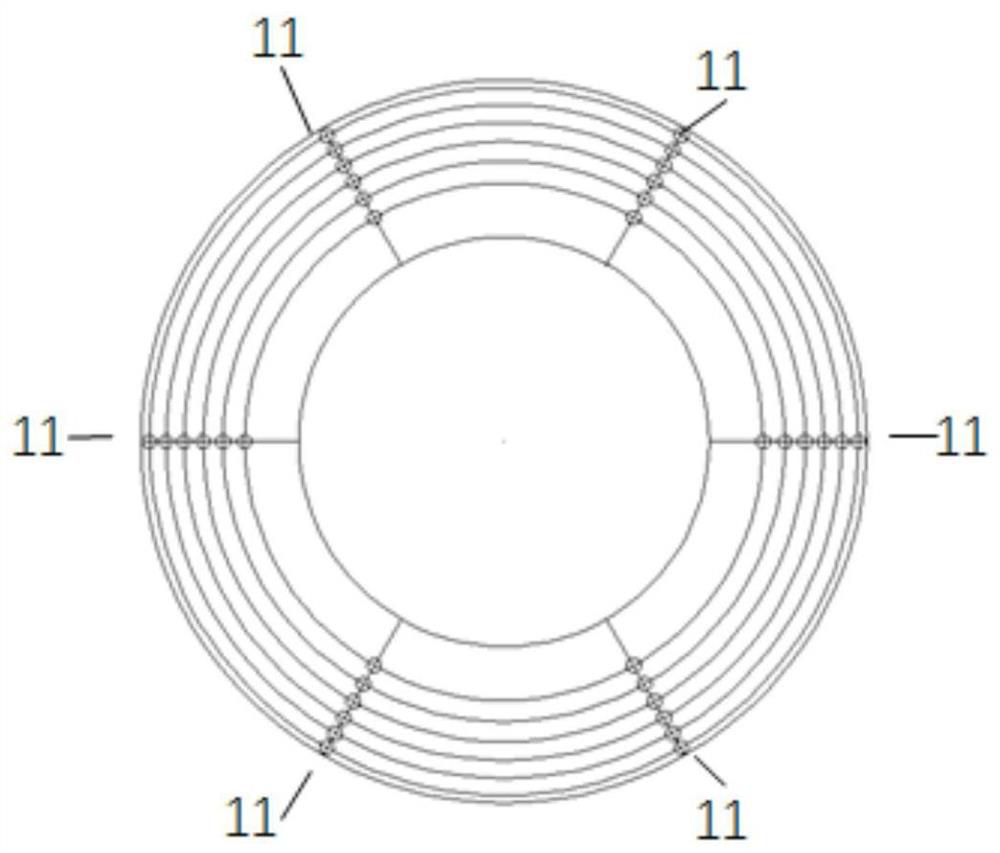

[0089] The outlet of the radial inlet chamber is connected to the inlet of the compressor through a connecting pipe, the connecting pipe is coaxially fixedly connected to one end of the outlet pipe through the interface flange, the other end of the outlet pipe is connected to the electric valve 5, and the outlet pipe close to the connecting pipe One end is fixedly installed with a variable frequency axial flow co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com