Imaging module and manufacturing method thereof

An imaging module and imaging technology, applied in image communication, TV, color TV parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

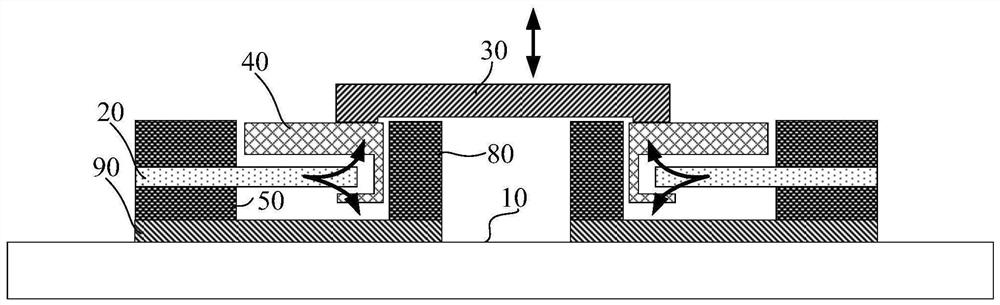

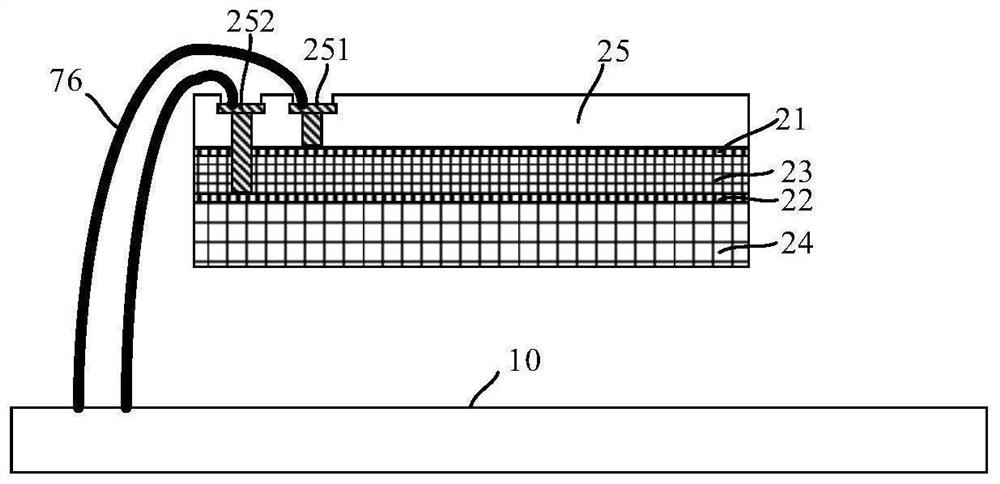

[0046] like figure 1 As shown, this embodiment provides an imaging module, including:

[0047] The moved element 30, the moved element 30 includes a lens group, an imaging sensing element, an aperture or a lens sheet;

[0048] a lifter connected to the surface of the moved element 30;

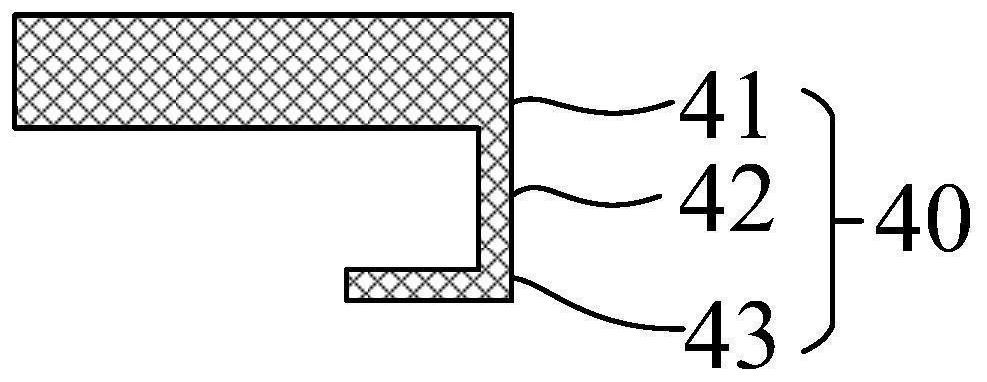

[0049] The lifter includes: a limiting device, a limiting groove 40, a piezoelectric element 20 and an external signal connection end,

[0050] The limiting device includes a base 90, and a support block 50 and a positioning block 80 located on the base 90, the base 90, the support block 50 and the positioning block 80 enclose a space, and the piezoelectric element 20 and the limiting groove 40 Located in the space, the positioning block 80 is located around the limiting groove 40;

[0051] The limiting groove 40 is fixedly connected with the surface of the moved element 30;

[0052]The piezoelectric element 20 includes a movable end and a fixed end, the fixed end is fixed on the support bl...

Embodiment 2

[0087] A method for manufacturing an imaging module, wherein the moved element 30 includes a lens group, an imaging sensing element, an aperture or a lens sheet, and the method includes:

[0088] provide the basis;

[0089] A lifter is formed on the base, the lifter includes: a limiting device, a limiting groove 40 and a piezoelectric element 20, the limiting device includes a base 90, and a support block 50 and a positioning block located on the base 90 80, the base 90, the support block 50 and the positioning block 80 enclose a space, the piezoelectric element 20 and the limiting groove 40 are located in the space, and the positioning block 80 is located around the limiting groove 40;

[0090] The limiting groove 40 is fixedly connected with the surface of the moved element 30;

[0091] The piezoelectric element 20 includes a movable end and a fixed end, the fixed end is fixed on the support block 50, and the movable end extends into the limiting groove 40;

[0092] The mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com