Rice acid fermentation process for producing L-lactic acid and ethyl acetate and special bacteria thereof

A technology of ethyl acetate and fermentation process, applied in the direction of lactobacillus, bacteria used in food preparation, application, etc., can solve the problems of unstable product quality, long production cycle of rice acid, etc., and achieve good taste and flavor, strong performance, High sensory evaluation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

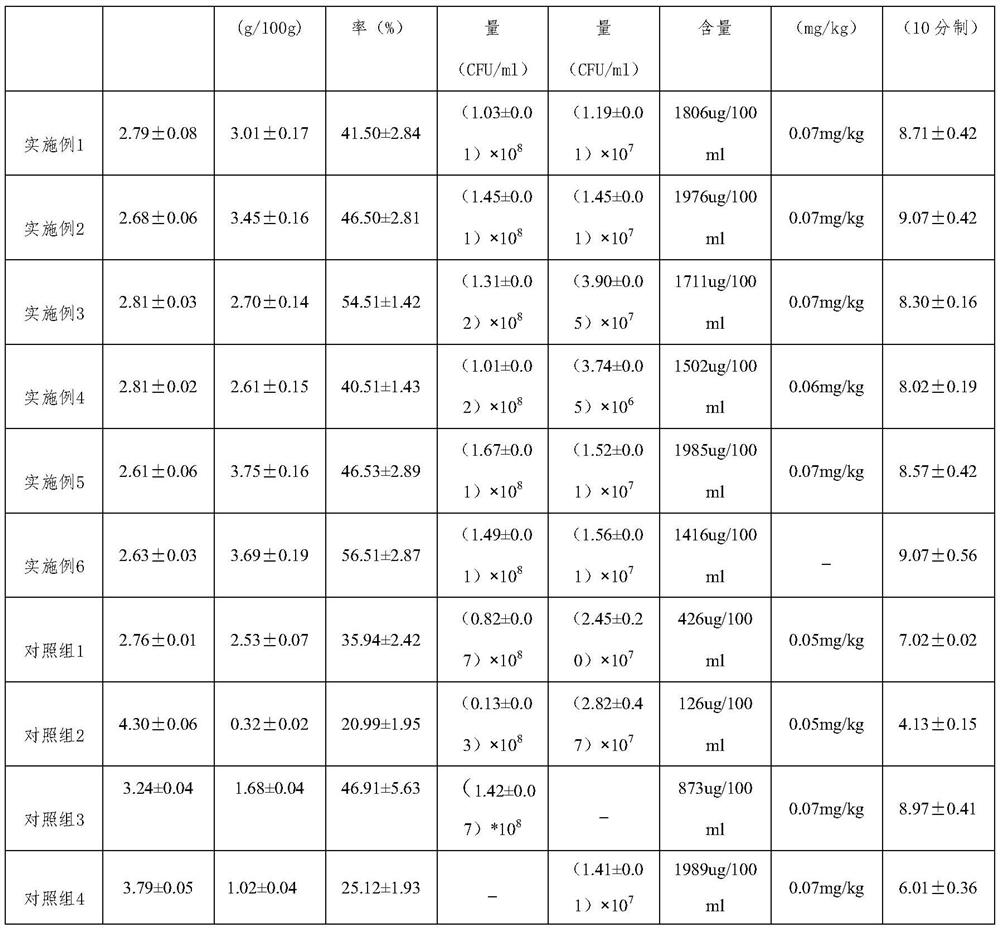

Examples

Embodiment 1

[0034] A rice acid fermentation process producing L-lactic acid and ethyl acetate, comprising the following processes:

[0035] (1) raw material pretreatment: high-speed pulverization of selenium rice, mixing, passing through an 80-mesh sieve twice to make rice flour; (2) boiling: mixing rice flour and water, the content of rice flour after mixing is 8%, heating and boiling, while Stir while heating;

[0036] (3) Gelatinization: put the boiled rice soup into a water bath for gelatinization, and stir while gelatinizing; to prevent local deterioration of the gelatinization liquid caused by uneven gelatinization; the gelatinization time is 30 minutes, and the gelatinization temperature is 60°C;

[0037] (4) Liquefaction: Add 1.0% of its quality high-temperature α-amylase to the gelatinized rice soup for liquefaction, the liquefaction time is 30min, and the liquefaction temperature is 95°C;

[0038] (5) deployment and sterilization: add honey with a mass of 5.0% to the liquefied ...

Embodiment 2

[0042] A rice acid fermentation process producing L-lactic acid and ethyl acetate, comprising the following processes:

[0043] (1) raw material pretreatment: crush selenium rice at high speed, mix, and pass through an 80-mesh sieve twice to make rice flour;

[0044] (2) Boil: mix rice flour and water, the content of rice flour after mixing is 8%, heat to boil, stir while heating;

[0045] (3) Gelatinization: put the boiled rice soup into a water bath for gelatinization, and stir while gelatinizing; to prevent local deterioration of the gelatinization liquid caused by uneven gelatinization; the gelatinization time is 30 minutes, and the gelatinization temperature is 60°C;

[0046] (4) Liquefaction: Add 1.0% of its quality high-temperature α-amylase to the gelatinized rice soup for liquefaction, the liquefaction time is 30min, and the liquefaction temperature is 95°C;

[0047] (5) Saccharification: add 0.02% of its mass glucoamylase to the liquefied rice soup, the saccharifica...

Embodiment 3

[0052] The difference between embodiment 3 and embodiment 2 is that what is added in the step (6) is not honey but the extract of A.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap