A Rice Acid Fermentation Process for Quickly Producing L-Lactic Acid and Its Special Bacteria

A fermentation process and special bacteria technology, applied in the direction of fermentation, bacteria, and microorganism-based methods, can solve the problems of sour soup with mixed flavor and acid, low L-lactic acid content, poor taste and flavor, etc., and achieve good antioxidant properties, Strong performance, good taste and flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

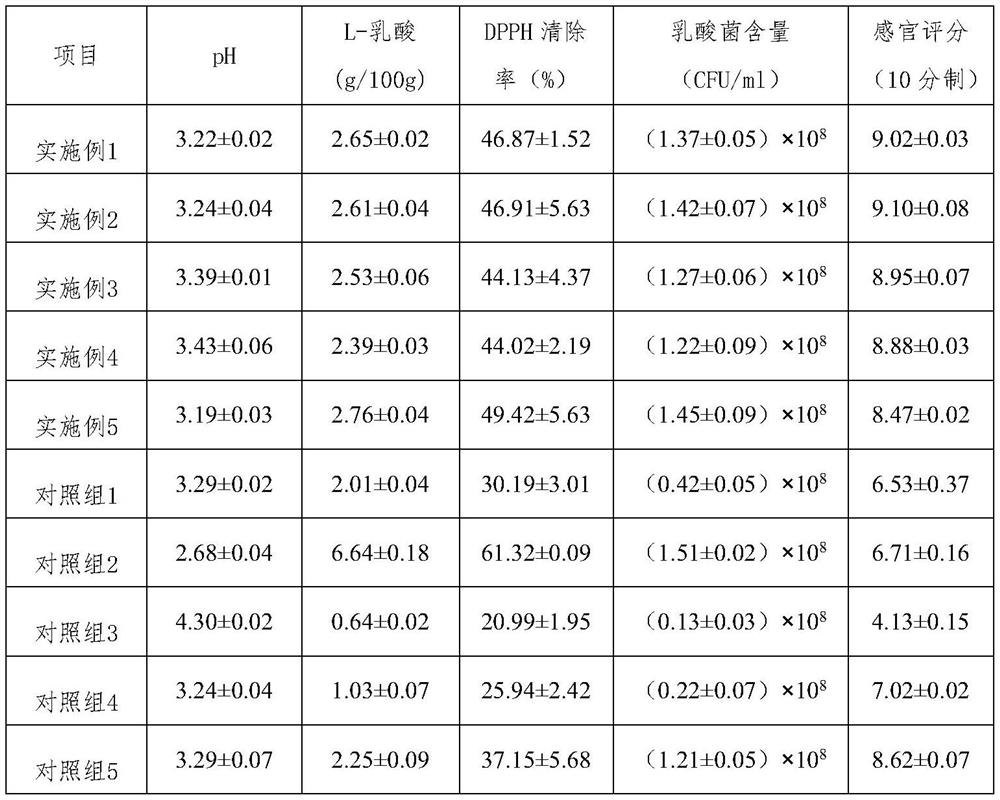

Examples

Embodiment 1

[0031] A rice acid fermentation process for rapidly producing L-lactic acid, comprising the following processes:

[0032] (1) Raw material pretreatment: the glutinous rice is pulverized at high speed, mixed, and passed through an 80-mesh sieve twice to make rice flour;

[0033] (2) Boiling: mix rice flour and water, the content of rice flour after mixing is 8%, heat to boil, and stir while heating;

[0034] (3) Gelatinization: put the boiled rice soup into a water bath to gelatinize, and stir while gelatinizing; to prevent the gelatinization liquid from deteriorating due to uneven gelatinization; the gelatinization time is 30min, and the gelatinization temperature is 60℃;

[0035] (4) Liquefaction: add 1.0% high-temperature α-amylase by mass to the gelatinized rice soup for liquefaction, the liquefaction time is 30min, and the liquefaction temperature is 95°C;

[0036] (5) Sterilization: pasteurized at 95°C for 20 minutes;

[0037] (6) Inoculation: when the rice soup is cool...

Embodiment 2

[0040] A rice acid fermentation process for rapidly producing L-lactic acid, comprising the following processes:

[0041] (1) Raw material pretreatment: the selenium rice is pulverized at high speed, mixed, and passed through an 80-mesh sieve twice to make rice flour;

[0042] (2) Boiling: mixing rice flour and water, the content of rice flour after mixing is 0.5%, heating and boiling, stirring while heating;

[0043] (3) Gelatinization: put the boiled rice soup into a water bath to gelatinize, and stir while gelatinizing; to prevent the gelatinization liquid from deteriorating due to uneven gelatinization; the gelatinization time is 30min, and the gelatinization temperature is 60℃;

[0044] (4) Liquefaction: add 1.0% high-temperature α-amylase by mass to the gelatinized rice soup for liquefaction, the liquefaction time is 30min, and the liquefaction temperature is 95°C;

[0045] (5) Saccharification: add 0.02% saccharification enzyme by mass to the liquefied rice soup, the s...

Embodiment 3

[0050] A rice acid fermentation process for rapidly producing L-lactic acid, comprising the following processes:

[0051] (1) Raw material pretreatment: the glutinous rice is pulverized at high speed, mixed, and passed through a 100-mesh sieve twice to make rice flour;

[0052] (2) Boiling: mixing rice flour and water, the content of rice flour after mixing is 4.0%, heating and boiling, stirring while heating;

[0053] (3) Gelatinization: put the boiled rice soup into a water bath to gelatinize, and stir while gelatinizing; to prevent the gelatinization liquid from deteriorating locally due to uneven gelatinization; the gelatinization time is 40min, and the gelatinization temperature is 50℃;

[0054] (4) Liquefaction: add 1.0% of its mass of high-temperature α-amylase to the gelatinized rice soup for liquefaction, the liquefaction time is 40min, and the liquefaction temperature is 85°C;

[0055] (5) Saccharification: add 0.03% saccharification enzyme by mass to the liquefied ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com